Patents

Literature

32results about How to "Good mechanics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

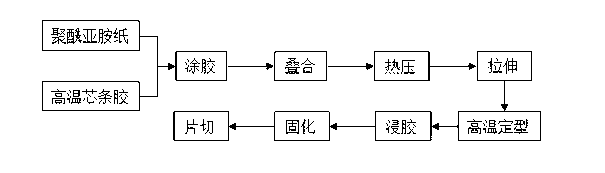

Preparation method of polyimide paper honeycomb core

ActiveCN103264530AExtended service lifeImprove heat resistancePaper/cardboard articlesSynthetic cellulose/non-cellulose material pulp/paperHeat resistanceHoneycomb

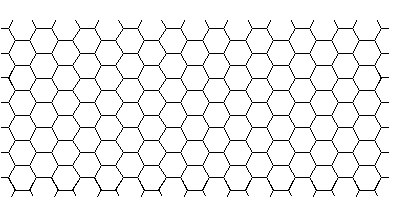

The invention relates to a preparation method of a polyimide paper honeycomb core. The method includes the following steps: (1) raw material paper is glued, laminated and hot-pressed, and a honeycomb stacked block is manufactured; (2) the honeycomb stacked block is molded at high temperature after being pulled, and a white honeycomb block is manufactured; (3) gum dipping is carried on the white honeycomb block, and the white honeycomb block is solidified; (4) a honeycomb after the gum dipping and solidification is sliced. The method is characterized in that the raw material paper is polyimide paper. Due to the fact that the polyimide paper is made of polyimide fibers, good characteristics of the polyimide fibers are inherited. Therefore, the prepared polyimide paper honeycomb core has better heat-resistant performance, dielectric performance, smoke and fire toxicity and mechanical performance compared with an aramid fiber paper honeycomb core in the prior art, the water absorption rate is low, the application field is widened, and service life of the honeycomb is prolonged in special environments. Production equipment of the aramid fiber paper honeycomb core in the prior art can be used, novel instruments and devices do not need to be added, process procedures are basically unchanged, operation is convenient, and equipment cost is not increased.

