Tissue engineering stent based on low-temperature rapid modeling and preparation method thereof

A tissue engineering scaffold, fast technology, applied in tissue regeneration, coating, medical science, etc., can solve the problems of excessive pore size and irregular shape of pure PLGA scaffolds, and achieve good biomechanical properties, high water content, and easy retention cell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Therefore, the preparation method of the tissue engineering scaffold based on low temperature rapid prototyping provided by the first embodiment of the present invention comprises the following steps:

[0056] (1) Dissolving PLGA in an organic solvent to obtain a PLGA solution, wherein the mass ratio of PLGA to organic solvent is 1:6-1:8 (for example, 1:6, 1:7 or 1:8). Preferably, the weight average molecular weight (Mw) of PLGA is 80000~200000gmol -1 (e.g. 80000, 100000, 120000, 150000 or 200000 gmol -1 ), more preferably 100000gmol -1 ). The low-temperature printing method of the present invention is especially suitable for the weight-average molecular weight (Mw) of 80,000-100,000 gmol -1 The PLGA material can avoid the change of material properties caused by high temperature heating. The organic solvent used in this step is preferably but not limited to: chloroform, dichloromethane, chloroform, dimethylsulfoxide, dimethylformamide or tetrahydrofuran.

[0057] (...

Embodiment 1

[0085] 1. Set the weight average molecular weight (Mw) to 100000gmol -1 PLGA and chloroform were mixed according to a mass ratio of 1:7 to obtain a PLGA solution.

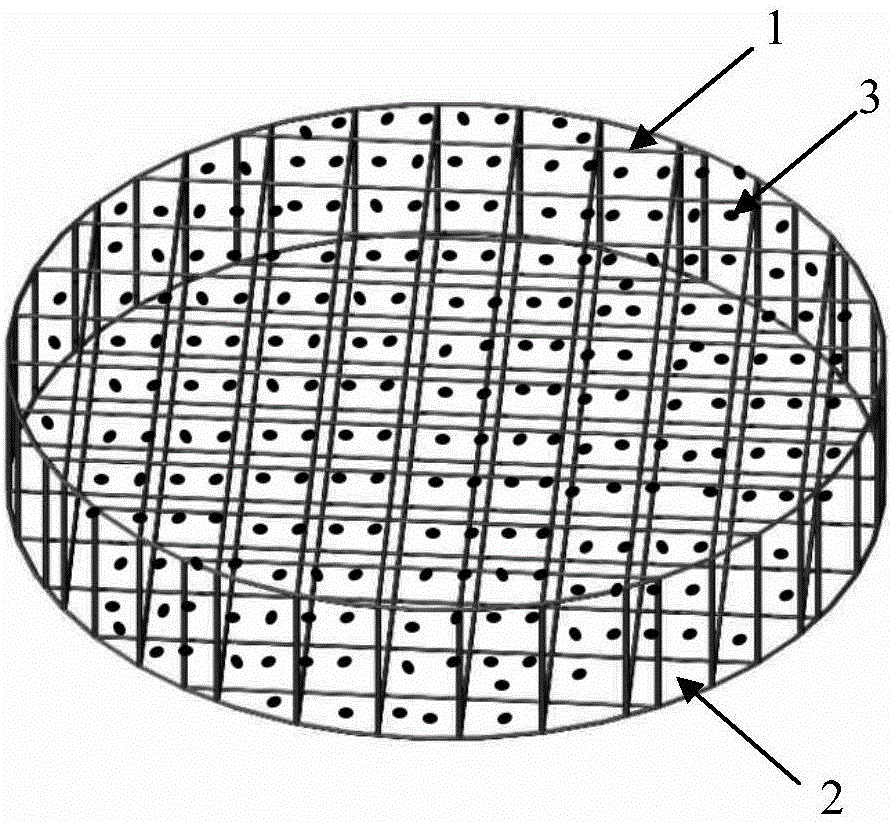

[0086] 2. Add NaCl particles to the PLGA solution to obtain a printing paste, wherein the mass ratio of PLGA to NaCl particles is 1:1, and the NaCl particles are NaCl particles filtered through a 400-mesh screen.

