Patents

Literature

70results about How to "Increased tangle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

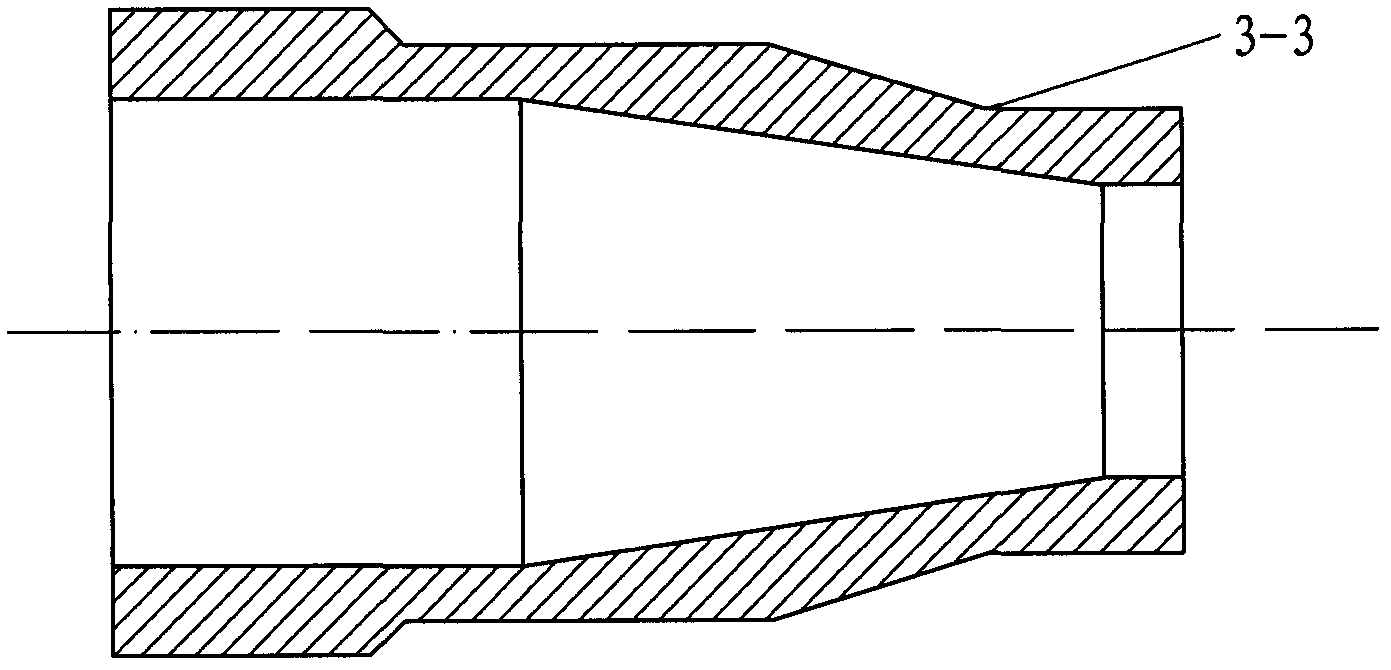

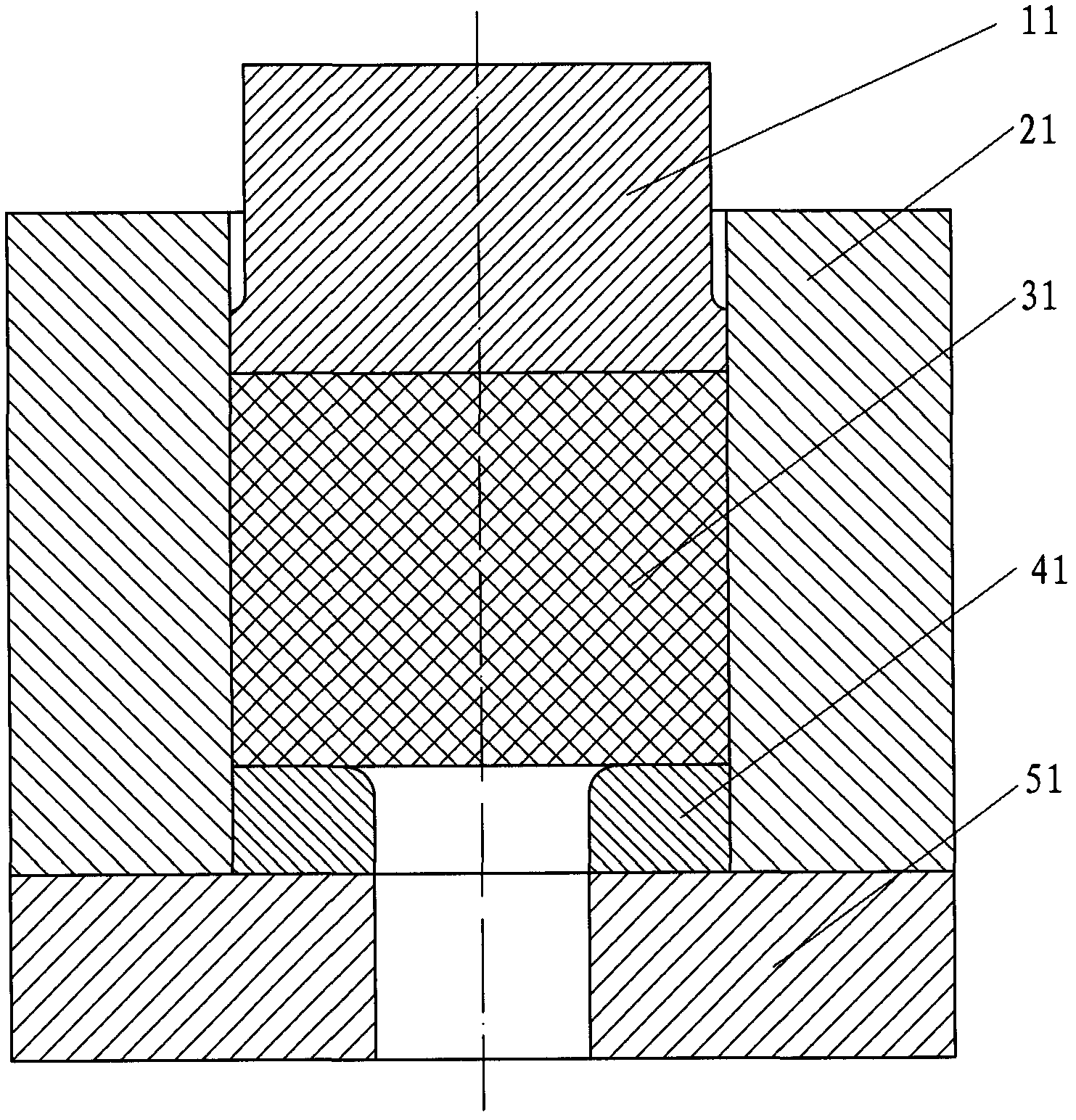

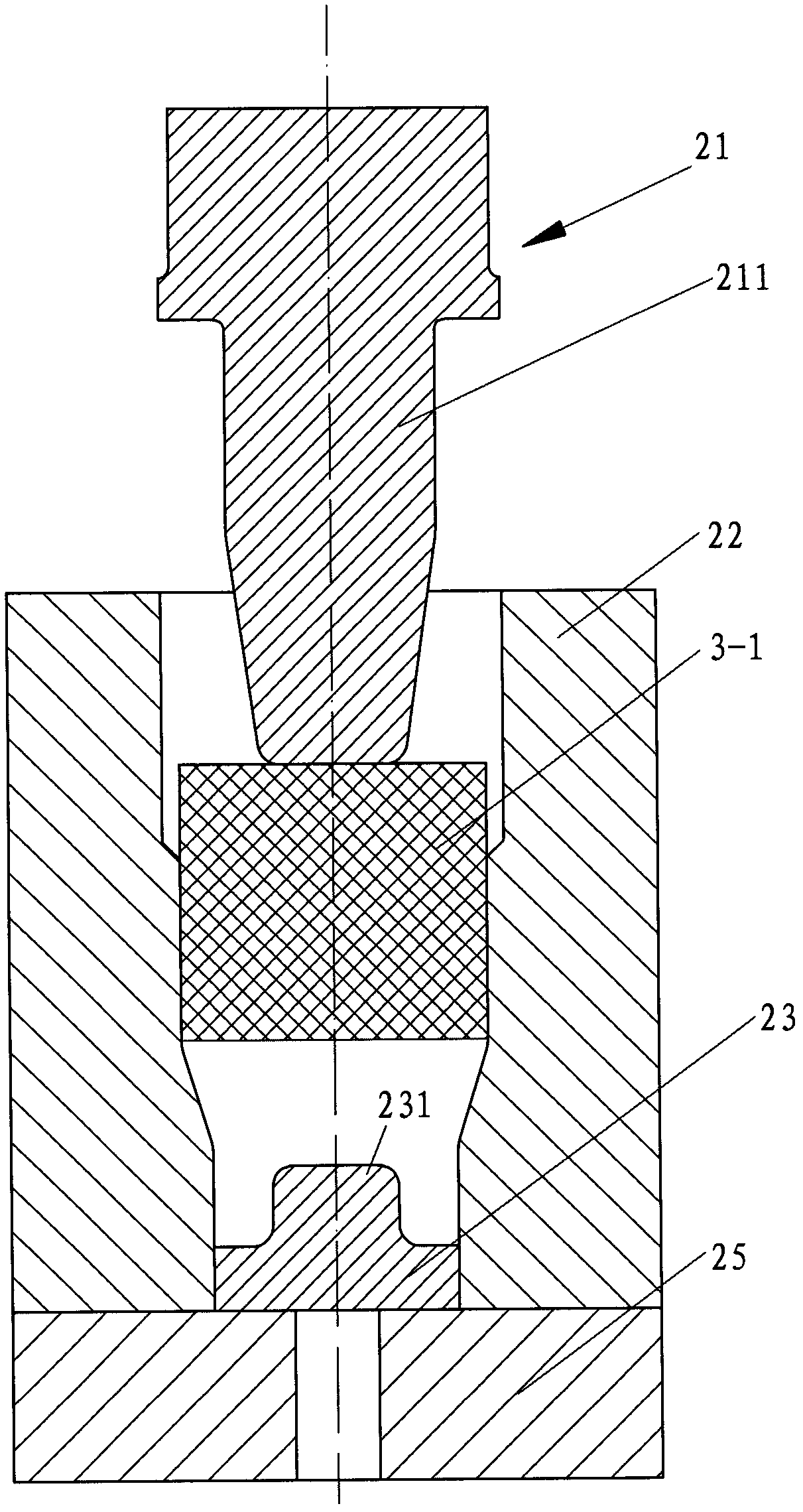

Preparation method of magnesium alloy variable-section cylindrical member by composite extrusion deformation

A preparation method of a magnesium alloy variable-section cylindrical member by composite extrusion deformation is characterized in that the method comprises the following steps: firstly, orderly performing homogenization pretreatment and hot extrusion deformation of an AZ80 magnesium alloy blank; preparing a variable-section cylindrical force-bearing member by forward and backward composite extrusion; finally performing turning and heat treatment to obtain a magnesium alloy variable-section cylindrical member. Compared with the prior art, the invention has the following advantages that the invention can prepare large-size cylindrical members; the material grain is fine; the mechanical properties are high; and the procedures are simple.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Semi-durable ramie nonwoven material for home textiles and production method thereof

InactiveCN102220674AGood for healthImprove protectionPattern makingNon-woven fabricsUltraviolet lightsNonwoven fabric

At present, natural fibrilia non-woven fabric materials are partial to a heavy type, and are mainly applied to the field of materials for automobiles, but the application of the natural fibrilia non-woven fabric materials to the field of home textiles is limited. The invention provides a semi-durable ramie nonwoven material for the home textiles, which comprises a matrix material and a surface modification layer formed by padding the matrix material in finishing liquid, wherein the matrix material comprises the following components in percentage by mass: 80 to 90 percent of ramie combed noil fibers and 10 to 20 percent of polylactic acid bi-component fibers; the finishing liquid comprises the following components in percentage by mass: 97.5 to 99.4 percent of polyacrylate bonding agent, 0.2 to 1.5 percent of hydrophilic organic silicon softening agent and 0.1 to 0.5 percent of penetrating agent; and the thickness of the ramie nonwoven material for the home textiles is between 0.5 and 1.5 millimeters, and the weight is between 60 and 120 grams / square meter. The semi-durable ramie nonwoven material has the functions of light weight, thinness, washability, antibacterium, acarid prevention, static resistance and ultraviolet light prevention, is soft in handfeel, and can be degraded completely after being discarded.