Owner:ARAMICORE COMPOSITE

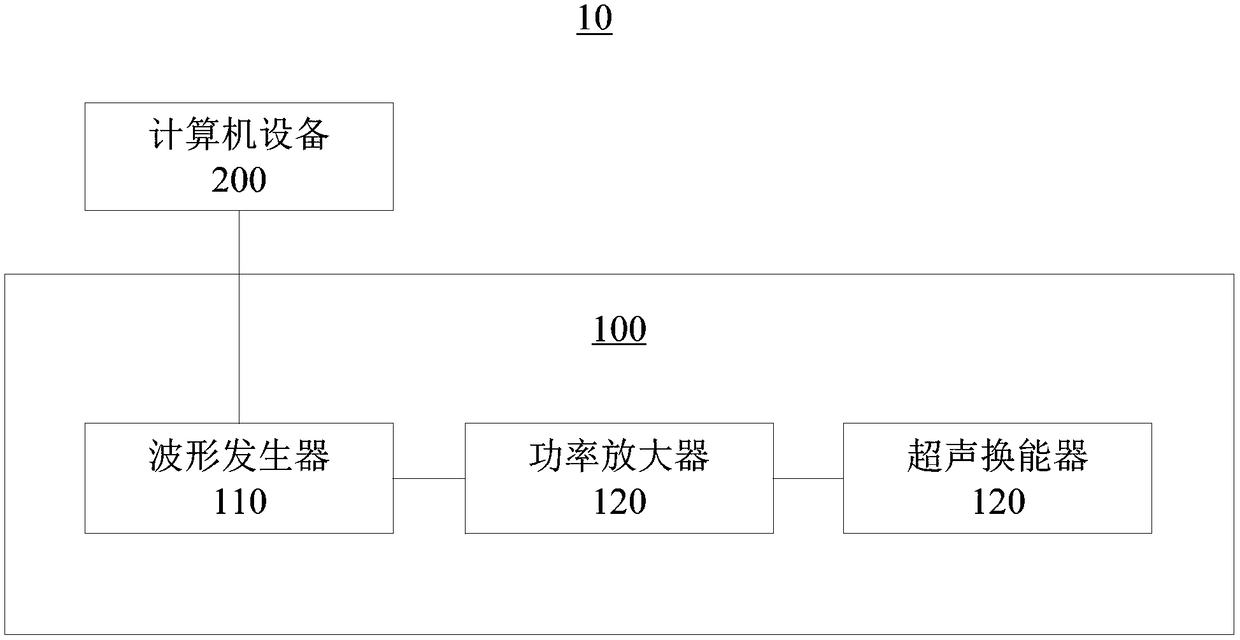

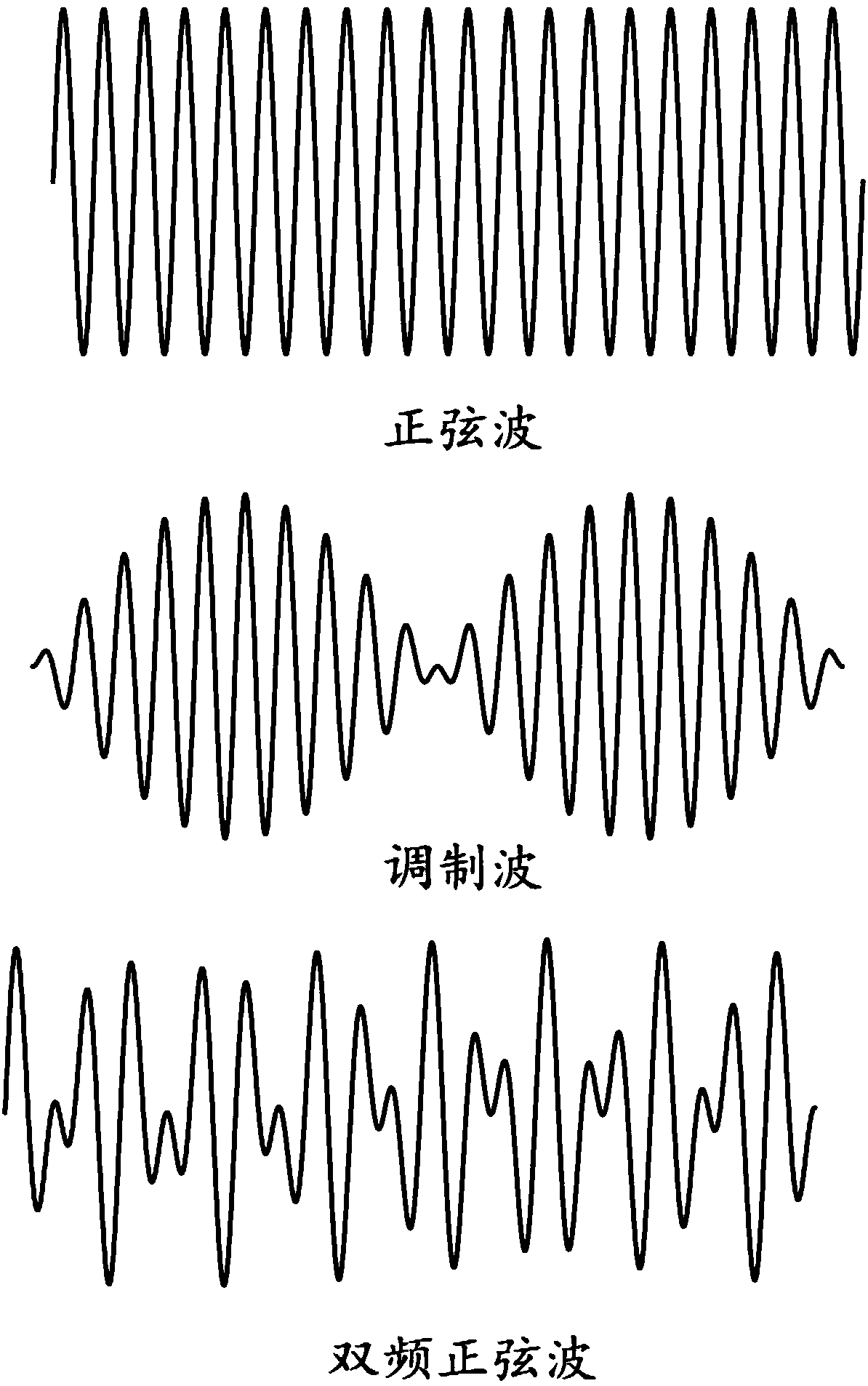

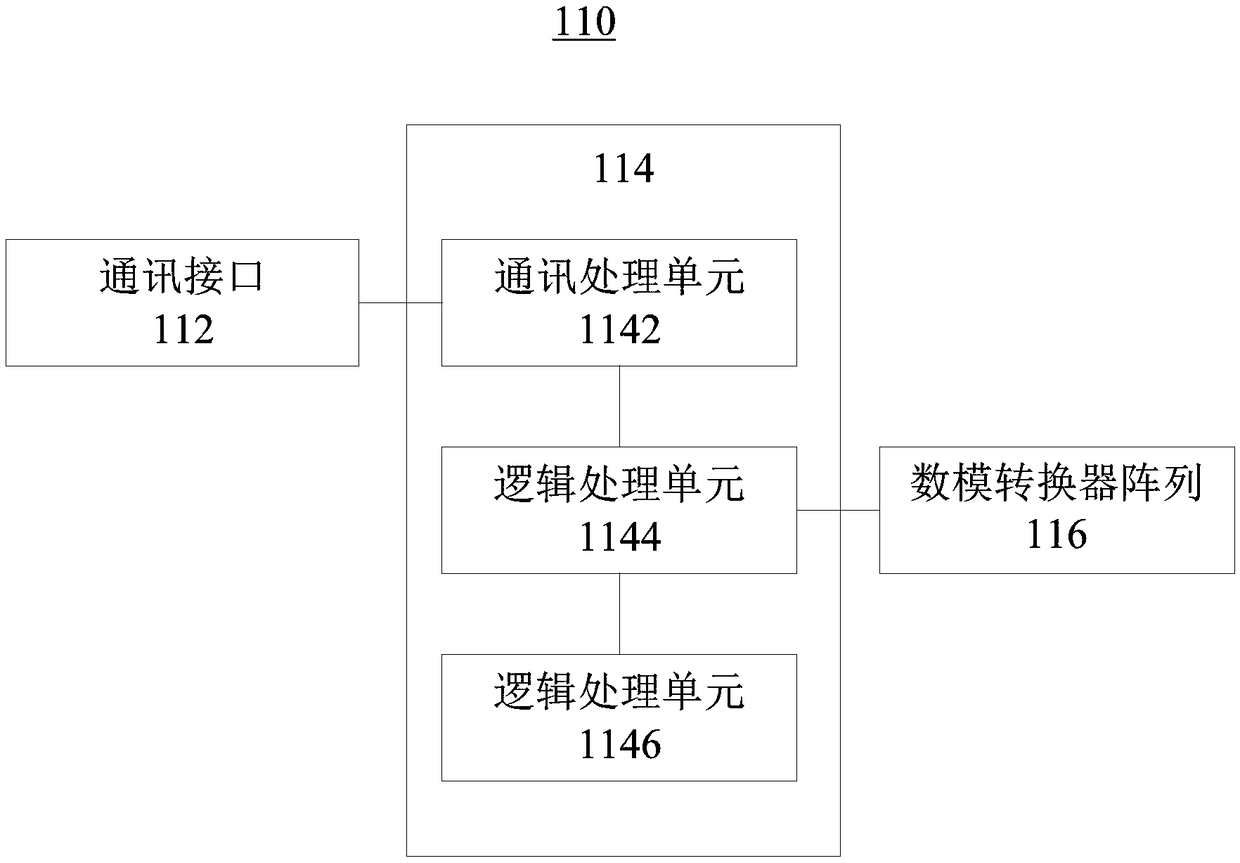

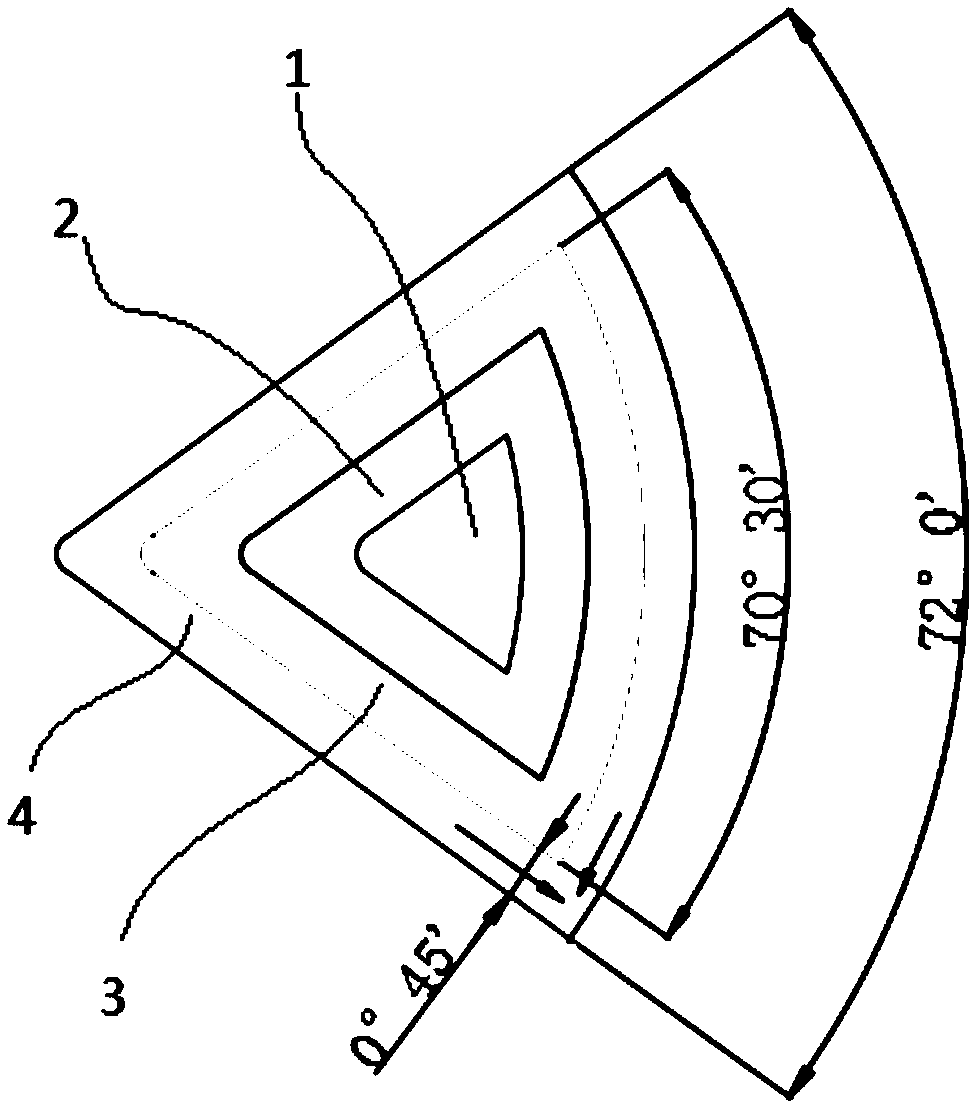

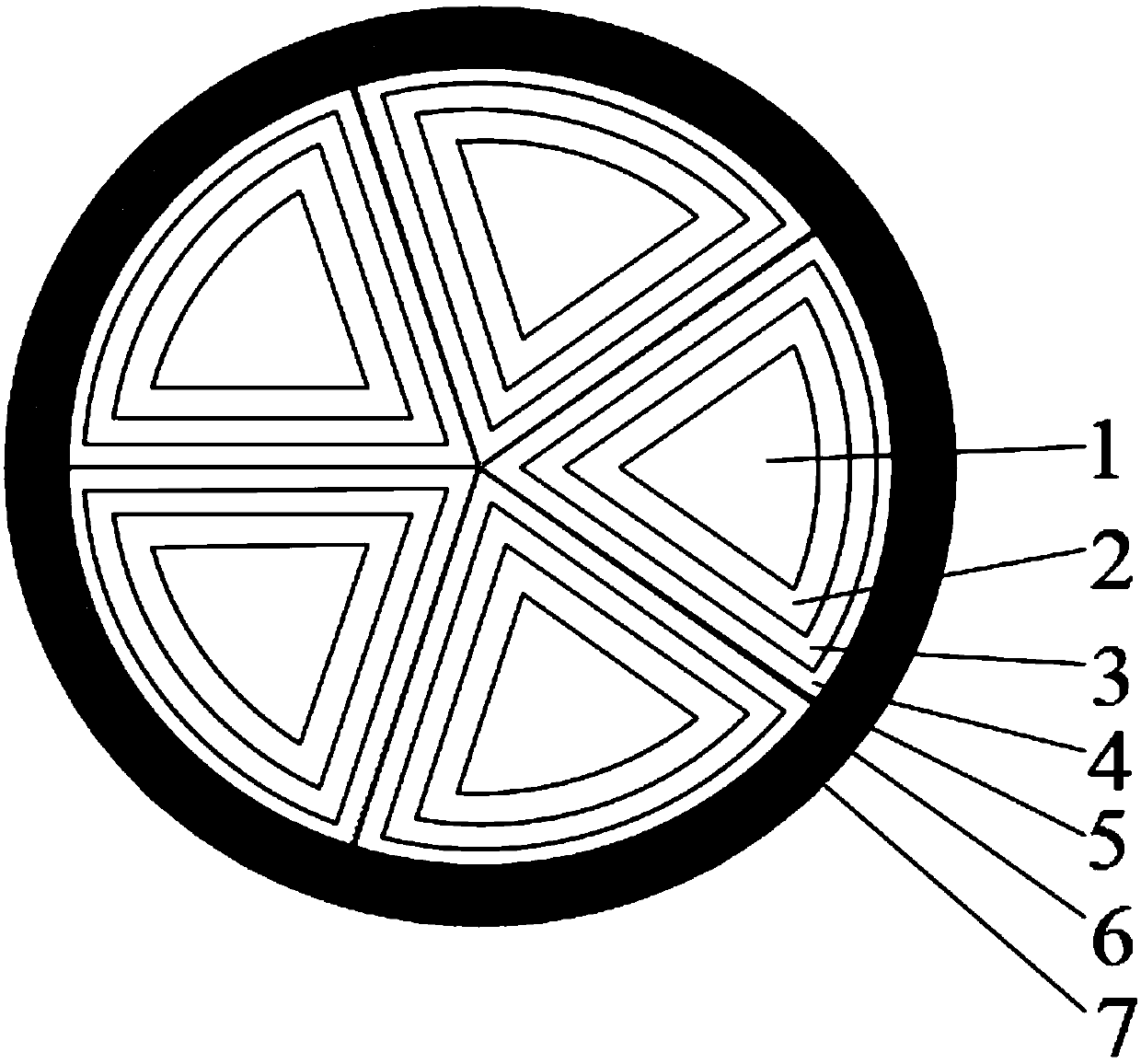

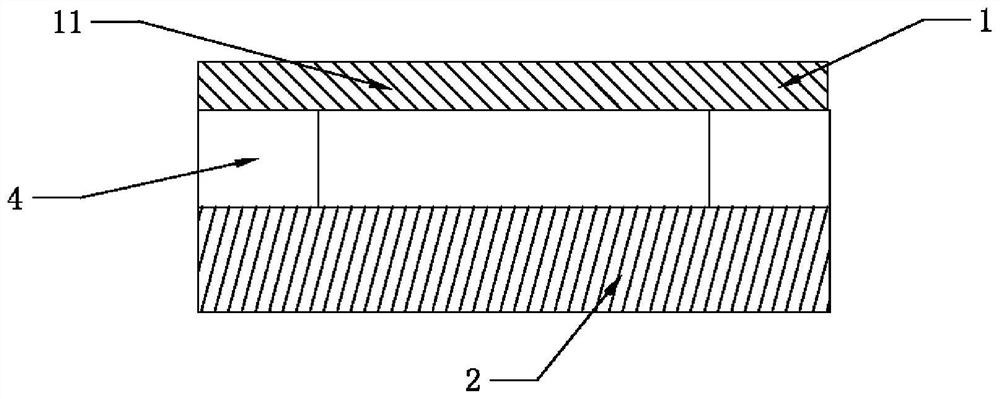

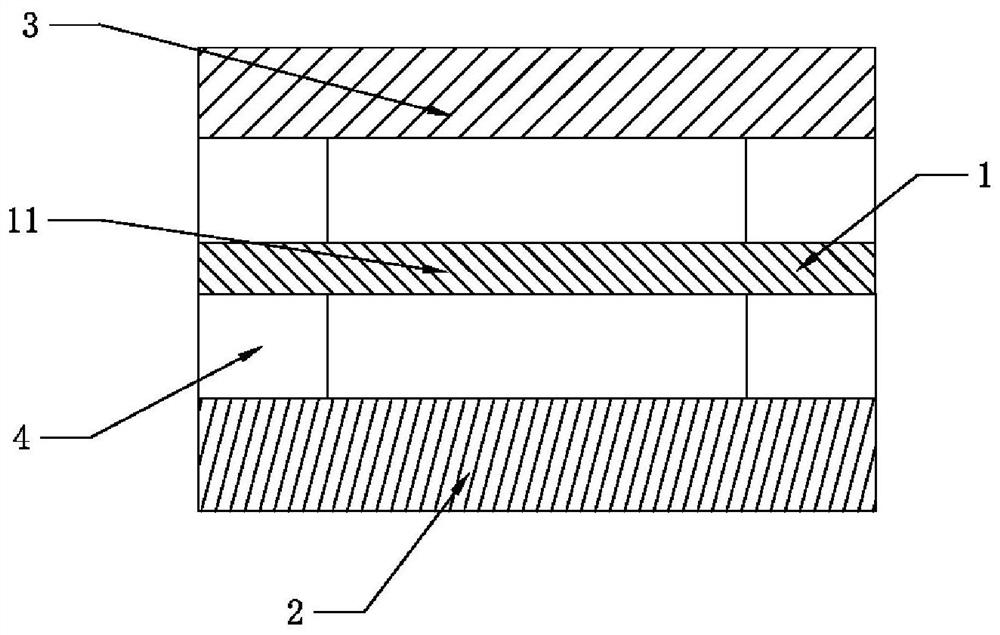

Ultrasonic excitation device, method and system

InactiveCN108144199AImprove performanceGood mechanicsUltrasound therapyAcoustic wave reradiationAudio power amplifierHigh pressure

The embodiment of the invention provides an ultrasonic excitation device, method and system. The ultrasonic excitation device comprises a waveform generator, a power amplifier, and an ultrasonic transducer array. The waveform generator is used for obtaining the ultrasonic excitation parameters of all channels, and then generating a waveform excitation signal of each channel according to the ultrasonic excitation parameters. The power amplifier is electrically connected with the waveform generator, and is used for carrying out the power amplification of the power amplification, and generating ahigh-voltage drive signal and inputting the high-voltage drive signal into the ultrasonic transducer array. The ultrasonic transducer array is used for generating ultrasonic waves on the corresponding elements according to the high-voltage drive signal, and comprises a plurality of elements, wherein each element is corresponding to one channel. Therefore, the device can give full display to the performances of the ultrasonic transducers, and obtains the better ultrasonic mechanical effect and thermal effect.

Owner:SHENZHEN INST OF ADVANCED TECH +1

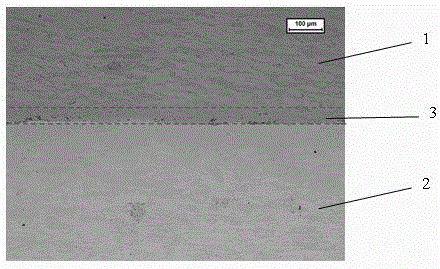

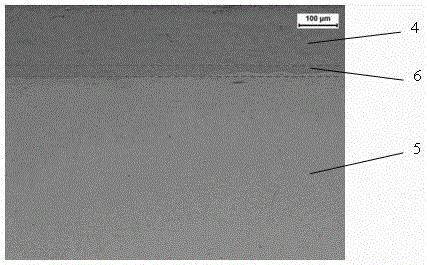

Method for preparing titanium-coated stainless steel composite plate

ActiveCN105018879AFlexible thickness adjustmentImprove corrosion resistanceMolten spray coatingSpherical shapedVolumetric Mass Density

The invention relates to a method for preparing a titanium-coated stainless steel composite plate by adopting superspeed injection deposition and rolling treatment. According to the method for preparing the titanium-coated stainless steel composite plate, a composite plate good in binding force is obtained by spraying pure titanium powder at a high speed and depositing the pure titanium powder on the surface of an activated base material, a titanium-coated stainless steel plate with a compact coating and with an interface in metallurgical bonding is obtained through hot rolling; and surface activating treatment is performed on the stainless steel base material by adopting a method of high-speed bombardment through spherical Al2O3 particles. According to the preparation method, the singe side or two sides of the surface of the stainless steel plate can be coated with titanium conveniently, and the thickness of a titanium-coated layer can be adjusted flexibly according to actual requirements. The preparation method is simple in process, good in controllability and high in production efficiency; and the prepared metal titanium plate has the advantages of being good in binding force, high in density, good in corrosion resistance and long in service life.

Owner:BAOSHAN IRON & STEEL CO LTD

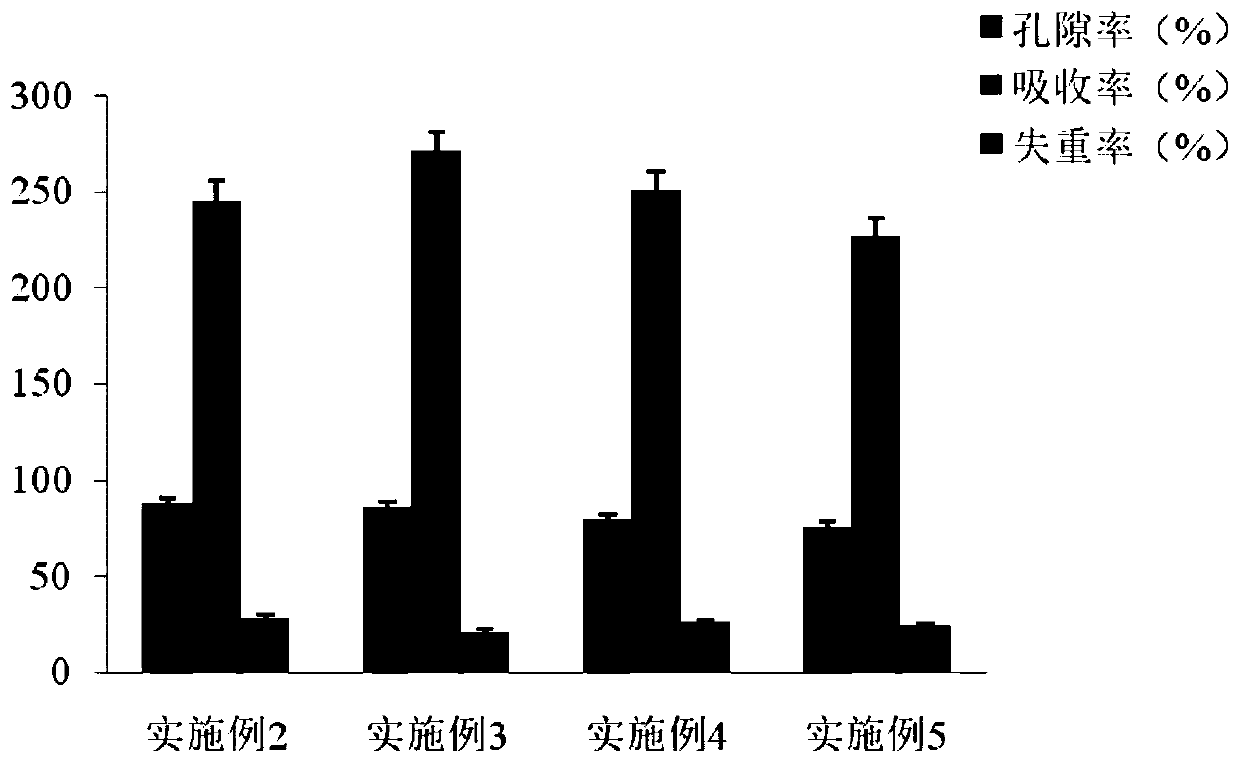

Preparation method of porous PVDF film for battery separator

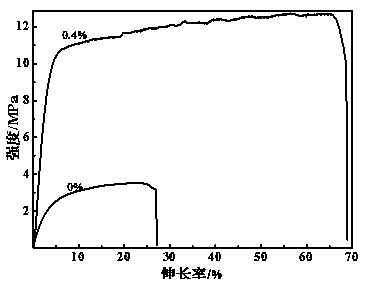

ActiveCN108695474AGood mechanical propertiesHigh liquid absorptionSecondary cellsCell component detailsCompound aPolymer modified

The invention discloses a preparation method of a porous PVDF film for a battery separator. In order to improve the film forming performance of a PVDF coating solution, a polymer modifier is selectedto mix with PVDF and is dissolved in a mixed solvent obtained by compounding a PVDF good solvent with different PVDF good solvents, or the mixed solvent system added with a small amount of poor solvents for full dissolving to obtain a homogeneous solution. In order to ensure the ionic penetration of the porous PVDF film, the porous PVDF film is made into a porous structure. A certain amount of pore-forming agent is added into the homogeneous solution, after full dissolving t, inorganic nanoparticles for a battery are added to improve electrochemical performances of the porous PVDF film on thebasis of improvement of mechanical properties. The PVDF coating solution prepared by the steps is used for scraping to form a film, the film is respectively pre-evaporated in air, solidified in a coagulation bath, eluted and dried to obtain the porous PVDF film for the battery separator.

