Solvent-free polyurethane intermediate layer resin of super-soft synthetic leather and preparation method of solvent-free polyurethane intermediate layer resin

A solvent-free polyurethane and synthetic leather technology, applied in the field of synthetic leather, to achieve the effects of good high temperature resistance, good mechanical properties, and low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A solvent-free polyurethane intermediate layer resin for super soft synthetic leather, composed of component A and component B in a mass ratio of 100:25,

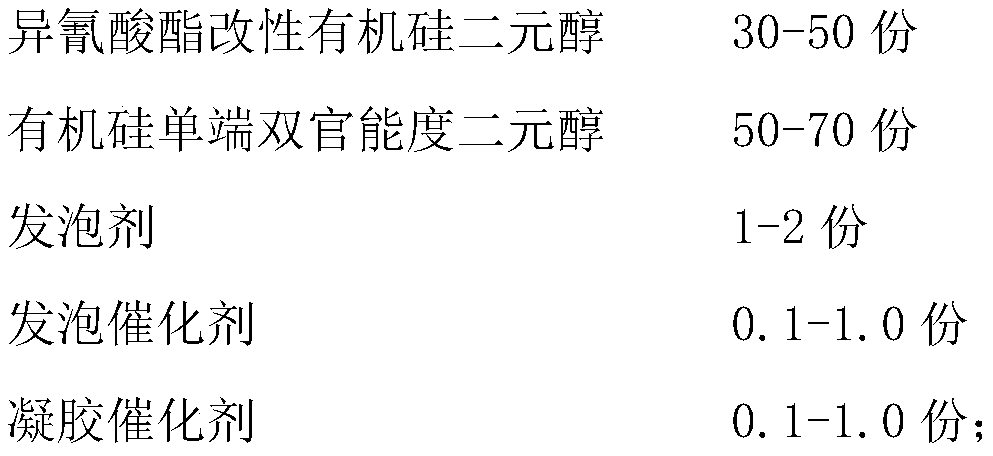

[0060] Wherein component A is composed of the following components in parts by mass:

[0061]

[0062] The B component is composed of the following components in parts by mass:

[0063] Isocyanate (4,4'-diphenylmethane diisocyanate, mixture of 4,4'-diphenylmethane diisocyanate and 2,4'-diphenylmethane diisocyanate) 180 parts

[0064] Silicone polyether diol 80 parts

[0065] Silicone diamine 20 parts

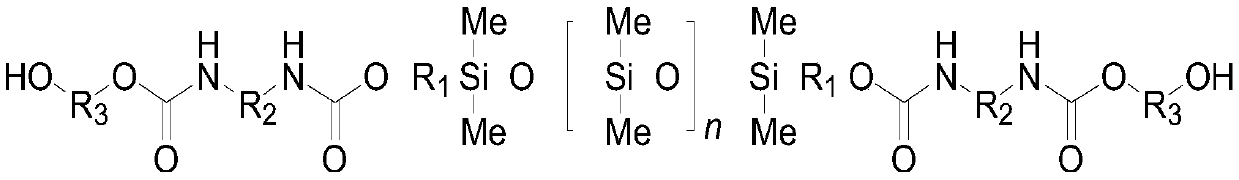

[0066] The isocyanate-modified silicone diol in the A component is composed of the following components in parts by mass:

[0067] Silicone glycol 100 parts

[0068] Isocyanate (carbodiimide-uretonimine modified MDI) 58 parts

[0069] Chain extender (1,4-butanediol) 18 parts

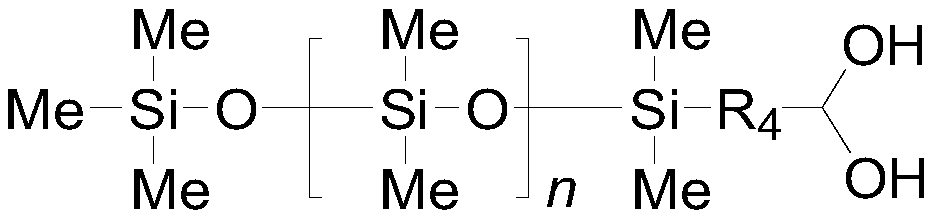

[0070] The organosilicon single-end difunctional dihydric alcohol selects the silicone single-end difunctional dihydric alcohol Tech-21...

Embodiment 2

[0085] A solvent-free polyurethane intermediate layer resin for super soft synthetic leather, composed of component A and component B in a mass ratio of 100:105,

[0086] Wherein component A is composed of the following components in parts by mass:

[0087]

[0088] The B component is composed of the following components in parts by mass:

[0089] Isocyanate (4,4'-diphenylmethane diisocyanate, mixture of 4,4'-diphenylmethane diisocyanate and 2,4'-diphenylmethane diisocyanate) 60 parts

[0090] Silicone polyether diol 90 parts

[0091] Silicone diamine 10 parts

[0092] The isocyanate-modified silicone diol in the A component is composed of the following components in parts by mass:

[0093] Silicone dihydric alcohol (molecular weight 1000) 100 parts

[0094] Isocyanate (toluene diisocyanate) 35 parts

[0095] Chain extender (ethylene glycol) 12.5 parts

[0096] Its preparation method comprises the following steps:

[0097] (1) Preparation of isocyanate-modified silic...

Embodiment 3

[0106]A solvent-free polyurethane intermediate layer resin for super soft synthetic leather, composed of component A and component B in a mass ratio of 100:48,

[0107] Wherein component A is composed of the following components in parts by mass:

[0108]

[0109] The B component is composed of the following components in parts by mass:

[0110] Isocyanate (4,4'-diphenylmethane diisocyanate, mixture of 4,4'-diphenylmethane diisocyanate and 2,4'-diphenylmethane diisocyanate) 120 parts

[0111] Silicone polyether diol 85 parts

[0112] Silicone diamine 15 parts

[0113] The isocyanate-modified silicone diol in the A component is composed of the following components in parts by mass:

[0114] Silicone glycol 100 parts

[0115] 52.5 parts of isocyanate (hydrogenated MDI)

[0116] Chain extender (1,3-propanediol) 15.2 parts

[0117] Products, Tech-2127 is a silicone polyether diol product with a molecular weight of 2000 produced by Shanghai Tiger Polymer Technology Co., Lt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com