Preparation method of high-thermal-conductivity AlSi alloy

A high thermal conductivity and alloy technology, applied in the field of material manufacturing, can solve the problems of unstable thermal conductivity, difficulty in meeting high thermal conductivity requirements, and unfavorable precision die-casting molding, etc., to achieve compact structure, improved thermal conductivity, and good die-casting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

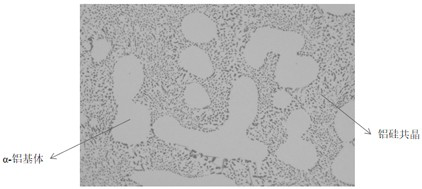

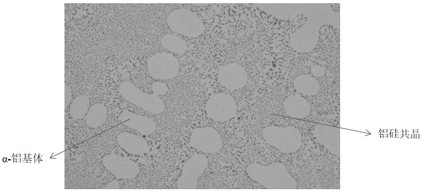

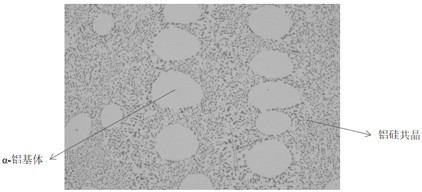

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of high thermal conductivity AlSi alloy preparation method, comprises the following steps:

[0036] (1) Raw material preparation: raw materials are prepared according to the alloy composition ratio, and the raw materials are Al99.85 pure aluminum ingots, Al-50Si, Al-10Sr and Al-3Sc master alloys;

[0037] (2) Melting: Put the pure aluminum ingot in the melting furnace to heat up and melt to form aluminum liquid; transfer the aluminum liquid in the melting furnace to the alloy furnace, raise the temperature to 760°C, add Al-50Si master alloy; wait for complete melting Afterwards, stir evenly for 10 minutes, and the temperature remains constant during the stirring process;

[0038] (3) Deslagging and degassing for the first time;

[0039] (4) Modification treatment: remove scum on the surface of molten aluminum, raise the temperature of molten aluminum to 770°C, add Al-10Sr intermediate alloy modifier, and stir evenly for 20 minutes;

[0040] (5) The ...

Embodiment 2

[0054] Embodiment 2: a kind of high thermal conductivity AlSi alloy preparation method, comprises the following steps:

[0055] (1) Raw material preparation: raw materials are prepared according to the alloy composition ratio, and the raw materials are Al99.85 pure aluminum ingots, Al-50Si, Al-10Sr and Al-3Sc master alloys;

[0056] (2) Melting: Put the pure aluminum ingot in the melting furnace to heat up and melt to form molten aluminum; transfer the molten aluminum in the melting furnace to the alloy furnace, raise the temperature to 770°C, and add Al-50Si master alloy; after it is completely melted Stir evenly for 20 minutes, and keep the temperature constant during the stirring process;

[0057] (3) Deslagging and degassing for the first time;

[0058] (4) Modification treatment: remove scum on the surface of molten aluminum, raise the temperature of molten aluminum to 780°C, add Al-10Sr intermediate alloy modifier, and stir evenly for 25 minutes;

[0059] (5) The secon...

Embodiment 3

[0073] Embodiment 3: a kind of high thermal conductivity AlSi alloy preparation method, comprises the following steps:

[0074] (1) Raw material preparation: raw materials are prepared according to the alloy composition ratio, and the raw materials are Al99.85 pure aluminum ingots, Al-50Si, Al-10Sr and Al-3Sc master alloys;

[0075] (2) Melting: Put the pure aluminum ingot in the melting furnace to heat up and melt to form aluminum liquid; transfer the aluminum liquid in the melting furnace to the alloy furnace, raise the temperature to: 780°C, add Al-50Si master alloy; wait for complete melting Afterwards, stir evenly for 30 minutes, and the temperature remains constant during the stirring process;

[0076] (3) Deslagging and degassing for the first time;

[0077] (4) Modification treatment: remove scum on the surface of molten aluminum, raise the temperature of molten aluminum to 800°C, add Al-10Sr intermediate alloy modifier, and stir evenly for 30 minutes;

[0078] (5) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com