Owner:HENAN INST OF ENG

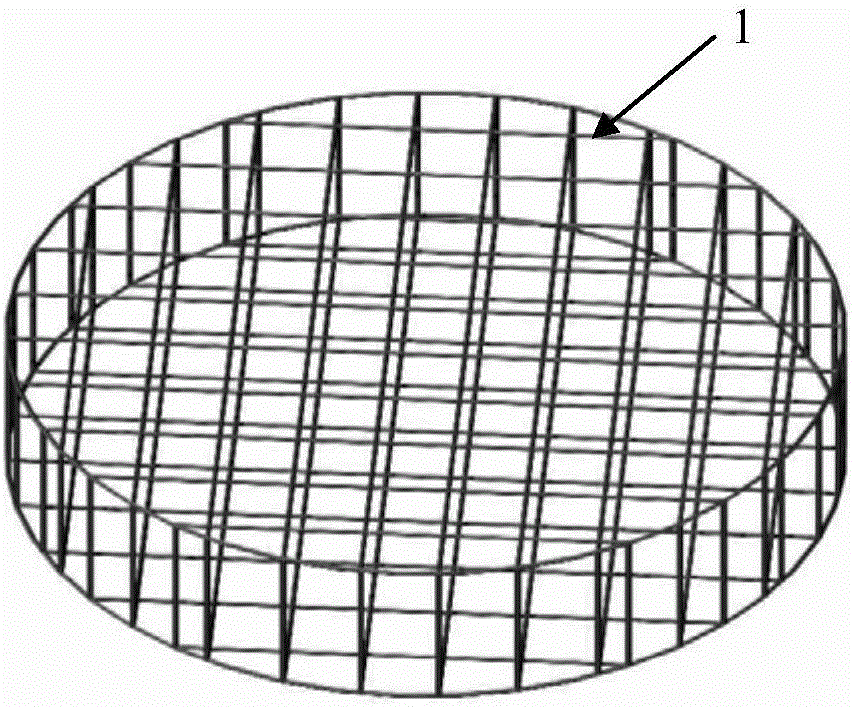

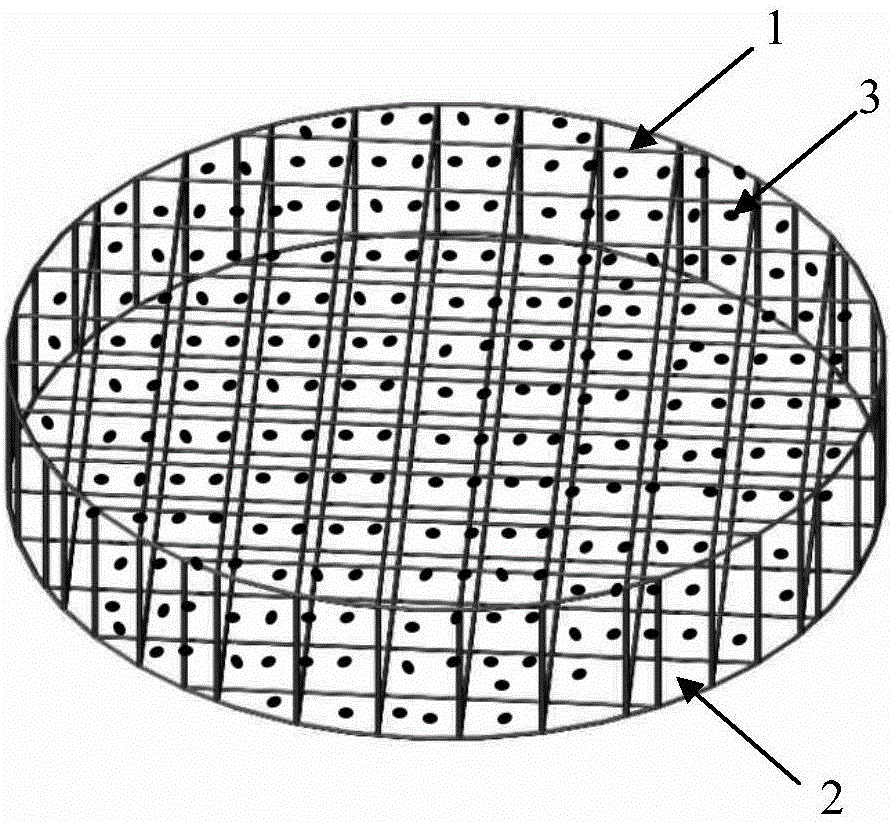

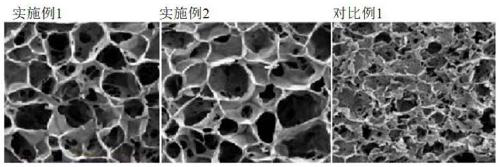

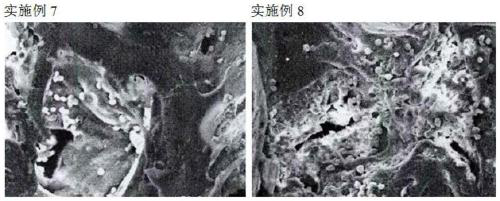

Tissue engineering stent based on low-temperature rapid modeling and preparation method thereof

ActiveCN106668948AOvercome sizeOvercome the defects that are too small (<100μm)Tissue regenerationCoatingsBiomechanicsMass ratio

The invention relates to a tissue engineering stent based on low-temperature rapid modeling and a preparation method thereof. The preparation method comprises the following steps: mixing a polylactic acid-glycolic acid copolymer and an organic solvent in a mass ratio of 1: 6 to 1: 8 to prepare a PLGA (polylactic acid-glycolic acid) solution, and adding sodium chloride granules to obtain a printing slurry, wherein the mass ratio of the sodium chloride granules to the PLGA is 1: 2 to 2: 1; setting the fiber diameter to be 200-300 microns, setting the fiber spacing to be 300-350 microns, printing out a stent body containing the sodium chloride granules at a speed of 3-6mm / s, and removing the organic solvent and the sodium chloride to obtain the tissue engineering stent based on the low-temperature rapid modeling. According to the invention, through addition of an excipient, low-temperature printing of a PLGA material is achieved, and the defect of a too large or too small aperture size caused by high-temperature fused printing of a PLGA stent is overcome; the prepared PLGA stent is moderate in aperture size, can easily store cells, and has good biomechanical properties.

Owner:杭州弘新生物科技有限公司

Novel cell culture method, cell culture system and application of cell culture system

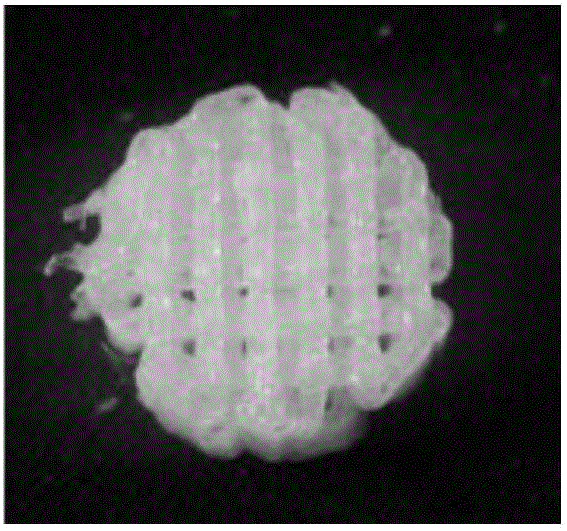

InactiveCN110272824AImprove compactnessImprove sintering performanceCompound screeningApoptosis detectionBiotechnology3D cell culture

The invention provides a novel cell culture method, a cell culture system and application of the cell culture system, and belongs to the field of biological materials and biotechnology. The three-dimensional cell culture system provided by the invention is used for in-vitro cell culture and comprises a packed bed cell reactor, wherein the reactor comprises a composite porous scaffold, and the composite porous scaffold comprises collagen, silk fibroin and hydroxyapatite. The method for three-dimensional cell culturing by using the system comprises the following steps of: setting the three-dimensional cell culture system; supplying the cell reactor with cells and a cell culture solution; and circularly filling the reactor with the cell culture solution, wherein the cell inoculation mode is dynamic inoculation. The porosity of the composite porous scaffold of the cell culture system and the uniformity and permeability of the pore structure are good so as to facilitate the transportation and transmission of moisture, ions and other nutrient substances, to have higher sensitivity to temperature, to respond to the change of ambient temperature, and to control the subsequent release of growth factors.

Owner:兰溪市立顺生物有限公司

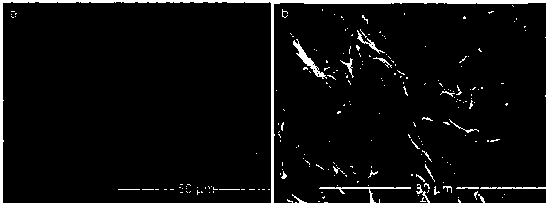

Medical absorbable Mg-Si alloy

The invention relates to a biologically absorbable magnesium alloy applied to medical implant materials and particularly suitable to be used as a corrodible and degradable bone implant material and adegradable scaffold material under human body environment. The biologically absorbable magnesium alloy comprises the following components in percentage by weight: 0.5 to 5.0 percent of silicon (Si) and the balance of magnesium (Mg), and possibly comprises a small amount of microelements such as manganese (Mn), calcium (Ca), rare earth (RE) and yttrium (Y); and the content of each microelement is not more than 1.5 percent, and the total content of the microelements is not more than 2.0 percent. The material has good biological compatibility and mechanical property, and has application value inthe medical field, such as intravascular interventional treatment of scaffolds, absorbable bone fixing instruments such as bone pegs, bone lammelae and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