Owner:JIAXING UNIV

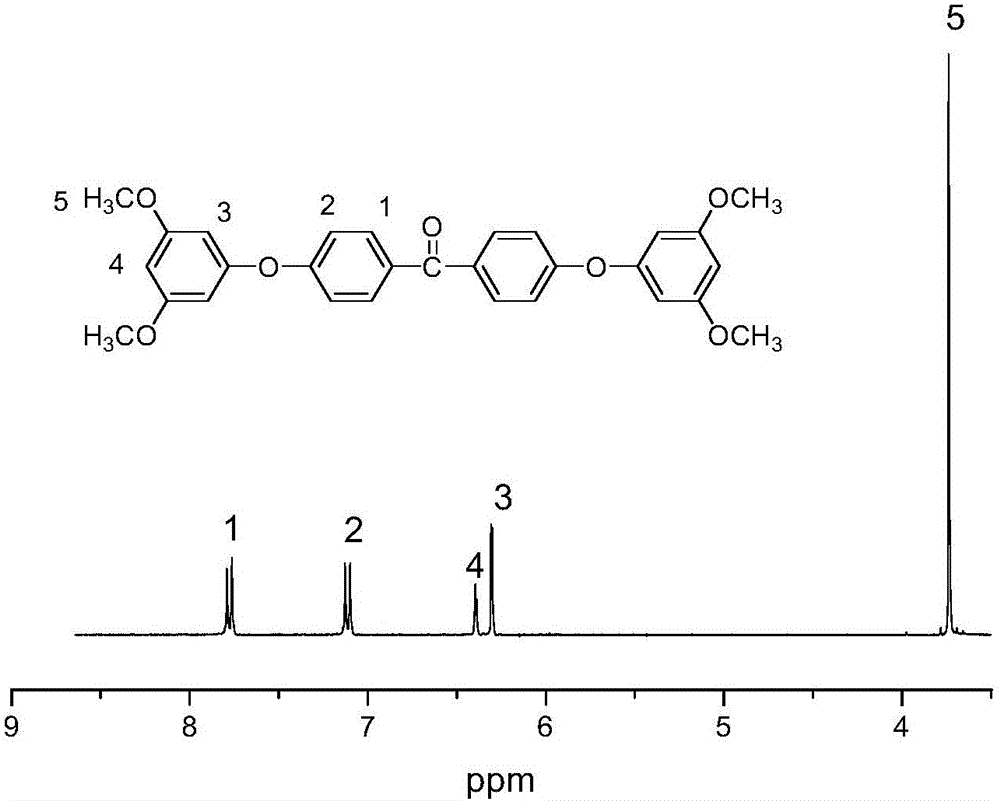

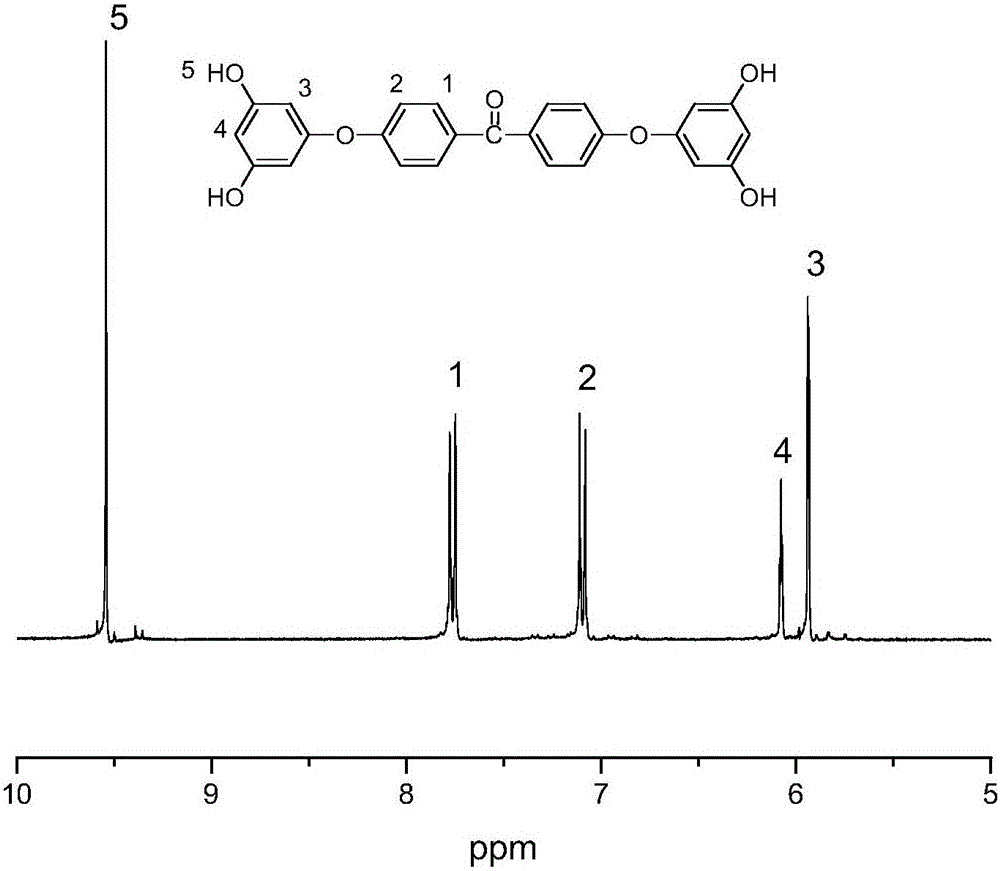

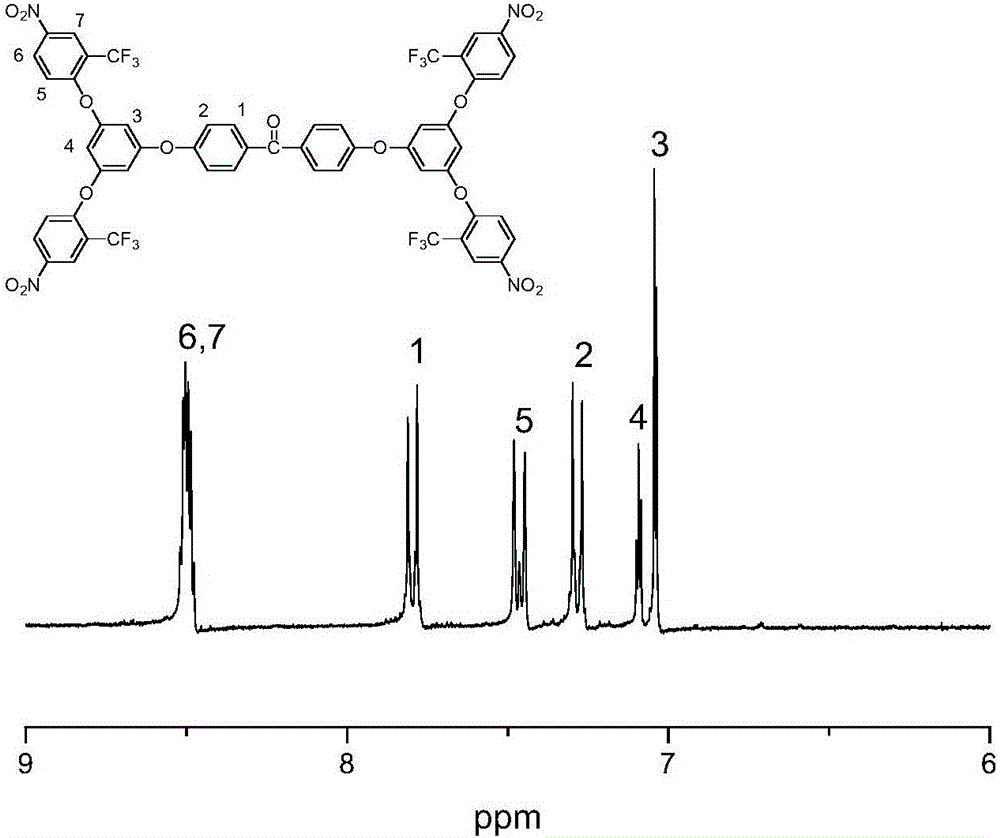

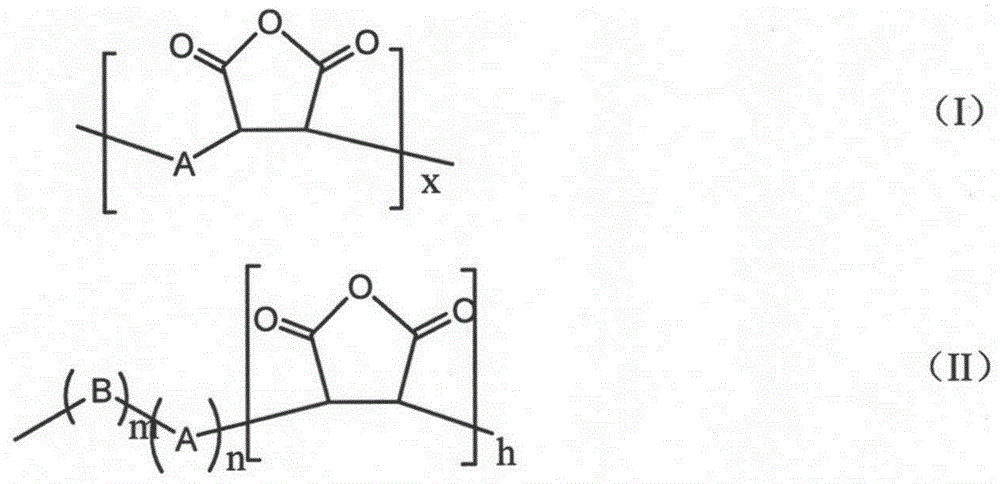

Tetramine monomer and preparation method and application thereof

InactiveCN106008185AImprove thermal stabilityImprove solubilityOrganic compound preparationCarbonyl compound preparationPolymer scienceEnd-group

The invention provides a tetramine monomer for synthesis of hyperbranched polyimide, and is used for solving the problems that a conventional polyimide has relatively poor thermal stability, film formation performance and other thermal properties and mechanical properties; through introduction of carbonyl and an ether chain into the tetraamine monomer, an obtained polymer has good solubility, thermal performance and mechanical properties. In addition, due to long synthesis route and large difficulty of a new electric-activity monomer, the characteristic that the hyperbranched polymer has a large number of end groups is utilized, a ferrocene group with electrochemical activity is introduced, the tetraamine monomer is subjected to a reaction with dianhydride and (4-amino)phenyl ferrocene, and the hyperbranched polyimide having ferrocene terminated and having the electrical activity can be easily prepared; the polymer can be used as an electrical storage material to be applied in the field of information storage.

Owner:JILIN UNIV

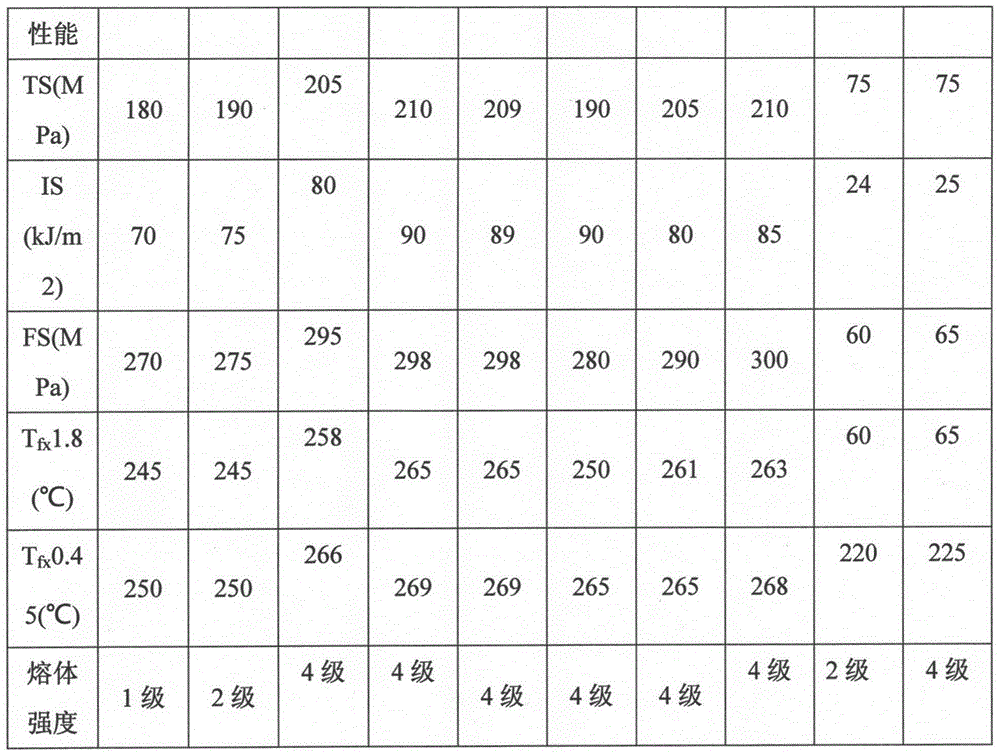

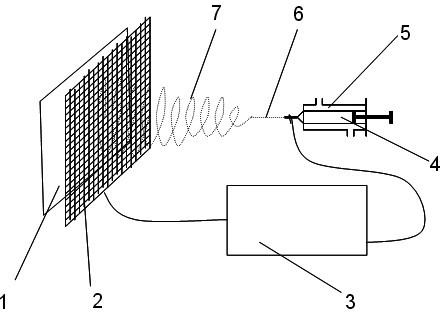

Micrometer/nanometer fiber composite filtering material and preparation method thereof

PendingCN109157915AImprove uniformityGuaranteed stabilityMembrane filtersFiltration separationFiberElectrospinning

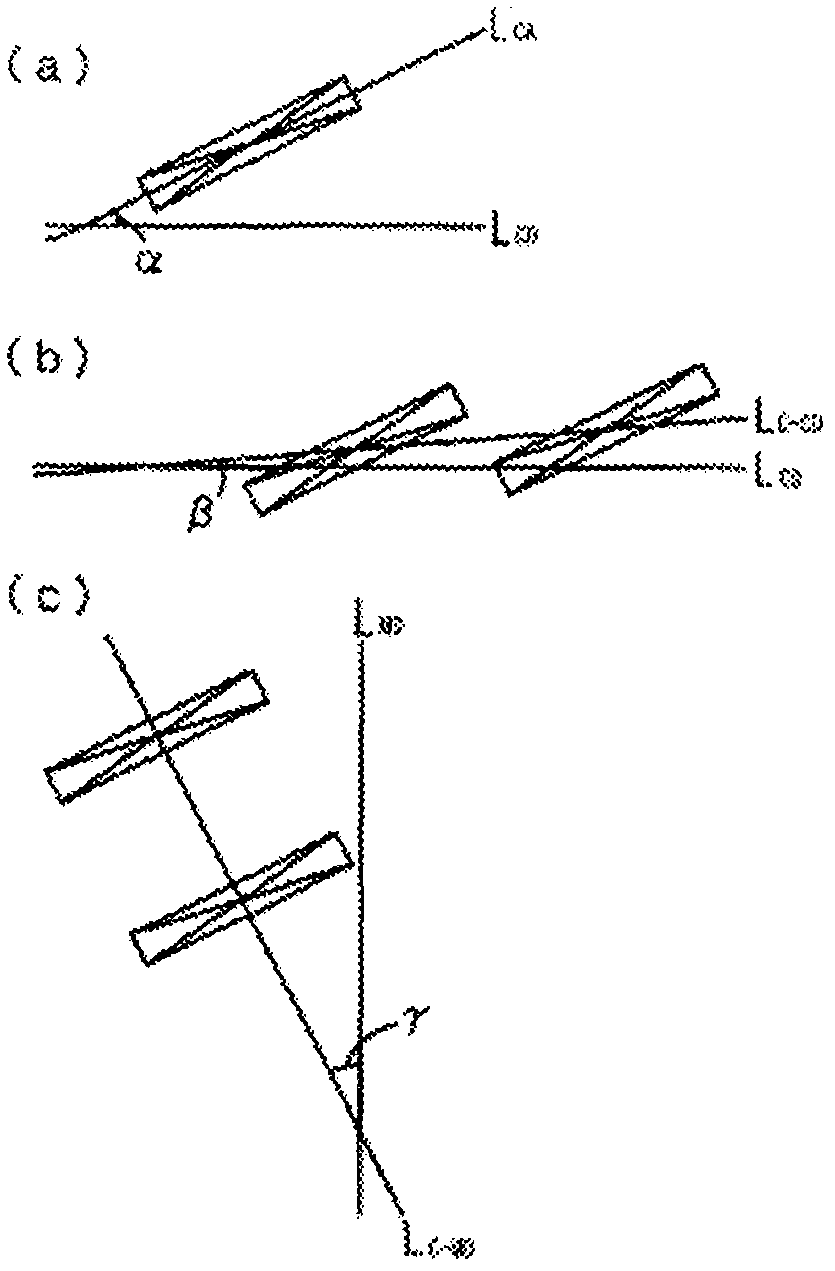

The invention discloses a micrometer / nanometer fiber composite filtering material and a preparation method thereof. The material comprises nanometer fiber and a single-layer micrometer fiber net; andthe structure is as follows: single or bunchy nanometer fiber is distributed on the surface of the single-layer micrometer fiber net uniformly or is embedded in a fiber assembly gap of the single-layer micrometer fiber net uniformly. The method comprises the following steps: preparing electrostatic spinning liquid; preparing the single-layer micrometer fiber net from micron-sized fiber and conveying the single-layer micrometer fiber net to a net conveying curtain with meshes; starting to perform electrostatic spinning by using the electrostatic spinning liquid, jetting single or bunchy nanometer fiber on the single-layer micrometer fiber net uniformly from an electrostatic spinning nozzle to form a single-layer micrometer / nanometer fiber composite net; and forming a continuous multi-layerstructure composite fiber net by using the single-layer micrometer / nanometer fiber composite net by a cross lapping mode, and performing mechanical consolidation to obtain the micrometer / nanometer fiber composite filtering material. The method is simple in production process, high in controllability and easy in industrialization.

Owner:TIANJIN POLYTECHNIC UNIV

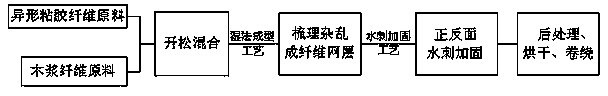

Water-flushing degradable non-woven fabric and production method thereof

InactiveCN103437066AImprove processing efficiencyImprove toughnessNon-woven fabricsHydrogenNonwoven fabric

The invention relates to a water-flushing degradable non-woven fabric and a production method thereof. Profiled viscose fibers and wood pulp fibers are directly used as raw materials and are opened and mixed, then the profiled viscose fibers and the wood pulp fibers are mutually twisted through wet process formation and spun-lacing reinforcement, hydrogen bonds are formed between the profiled viscose fibers and the wood pulp fibers and finally drying is performed to obtain the water-flushing degradable non-woven fabric. By adopting the scheme, the strength of the water-flushing degradable non-woven fabric is high, the water-flushing degradable non-woven fabric can be quickly and fully degraded under the effect of water flushing and the production process is simple.

