Environment-friendly wide-temperature aluminum alloy anodic oxidation electrolyte and preparation method and application thereof

Anodizing, aluminum alloy technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of acid-base imbalance, reduce field-assisted dissolution effect, hidden safety hazards, etc., to improve surface mechanical properties, widen Anodizing temperature, reducing the effect of surface pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

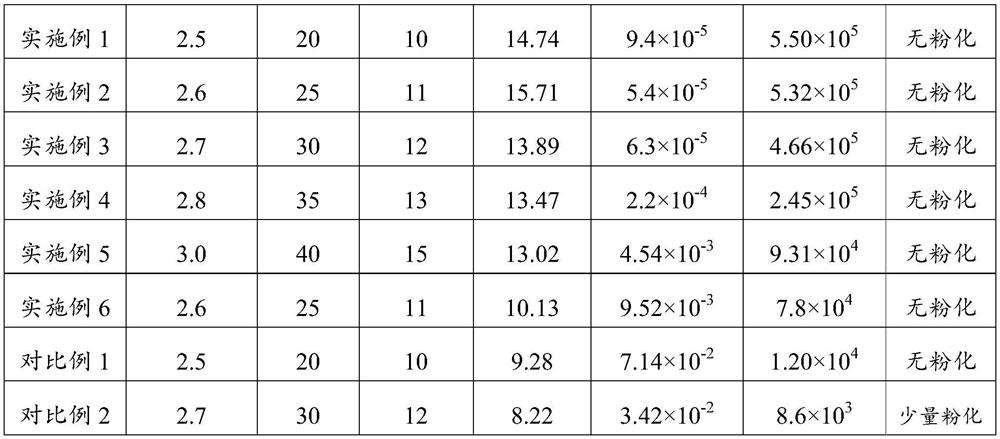

Embodiment 1

[0047] An aluminum alloy anodic oxidation electrolyte, containing sulfuric acid, triethanolamine, ethanol and cerium nitrate in the electrolyte, wherein: the mass concentration of sulfuric acid is 100g / L, the mass concentration of triethanolamine is 15g / L, and the mass concentration of ethanol is 25g / L, the molar concentration of cerium nitrate is 0.05mol / L.

[0048] A method for preparing an aluminum alloy anodic oxidation electrolyte, comprising the following steps:

[0049] Dissolving triethanolamine in the ethanol solution, and magnetic stirring for 5 minutes, to obtain a triethanolamine solution;

[0050] Slowly add 98wt.% concentrated sulfuric acid into distilled water to dilute into 100g / L dilute sulfuric acid solution, and cool the dilute sulfuric acid solution to room temperature;

[0051] Add the triethanolamine solution into the dilute sulfuric acid solution, then add cerium nitrate, and stir for 5 minutes to obtain the aluminum alloy anodic oxidation electrolyte ...

Embodiment 2

[0058] An aluminum alloy anodic oxidation electrolyte, containing sulfuric acid, triethanolamine, ethanol and cerium nitrate in the electrolyte, wherein: the mass concentration of sulfuric acid is 110g / L, the mass concentration of triethanolamine is 20g / L, and the mass concentration of ethanol is 30g / L, the molar concentration of cerium nitrate is 0.06mol / L.

[0059] A method for preparing an aluminum alloy anodic oxidation electrolyte, comprising the following steps:

[0060] Dissolving triethanolamine in the ethanol solution, and magnetic stirring for 8 minutes, to obtain a triethanolamine solution;

[0061] Slowly add 98wt.% concentrated sulfuric acid into distilled water to dilute to 110g / L dilute sulfuric acid solution, and cool the dilute sulfuric acid solution to room temperature;

[0062] Add the triethanolamine solution into the dilute sulfuric acid solution, then add cerium nitrate, and stir for 10 minutes to obtain the aluminum alloy anodic oxidation electrolyte o...

Embodiment 3

[0069] An aluminum alloy anodic oxidation electrolyte, containing sulfuric acid, triethanolamine, ethanol and cerium nitrate in the electrolyte, wherein: the mass concentration of sulfuric acid is 120g / L, the mass concentration of triethanolamine is 23g / L, and the mass concentration of ethanol is 33g / L, the molar concentration of cerium nitrate is 0.07mol / L.

[0070] A method for preparing an aluminum alloy anodic oxidation electrolyte, comprising the following steps:

[0071] Dissolving triethanolamine in the ethanol solution, and magnetic stirring for 10 minutes, to obtain a triethanolamine solution;

[0072] Slowly add 98wt.% concentrated sulfuric acid into distilled water to dilute to 120g / L dilute sulfuric acid solution, and cool the dilute sulfuric acid solution to room temperature;

[0073] Add the triethanolamine solution into the dilute sulfuric acid solution, then add cerium nitrate, and stir for 5 minutes to obtain the aluminum alloy anodic oxidation electrolyte o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com