Preparation method of compacted split conductor

A technique of splitting and compacting conductors, which is applied in cable/conductor manufacturing, electrical components, circuits, etc. It can solve problems such as low compaction coefficient and conductor flashing, and achieve reduced skin effect, uniform current, and small bursting pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a compacted and divided conductor, comprising the following steps:

[0028] 1) Calculate the diameter according to the target cross-sectional area of the fan-shaped strand conductor to be made, and formulate a layering scheme:

[0029] 160-200mm 2 The strand conductor is divided into inner and outer layers plus 2 outer layers; 200-300mm 2 The strand conductor is divided into inner core plus 3 outer layers; 300-400mm 2 The strand conductor is divided into inner core plus 4 outer layers; 400-500mm 2 The strand conductor is divided into inner core plus 5 outer layers;

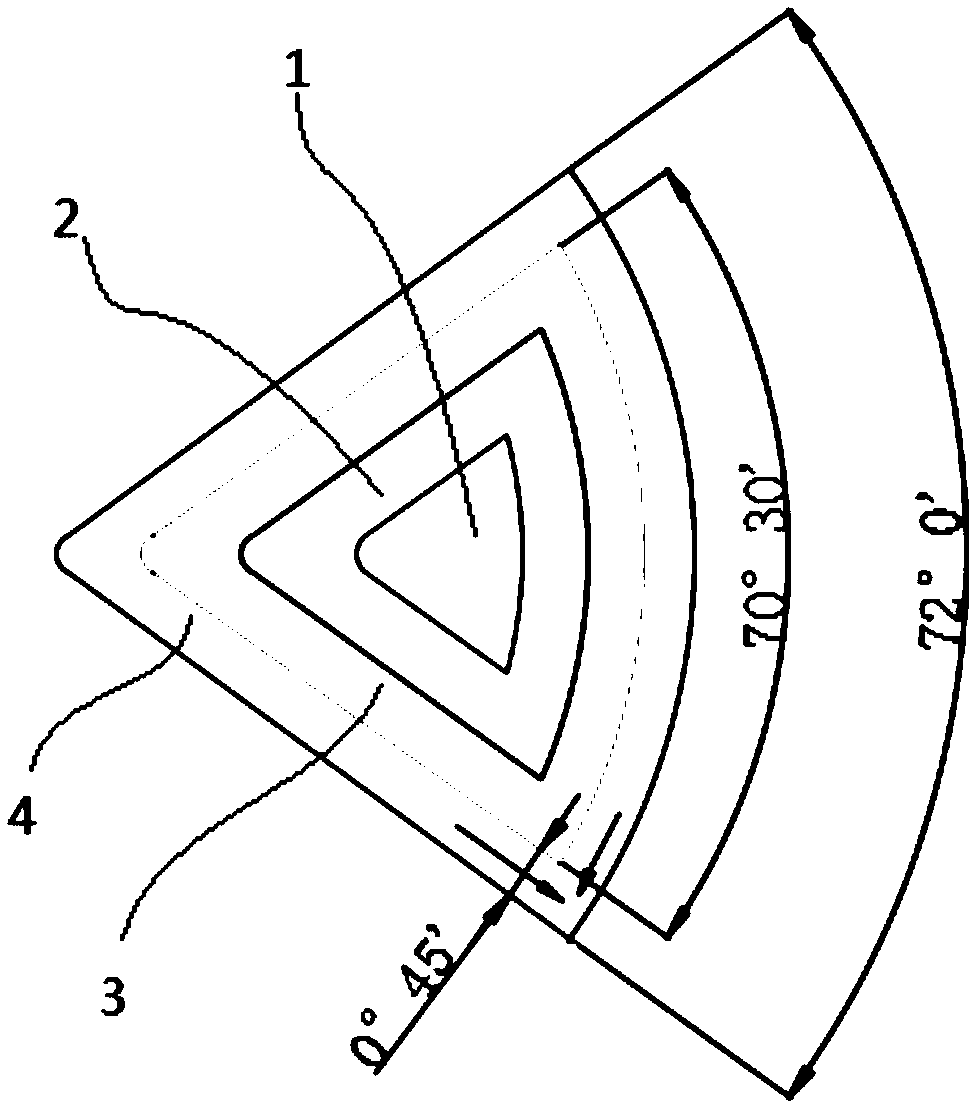

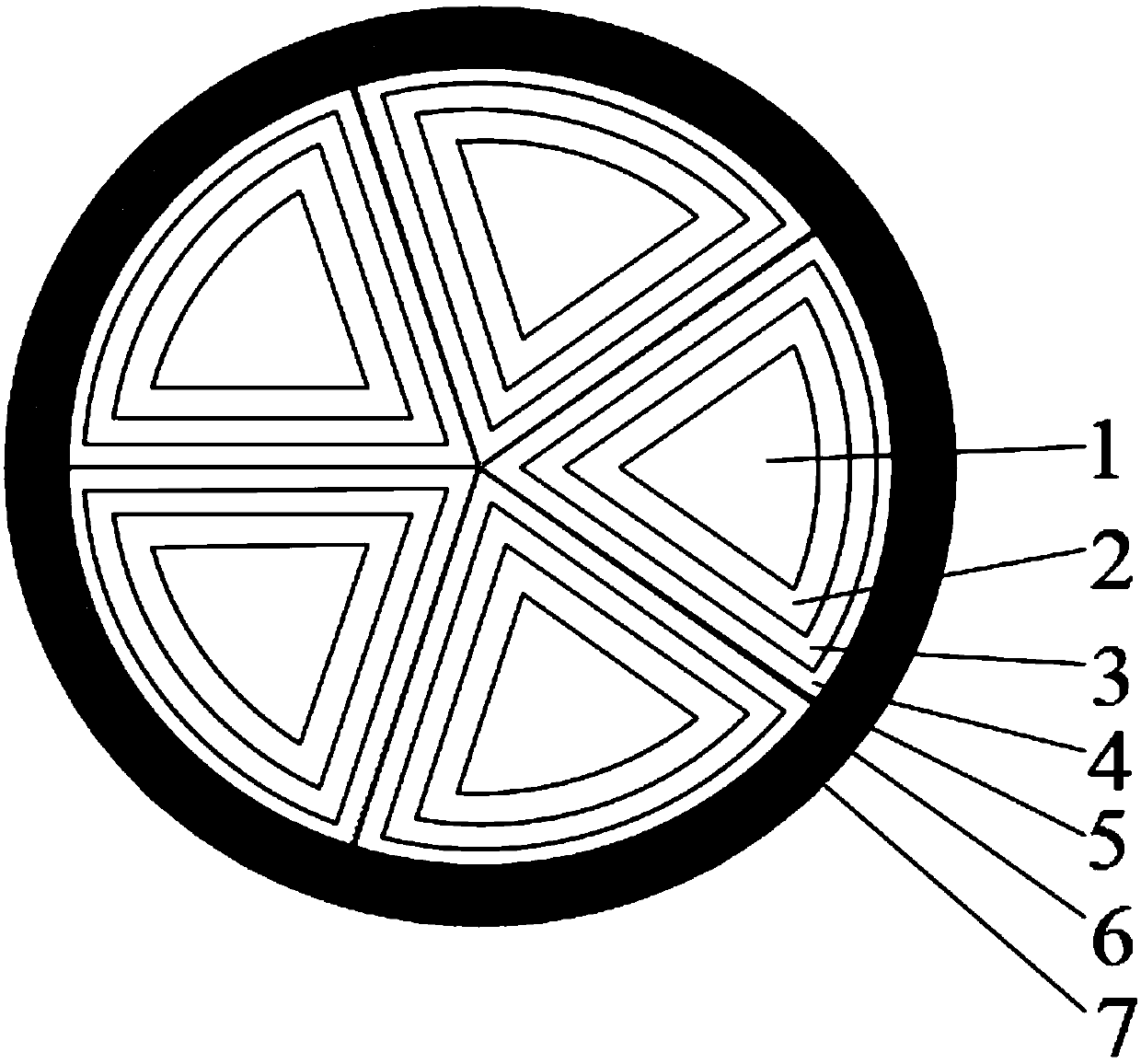

[0030] The cross-sectional area of each conductor layer is equal, the angle of the fan-shaped strand conductors from the outside to the inside decreases by 1-2°, and the angle of the outermost conductor is 72°;

[0031] 2) Use copper conductors that meet the national standard as raw materials, wire drawing and annealing, and press into fan-shaped stock c...

Embodiment 1

[0037] The cross-sectional area is 800mm 2 A method for preparing a compacted split conductor, comprising the steps of:

[0038] 1) Draw up a layering scheme: layering with the inner core plus 2 layers of cladding; the cross-sectional area of the inner core is 160 / 3mm 2 ;The cross-sectional area of the first outer layer is 160 / 3mm 2 ;The cross-sectional area of the second outer layer is 160 / 3mm 2 ; The included angle of the inner core is 69°, the included angle of the first outer layer is 70°30′; the included angle of the second outer layer is 72°;

[0039] 2) Use copper conductors that meet the national standard as raw materials, wire drawing and annealing, and press into fan-shaped stock conductors as the core;

[0040] 3) hot-pressing the copper conductor after wire drawing and annealing in step 2) into a sheet, coating the inner core obtained in step 2), and pressing the outer layer tightly to obtain the first outer layer;

[0041] 4) hot-pressing the copper cond...

Embodiment 2

[0044] The cross-sectional area is 1200mm 2 A method for preparing a compacted split conductor, comprising the steps of:

[0045] 1) Draw up a layering scheme: layering in the way of core 1 plus 3 layers of cladding; the cross-sectional area of core 1 is 60mm 2 ; The cross-sectional area of the first outer layer 2 is 60mm 2 ; The cross-sectional area of the second outer layer 3 is 60mm 2 ; The cross-sectional area of the third outer layer 4 is 60mm 2 The included angle of the inner core 1 is 67°30′; the included angle of the first outer layer 2 is 69°, the included angle of the second outer layer 3 is 70°30′; the included angle of the third outer layer 4 is 72°;

[0046] 2) Use copper conductors conforming to national standards as raw materials, wire drawing and annealing, and press them into fan-shaped stock conductors as the core 1;

[0047] 3) hot-pressing the copper conductor after wire drawing and annealing in step 2) into a sheet, covering the inner core 1 ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com