Owner:HANGZHOU NBOND NONWOVENS

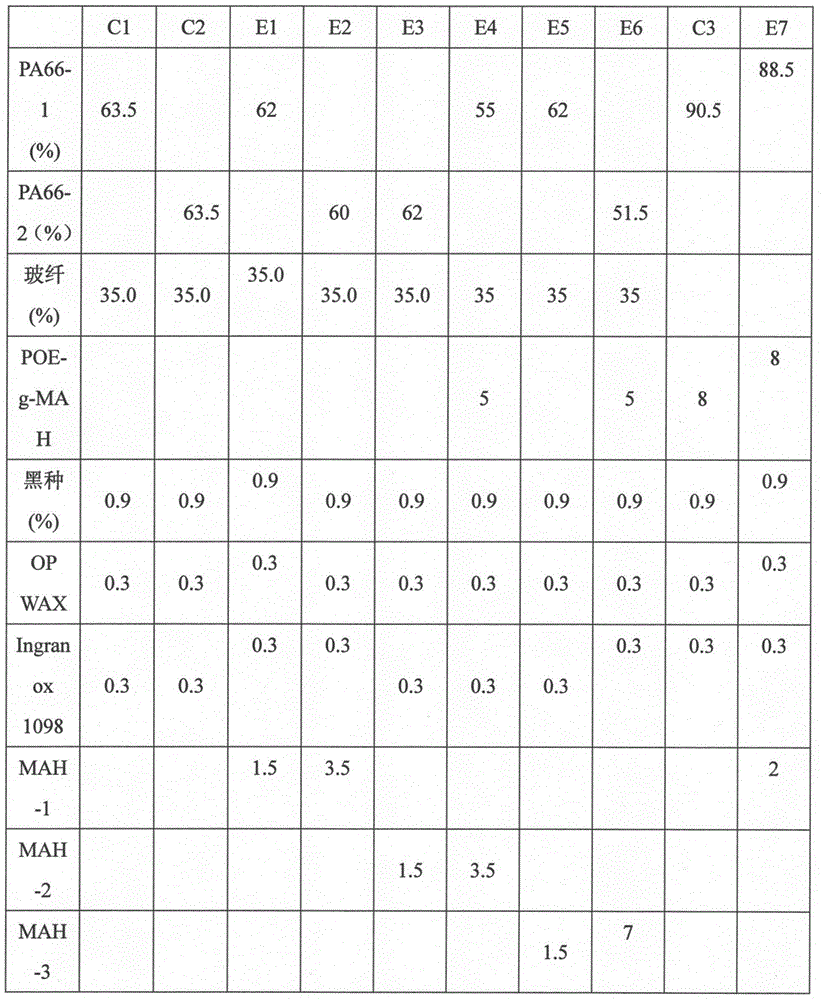

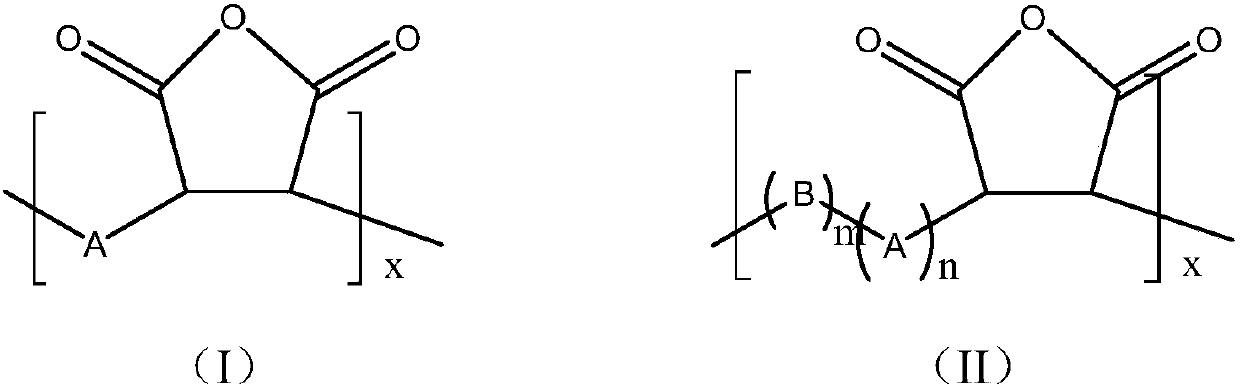

Polyamide composition suitable for extrusion molding, blow molding and foaming multi uses and preparation method thereof

The present invention relates to a polyamide composition suitable for extrusion molding, blow molding and foaming multi uses, the polyamide composition is characterized by comprising 49 to 89% (by weight) of thermoplastic polyamide resin, 0.01 to 10% (by weight) of maleic anhydride copolymer, 0 to 50% (by weight) of filler, 0 to 20% (by weight) of an impact-resistant modifier and 0.1 to 2% (by weight) of an additive, wherein the maleic anhydride copolymer is prepared by alternating copolymerization or block copolymerization of maleic anhydride and one or two alkenyl-containing monomers which contain heteroatom or does not contain heteroatom. The polyamide composition has the advantages of high melt strength increase and significantly enhanced mechanical properties, is suitable for machining or molding process requiring higher melt strength, and is particularly suitable for extrusion molding, blow molding and foaming and the like.

Owner:SHANGHAI KINGFA SCI & TECH

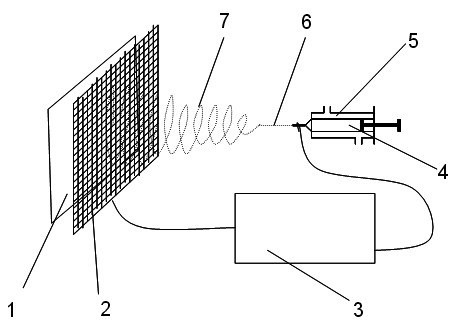

Polyvinyl alcohol nanofiber, and preparation method and device thereof

ActiveCN102586928ALow viscosityImprove spinnabilityFilament/thread formingMonocomponent synthetic polymer artificial filamentNonwoven fabricHydroxy compound

The invention discloses polyvinyl alcohol (PVA) fiber, and a preparation method and a preparation device thereof. The method comprises the following steps: dissolving polyvinyl alcohol into distilled water; adding 1 to 5 weight percent of water soluble hydroxyl terminated hyperbranched polyester; placing the obtained mixed liquor at the temperature of between -20 and -70 DEG C and freezing for 8 to 24 hours; defreezing and heating at room temperature to prepare spinning liquor with the viscosity of 180 to 550 mpa.s; and obtaining high strength polyvinyl alcohol nano-fiber nonwoven fabric with the strength of 1,045 to 1,800 N / m<2> on a receiving screen by an electrostatic spinning process. The PVA liquor is frozen and defrozen, so the intermolecular chain entanglement is improved, more intermolecular hydrogen bonds are formed, and the tensile strength of the obtained nano-fiber can be obviously improved. The invention has a simple process, is pollution free in the production process and contributes to quick development and popularization application of the PVA nano-fiber.

Owner:仙桃市茂盛塑料制品有限公司

Polyamide composition and preparation method thereof

The invention provides a polyamide composition and a preparation method thereof. The polyamide composition has high melt strength and is characterized in comprising thermoplastic polyamide resin and a maleic anhydride copolymer. The maleic anhydride copolymer is obtained through alternating copolymerization or block copolymerization of maleic anhydride and one or two monomers comprising alkenyl. The composition provided by the invention has relatively high melt strength and hydrolysis resistance.

Owner:SHANGHAI KINGFA SCI & TECH

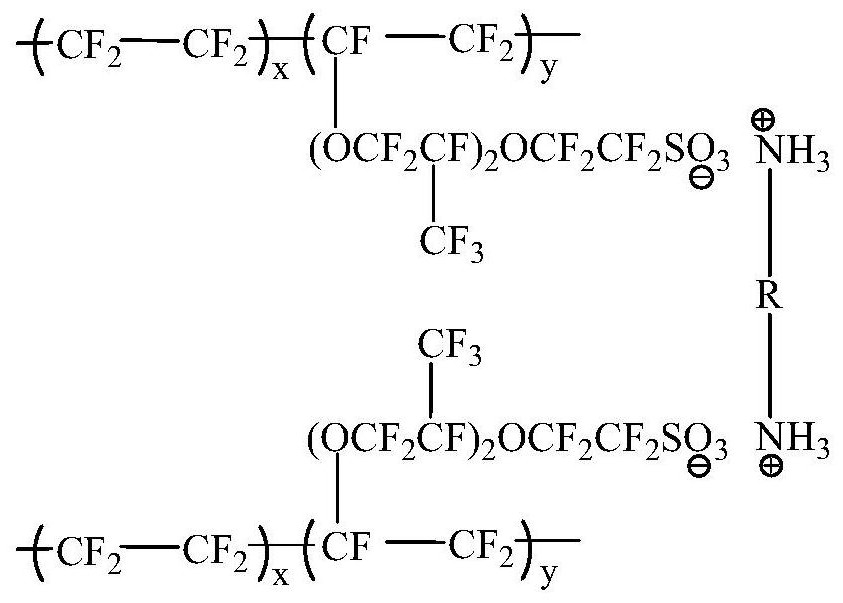

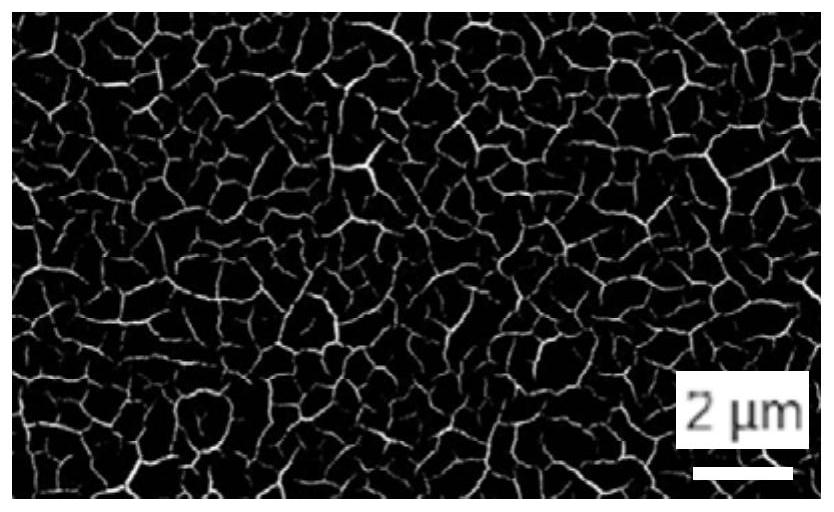

Catalyst slurry for membrane electrode, method for producing same, catalyst-coated membrane, and membrane electrode

InactiveCN112259753AAvoid crackingLarge particle sizeFinal product manufactureCell electrodesCoated membranePtru catalyst

The invention belongs to the field of fuel cells, and particularly relates to catalyst slurry for a membrane electrode, a preparation method of the catalyst slurry, a catalyst coating membrane and themembrane electrode. The catalyst slurry for the membrane electrode is prepared from the following components: a catalyst, perfluorosulfonic acid resin, a solvent and an additive, wherein the additiveis a compound or a polymer containing at least two nitrogen-containing functional groups. By using the catalyst slurry and adopting a cathode and anode direct coating method to prepare a catalyst coating film, the catalyst coating film with few cracks can be prepared.

Owner:SINOHYKEY TECH CO LTD

Spunlace non-woven material containing natural dry petals and preparation method thereof

ActiveCN108532123AIncrease health functionNo pollution in the processNon-woven fabricsFiberPersonal care

The invention relates to the technical field of spunlace non-weaving, and discloses a spunlace non-woven material containing natural dry petals and a preparation method thereof. The spunlace non-wovenmaterial comprises dry fiber webs and wet fiber webs which are intertwined, and the intact natural dry petals are placed between the wet fiber webs and the dry fiber webs; the natural dry petals areselected from petals which use carotenoids as main pigments and have colors from yellow to red, and the length-width ratio of the natural dry petals is smaller than 10:1. According to the spunlace non-woven material, the characteristics of dry-laid web and wet-laid web spunlace processes are fully utilized, and the whole petals with natural morphology are uniformly distributed in the spunlace non-woven material, so that the spunlace non-woven material has natural beauty care effects, the aesthetic feeling of cloth covers of personal care materials are enhanced, and the technical problems of petal colour fading, color diffusion, short product storage period and easy falling of petals during the production and use process are effectively solved through reasonable process coordination.

Owner:HANGZHOU NBOND NONWOVENS

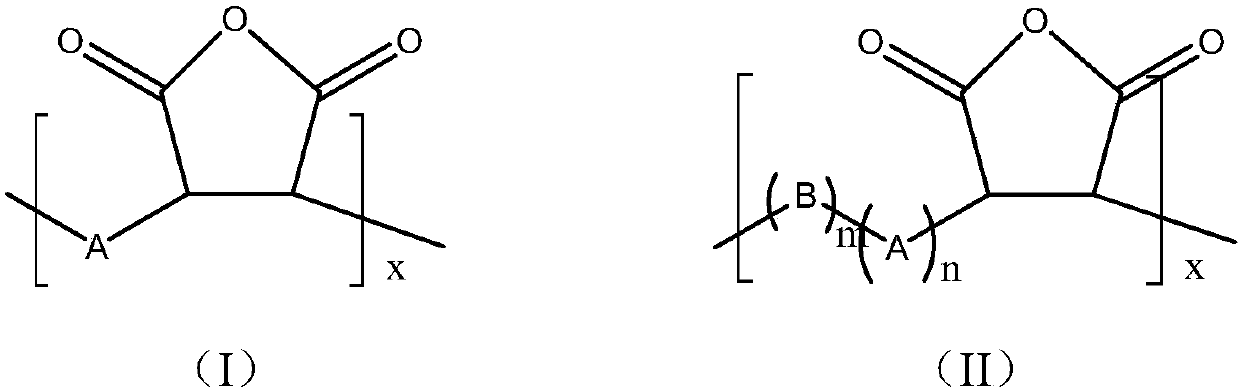

Polyamide composition with good appearance

The invention discloses a polyamide composition with good appearance, prepared from, by weight, 49-89% of thermoplastic polyamide resin, 0.01-10% of a maleic anhydride copolymer, 0-50% of a filler, 0-20% of an anti-impact modifier, and 0.01-20% of a polyhydroxy compound, wherein the maleic anhydride copolymer is one of alternating copolymers or block copolymers made by means of mass polymerization. The maleic anhydride copolymer of special structure is added into a polyamide system, so that melt strength and mechanical properties of the polyamide composition are improved; the polyhydroxy compound is introduced, so that the appearance of the polyamide composition is greatly improved, and the mobility worsening due to the introduction of maleic anhydride copolymers is particularly improved;the maleic anhydride copolymer is particularly suitable for processing or forming procedures having high melt strength requirement, especially extrusion molding, blow molding, foaming and the like.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

Film with high drawing ratio and production method thereof

ActiveCN109093978AImprove tensile propertiesImprove mechanical propertiesSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a film with a high drawing ratio. The film is composed of an outer layer, an intermediate layer and an inner layer. The outer layer is a metallocene linear low density polyethylene and ethylene modified polyethylene glycol terephthalate blending modified resin; the intermediate layer comprises the compositions of maleic anhydride grafted low density polyethylene and graphene oxide modified low density polyethylene; and the inner layer is polyamide-11 or polyamide-12. The invention also discloses a production method of the film with the high drawing ratio. Compared withthe prior art, the packaging film has the advantages of high drawing ratio, low cost, good comprehensive performance, strong market competitive strength and the like. The invention also discloses theproduction method of the film with the high drawing ratio.

