Rotary sliding contact type center rod conductive device

A conductive device, contact technology, applied in the direction of two-part connection device, parts of the connection device, device for joining/disconnecting connection parts, etc., can solve problems such as difficult power transmission, and achieve good power and signal transmission functions, The effect of good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

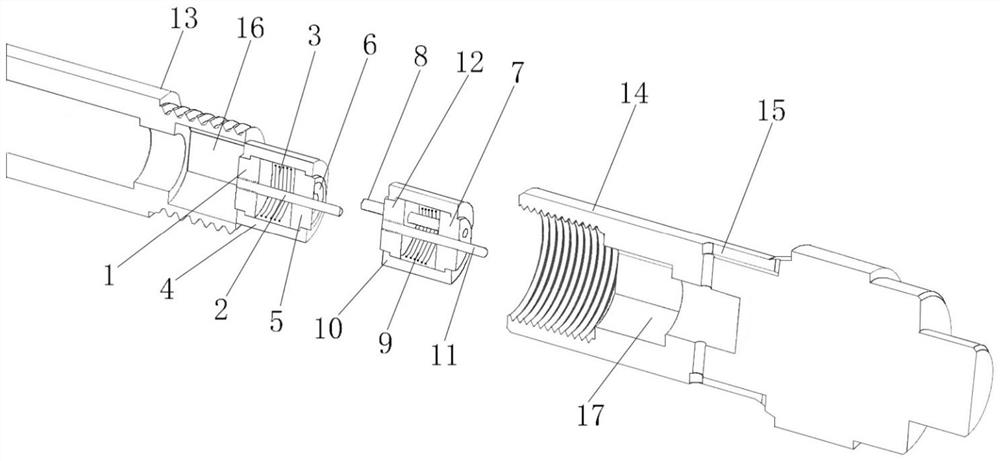

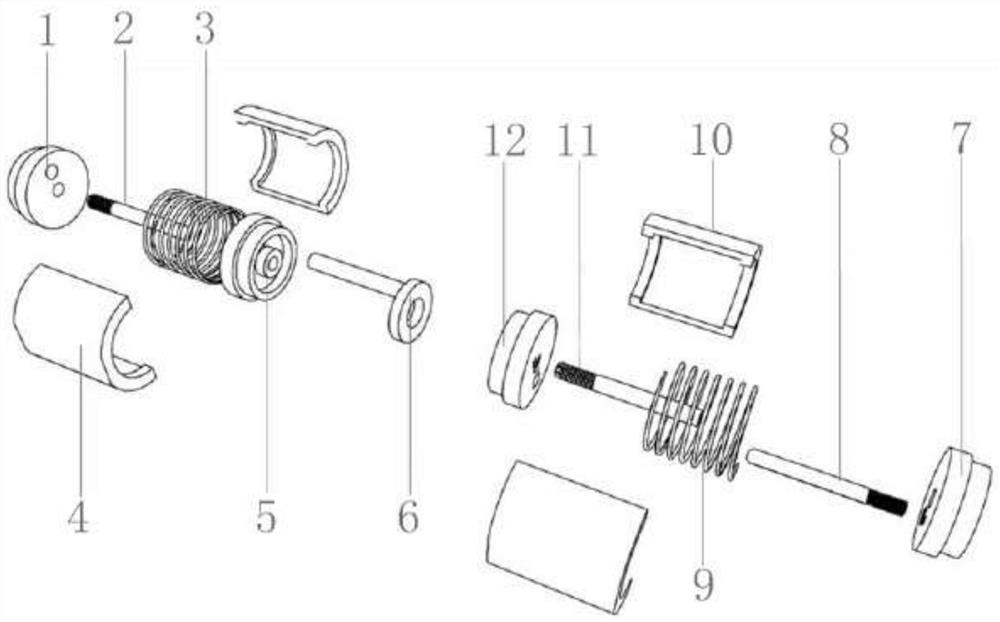

[0032]A rotary-sliding contact-type central pole conducting device, comprising a first conducting mechanism, a second conducting mechanism, a first central pole 13, and a second central pole 14, the first central pole 13 and the second central pole 14 are detachable connection, the first central rod 13 is provided with a mounting groove A16 corresponding to the first conductive mechanism, the first conductive mechanism is installed in the mounting groove A16, and the second central rod 14 is provided with a mounting groove A16 corresponding to the second conductive mechanism. The installation groove B17, the second conductive mechanism is installed in the installation groove B17, when the first central rod 13 and the second central rod 14 are connected, the first conductive mechanism and the second conductive mechanism are press fit to form a contact connection structure ; The first conductive mechanism includes a tailstock A1, a conductive component A2, an elastic component A3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com