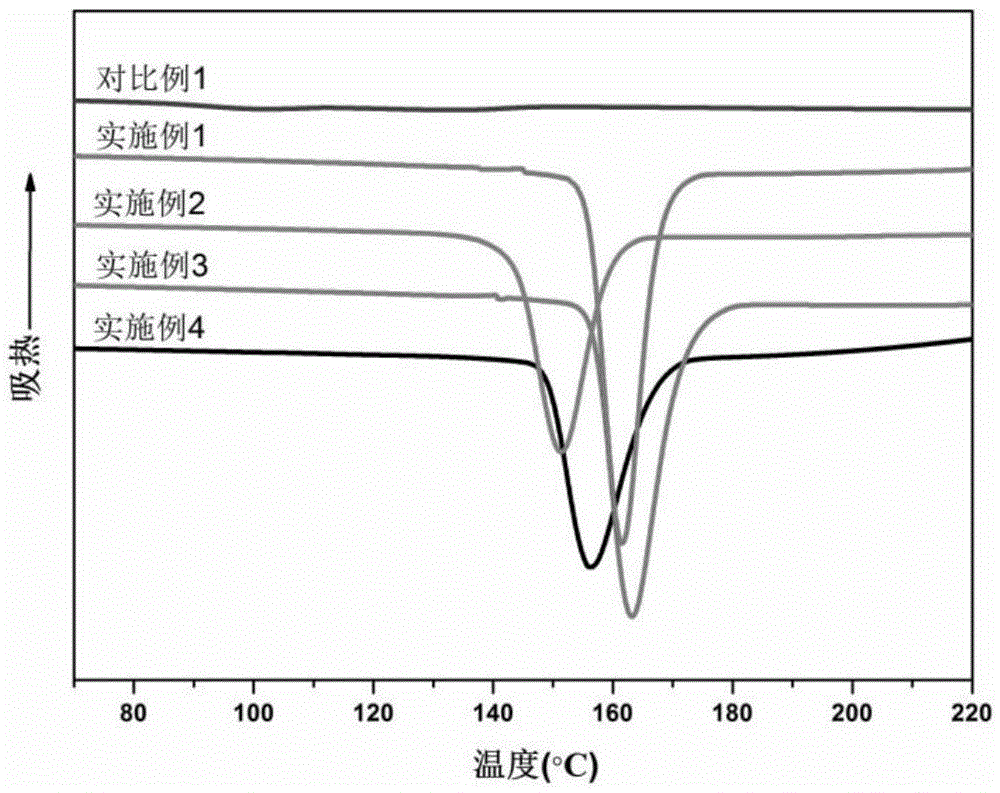

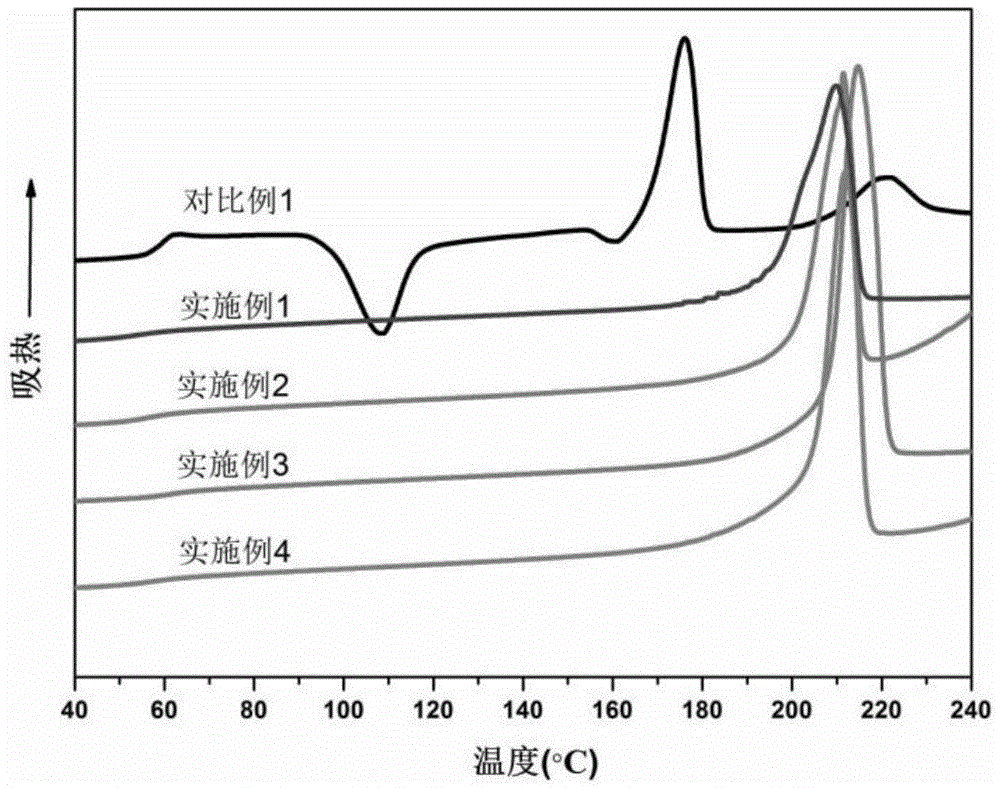

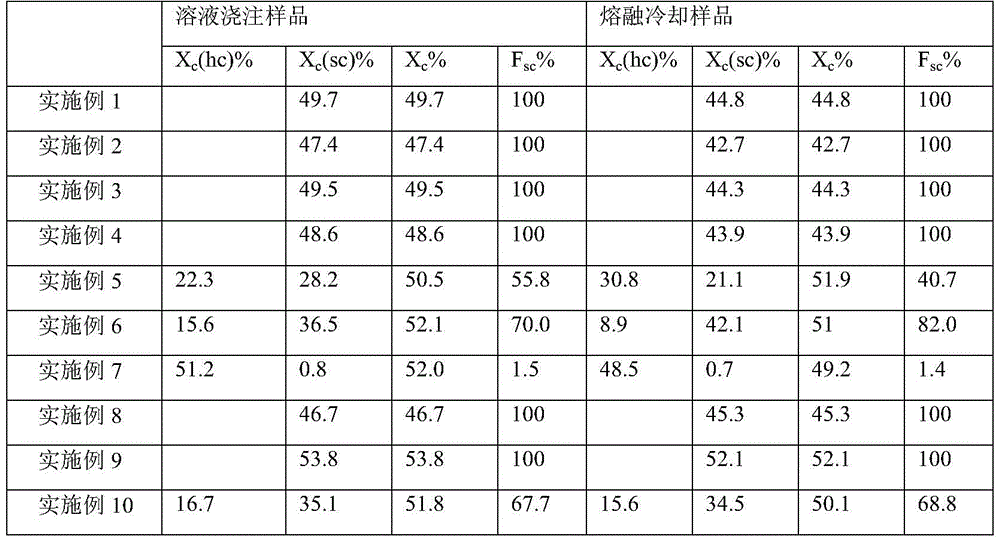

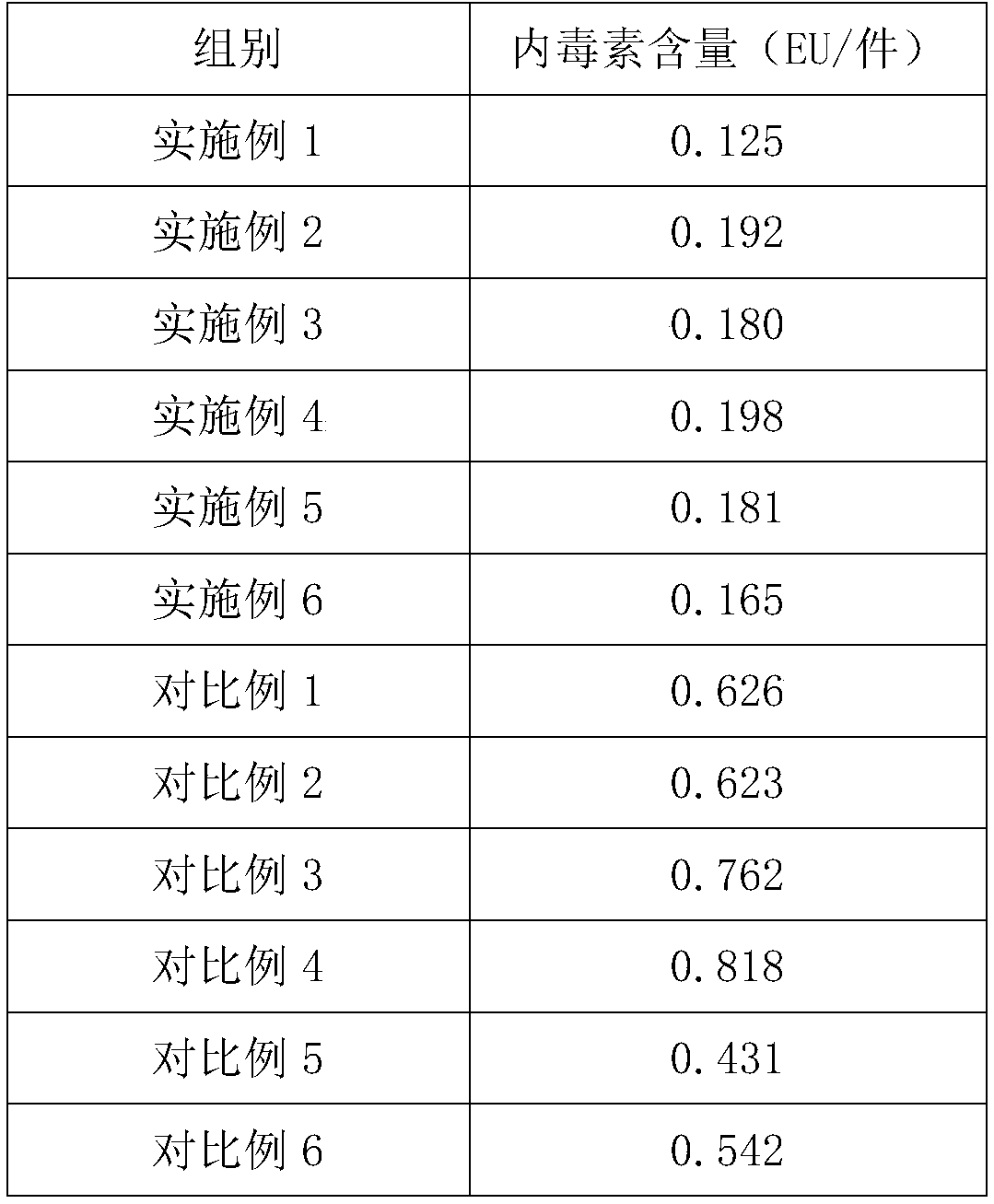

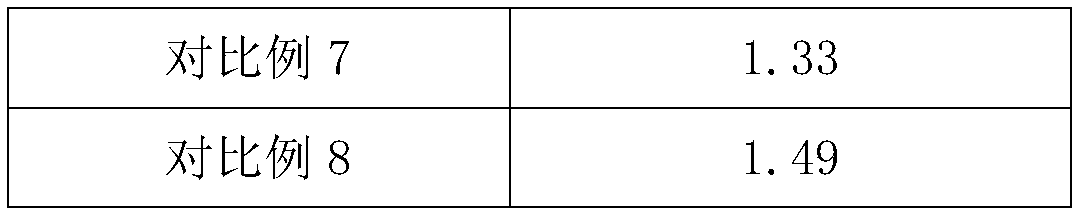

Nano particle grafted stereoblock polylactic acid, preparation method and application of nano particle grafted stereoblock polylactic acid

Owner:SICHUAN UNIV

Artificial biological dura mater and preparation method thereof

ActiveCN108815578AImprove mechanical propertiesImprove stitching effectTissue regenerationProsthesisMass ratioBiocompatibility Testing

The invention belongs to the technical field of bio-based materials, and particularly relates to an artificial biological dura mater and a preparation method thereof. The artificial biological dura mater is prepared from the following raw materials of bacterial cellulose and collagen according to a mass ratio of (0.1 to 3):10; any crosslinking agent is not added, so that the adverse effect to therepair process of the dura mater by the crosslinking agent is reduced, and the clinical use safety of the dura mater product is improved. The artificial biological dura mater has the advantages that the artificial biological dura mater is prepared by an electrostatic spinning method; the pH (potential of hydrogen), temperature and other technology conditions are strictly controlled, so that the good biocompatibility and mechanical property are realized, the requirement of operation suture in the clinical use process is met, and the leakage of cerebrospinal fluid is effectively prevented.

Owner:NKD PHARMA CO LTD

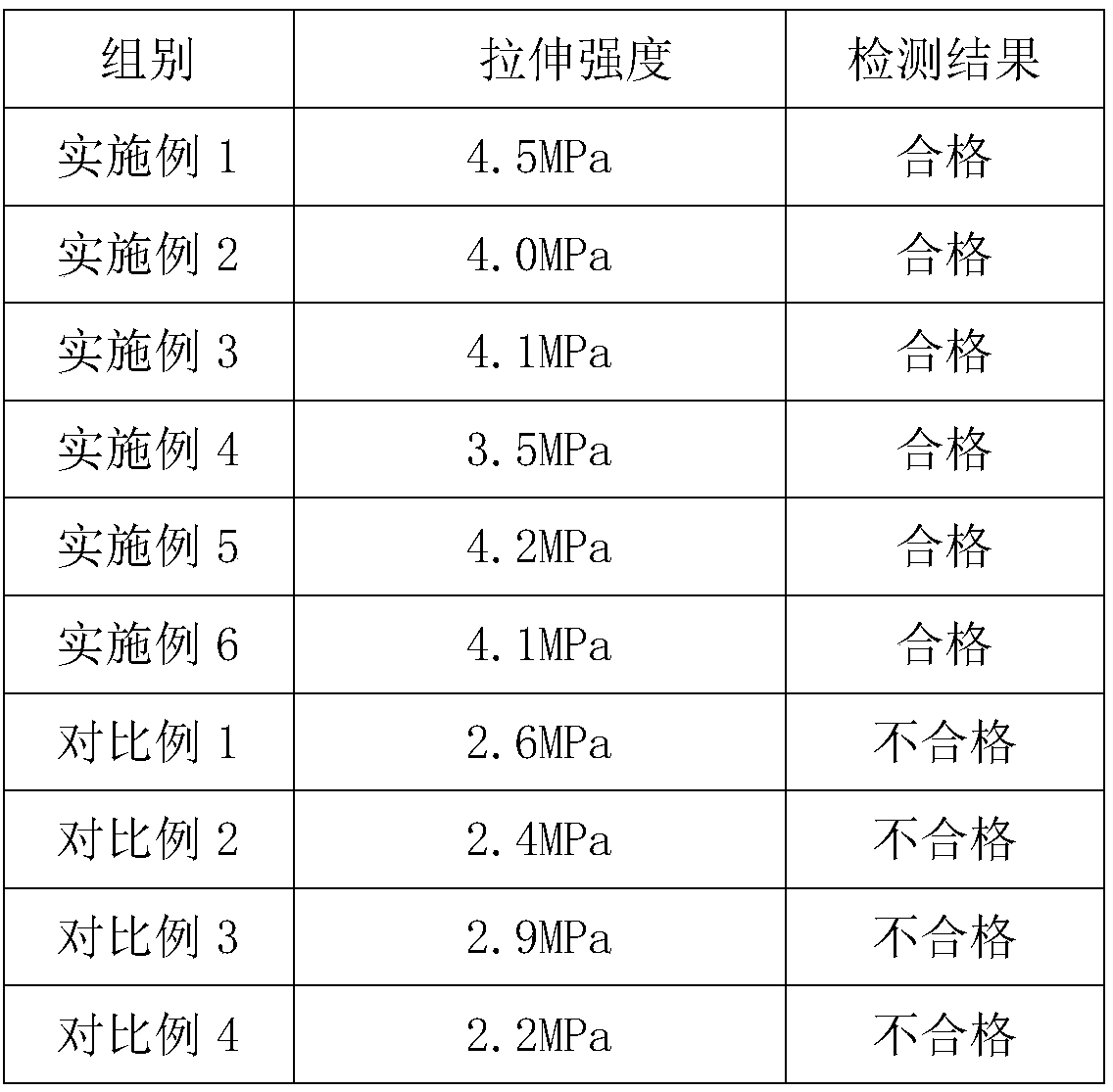

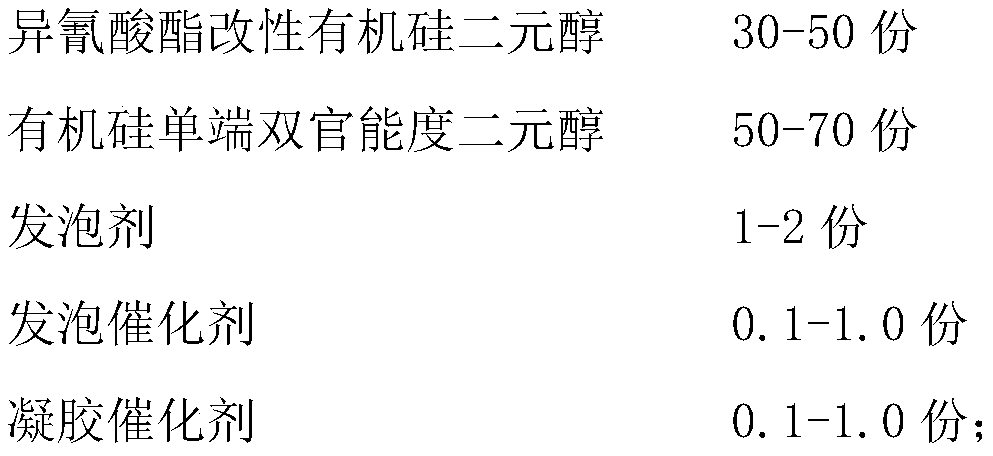

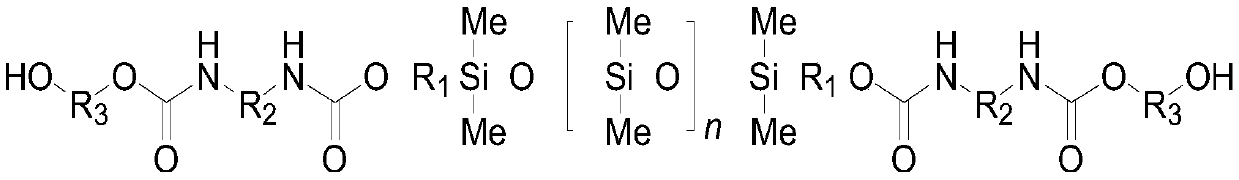

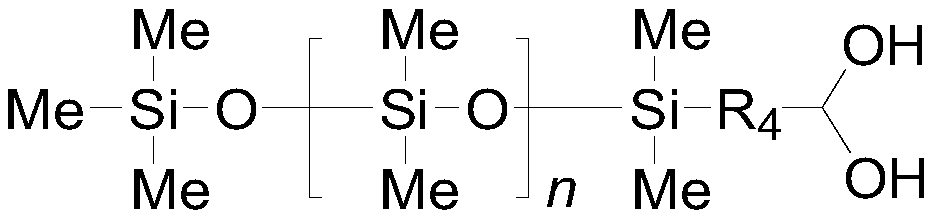

Solvent-free polyurethane intermediate layer resin of super-soft synthetic leather and preparation method of solvent-free polyurethane intermediate layer resin