Owner:NINGBO HONGYAN PACKING MATERIAL

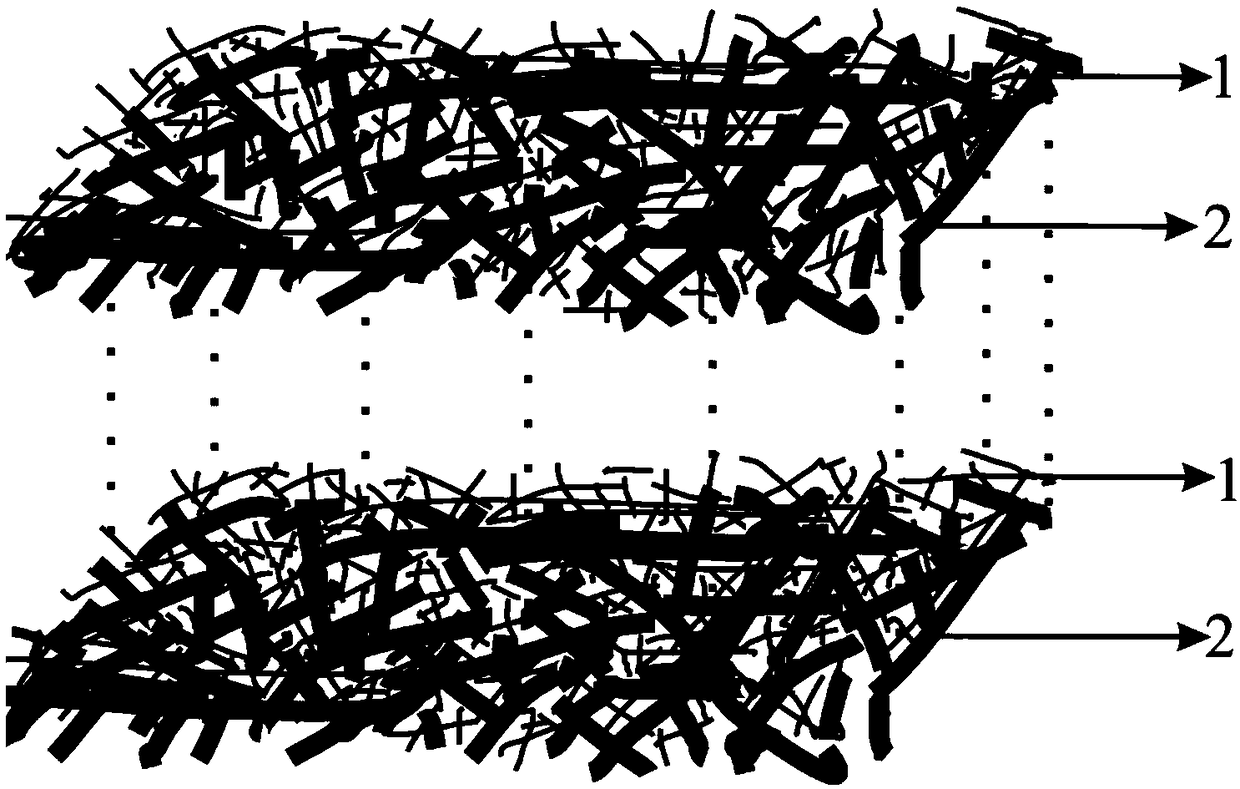

Nonwoven fabric and method for manufacturing same

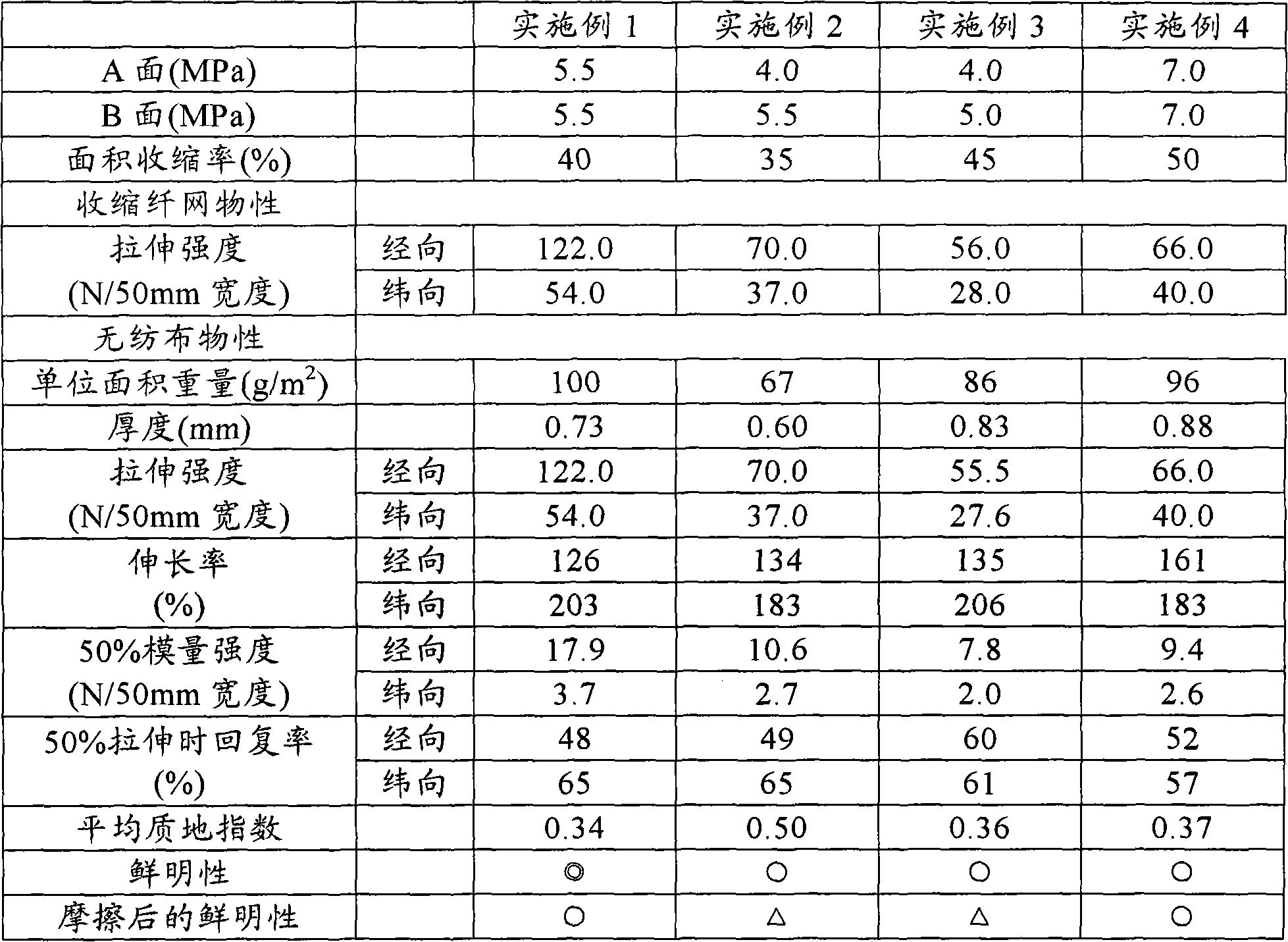

Provided are an extensible nonwoven fabric on which the source, the medicinal component, a pattern and / or other pieces of information are recognizable not only at beginning of the use of the fabric but also during use; and a method for manufacturing the nonwoven fabric. The nonwoven fabric of the invention is a nonwoven fabric made mainly of highly crimped fibers, partially having a compressed region where no fibers are melted and bonded to each other, and having a tensile strength of 25 N / 5-cm-width or more in both the machine direction and the cross direction. This nonwoven fabric may be manufactured by causing a water jet having a pressure of 5 MPa or more to act onto a fiber web made mainly of a latent crimpable fiber, thereby forming an entangled fiber web, causing heat to act onto the entangled fiber web, thereby crimping the latent crimpable fiber to convert the fiber to a highly crimped fiber and contracting, at the time of the conversion, the area of the entangled fiber web by 30% or more, thereby forming a contracted fiber web, and embossing the contracted fiber web in such a manner that the fibers are not melted and bonded to each other.

Owner:JAPAN VILENE CO LTD

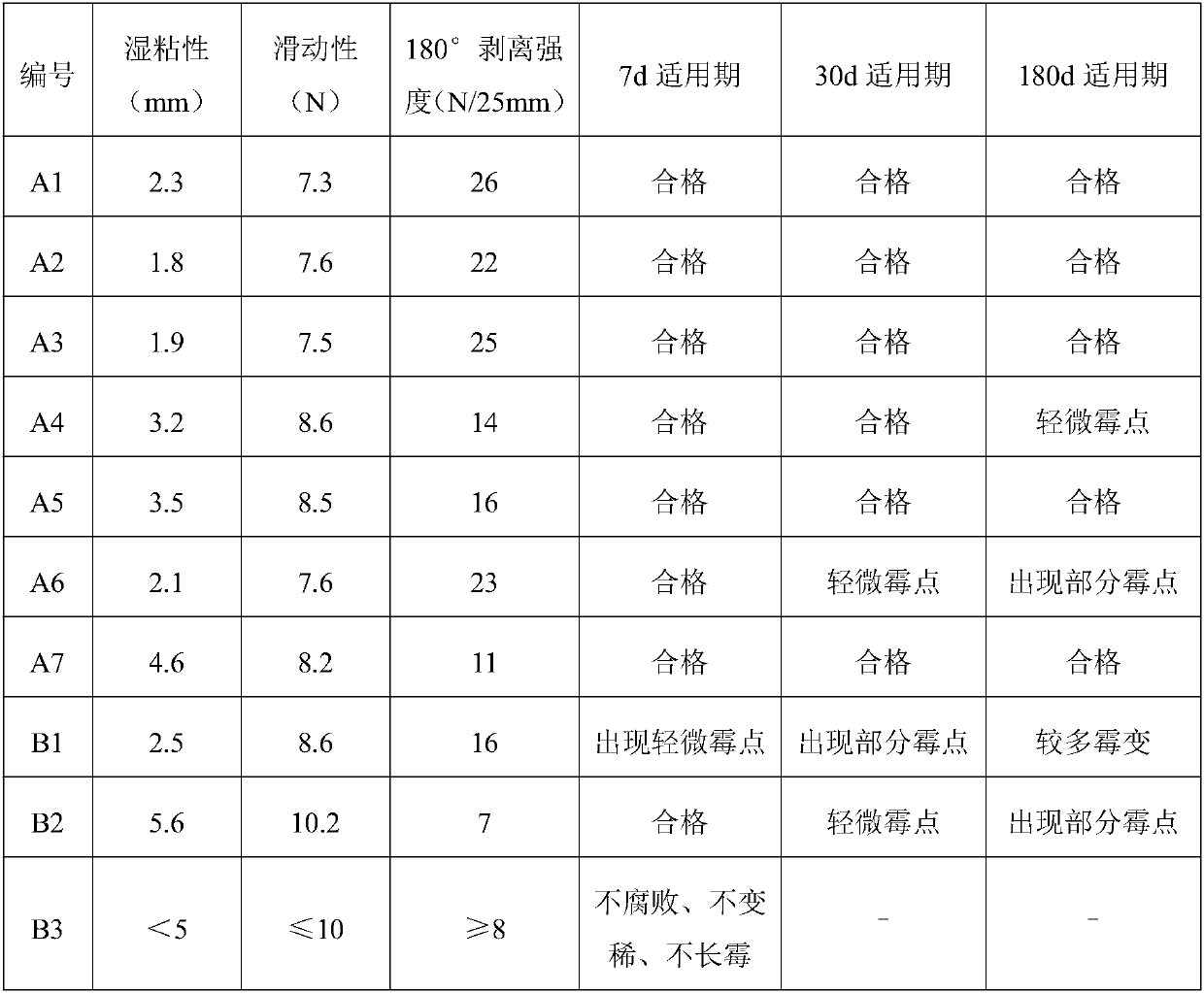

Environment-friendly glutinous-rice gum for sheet production and preparation method of gum

ActiveCN107722870AImprove lipophilicityImprove antibacterial propertiesNon-macromolecular adhesive additivesStarch adhesivesCarrageenanStearic acid

The present invention provides an environment-friendly glutinous-rice gum for plate production and a preparation method of the gum. The method comprises the following steps: 1) mixing a modifier, glacial acetic acid and absolute ethanol to prepare a mixed solution M1; 2) under a pH condition of 3-5, dropwise adding tetrabutyl titanate into the above prepared mixture M1, and performing mixing for 1-2 h at a temperature of 60-100 DEG C to obtain a colloid M2; and 3) mixing glutinous rice flour, the colloid M2, didecyl dimethyl ammonium chloride, carrageenan, xanthan gum, locust bean gum, sodiumcarboxymethylcellulose and water to prepare the environment-friendly glutinous-rice gum for sheet production, wherein the modifier is at least one selected from of pentaerythritol, propylene glycol, neopentyl glycol and stearic acid. The glutinuous-rice gum achieves advantages of environmental protection, high adhesion, corrosion resistance and the like.

