Heat treatment method for wide-diameter H-shaped steel roll collar

A technology of H-beam and roll ring, applied in the field of roll ring manufacturing, can solve the problems of increasing the company's manufacturing cost, long production cycle, cracking of workpieces, etc., and achieve the effect of short temperature uniformity time, reduced equipment failure, and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

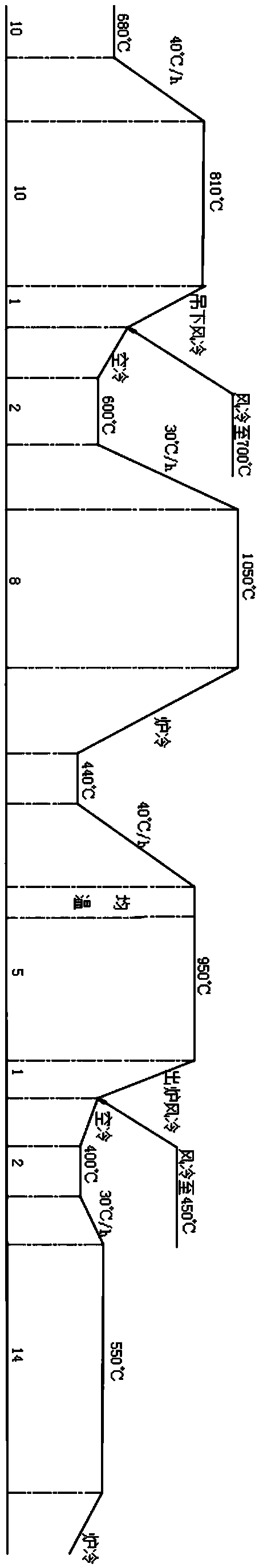

[0033] A heat treatment process for a wide-diameter H-shaped steel roll ring, comprising the following steps:

[0034] (1) After the H-shaped steel roll ring is formed, heat the box and transfer to heat treatment;

[0035] (2) Heat the formed roller ring to 800°C at a heating rate of 40°C / h, and keep it warm for 10 hours to perform spheroidization treatment;

[0036] (3) Hang the roller ring heated in step (2) and air-cool it to 700°C, then air-cool it to 600°C, keep it warm for 2 hours, and cut the ring by cold work;

[0037] (4) With a heating rate of 30°C / h, heat the roller ring after step (3) air-cooled and heat-insulated to 1050°C, and keep it warm for 5 hours, and carry out high-temperature diffusion treatment;

[0038] (5) Cool the roller ring furnace after the high-temperature diffusion in step (4) to 440° C., and keep it warm for 2 hours.

[0039] (6) With a heating rate of 40° C. / h, the roller ring after step (5) furnace cooling and heat preservation is heated to 9...

Embodiment 2

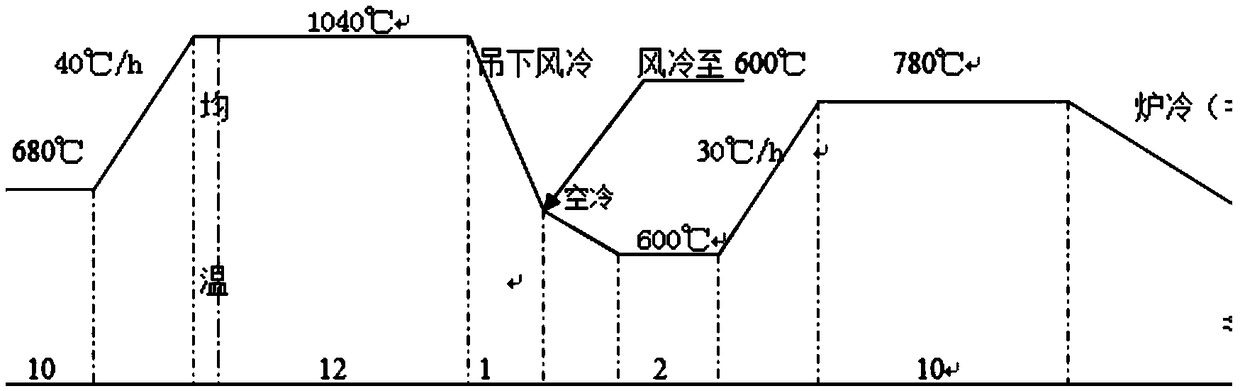

[0048] A heat treatment process for a wide-diameter H-shaped steel roll ring, comprising the following steps:

[0049] (1) After the H-shaped steel roll ring is formed, heat the box and transfer to heat treatment;

[0050] (2) Heat the formed roller ring to 850°C at a heating rate of 45°C / h, and keep it warm for 12 hours to perform spheroidization treatment;

[0051] (3) Hang the roller ring heated in step (2) and air-cool it to 750°C, then air-cool it to 650°C, keep it warm for 2.5 hours, and cut the ring by cold work;

[0052] (4) At a heating rate of 35°C / h, heat the roller ring after step (3) air-cooled and heat-insulated to 1100°C, and keep it warm for 8 hours to perform high-temperature diffusion treatment;

[0053] (5) Cool the roller ring furnace after the high-temperature diffusion in step (4) to 450° C., and keep it warm for 2.5 hours.

[0054] (6) With a heating rate of 45° C. / h, the roller ring after step (5) furnace cooling and heat preservation is heated to 100...

Embodiment 3

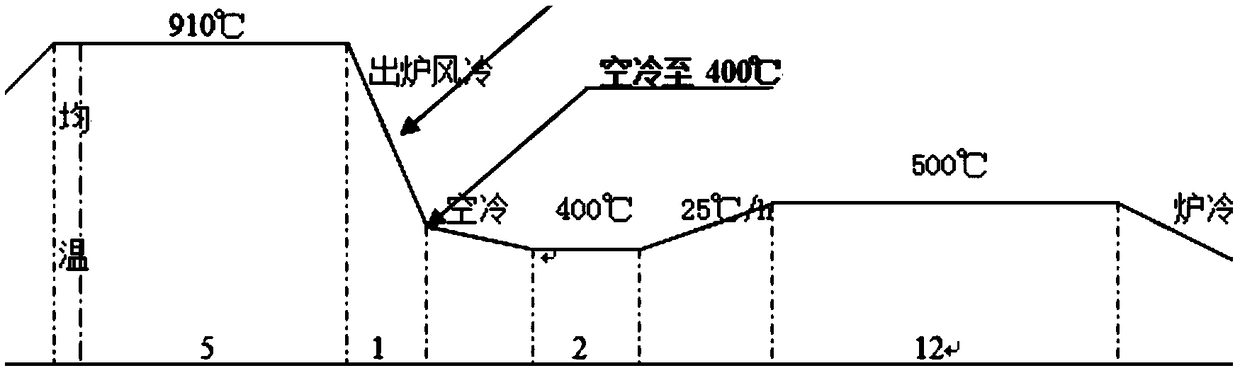

[0063] A heat treatment process for a wide-diameter H-shaped steel roll ring, comprising the following steps:

[0064] (1) After the H-shaped steel roll ring is formed, heat the box and transfer to heat treatment;

[0065] (2) At a heating rate of 42°C / h, heat the formed roller ring to 825°C and keep it warm for 11 hours to perform spheroidization treatment;

[0066] (3) Hang the roller ring heated in step (2) and air-cool it to 725°C, then air-cool it to 625°C, keep it warm for 2.5 hours, and cut the ring by cold work;

[0067] (4) At a heating rate of 32° C. / h, heat the roller ring after step (3) air cooling and heat preservation to 1075° C., and keep it warm for 7 hours to carry out high temperature diffusion treatment;

[0068] (5) Cool the roller ring furnace after the high-temperature diffusion in step (4) to 460° C., and keep it warm for 3 hours.

[0069] (6) With a heating rate of 42° C. / h, the roller ring after step (5) furnace cooling and heat preservation is heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com