The invention provides solvent-free polyurethane intermediate layer resin of super-soft synthetic leather and a preparation method of the solvent-free polyurethane intermediate layer resin. The solvent-free polyurethane intermediate layer resin is prepared from a component A and a component B which are in the proportion of 100:25-100:105, wherein the component A is prepared from cyanate modified organosilicone diol, organosilicon single-end double-function diol, a foaming agent, a foaming catalyst and a gel catalyst, and the component B is prepared from isocyanate, organosilicon polyether dioland organosilicon diamine. The balance design of super softness and good mechanical properties of the resin is achieved by reducing the degree of phase separation between the soft segment and the hard segment in the molecular structure and combining with the excellent mechanical properties of organic silicon, and the softness of the material is remarkably improved.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

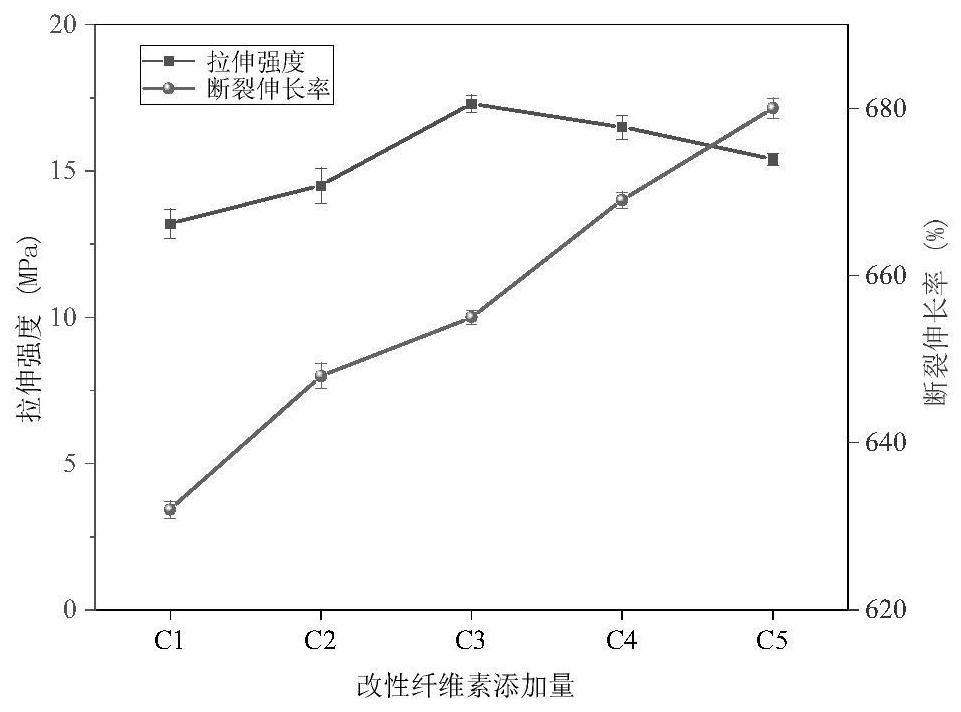

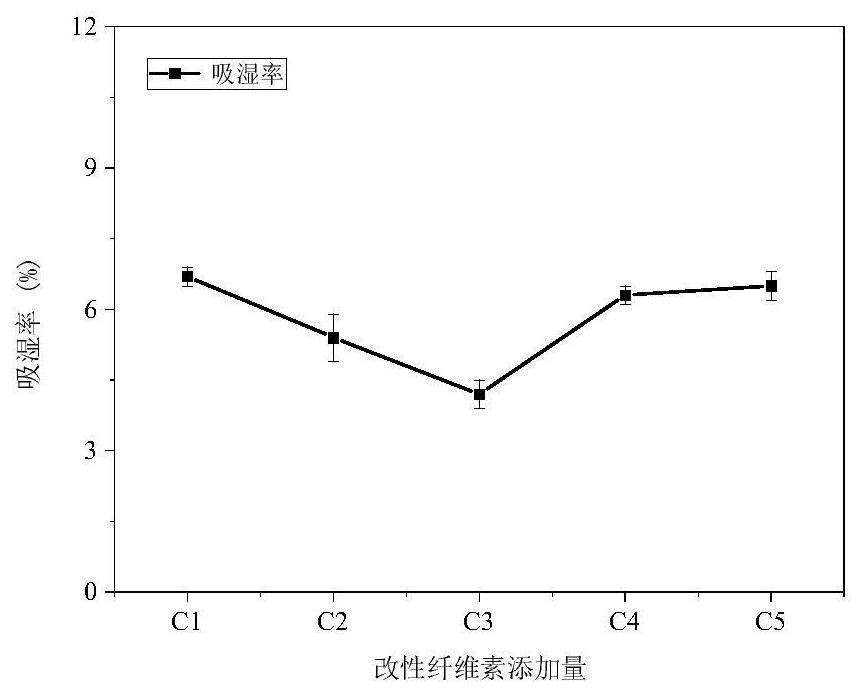

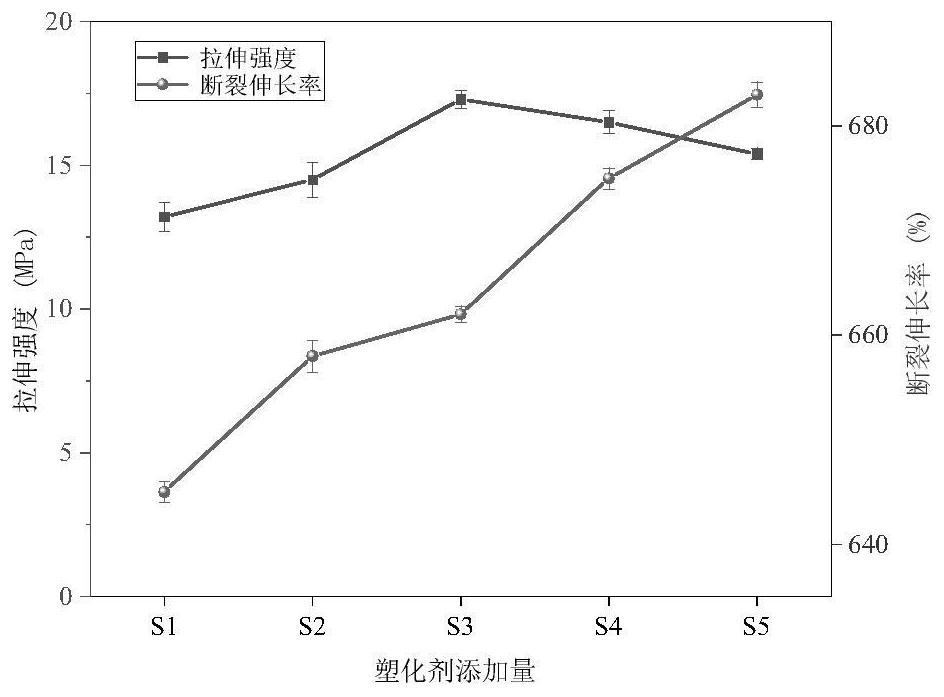

Starch/cellulose/PBAT composite film and preparation method thereof

ActiveCN113248798AImprove processing efficiencyGood mechanicsGrain treatmentsRetrogradation (starch)Polymer science

The invention discloses a starch / cellulose / PBAT composite film which comprises the following components in parts by mass: 100 parts of starch, 1-10 parts of modified cellulose, 5-20 parts of a plasticizer, 0.5-4 parts of a lubricant, 0.5-4 parts of a stabilizer, 1-5 parts of a coupling agent, 2-10 parts of an adhesive and 50-100 parts of PBAT. The composite film is good in mechanical property and retrogradation resistance, good in processability, high in processing efficiency, simple in preparation process, low in cost and suitable for large-scale production, and the actual filling amount can reach 60%. The starch / cellulose / PBAT composite master batch premixed composite material is directly prepared by creatively utilizing a ball milling method. The dispersity of reinforcement cellulose in a PBAT / starch matrix is improved while refining treatment is carried out, starch is plasticized and grafted with cellulose, and a particle reinforcing effect is achieved. The starch is entangled with PBAT molecules, and high-strength and easy-to-process thermoplastic starch is obtained through mechanochemical modification.

Owner:NINGBO UNIV

Environment-friendly flame retardant fame-retardant nylon 6 and preparation method thereof

The invention discloses environment-friendly phosphorus-nitrogen one-component intumescent flame retardant-modified nylon 6 which is prepared from the following components in parts by weight: 50-90 parts of nylon 6, 5-25 parts of a phosphorus-nitrogen one-component intumescent flame retardant, 2-10 parts of an inorganic synergistic flame retardant, 2-10 parts of a compatilizer and 1-5 parts of an antioxidant. The invention further discloses a preparation method of the environment-friendly phosphorus-nitrogen one-component intumescent flame retardant-modified nylon 6. A safe and environment-friendly high-performance nylon 6-modified material with good mechanical properties and a good flame-retardant property is obtained through introducing environment-friendly common flame-retardant nylon 6 with the good flame-retardant property and water solubility resistance of the phosphorus-nitrogen one-component intumescent flame retardant and the inorganic synergistic flame retardant; and the environment-friendly phosphorus-nitrogen one-component intumescent flame retardant-modified nylon 6 has good development potential and wide application prospects.

Owner:陈霞

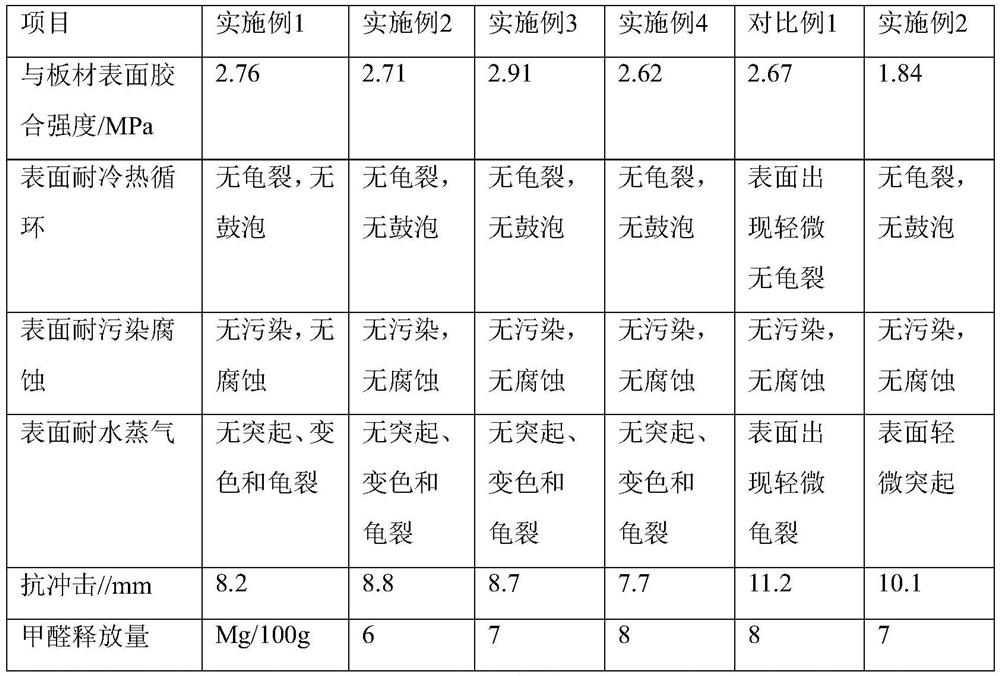

Weather-proof decorative paper and preparation method thereof

PendingCN112301797AGood weather resistanceAccelerated corrosionSpecial paperNon-macromolecular organic additionWeather resistanceProcess engineering

The invention relates to the technical field of decorative paper, in particular to weather-proof decorative paper and a preparation method thereof. The decorative paper comprises a base paper layer, an impermeable adhesive layer coating the surface of the base paper layer and a protective adhesive layer attached to the upper surface of the impermeable adhesive layer, and the base paper layer is provided with an ink pattern layer. The decorative paper has excellent weather resistance, corrosion resistance and mechanical properties, and is long in service life, good in appearance effect and highin practicability. The preparation method of the weather-proof decorative paper is simple, efficient, convenient to operate and control, stable in product quality and beneficial to industrial production.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

Preparation method of poly-4-methylpentene nanosheet composite film

The invention discloses a poly-4-methylpentene nanosheet composite film which is characterized by being prepared from the following raw materials in parts by weight: 40-55 parts of poly-4-methyl-1-pentene, 10-15 parts of amino-terminated hyperbranched polybenzimidazole, 3-6 parts of a surface-modified graphene nanosheet / ceramic nanosheet composite, 1-3 parts of allyl glycidyl ether and 0.5-1.5 parts of N-[4-cyan-3-(trifluoromethyl) phenyl] methyl epoxy acrylamide. The invention also discloses a preparation method of the poly-4-methylpentene nanosheet composite film. The poly-4-methylpentene nanosheet composite film is small in dielectric loss, large in dielectric constant, good in thermal stability, high in breakdown field strength, good in flexibility, small in mass and easy to process.