Owner:开平市板卫士装饰材料有限公司

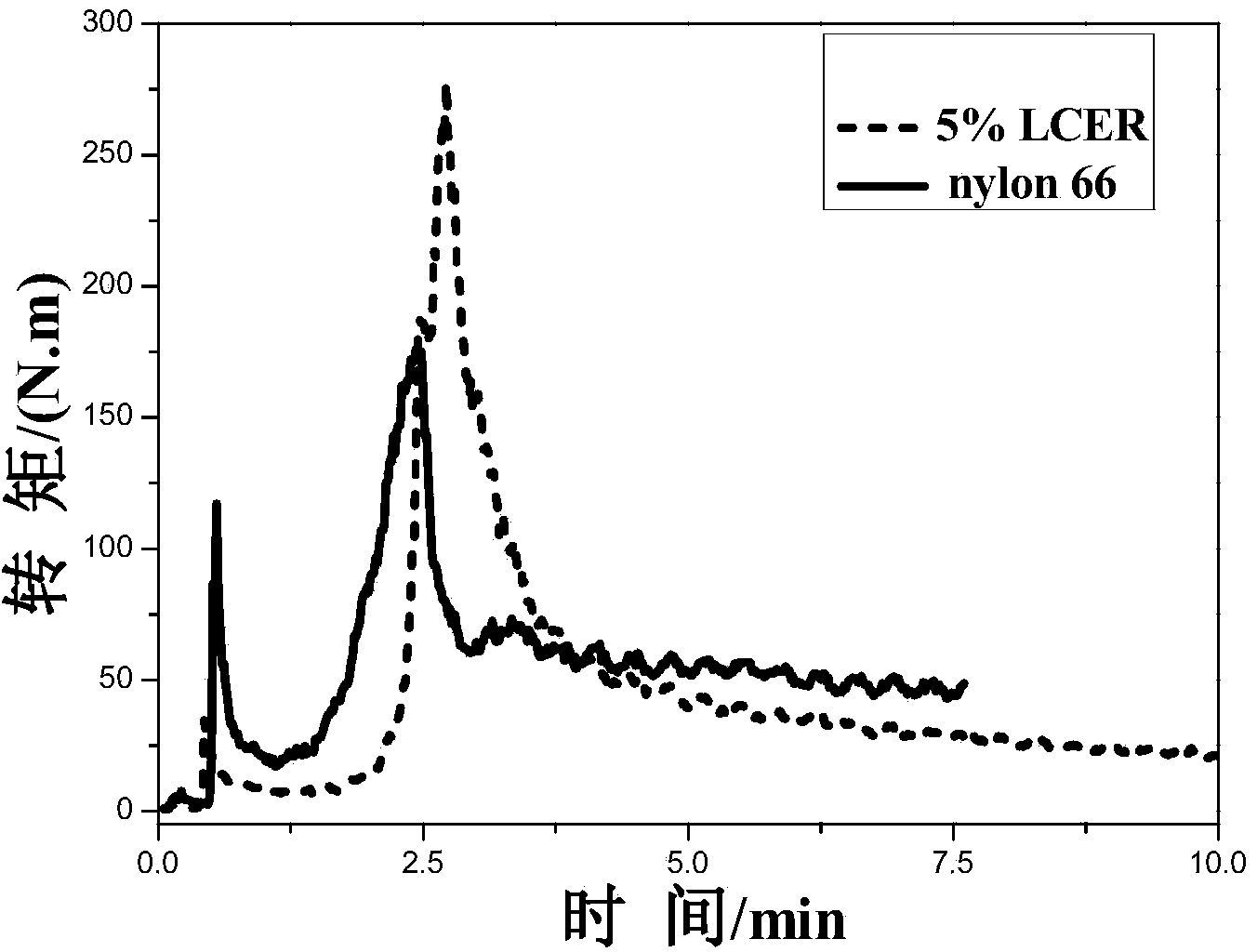

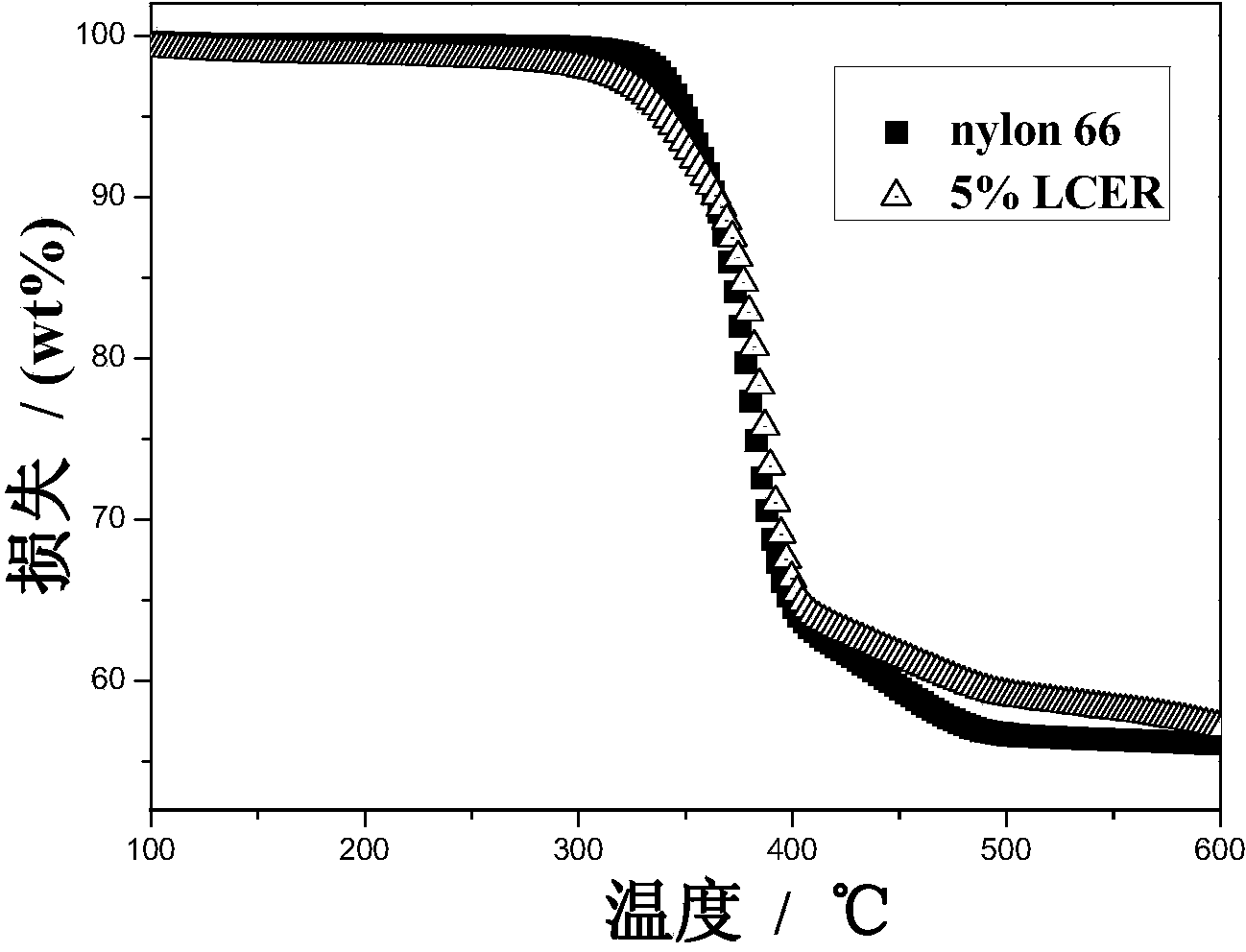

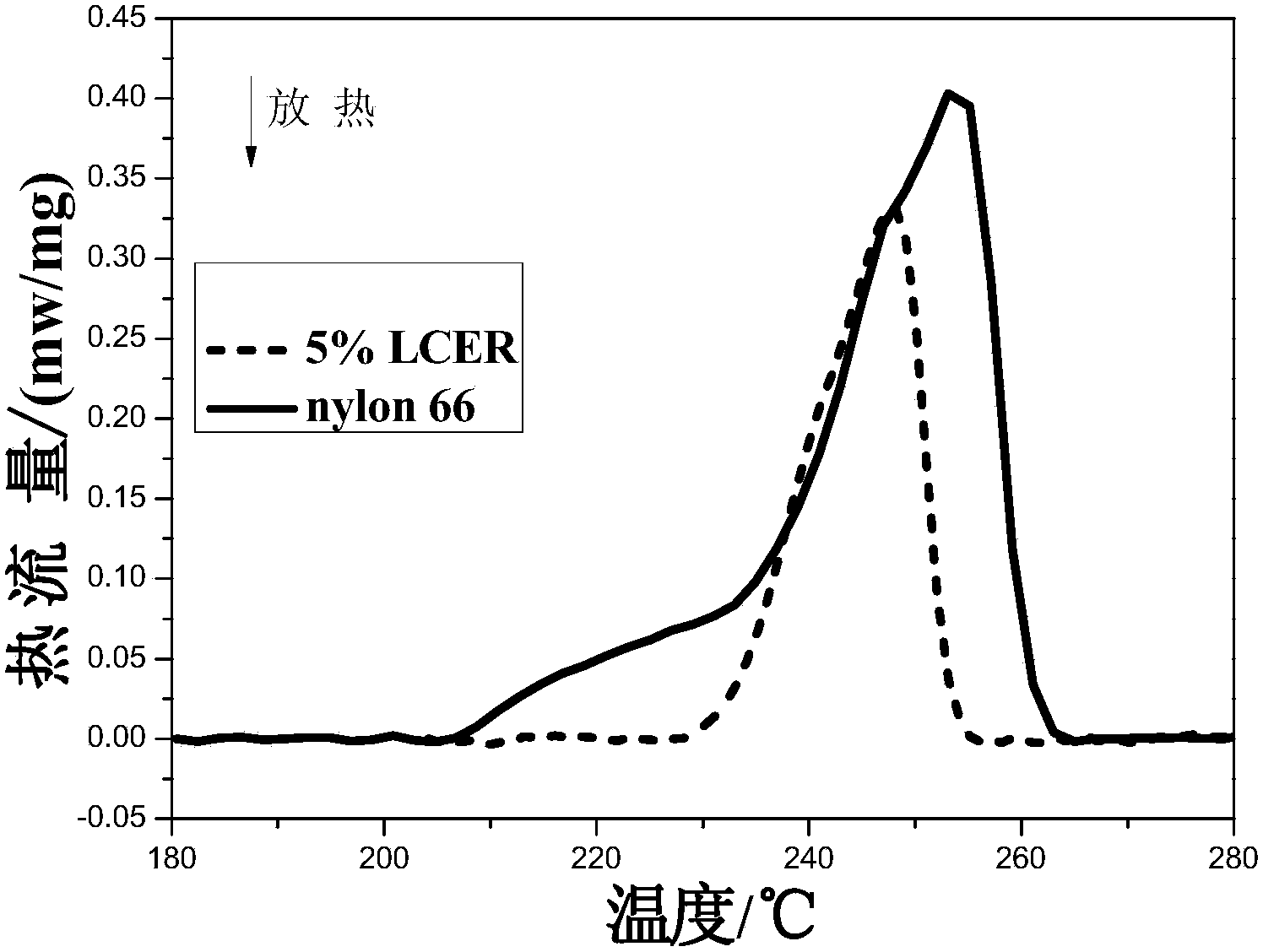

Method using epoxy resin liquid crystal to modifying nylon performance

The invention discloses a method using epoxy resin liquid crystal to modifying nylon performance. The method comprises the following steps: epoxy resin liquid crystal and nylon 66 are uniformly mixed and dried; the blend is added into a Haake rheometer for banburying; after banburying for 8-15 minutes in Haake rheometer at 260-270 DEG C, the material is discharged and cooled at room temperature, and then is stored in sealing bags; the mass of the epoxy resin liquid crystal is 5-10% of that of the mixture; the epoxy resin liquid crystal is blended with a crystal high-molecular material whose main chain contains proton donor or the like, and at a certain temperature, the epoxy resin liquid crystal is introduced into polymer side chain, thereby reducing melting temperature of the polymer itself, and improving processing performance of the material itself. the melting temperature of modified nylon can be reduced to 231.1 DEG C at the lowest, which is 20 DEG C lower than that of the pure nylon 66. The initial decomposition temperature can be increased to 366.1 DEG C at the highest, which is 8 DEG C higher than that of the pure nylon 66.

Owner:SOUTH CHINA UNIV OF TECH

Proparation technology of conductive polyaniline

A electrically conductive polyphenylamine with high solubility, mechanical performance and adhesion is prepared from the hydroxyalkylthio ring substituted phenylamine and the siloxyalkylthio ring substituted phenylamine through copolymerizing under existence of oxidant and long-chain alkylprotonic acid.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

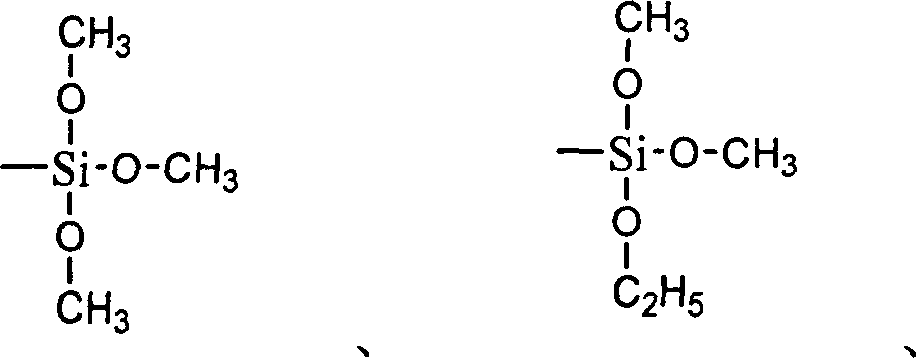

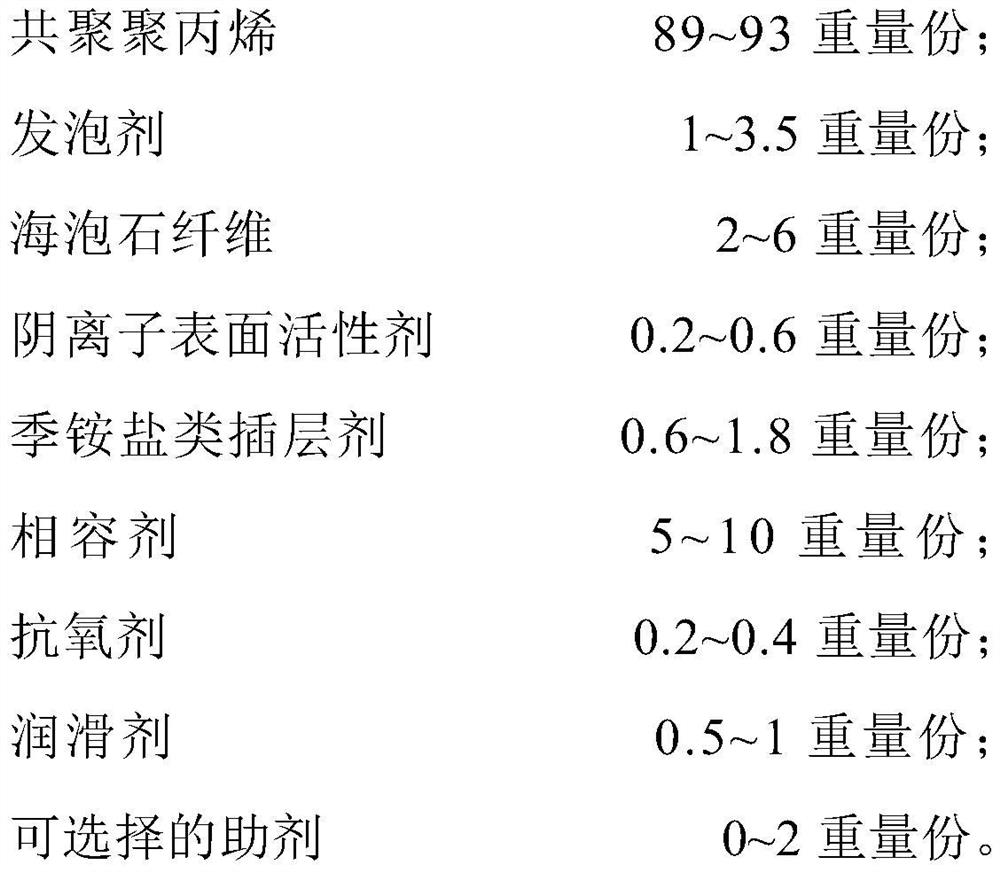

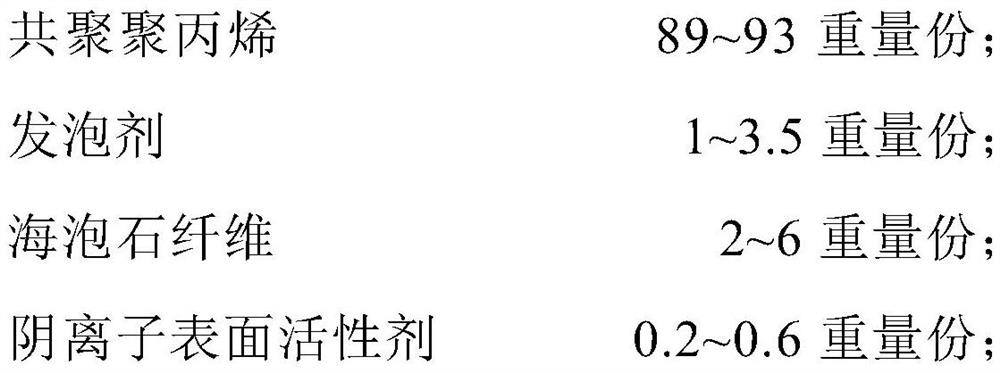

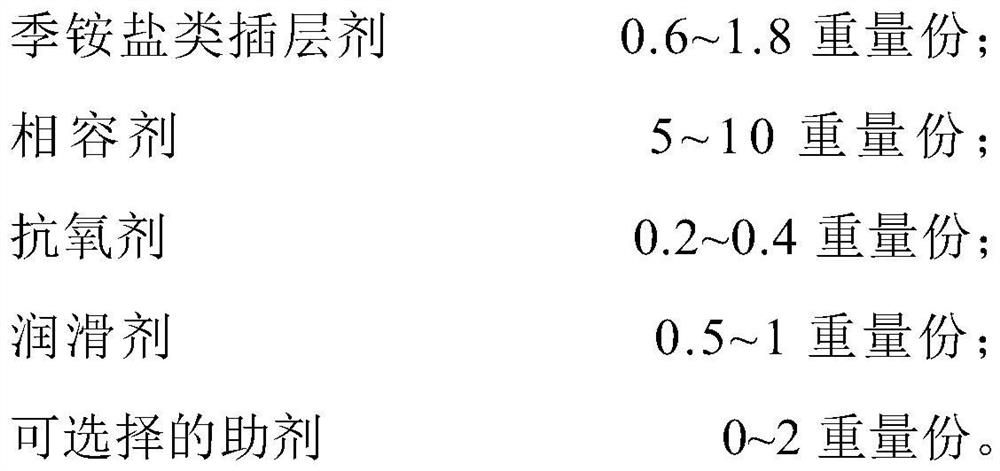

A kind of lightweight polypropylene micro-foaming composite material and preparation method thereof

The invention relates to the technical field of high polymers and in particular relates to a lightweight polypropylene micro-foamed composite material and a preparation method thereof. The lightweightpolypropylene micro-foamed composite material is prepared from a raw material composition; the raw material composition is prepared from the following components in parts by weight: 89 to 93 parts ofcopolymerized polypropylene, 1 to 3.5 parts of a foaming agent, 2 to 6 parts of sepiolite fiber, 0.2 to 0.6 part of an anionic surfactant, 0.6 to 1.8 parts of a quaternary ammonium salt intercalationagent, 5 to 10 parts of a compatilizer, 0.2 to 0.4 part of an antioxidant, 0.5 to 1 part of a lubricant and 0 to 2 parts of a selective auxiliary agent. According to the lightweight polypropylene micro-foamed composite material, the modified sepiolite fibers are added into polypropylene, so that the mechanical strength of the polypropylene is remarkably increased and a pore diameter of foam poresis thinned; the utilization requirements of manufacturing parts including automobile door plates, air channels, central channels, stand columns and the like can be met, and the lightweight polypropylene micro-foamed composite material has profound significance in automobile weight reduction.