[0087] 3. Put the printing slurry into the nozzle of the fused deposition modeling three-dimensional printer, and prepare for printing at room temperature such as 24°C and an air pressure of 200kPa.

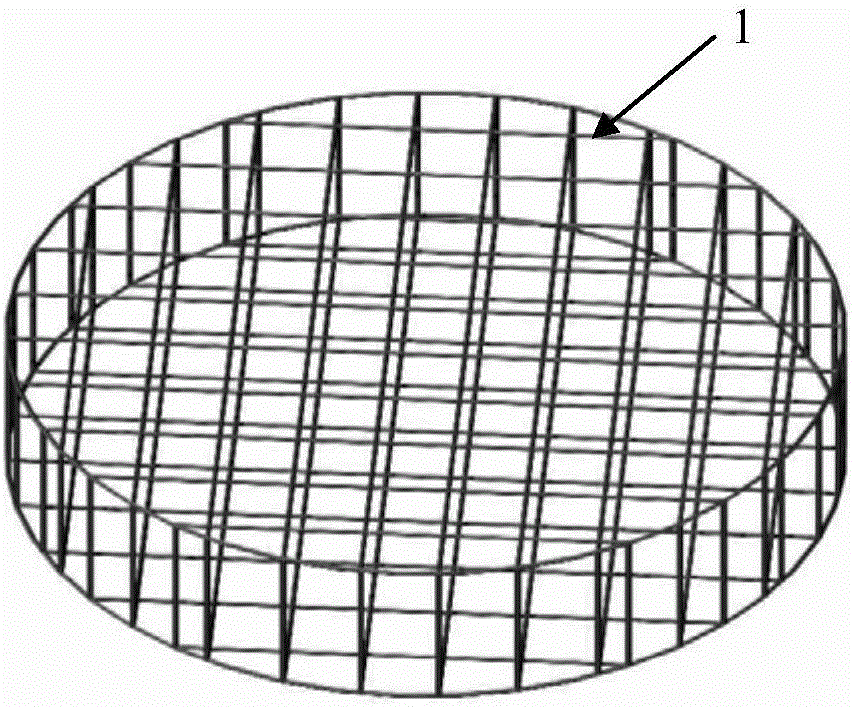

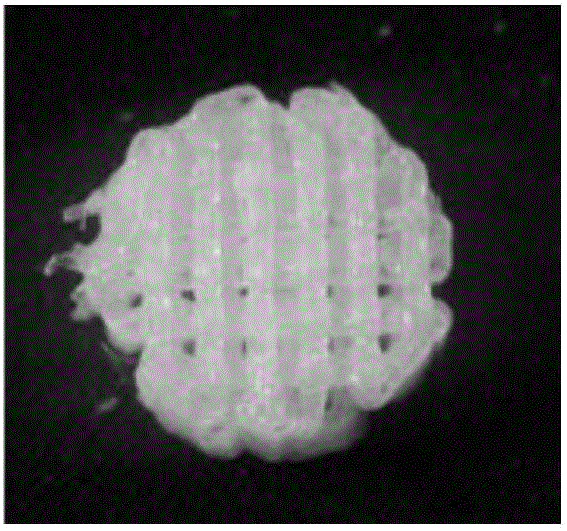

[0088] 4. Set the fiber diameter to 300 μm and the fiber spacing to 300 μm, and print out a cylindrical scaffold body containing NaCl particles at a speed of 4 mm / s. The cylinder has a diameter of 9 mm and a thickness of 2 mm.

[0089] 5. Dry the stent body in an oven at 37°C for 48 hours.

[0090] 6. Soak the dried stent body in water for 48 hours, and dry to obtain the stent body after NaCl dissolves. ...

Embodiment 2 to 10

[0092] Examples 2 to 10 were carried out in substantially the same manner as Example 1 except for the contents of Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com