Double-faced adhesive tape and forming process thereof

A technology of double-sided tape and adhesive layer, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problems of poor alkali resistance and insufficient adhesion, and achieve good performance stability and low molding cost. , to avoid the effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

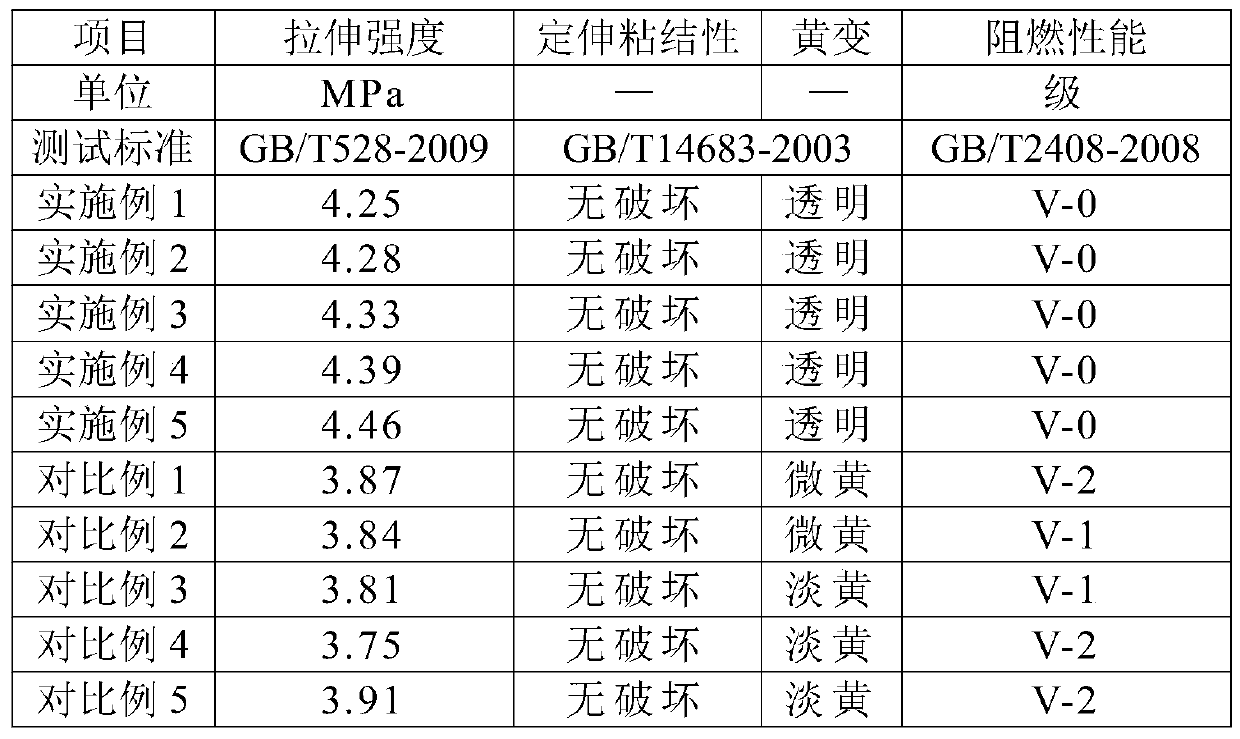

Examples

Embodiment 1

[0033] A double-sided adhesive tape is characterized in that it includes a film protection layer, an adhesive layer and a substrate layer from top to bottom, and the film protection layer is prepared by mixing the following components in parts by weight uniformly : 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid / pyrazolo[1,5-a][1,3,5]triazine-2,4-di Alcohol polycondensate 40 parts polycondensate, PBT resin 10 parts, PET resin 10 parts.

[0034] The 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid / pyrazolo[1,5-a][1,3,5]triazine-2,4- The preparation method of diol polycondensate comprises the steps of: combining 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid, pyrazolo[1,5-a][1, 3,5]

[0035] Add triazine-2,4-diol, catalyst, and tetrabutylammonium bromide into the polymerization reactor, at a pressure of 0.4MPa and a temperature of 260°C

[0036] The esterification reaction is carried out under the pressure, and the esterification reaction is completed when the theoretic...

Embodiment 2

[0043] A double-sided adhesive tape is characterized in that it includes a film protection layer, an adhesive layer and a substrate layer from top to bottom, and the film protection layer is prepared by mixing the following components in parts by weight uniformly : 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid / pyrazolo[1,5-a][1,3,5]triazine-2,4-di Alcohol polycondensate 45 parts, PBT resin 12 parts, PET resin 11 parts.

[0044] The 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid / pyrazolo[1,5-a][1,3,5]triazine-2,4- The preparation method of diol polycondensate comprises the steps of: combining 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid, pyrazolo[1,5-a][1, 3,5] Triazine-2,4-diol, catalyst, and tetrabutylammonium bromide are added to the polymerization reactor, and the esterification reaction is carried out at a pressure of 0.5MPa and a temperature of 265°C until the theoretical water output reaches 98%. The esterification reaction is completed at the above, and th...

Embodiment 3

[0050] A double-sided adhesive tape is characterized in that it includes a film protection layer, an adhesive layer and a substrate layer from top to bottom, and the film protection layer is prepared by mixing the following components in parts by weight uniformly : 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid / pyrazolo[1,5-a][1,3,5]triazine-2,4-di 50 parts of alcohol polycondensate polycondensate, 15 parts of PBT resin, 13 parts of PET resin.

[0051] The 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid / pyrazolo[1,5-a][1,3,5]triazine-2,4- The preparation method of diol polycondensate comprises the steps of: combining 3,3-difluoro-[1,1-biphenyl]-4,4-dicarboxylic acid, pyrazolo[1,5-a][1, 3,5] Triazine-2,4-diol, catalyst, and tetrabutylammonium bromide are added to the polymerization reactor, and the esterification reaction is carried out at a pressure of 0.55MPa and a temperature of 270°C until the theoretical water output reaches 98%. The esterification reaction is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com