Owner:ORINKO NEW MATERIAL CO LTD

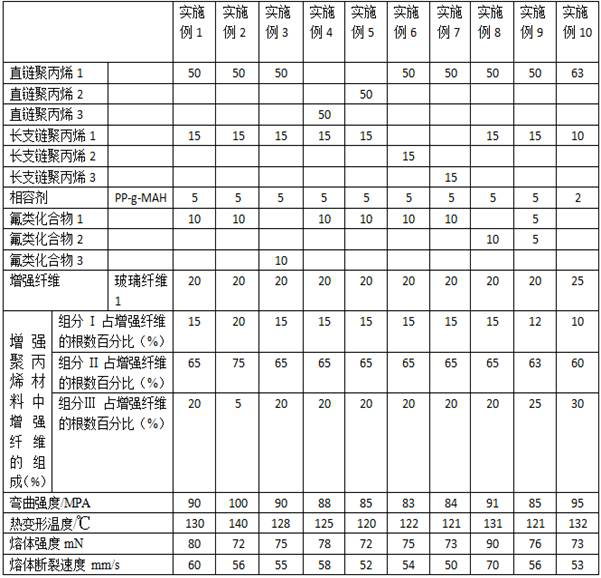

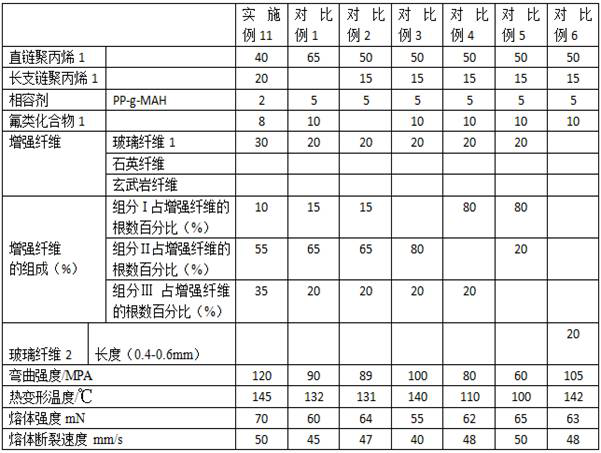

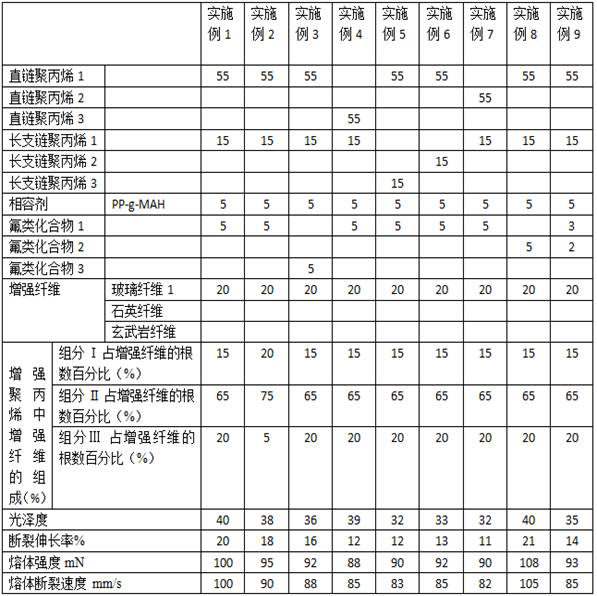

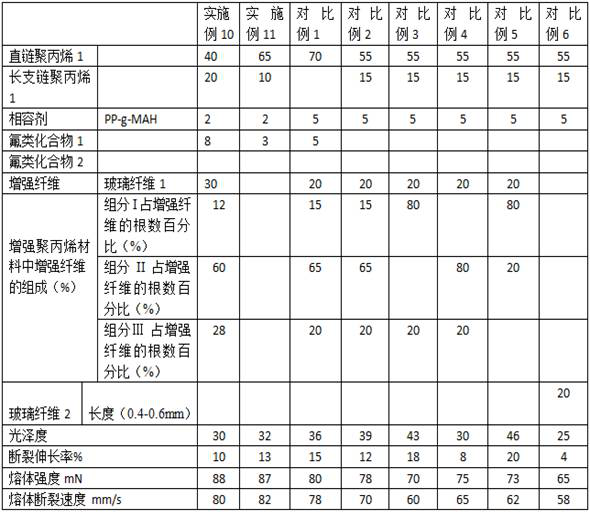

Reinforced polypropylene material and preparation method and application thereof

The invention discloses a reinforced polypropylene material and a preparation method and application thereof. The reinforced polypropylene material comprises the following components in parts by weight: 20-80 parts of straight-chain polypropylene; 5-40 parts of long-chain branched polypropylene; 0.5-25 part of a compatilizer; 5-60 parts of reinforcing fibers; 1-20 parts of a fluorine compound; the prepared polypropylene material has high melt strength and good rigidity and heat resistance, and is mainly suitable for blow molding, plastic uptake and other occasions.

Owner:KINGFA SCI & TECH CO LTD

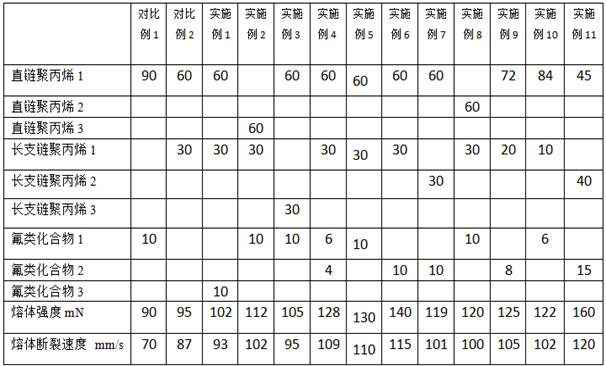

High-melt-strength polypropylene material as well as preparation method and application thereof

The invention discloses a high-melt-strength polypropylene material as well as a preparation method and application thereof. The high-melt-strength polypropylene material comprises the components in parts by weight: 10-90 parts of straight-chain polypropylene, 0.5-50 parts of polypropylene with a long branched chain, and 0.01-20 parts of a fluorine compound. Long molecular chains of straight-chain polypropylene are utilized to increase entanglement among the molecular chains, thereby being beneficial to enhancing the stability of the melt during extrusion and plastic uptake; by adding the polypropylene with the long branched chain and utilizing the branched chain structure, the melt strength can be greatly improved; and the fluorine compound is not molten in the forming process, and can be stretched into fibers under the action of the melt, so that the polypropylene molecular chain and the fluorine compound fibers form an interpenetrating network, and the melt strength of the whole material is further improved. The polypropylene material prepared in the method has high melt strength, and is mainly suitable for blow molding, plastic uptake and other occasions.

Owner:KINGFA SCI & TECH CO LTD

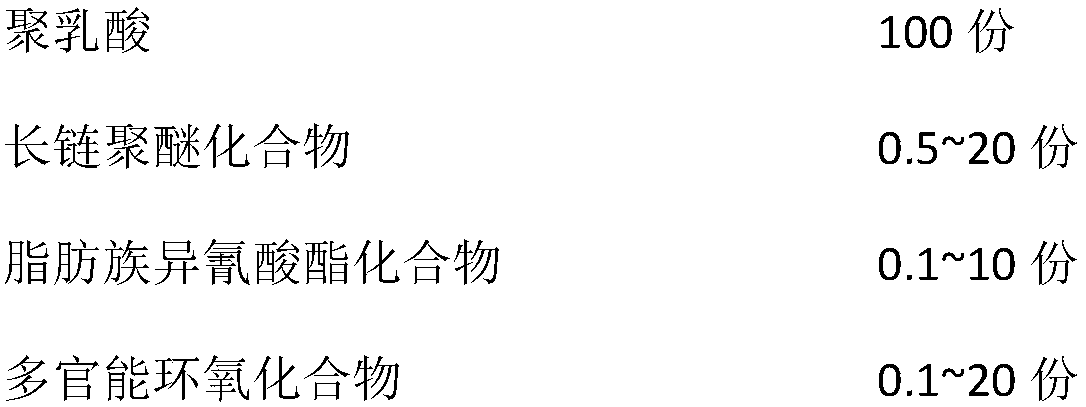

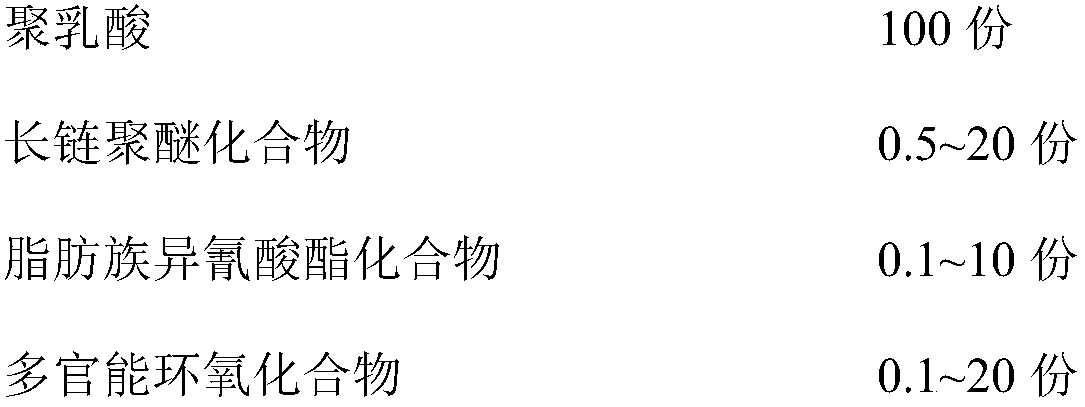

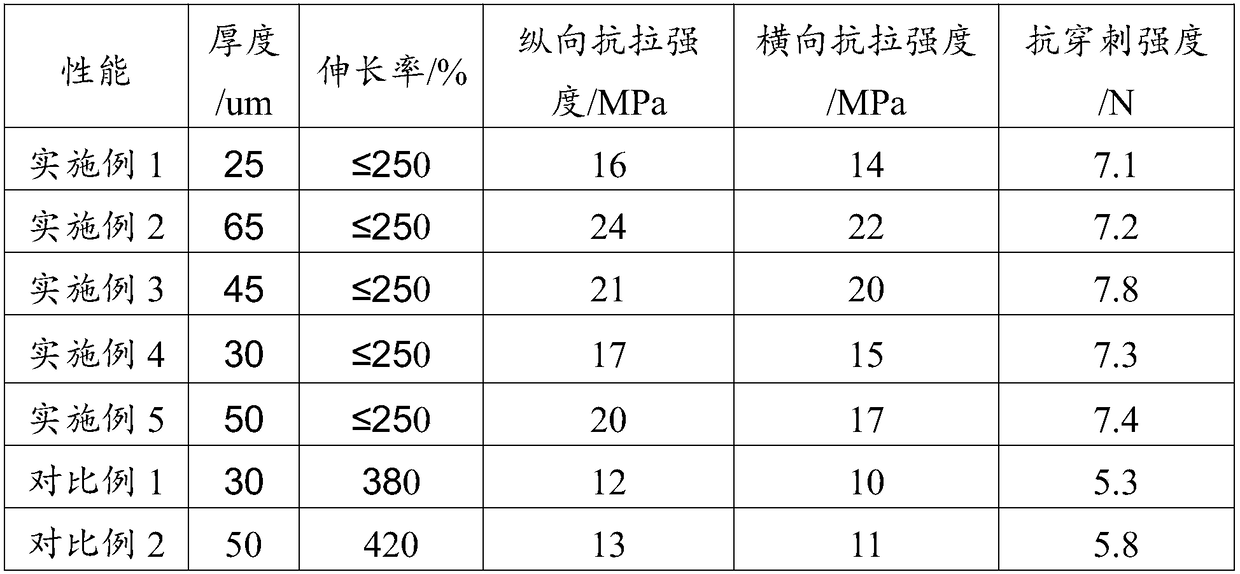

High-strength polylactic acid bone fixation material and preparation method thereof

The invention discloses a high-strength polylactic acid bone fixation material and a preparation method thereof. The high-strength polylactic acid bone fixation material is characterized in that a multifunctional long-chain flexible branching agent is prepared by virtue of reaction of polyether and aliphatic isocyanate and is combined with a multifunctional epoxy compound for use, and long-chain branched polylactic acid is prepared by virtue of a simple, convenient and feasible reactivity processing method, so that the entanglement degree of chains among polylactic acid molecules is increased,and the tensile property of polylactic acid is improved; and by introducing a polyether long chain, polylactic acid is endowed with relatively good impact toughness, and a high-power uniformly-orientated polylactic acid material is prepared on that bases by virtue of a double-shaft solid phase thermal stretching method, so that the mechanical strength of the polylactic acid material as the bone fixation material is substantially enhanced, and meanwhile, the biocompatibility of the polylactic acid material is improved.

Owner:SICHUAN UNIV

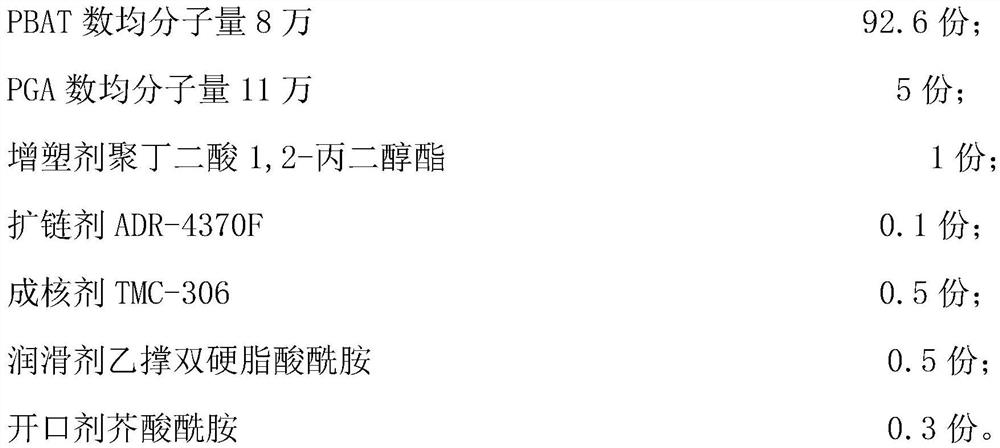

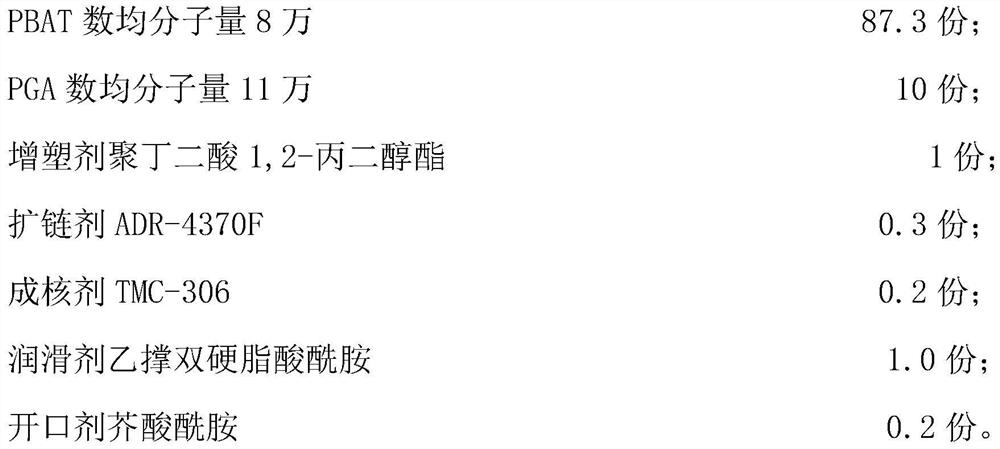

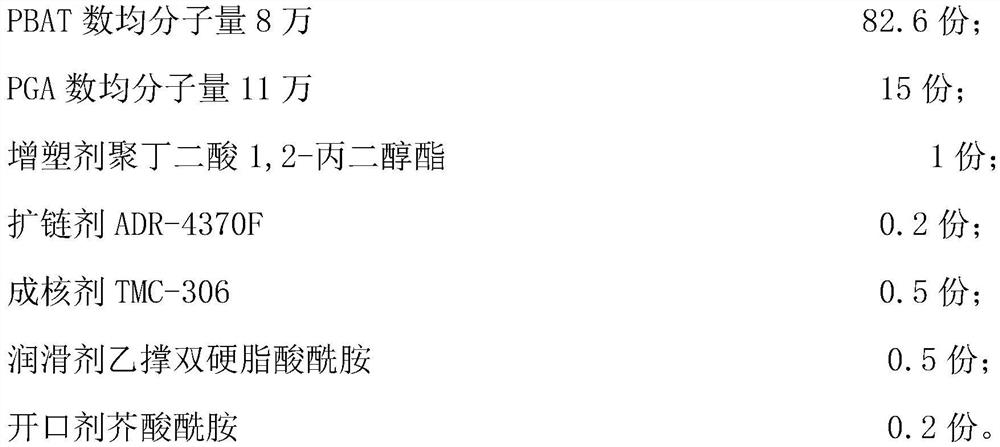

Completely biodegradable film and preparation method thereof

PendingCN113956630AImprove biodegradabilityIncreased tensile elongation at break and tear strengthPlasticizerStearic acid

The invention discloses a completely biodegradable film and a preparation method thereof. The completely biodegradable film is prepared from poly(butylene adipate-co-terephthalate), polyglycolic acid, a chain extender styrene-acrylic acid-glycidyl methacrylate copolymer, a plasticizer poly(succinic acid-1, 2, 4-trimethyl-1, 3-pentanedionate), a plasticizer poly (butylene adipate-co-butylene terephthalate), a plasticizer polysuccinic acid-1, 2-propylene glycol ester, a nucleating agent, a lubricant ethylene bisstearamide and an anti-blocking agent erucyl amide. The preparation method comprises the following steps: weighing the components according to the formula, mechanically mixing to form a premix, metering and adding the plasticizer polysuccinic acid-1, 2-propylene glycol ester from a liquid feeding port of a twin-screw extruder, carrying out melt extrusion, water cooling, pelletizing and drying to obtain special resin for film blowing, and carrying out blow molding film forming through a film blowing machine to obtain the completely biodegradable film. The chain extender, the nucleating agent and the plasticizer can effectively improve the tensile elongation at break and tear strength of the film and obviously improve the rheological behavior of the material, and the film has good mechanical properties and excellent biodegradability and can replace PE, PP, PVC and the like to prepare films and sheets.