Owner:苏州市新广益电子股份有限公司

Environment-friendly composite flame retardant special for copper-clad plate and preparation method thereof

InactiveCN111073058AImprove flame retardant performanceImprove mechanical propertiesAluminium hydroxideCopper

The invention relates to the technical field of flame-retardant processing, in particular to an environment-friendly composite flame retardant special for a copper-clad plate and a preparation methodthereof. The composite flame retardant comprises a synergistic flame retardant, magnesium hydroxide and aluminum hydroxide, wherein the magnesium hydroxide is superfine modified magnesium hydroxide; the aluminum hydroxide is superfine modified aluminum hydroxide; the mass ratio of the synergistic flame retardant, the superfine modified magnesium hydroxide and the superfine modified aluminum hydroxide is 1: (3-14): (2-8). The composite flame retardant special for the copper-clad plate has high cost performance, is environment-friendly and non-toxic, and can improve the flame retardant propertyand mechanical property of the copper-clad plate.

Owner:HEFEI ZHONGKE FLAME RETARDANT NEW MATERIAL

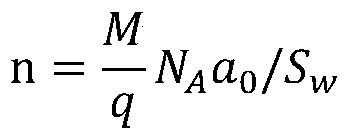

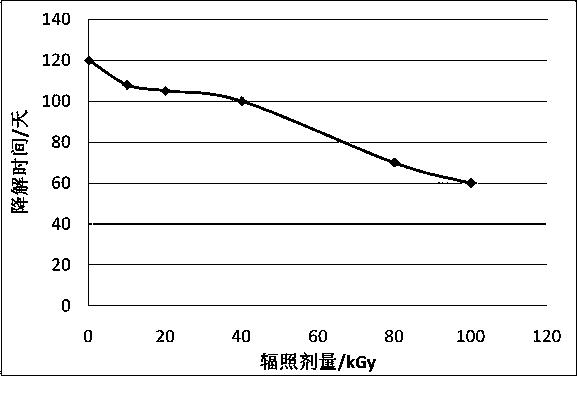

Preparation method for controllable biodegradable material

The invention discloses a preparation method for a controllable biodegradable material. The preparation method is characterized by comprising the following steps of: 1) starch radiation modification; 2) mixing: adding a nanometre assistant, polyvinyl alcohol, stearic acid, polylactic acid, a radiation sensitizer and an accelerant in the treated modified starch, adequately stirring, and uniformly mixing; 3) radiation copolymerization: placing the mixed sample in an aluminium foil bag carrying out packaging and sealing treatment in a vacuum or by charging nitrogen, and then carrying out radiation treatment on the packaged sample; 4) granulation / membrane preparation: uniformly pouring the mixture subjected to radiation copolymerization in a double-screw double-exhaust extrusion granulator group or a double-screw double-exhaust extrusion pelletizer group, and carrying out extrusion granulation or pelletizing; 5) radiation degradation rate control: radiating the product obtained by granulation / membrane preparation while controlling the dosage to be 10-100 kGy and controlling the dosage non-uniformity U of the product to be not greater than 1.3. According to the preparation method disclosed by the invention, the problems of cumbersome process, high-temperature energy consumption, and inevitably-brought pollutant discharge of a common chemical method are overcome, and the object of controlling the decomposition rate is realized.

Owner:赵永富

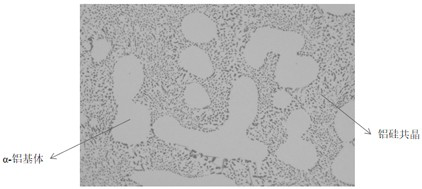

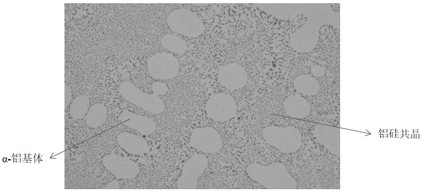

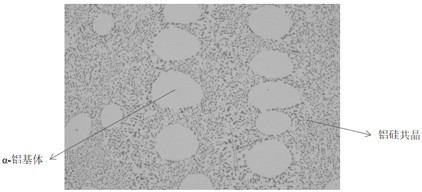

Preparation method of high-thermal-conductivity AlSi alloy

InactiveCN113846252AReduce impurity componentsImproves tissue compactnessTemperature controlSilicon alloy

The invention relates to a preparation method of a high-thermal-conductivity AlSi alloy. The preparation method comprises the following steps: preparing materials, wherein raw materials are prepared according to the composition proportion of the alloy; melting, wherein a pure aluminum ingot is placed in a smelting furnace to be heated and melted to form molten aluminum; transferring molten aluminum in the smelting furnace into an alloying furnace, increasing the temperature to 760-780 DEG C, and adding an Al-50Si intermediate alloy; after the molten aluminum is completely melted, uniformly stirring for 10-30 minutes, and performing modification treatment by keeping the temperature unchanged in the stirring process: removing scum on the surface of the molten aluminum, increasing the temperature of the molten aluminum to 770 DEG C, and adding an Al-10Sr intermediate alloy modifier; conducting refining treatment, wherein the temperature of molten aluminum in the alloying furnace is controlled to be 770 DEG C, and an Al-3Sc intermediate alloy is added; and conducting heat treatment, wherein the temperature is gradually increased to 240-255 DEG C within one hour, heat preservation is conducted for 0.5 hour, then the temperature is gradually increased to 335-350 DEG C within one hour, heat preservation is conducted for 2 hours, and then furnace cooling is conducted to the room temperature. The aluminum-silicon alloy which is excellent in comprehensive performance and high in heat conductivity is prepared by carrying out process integration innovation improvement on the aspects of melt refining, modification refining, artificial aging heat treatment and the like, and the aluminum-silicon alloy has important application and popularization value.

Owner:南通鸿劲金属铝业有限公司

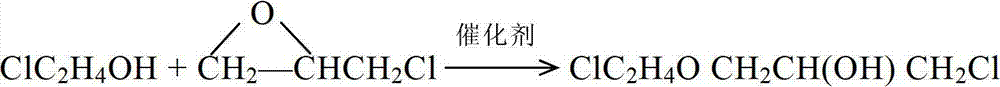

Synthesis method of 2-hydroxyl-3-chloropropyl-2'-chloroethyl ether, and application thereof

ActiveCN102757314AGood mechanicsGood fuel resistanceEther preparation from oxiranesPolysulfide rubberSynthesis methods

The invention provides a synthesis method of 2-hydroxyl-3-chloropropyl-2'-chloroethyl ether, and an application thereof. The method comprises the steps of: firstly, mixing 2-chlorohydrin and a catalyst, and heating up to be at 45 DEG C; maintaining the temperature of 45 DEG C, and slowly dripping epoxy chloropropane into the mixture within 1-1.5 hours; then, controlling the reaction temperature to be within the range of 45-80 DEG C and the reaction time to be within the range of 3-5 hours, wherein the molar ratio between the 2-chlorohydrin and the epoxy chloropropane is 1.5-5.0, and the mass fraction of the catalyst accounts 0.2-1.5% of that of the epoxy chloropropane; and finally, carrying out vacuum distillation on reaction liquid, and collecting fraction under 1.33kPa at 114-117 DEG C. The 2-hydroxyl-3-chloropropyl-2'-chloroethyl ether synthesized by using the method can be taken as a comonomer for preparing polysulfide rubber, and the prepared polysulfide rubber has relatively good mechanical property and fuel resistance.

Owner:锦西化工研究院有限公司

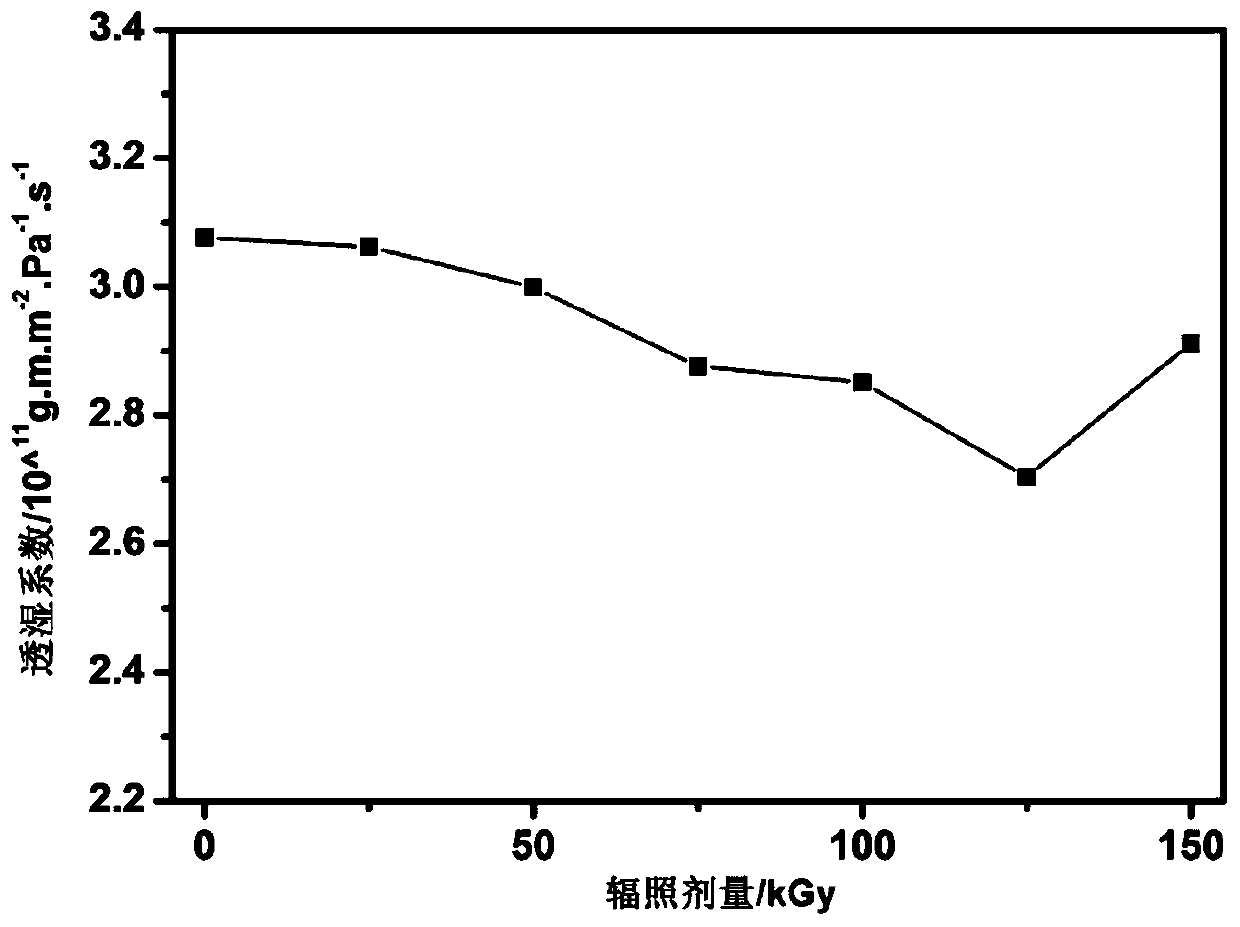

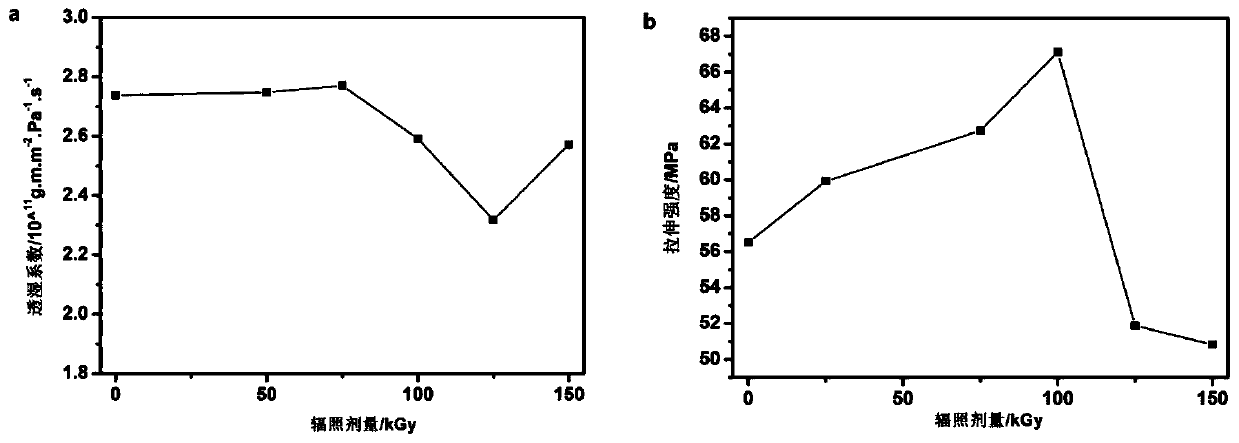

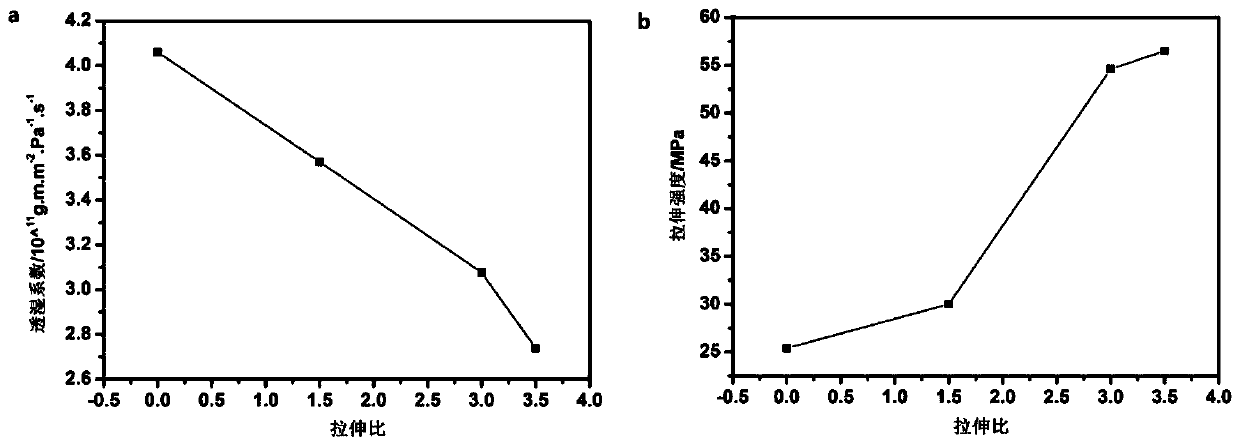

Water vapor barrier biodegradable polymer film as well as preparation and application thereof

