Novel cell culture method, cell culture system and application of cell culture system

A culture system and in vitro cell culture technology, applied in biomaterials and biological fields, can solve complex and unfavorable problems, achieve the effects of protecting activity, promoting growth and differentiation, and benefiting growth and differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

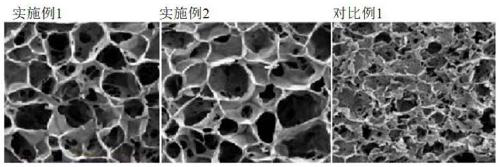

Embodiment 1

[0062] A method for preparing a composite porous support, comprising:

[0063] The sodium chloride is sieved, and the particle size of the sieved sodium chloride is 283-300 μm, and then mixed with hydroxyapatite in a ratio of 1:0.03;

[0064] Pack the mixture of sodium chloride and hydroxyapatite tightly into a plastic syringe;

[0065] After mixing the liver cell activity factor HGF, collagen solution and silk fibroin solution at a ratio of 1:4, dissolve the double active ester polyethylene glycol in dimethyl sulfoxide, and then add it dropwise to the collagen and silk fibroin solution. In the mixed solution of plain protein, the concentration of polyethylene glycol of bisactive ester in the mixed solution is 0.02%, under certain pH value and temperature condition, stirring reaction;

[0066] Pour into the syringe, immediately press the plunger of the syringe, and place it at room temperature;

[0067] Remove the material from the syringe, soak it with ethanol, and then was...

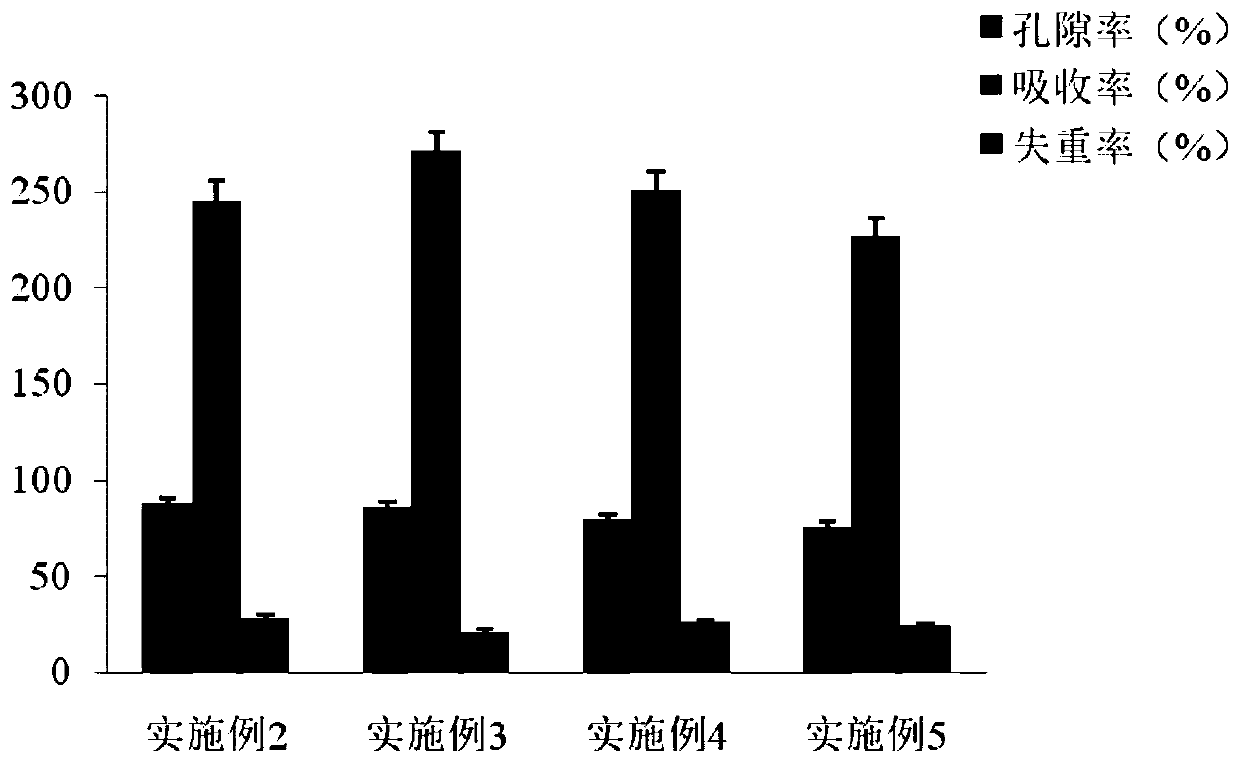

Embodiment 2

[0069] A method for preparing a composite porous support, comprising:

[0070] The sodium chloride is sieved, and the particle size of the sieved sodium chloride is 283-300 μm, and then mixed with hydroxyapatite in a ratio of 1:0.03;

[0071] Pack the mixture of sodium chloride and hydroxyapatite tightly into a plastic syringe;

[0072] After mixing the liver cell activity factor HGF, collagen solution and silk fibroin solution at a ratio of 1:4, dissolve the double active ester polyethylene glycol in dimethyl sulfoxide, and then add it dropwise to the collagen and silk fibroin solution. In the mixed solution of plain protein, make the concentration of bisactive ester polyethylene glycol in the mixed solution be 0.02%, add catecholamine, make the concentration of catecholamine in the mixed solution be 0.04%, under certain pH value and temperature condition, stirring reaction;

[0073] Pour into the syringe, immediately press the plunger of the syringe, and place it at room t...

Embodiment 3

[0076] A method for preparing a composite porous support, comprising:

[0077] The sodium chloride is sieved, and the particle size of the sieved sodium chloride is 283-300 μm, and then mixed evenly with hydroxyapatite in a ratio of 1:0.02;

[0078] Pack the mixture of sodium chloride and hydroxyapatite tightly into a plastic syringe;

[0079] After mixing the liver cell activity factor HGF, collagen solution and silk fibroin solution at a ratio of 1:4, dissolve the double active ester polyethylene glycol in dimethyl sulfoxide, and then add it dropwise to the collagen and silk fibroin solution. In the mixed solution of plain protein, make the concentration of bisactive ester polyethylene glycol in the mixed solution be 0.03%, add catecholamine, make the concentration of catecholamine in the mixed solution be 0.05%, under certain pH value and temperature condition, stirring reaction;

[0080] Pour into the syringe, immediately press the plunger of the syringe, and place it at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com