Nano particle grafted stereoblock polylactic acid, preparation method and application of nano particle grafted stereoblock polylactic acid

A nanoparticle and stereoblock technology, applied in the fields of nanomaterials and physical chemistry, can solve the problems of poor thermal stability, coexistence, unfavorable material processing and molding, etc. Efficiency and effect of melt stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. Use 0.1g surface-OHized multi-walled carbon nanotubes (CNT) as initiator and 2ml Sn(Oct) with a concentration of 0.05g / ml 2 The toluene solution is the catalyst, and 200ml toluene is the solvent. It catalyzes the ring-opening polymerization of 40g L-lactide at 125°C for 24h, flocculates several times to obtain CNT-g-PLLA, and fully vacuum-drys to obtain about 20g sample;

[0028] Step 2. Using 15g of CNT-g-PLLA obtained in step 1 as initiator, 1ml of Sn(Oct)2 in toluene solution with a concentration of 0.05g / ml as catalyst, 200ml of toluene as solvent, catalyzing 15g of dextro-lactide Perform ring-opening polymerization at 125°C for 24 hours, flocculate several times to obtain CNT-g-PLLA-PDLA, and fully vacuum dry to obtain about 20g sample;

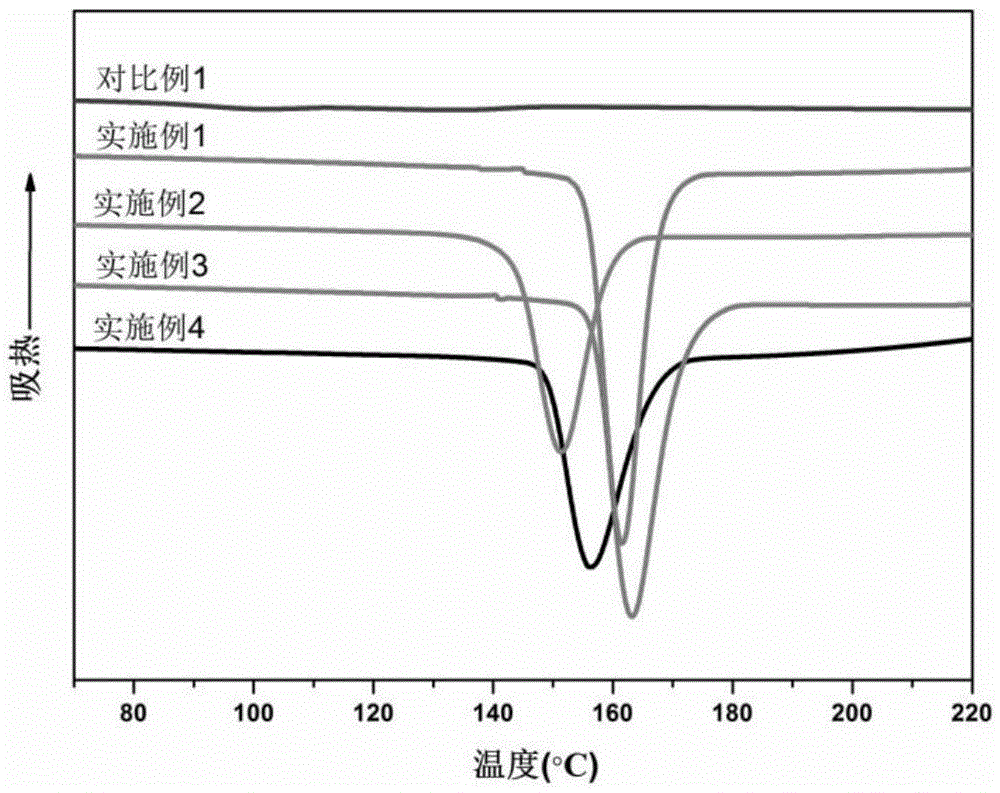

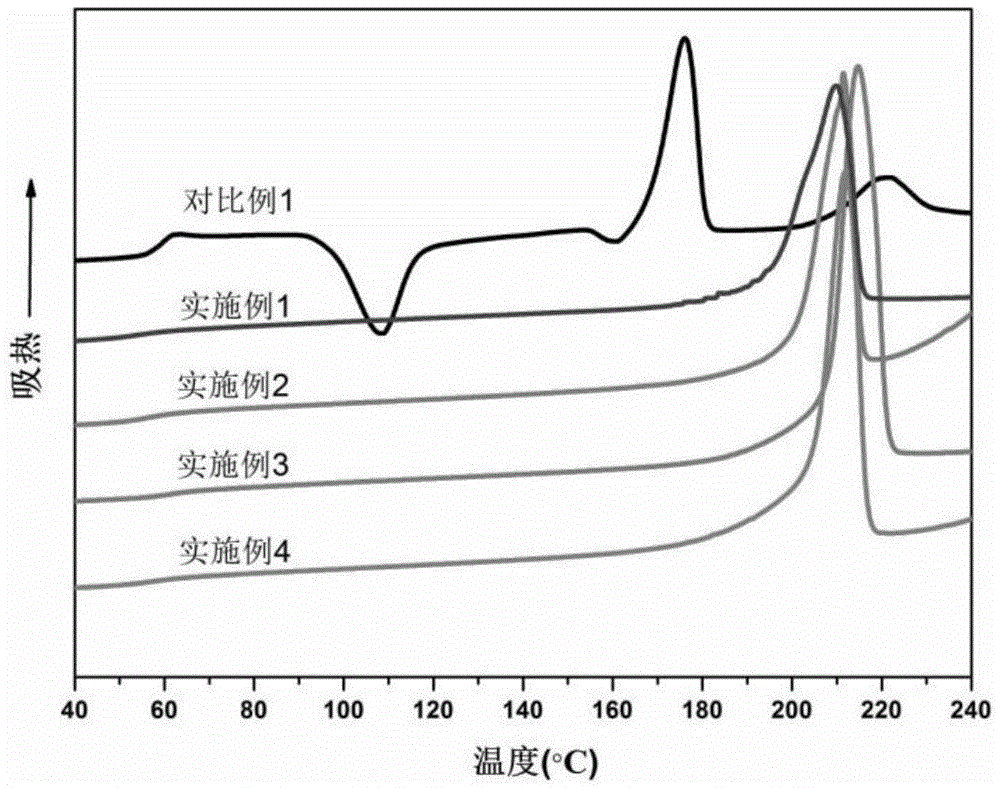

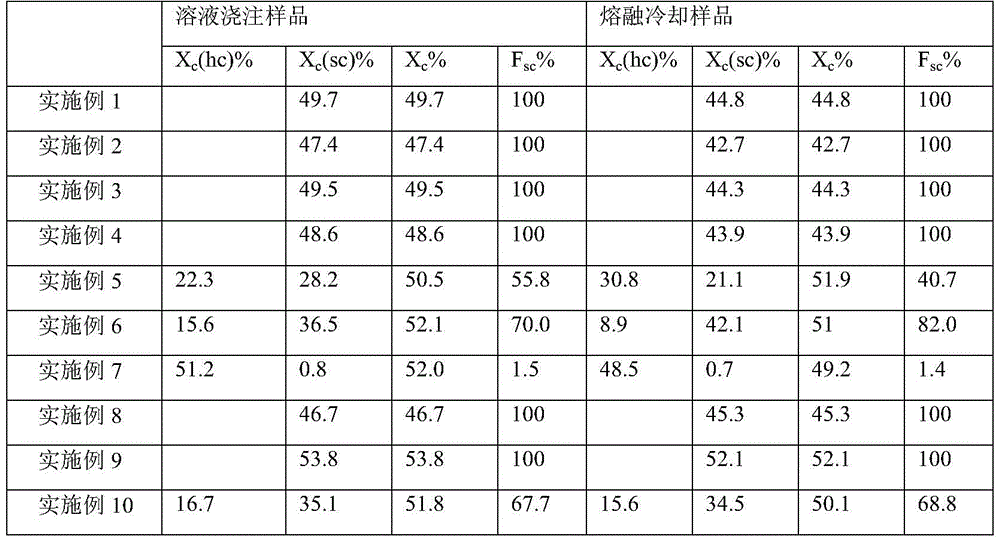

[0029] Step 3. Dissolve 1 g of the sample obtained in Step 2 in 50 ml of a mixed solvent of dichloromethane containing 10% hexafluoroisopropanol, stir vigorously for 3 hours, cast into a thin sheet of about 0.1 mm, and fully vac...

Embodiment 2

[0032] According to the same method in Example 1, the surface of nano-silica was grafted with stereoblock polylactic acid——SiO 2 -g-PLLA-PDLA, and perform the same experimental procedure.

Embodiment 3

[0034] According to the same method in Example 1, the graphene surface grafted stereo block polylactic acid-GO-g-PLLA-PDLA was prepared, and the same experimental procedure was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com