Environment-friendly composite flame retardant special for copper-clad plate and preparation method thereof

A composite flame retardant and environmentally friendly technology, which is applied in the field of special environmentally friendly composite flame retardants for copper clad laminates and its preparation, can solve the problems of environmental pollution of electronic products, large amount of smoke, and impact on human and animal health, etc. Flame retardancy and mechanical properties, reduced dosage, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

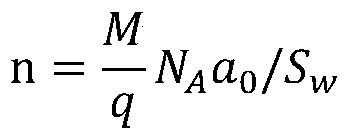

Method used

Image

Examples

preparation example Construction

[0036] In one embodiment, the preparation method of the ultra-fine modified magnesium hydroxide includes the following steps: put the magnesium hydroxide micropowder into a mixer, stir evenly and heat to 70-105°C, and use the spray method to modify the surface The ethanol solution of the agent A is added into the powder, the ethanol solution of the surface modifier A accounts for 3-5% of the weight of the magnesium hydroxide micropowder, and the mixture is stirred evenly to obtain the powder.

[0037] In a preferred embodiment, the surface modifier A is selected from polyvinyl alcohol and / or fatty alcohol polyoxyethylene ether.

[0038] In a preferred embodiment, the surface modifier A is fatty alcohol polyoxyethylene ether.

[0039] In a preferred embodiment, the ethanol solution of the surface modifier A is to dissolve the surface modifier A in the ethanol solution with a concentration of 3 mol / L.

[0040] In a preferred embodiment, the particle size of the ultrafine modifi...

Embodiment 1

[0056] Embodiment 1 provides an environmentally friendly composite flame retardant for copper clad laminates, including a synergistic flame retardant, magnesium hydroxide, and aluminum hydroxide; the magnesium hydroxide is ultrafine modified magnesium hydroxide; the hydroxide Aluminum is ultrafine modified aluminum hydroxide; the mass ratio of the synergistic flame retardant, ultrafine modified magnesium hydroxide, and ultrafine modified aluminum hydroxide is 1:8:5.

[0057] The synergistic flame retardant is ceramic zinc borate.

[0058] The particle size of the ceramized zinc borate is 3 μm.

[0059] The preparation method of the ultrafine modified magnesium hydroxide includes the following steps: put the magnesium hydroxide micropowder into a mixer, stir evenly and heat to 85°C, and add the ethanol solution of surface modifier A into the powder by spraying method , the ethanol solution of the surface modifying agent A accounts for 4% of the weight of the magnesium hydroxid...

Embodiment 2

[0070] Embodiment 2 is basically the same as Embodiment 1, the only difference is that it includes synergistic flame retardant, magnesium hydroxide, aluminum hydroxide; the magnesium hydroxide is ultrafine modified magnesium hydroxide; the aluminum hydroxide is ultrafine Finely modified aluminum hydroxide; the mass ratio of the synergistic flame retardant, superfine modified magnesium hydroxide, and superfine modified aluminum hydroxide is 1:5:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com