Tetrafluoroethylene-hexafluoropropylene copolymer communication optical cable protective jacket material and preparation method thereof

A technology of polyfluoroethylene propylene and communication optical cable, which is applied in the direction of cables, insulated cables, conductors, etc. It can solve the problems of poor heat resistance, aging resistance, poor chemical stability, limited use range, and shortened service life to achieve electrical insulation Excellent performance and mechanical properties, long service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

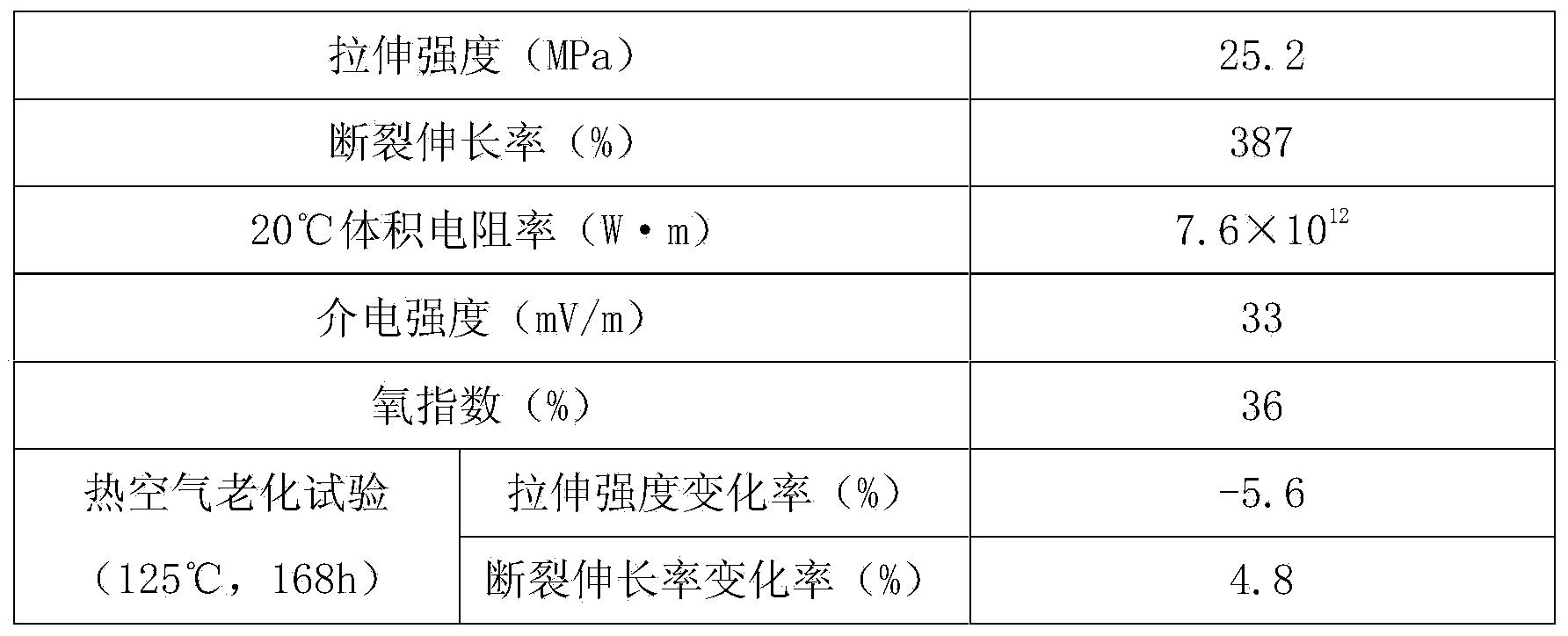

[0013] A polyperfluoroethylene propylene communication optical cable sheathing material, made of the following raw materials in weight (kg): polyperfluoroethylene propylene 76, vinyl chloride-butyl acrylate copolymer 48, regenerated material 24, oleoyl diethanolamine 4.5 , Pentabromobenzyl polyacrylate 12, nickel dibutyldithiocarbamate 1.5, condensed aluminum phosphate 14, acetyl tributyl citrate 18, 4,4-diphenylisopropyl diphenylamine 2.5, bisphenol phosphite A ester 6, earthy graphite powder 12, zinc laurate 3, behenic acid amide 4, calcined andalusite powder 12, p-tert-butylcatechol 1.5;

[0014] The preparation method of the regenerated material is as follows: (1) take the following raw materials of weight (kg): PVC waste 45, PP waste 40, ABS nozzle material 17, PETG leftover material 12, aramid pulp 8, refractory brick shavings 14, powder Coal ash 10, oil shale slag 7, waste glass powder 5, carbide slag 4.5, ethylene glycol diglycidyl ether 3.5, acetyl ricinoleic acid but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com