ActiveCN111234279AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersPolymer sciencePlastic mulch

The invention belongs to the field of biodegradable materials. The invention discloses a water vapor barrier biodegradable polymer film as well as preparation and application thereof. The preparationmethod comprises the following steps: blending the biodegradable polymer and the cross-linking agent to obtain a special material, molding the special material to form a thick film, carrying out bidirectional stretching on the thick film, and carrying out electron beam irradiation to obtain the water vapor barrier biodegradable polymer film, thereby improving the water vapor barrier property of the biodegradable polymer film. According to the invention, the overall flow process design of the preparation method is improved, wherein the biodegradable polymer film is modified by using a two-way stretching process and an electron beam irradiation technology, so that the problem of poor water vapor barrier property of the biodegradable polymer film can be effectively solved, and the biodegradable polymer film can be widely applied to the fields of agricultural mulching films, food and daily necessity packaging, electronic product packaging and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

LCP acoustic film and preparation method thereof

ActiveCN110776726ASimple processEasy to operatePolymeric diaphragmsPolymer scienceElectric properties

The invention discloses an LCP acoustic film, which is prepared from the following raw materials by weight: 15-20 parts of a vinyl fluorine-containing cyclohexyl methyl ether liquid crystal compound / methyl methacrylate / 4-acryloyloxybenzophenone / single-terminal vinyl silicone oil copolymer, 50-60 parts of a liquid crystal polymer, 30-40 parts of poly1,4-dihydroxy-2-butene 2,7-naphthalenedicarboxylate, 8-12 parts of vinyl-POSS, 0.2-0.4 part of a heat stabilizer, 0.1-0.4 part of a lubricant, 0.1-0.3 part of an antioxidant and 0.02-0.05 part of an initiator. The invention further provides a preparation method of the LCP acoustic film. According to the invention, the LCP acoustic film retains the advantages of heat resistance, molding processability, dimensional stability, optical performance,electrical performance, chemical resistance, excellent flame retardancy, low dielectric constant and dielectric loss of LCP, and further has good weather resistance, good heat resistance, good mechanical property, good sensitivity and good consistency.

Owner:苏州市新广益电子股份有限公司

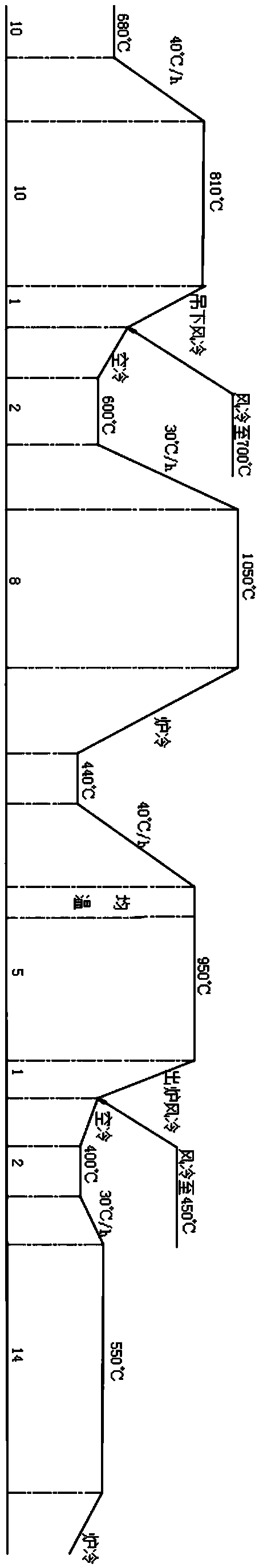

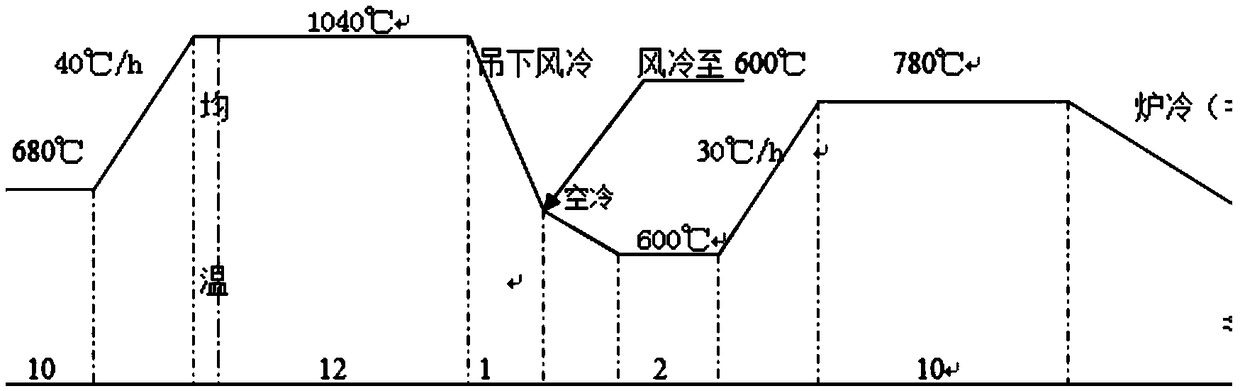

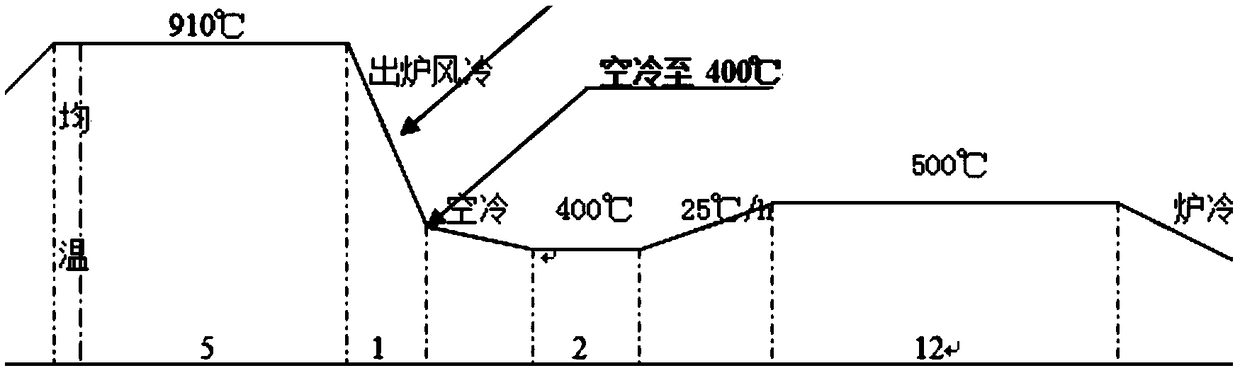

Heat treatment method for wide-diameter H-shaped steel roll collar

InactiveCN108823392AHigh hardnessGood core carbideFurnace typesHeat treatment furnacesCarbideHardness

The invention discloses a heat treatment method for a wide-diameter H-shaped steel roll collar and belongs to the technical field of roll collar manufacture. The heat treatment method has a technicalbreakthrough in wide-diameter H-shaped steel roll collar (phi 1600) manufacture and provides relevant manufacturing process parameters. The wide-diameter H-shaped steel roll collar has good hardness,core carbide and mechanical properties. The method comprises: spheroidization treatment and then cold cutting of the collar. Since the utilization rate of a blank is only 50 to 60%, after cold cutting, a large amount of a residual material and a protective layer are removed and the thickness of the workpiece is reduced so that the later high-temperature diffusion treatment process is promoted. Thetime of the existing high-temperature diffusion treatment process is 12h. After cold cutting of the collar, energy consumption of a large amount of residual materials is avoided, the energy consumption of high temperature diffusion is effectively reduced, the heat transfer effects are good, temperature equalization time is short, the time of high-temperature diffusion treatment is in 5-8h and isshortened by more than half, the diffusion is more complete and the quality of the matrix is good.

Owner:成都三强轧辊股份有限公司

Adhesive for building board joint processed from waste stone

InactiveCN112480849AReduce wasteImprove visual effectsNon-macromolecular adhesive additivesStarch derivtive adhesivesPtru catalystAdhesive

The invention belongs to the technical field of building processing, and relates to an adhesive for a building board joint processed from waste stone. The adhesive comprises the following raw materials in parts by mass: 10-60 parts of calcium powder; 10-60 parts of silicon powder; 8-40 parts of redispersible latex powder; 15-30 parts of polymer rubber powder; 8-15 parts of hollow ceramic microbeads; 2-10 parts of modified starch; 0.2 to 3 parts of a cross-linking agent; 0.2 to 3 parts of a catalyst; 0.2-3 parts of a curing agent; 0.2 to 1 part of an accelerant; wherein the source of the calcium powder is marble crushed aggregates, and the source of the silicon powder is granite crushed aggregates. According to the adhesive, through combination of multiple component raw materials, industrial crushed aggregates are effectively utilized while the bonding strength and waterproofness are guaranteed, a better vertical face effect is formed by the adhesive and the microcrystal foaming heat preservation plates, and the adhesive is specially used for bonding the microcrystal foaming heat preservation plates.

Owner:NINGXIA BLACK GOLD TECH CO LTD

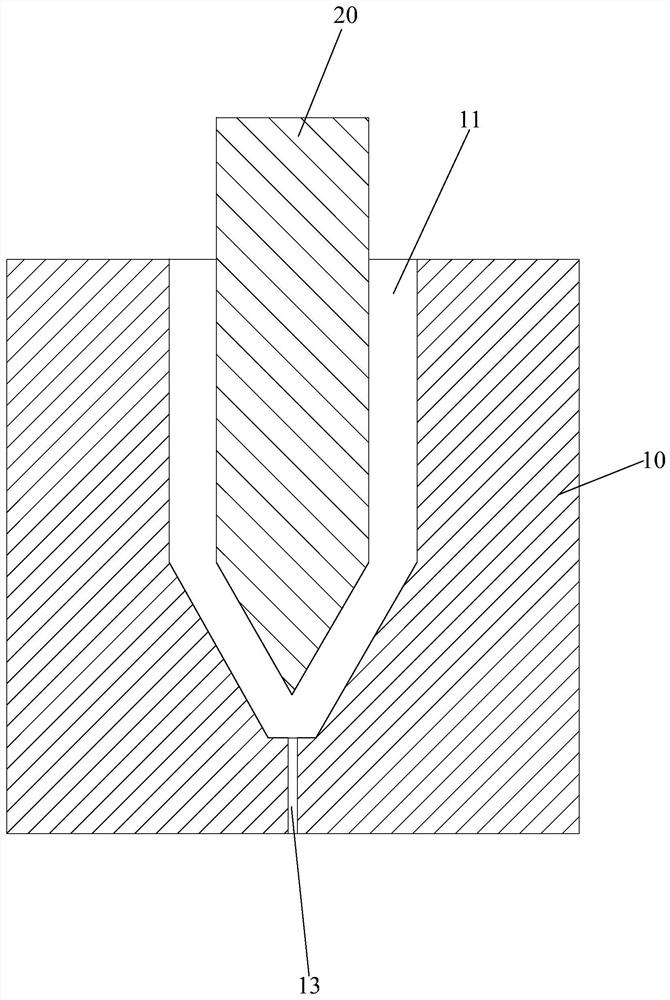

Corrosion-resistant orthopedic degradable screw and manufacturing method thereof

PendingCN112916694ACompact structureGood mechanicsShaping toolsInternal osteosythesisComposite materialCorrosion resistant

The invention discloses a manufacturing method for a corrosion-resistant orthopedic degradable screw. The manufacturing method comprises the following steps that (1) a degradable metal bar, a female die and a stamping male die are provided, an open conical die cavity is formed in the female die, the other side of the die cavity communicates with an overflow hole, and the stamping male die is provided with a tip; (2) the degradable metal bar is placed in the die cavity of the female die, the stamping male die is operated to impact the degradable metal bar, the stamping male die impacts a groove in the degradable metal bar in the impact process, and a part of metal flows outsides from the overflow hole; and (3) the orthopedic screw is obtained in the die cavity through repeated impacting for a certain time for multiple times. According to the manufacturing method, through cooperation of the female die and the stamping male die, the degradable metal bar is hammered and stamped for multiple times to obtain the orthopedic screw which is of a compact structure and good in mechanical properties, so that the corrosion resistance of the orthopedic screw is improved, the degradation rate is low after the orthopedic screw is implanted into a human body, the process is simple, and the cost is low. The invention further provides the corrosion-resistant orthopedic degradable screw manufactured by the method.