Owner:江苏碧升生物新材料有限公司 +1

Reinforced polypropylene material, preparation method and application thereof

The invention discloses a reinforced polypropylene material, a preparation method and application thereof. The reinforced polypropylene material comprises the following components in parts by weight: 30-70 parts of straight-chain polypropylene, 2-50 parts of long branched chain polypropylene, 1-20 parts of a compatilizer, 5-60 parts of reinforcing fibers, 0.1-20 part of a fluorine compound. According to the invention, the polypropylene material prepared by the method is high in surface gloss, good in toughness and high in melt strength, and is mainly suitable for blow molding, plastic uptake and other occasions.

Owner:KINGFA SCI & TECH CO LTD

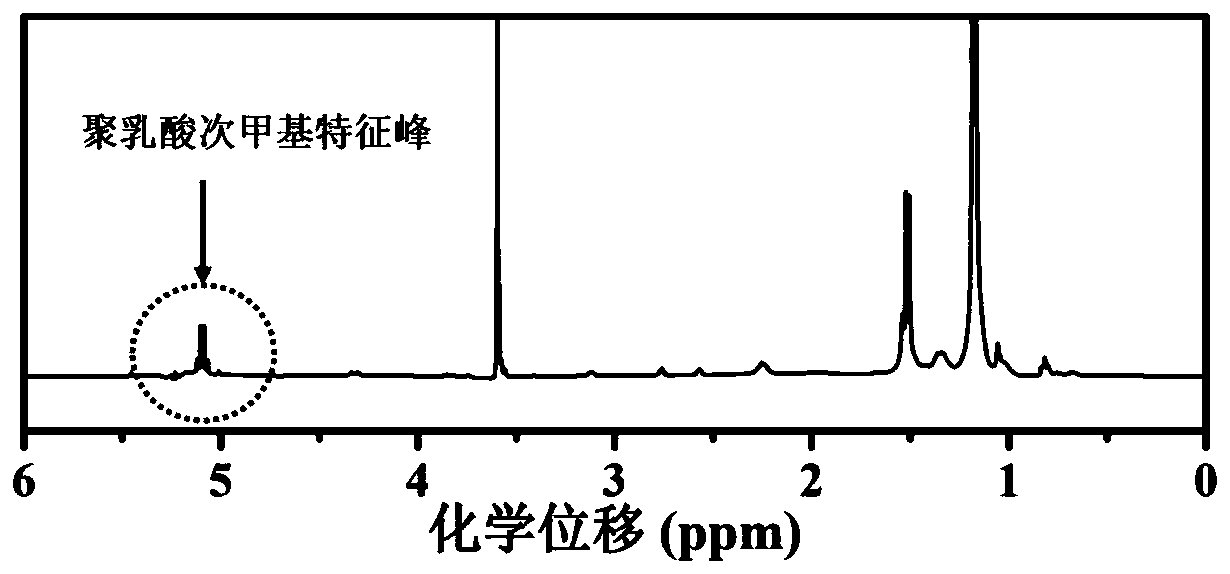

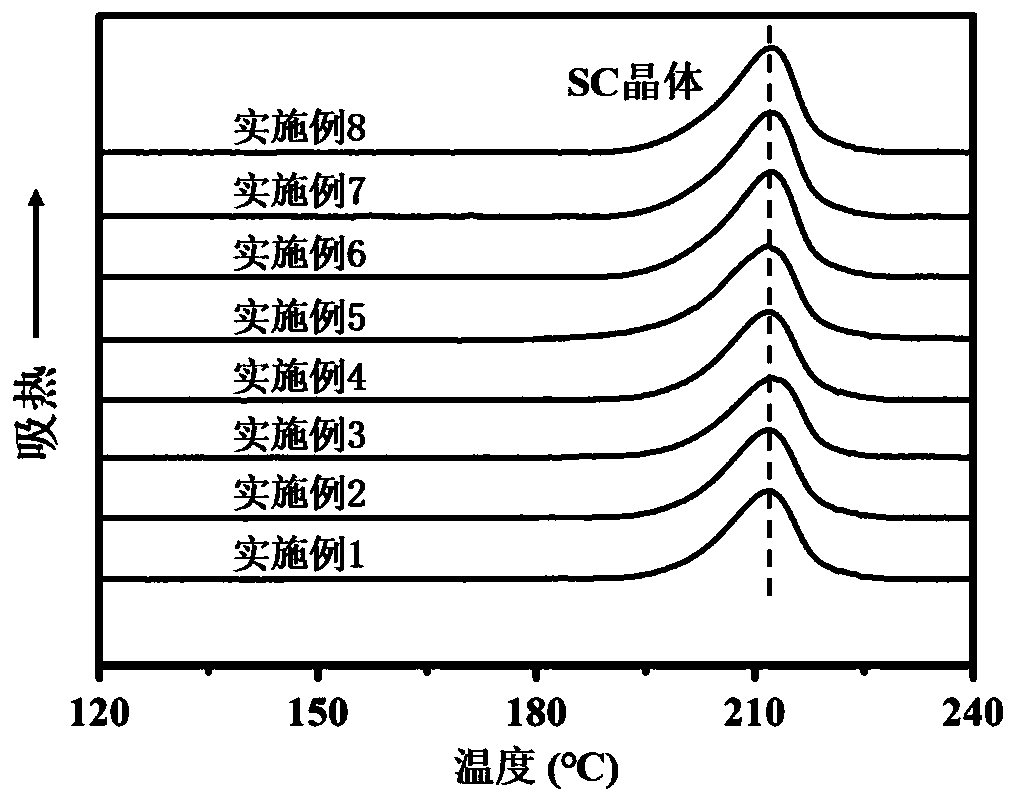

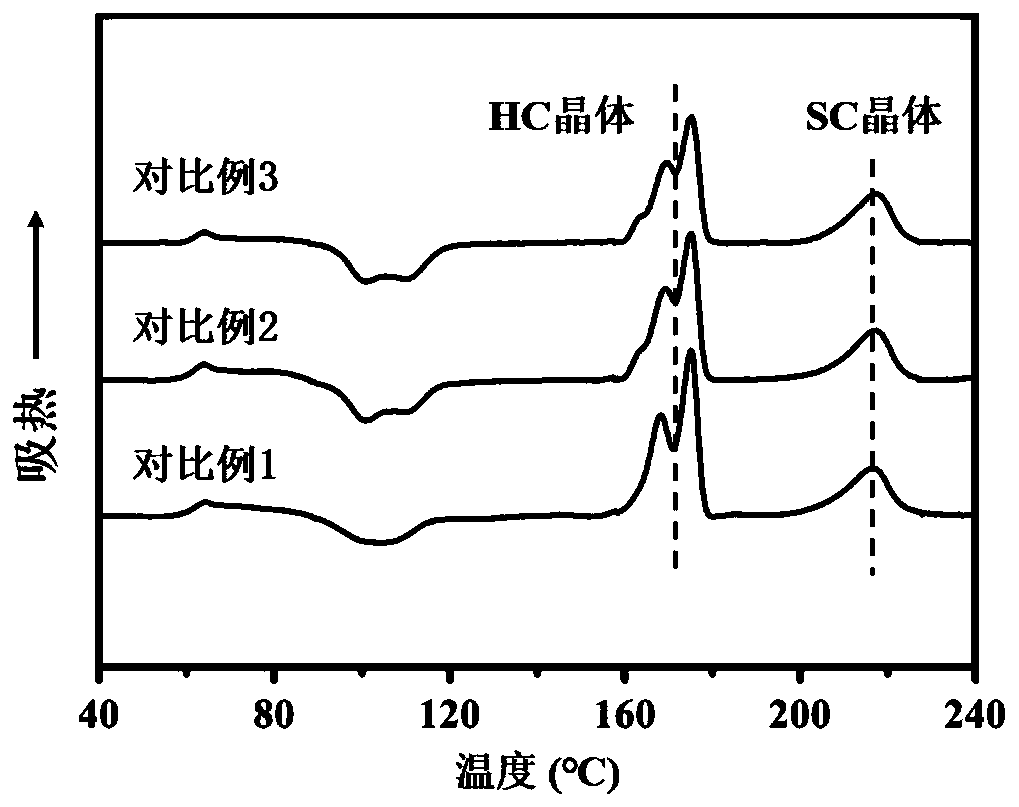

Stereo-complex polylactic acid material or product with excellent melt stability and melt processability and preparation method thereof

The invention discloses a stereo-complex polylactic acid material or product with excellent melt stability and melt processability and a preparation method thereof. A grafting agent, a catalyst, L-polylactic acid and D-polylactic acid are mixed uniformly, then the mixed materials are added into a melting mixer, the mixed materials are blended and granulated, and the granules are melted, processed,and molded to obtain the SC-PLA material or product with excellent melt stability and melt processability. Part of PLA molecular chains are grafted to molecular chains of the grafting agent in-situ by virtue of a reactive blending technology, so that a grafted copolymer with a long branch chain structure is obtained, the melt stability of SC-PLA is effectively improved, and the obtained SC-PLA also has good melt processability. The preparation method is simple, feasible, green and efficient, and large-scale industrial production is easy to realize.

Owner:SICHUAN UNIV

Film with high tensile strength and production method

ActiveCN109177400AHigh strengthImprove mechanical propertiesSynthetic resin layered productsFlat articlesLow-density polyethyleneHigh surface

The invention relates to a film with high tensile strength. The film is a seven-layer compound film. The film comprises a layer A, a layer B, a layer C, a layer D, a layer E, a layer F and a layer G from outer to inner starting from the cross section of the film, wherein the layer A is composed of a blending modified resin of metallocene polyethylene and ethylene modified PET; the layer B is madefrom graphene oxide modified low-density polyethylene; the layer C is made from maleic anhydride grafted low-density polyethylene; the layer D is made from ultra-high molecular weight polyethylene; the layer E is made from maleic anhydride grafted low-density polyethylene; the layer F is made from graphene oxide modified low-density polyethylene; the layer G is made from polyvinylidene fluoride. Compared with a common film, the film with high tensile strength provided by the invention has higher strength, no spreading of damaged holes, higher surface viscosity and higher tensile strength, so that the film with high tensile strength can be applied to special occasions.

Owner:NINGBO HONGYAN PACKING MATERIAL

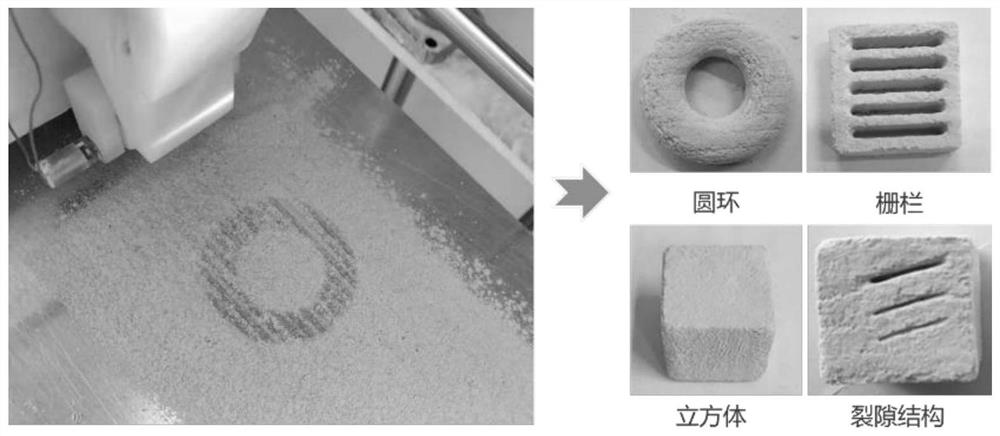

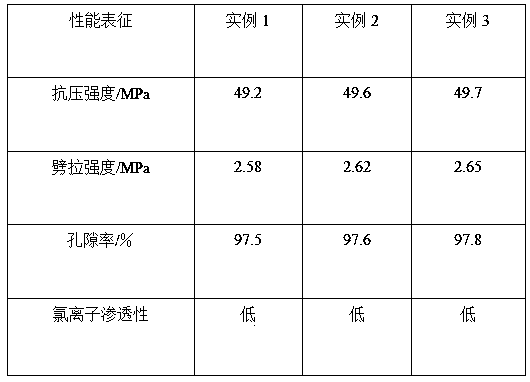

Material for powder 3D printing test model and preparation method thereof

ActiveCN112759298AHas molding strengthWith printing precisionAdditive manufacturing apparatusMagnesium phosphateMagnesium orthophosphate

The invention provides a material for a powder 3D printing test model and a preparation method of the material. The material is prepared from the following materials: magnesium phosphate cement, a spreadability adjusting component, a cohesiveness adjusting component and a reinforcing component. The material has the characteristics of good forming strength, high setting speed, high early strength, high printing precision and the like, can greatly improve the problem that the conveying, spraying and building processes of powder and liquid materials in the traditional Portland cement material and powder 3D printing are difficult to adapt, and can be used for manufacturing a cement space bracket structure with good mechanical properties and printing precision; the material meets the requirements of replicability and controllability of a physical test model with a complex structure, effectively combines various mechanism researches with test verification methods, further verifies the reliability of a mechanism theory, and has a better application prospect.