Owner:东莞立德生物医疗有限公司

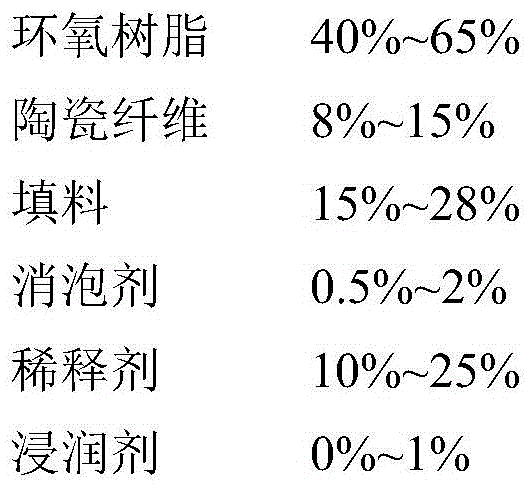

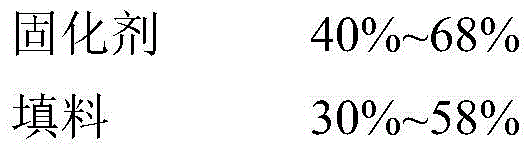

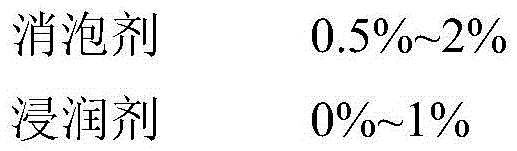

Insulation box filling adhesive and preparation method thereof

The invention provides an insulation box filling adhesive. The insulation box filling adhesive comprises a component A and a component B in a weight ratio of (2-4) to 1, wherein the component A comprises epoxy resin, ceramic fibers, fillers, defoaming agents, diluents and an impregnating compound; the component B comprises curing agents, the fillers, the defoaming agents and the impregnating compound. The insulation box filling adhesive has the beneficial effects that the thixotropy and compactness of the filling adhesive are improved, so that the filling adhesive can be individually used for filling insulation boxes at winding ends, without putty for sealing, and is beneficial to saving the material cost and improving the industrial production efficiency.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

Acrylic elastomer latex for building sealing paste, and preparation method thereof

InactiveCN109694442AAdjustable hardnessModerate hardnessAmide/imide polymer adhesivesEster polymer adhesivesSodium bicarbonateCross-link

The invention relates to an acrylic elastomer latex for building sealing paste, and a preparation method thereof, and belongs to the technical field of latexes, wherein the acrylic elastomer latex comprises: dodecyl methacrylate, tetradecyl methacrylate, methyl methacrylate, a methylol acrylamide post-cross-linking agent, tetraglycol dimethacrylate, an OP-10 emulsifier, a sodium laurylsulfonate emulsifier, a sodium bicarbonate initiator, a potassium persulfate initiator, and deionized water. The acrylate-based elastomer latex resin prepared from the acrylic elastomer latex of the present invention has good elasticity and excellent comprehensive mechanical properties.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Double-faced adhesive tape and forming process thereof

ActiveCN111574935AImprove universalitySimple molding processFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceWeather resistance

The invention discloses a double-faced adhesive tape that is characterized by sequentially comprising a film protection layer, an adhesive layer and a base material layer from top to bottom. The filmprotection layer is prepared by uniformly mixing the following components, by weight: 40 to 60 parts of 3, 3-difluoro-[1, 1-biphenyl]-4, 4-dicarboxylic acid / pyrazolo [1, 5-a] [1, 3, 5] triazine-2, 4-diol polycondensate, 10 to 20 parts of PBT resin and 10 to 15 parts of PET resin. Meanwhile, the invention further discloses a forming process of the double-faced adhesive tape. The double-faced adhesive tape disclosed by the invention is excellent in chemical resistance, good in weather resistance and high-temperature resistance, high in bonding strength and mechanical property and good in comprehensive performance.

Owner:深圳市中鑫通科技有限公司

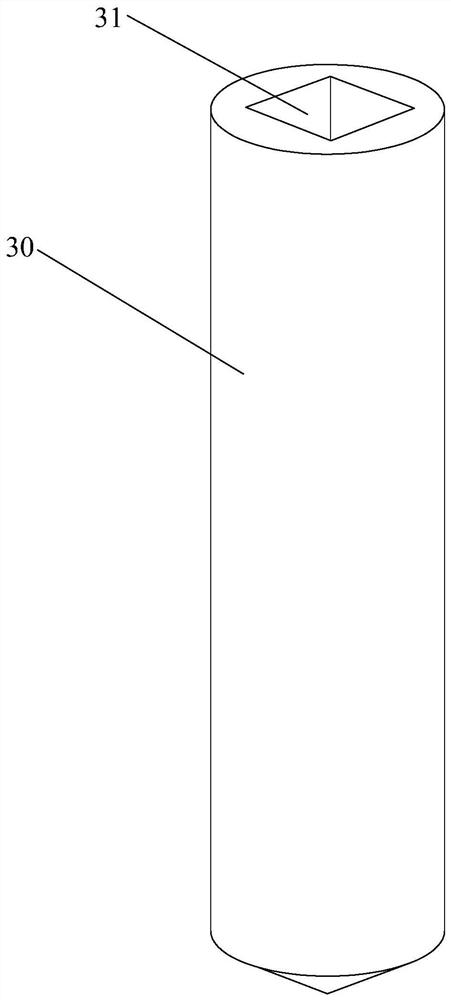

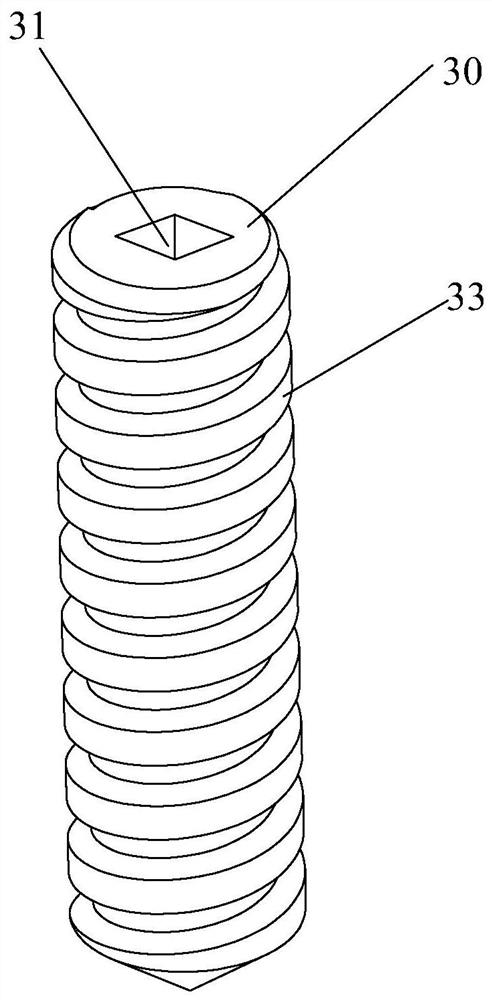

Preparation method of compacted split conductor

ActiveCN109686505AGood electricityGood mechanicsCable/conductor manufactureCopper conductorMaterials science

The invention discloses a preparation method of a compacted split conductor. The preparation method comprises the following steps that 1, according to a target sectional area, a layering scheme is prepared; 2, an inner core is formed through wiredrawing, annealing and compaction; 3, a wiredrawn copper conductor is compressed into a slice, and then the inner core is coated with the slice as an external layer, coating is conducted in sequence, and fan-shaped strand conductors are obtained; 4, the five fan-shaped strand conductors are subjected to cabling to form the circular compacted split conductor, the compacted split conductor is wrapped with a semi-conductive tape, fixed and then wrapped with a PVC protecting belt. The preparation method of the compacted split conductor can effectivelyreduce the phenomena of flashes and corner burst of the compacted conductor, the compaction coefficient of the conductor can be improved, the outer diameter of the conductor can be effectively reduced, the outer layer of the compacted conductor and the inner core are high in axial stretching rate, and after cabling, the conductor is uniform in electrical conductivity.

Owner:广州岭南电缆股份有限公司

Waterproof sound-transmitting membrane assembly and MEMS equipped with waterproof sound-transmitting membrane assembly

ActiveCN112929798APlay a protective effectInfluence of waterproof and sound permeabilityMicrophonesPolymeric diaphragmsMicro electrical mechanical systemsEngineering

The invention relates to a waterproof sound transmission membrane assembly, which comprises a waterproof sound transmission membrane and a supporting layer, the supporting layer is located on the side, away from the external environment, of the waterproof sound transmission membrane, the supporting layer is a high-molecular polymer layer, the price is low, and overall installation and processing of the waterproof sound transmission membrane assembly are facilitated; meanwhile, the elastic modulus of the supporting layer is 40-400 MPa, and the supporting layer has a large supporting effect on the waterproof sound-transmitting membrane, so that the water pressure resistance of the whole waterproof sound-transmitting membrane assembly is 20-500 kPa, and the water pressure resistance is large; meanwhile, a plurality of supporting holes are formed in the supporting layer, so that the sound transmission performance of the supporting layer is improved, the sound blocking amount of the waterproof sound transmission membrane assembly in the audio frequency range of 100-10000 Hz is smaller than 3 dB, and the sound transmission performance is good; in addition, the waterproof performance of the waterproof sound transmission membrane assembly is IP64 or IP65 or IP66 or IP67 or IP68, and the waterproof performance is high; the waterproof sound transmission membrane assembly is not only suitable for 3C electronic products, but also suitable for electronic products working underwater, and is especially suitable for being applied to MEMS and other micro electro mechanical systems.

Owner:HANGZHOU IPRO MEMBRANE TECH

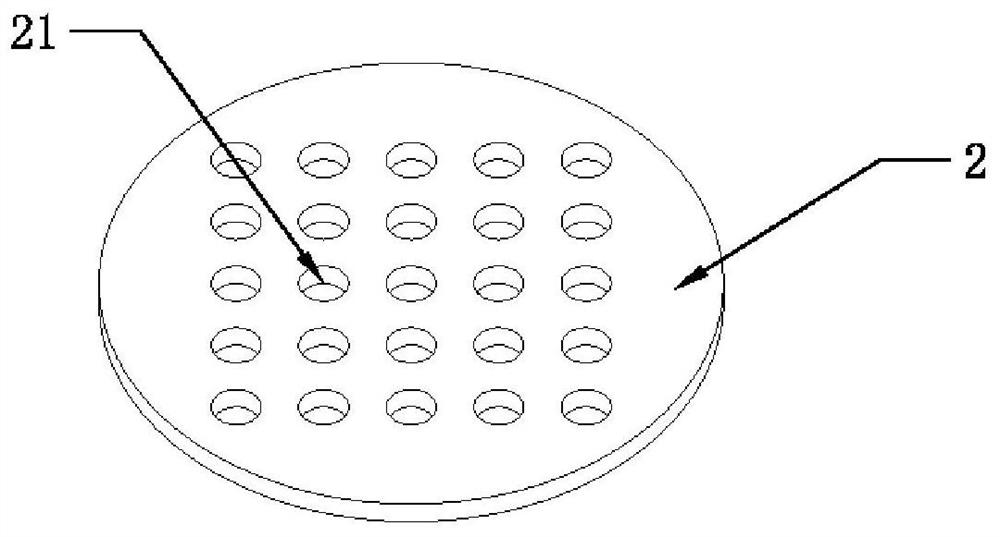

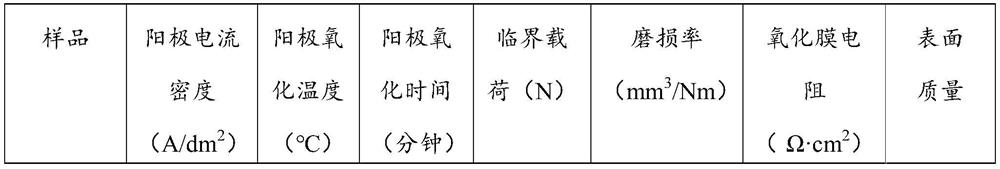

Environment-friendly wide-temperature aluminum alloy anodic oxidation electrolyte and preparation method and application thereof

ActiveCN114016107AReduce internal stressReduce surface chalkingAnodisationProcess efficiency improvementElectrolytic agentPhysical chemistry

The invention belongs to the technical field of metal surface machining, and particularly discloses an environment-friendly wide-temperature aluminum alloy anodic oxidation electrolyte and a preparation method and application thereof. The aluminum alloy anodic oxidation electrolyte comprises an organic complexing agent and rare metal salt. The organic complexing agent comprises an alcohol amine compound; the rare metal salt comprises cerium salt; the aluminum alloy anodic oxidation electrolyte is prepared by mixing all the raw materials. When the aluminum alloy anodic oxidation electrolyte is used for anodizing aluminum alloy, high anodic oxidation current density can be adopted; anodic oxidation is completed within a short anodic oxidation time, an anodic oxidation film layer with excellent mechanical properties and corrosion resistance can still be formed within a wide temperature range of 20-40 DEG C, the critical load is 10.13-15.71 N, the wear rate is 5.4*10<-5>-9.52*10<-3> mm / Nm, and the oxidation film resistance is 7.8*10<4>-5.5*10<5> omega.cm<2>.

Owner:FOSHAN UNIVERSITY

Tetrafluoroethylene-hexafluoropropylene copolymer communication optical cable protective jacket material and preparation method thereof

InactiveCN104312064AImprove performanceGood insulationInsulated cablesInsulatorsHexafluoropropylenePhosphoric acid

The invention discloses a tetrafluoroethylene-hexafluoropropylene copolymer communication optical cable protective jacket material and a preparation method thereof. The tetrafluoroethylene-hexafluoropropylene copolymer communication optical cable protective jacket material is prepared from the following raw materials in part by weight: 68 to 82 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 36 to 54 parts of vinyl chloride-ethylene-butyl acrylate copolymer, 18 to 32 parts of reworked material, 3 to 6 parts of oleoyl diethanol amine, 10 to 15 parts of polypentabromobenzyl acrylate, 1 to 2 parts of nickel dibutyl dithiocarbamate, 12 to 16 parts of condensed phosphoric acid, 16 to 22 parts of acetyl tributyl citrate, 2 to 3 parts of 4,4-bis(phenylisopropyl)diphenylamine, 4 to 8 parts of bisphenol A alkyl phosphate, 10 to 15 parts of amorphous graphite powder, 2 to 4 parts of zinc laurate, 3 to 5 parts of behenamide, 10 to 15 parts of calcined andalusite powder and 1 to 2 parts of 4-tert-butylcatechol. The protective jacket disclosed by the invention has excellent comprehensive performance, excellent electrical insulation property and mechanical property, excellent heat resistance, chemical stability, creep resistance and aging resistance, a long service life, a wide application range and wide market prospect.

Owner:安徽电信器材贸易工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com