Owner:HEBEI UNIV OF TECH

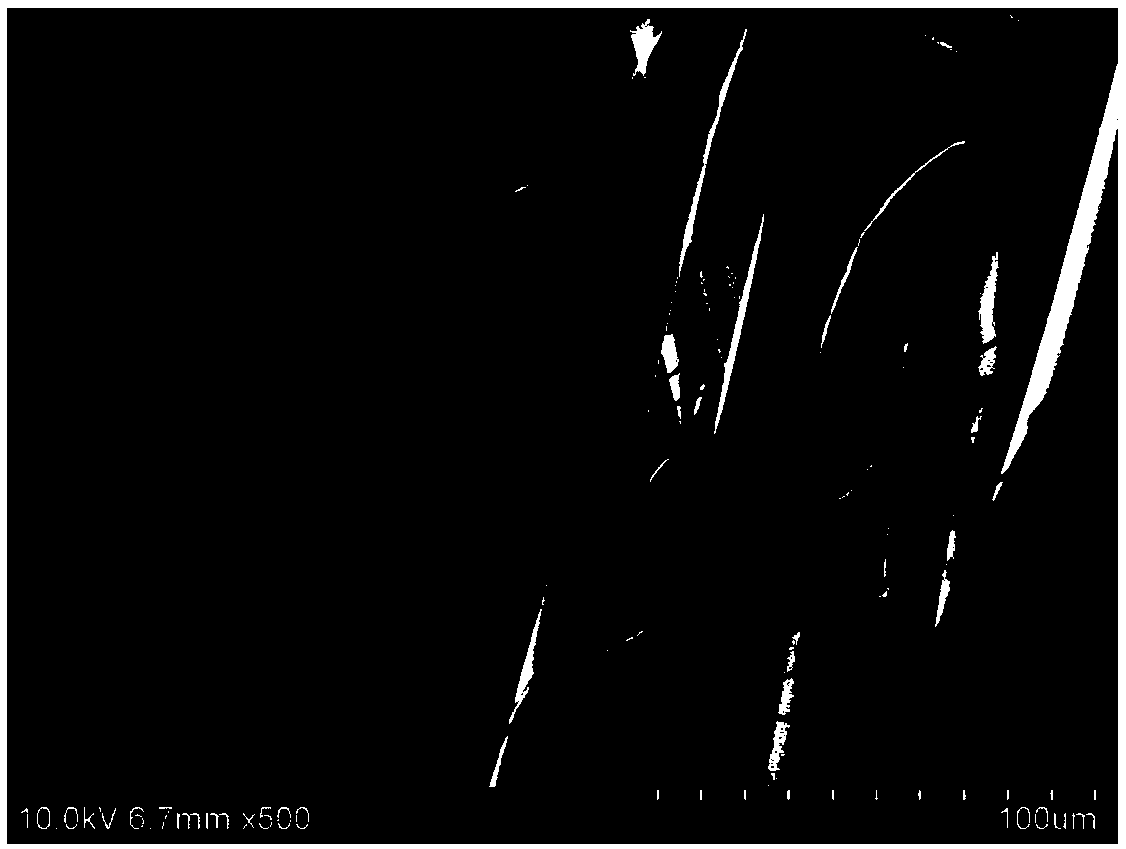

Preparation method of highly-impermeable rubber concrete material

InactiveCN109896789AEvenly dispersedIncreased tangleSolid waste managementCeramicwareRubber materialFiber

The invention relates to a preparation method of a highly-impermeable rubber concrete material, and belongs to the technical field of concrete materials. A sol material is prepared by using anhydrousaluminum chloride and aluminum powder as aluminum sources and tetraethyl orthosilicate as a silicon source, the surface of a rubber material is coated with the sol material, and the uniform dispersionof the sol material on the surface of the rubber material body forms new entanglement points, so the entanglement of the rubber material and the molecular chain of the surface of the concrete material is enhanced, thereby the tensile strength of the composite material is increased; and coating modification using the sol makes the sol and the rubber material form a good wetting interface, so fibers, a mixture and the rubber material are uniformly dispersed in a matrix; and modification using the sodium hypochlorite composite silica sol and surface oxidation and chlorination using sodium hypochlorite are carried out to realize the surface modification of rubber composite material, so the number of polar groups on the surface is increased, the wettability is improved, the roughness is improved, the mechanical strength of the material is improved, and the impermeability of the material is improved.

Owner:江苏常大绿恒环境工程有限公司

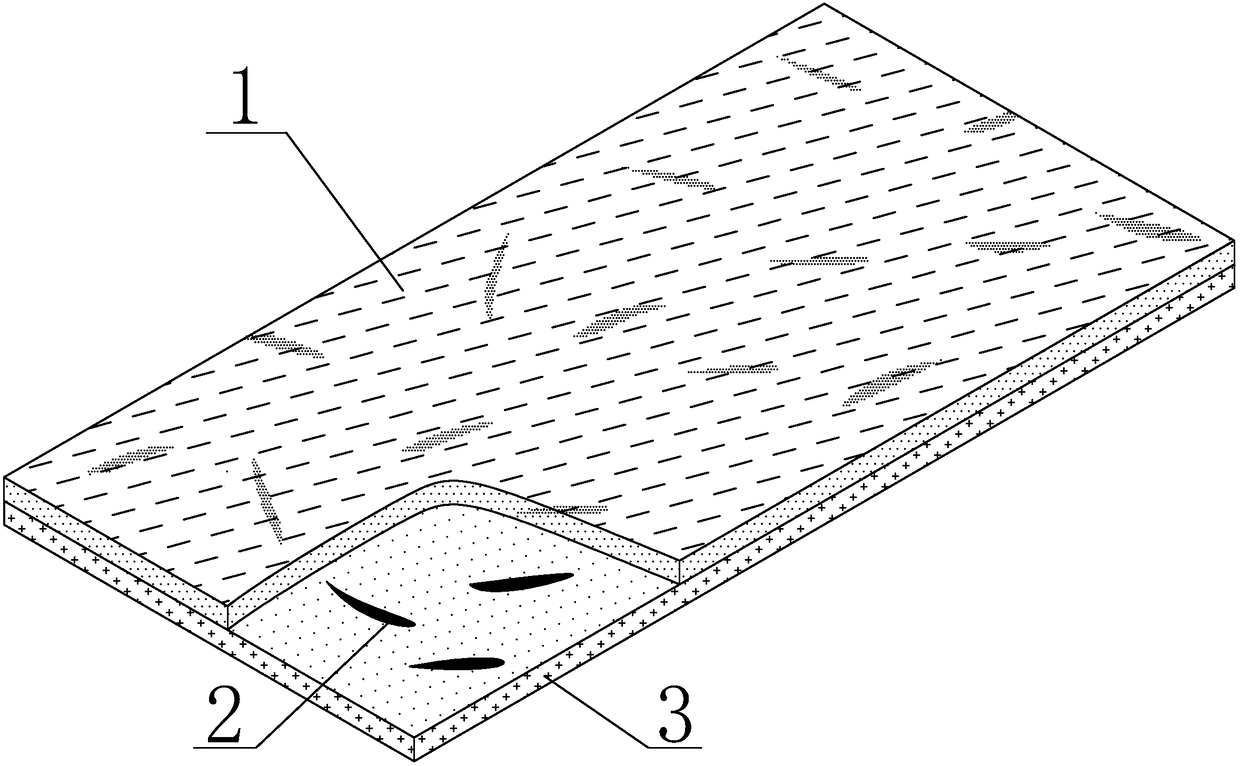

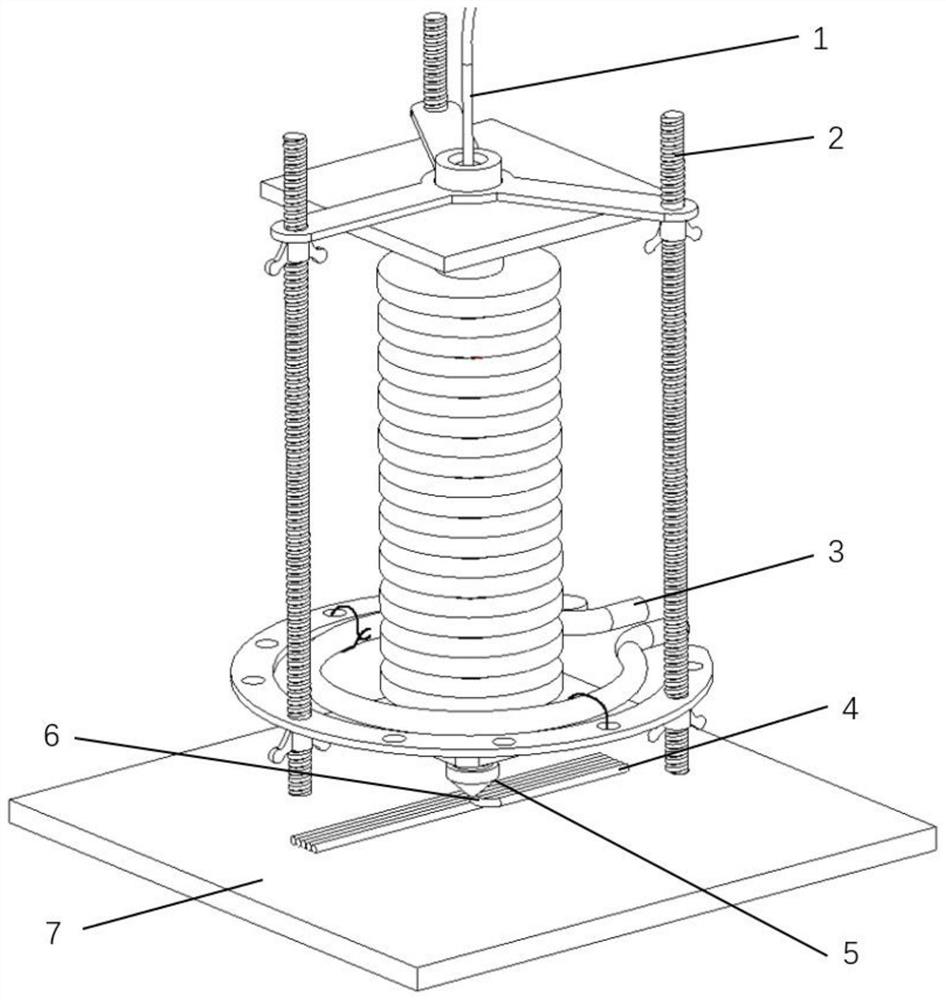

3D printing system and method for improving interlayer connection strength through irradiation heating

PendingCN113400647AImprove connection strengthIncrease profitManufacturing heating elements3D object support structuresPhysicsInfrared lamp

The invention discloses a 3D printing system and method for improving interlayer connection strength through irradiation heating. An infrared lamp tube is of an annular structure, and is arranged on a printer nozzle in a sleeve mode through a fixing device, and a semi-crystalline polymer material for printing passes through the center of the infrared lamp tube to achieve preheating; and a printed layer and a layer to be printed arranged on a substrate below the printer nozzle are secondarily heated through the infrared lamp tube. According to the system and method, the connection strength between layers is effectively improved; and meanwhile, the heat preservation effect is achieved for a period of time, and the interlayer connection can be effectively improved on the basis of previous preheating.

Owner:XI AN JIAOTONG UNIV

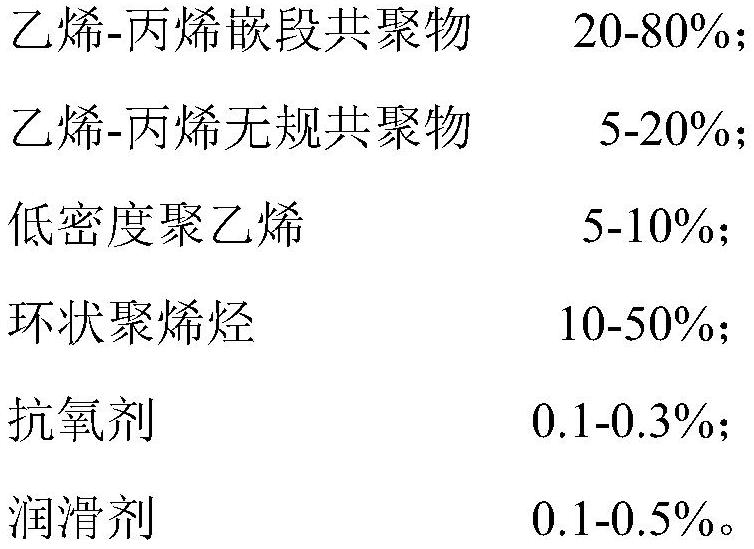

High-welding-strength polypropylene composition as well as preparation method and application thereof

ActiveCN112094472AIncreased tangleImprove interface compatibilityLow-density polyethylenePolymer science

The invention relates to a high-welding-strength polypropylene composition as well as a preparation method and application thereof. The high-welding-strength polypropylene composition comprises an ethylene-propylene block copolymer, an ethylene-propylene random copolymer, low-density polyethylene, cyclic polyolefin, an antioxidant and a lubricant. By adding the low-density polyethylene and the ethylene-propylene random copolymer, a synergistic effect is achieved for improving the melt strength and the welding strength of the product, a thin-wall extrusion pipe can be formed, and the product isexcellent in welding strength and good in sealing performance and has a good application prospect.

Owner:SHANGHAI KINGFA SCI & TECH +1

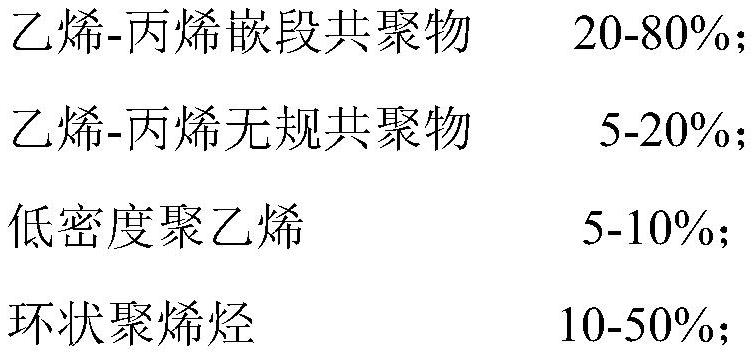

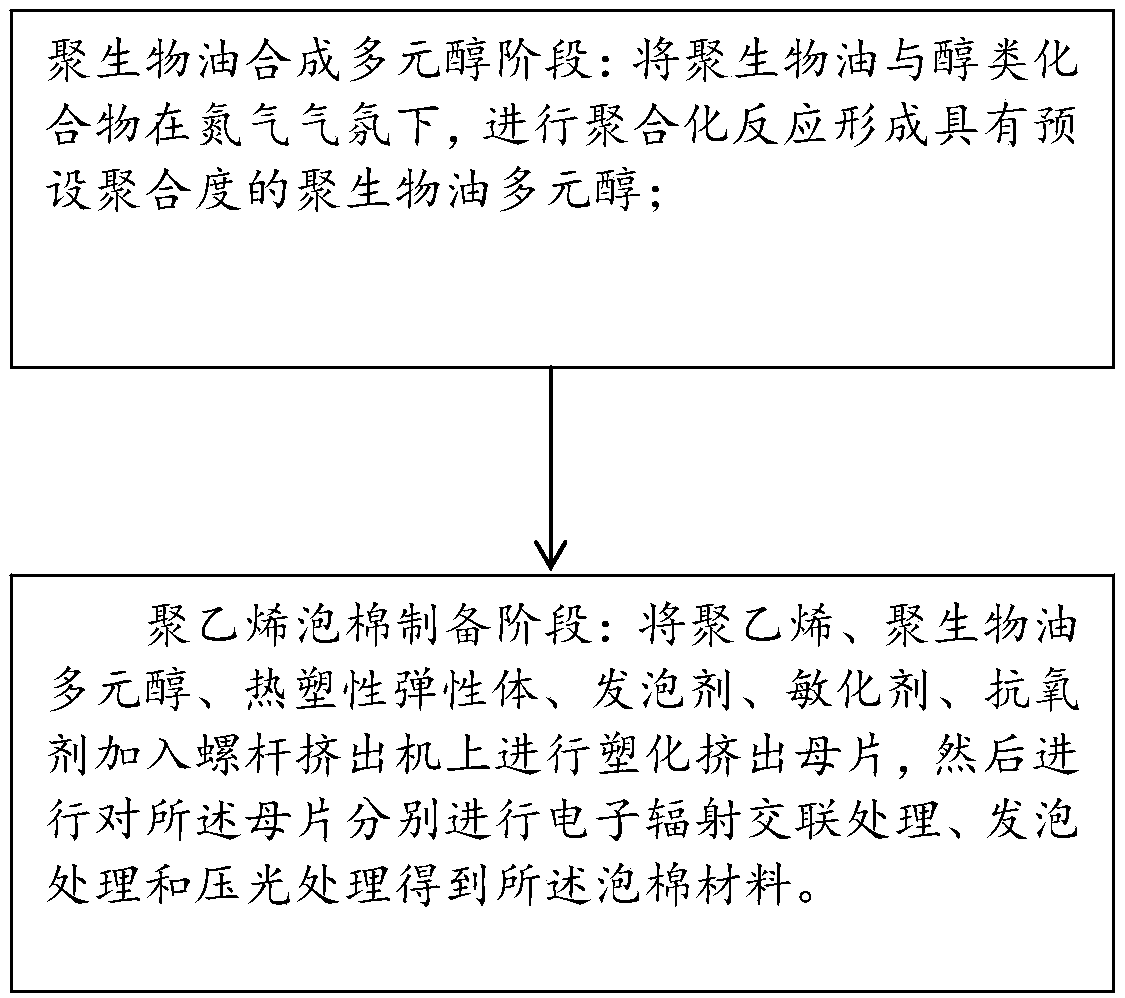

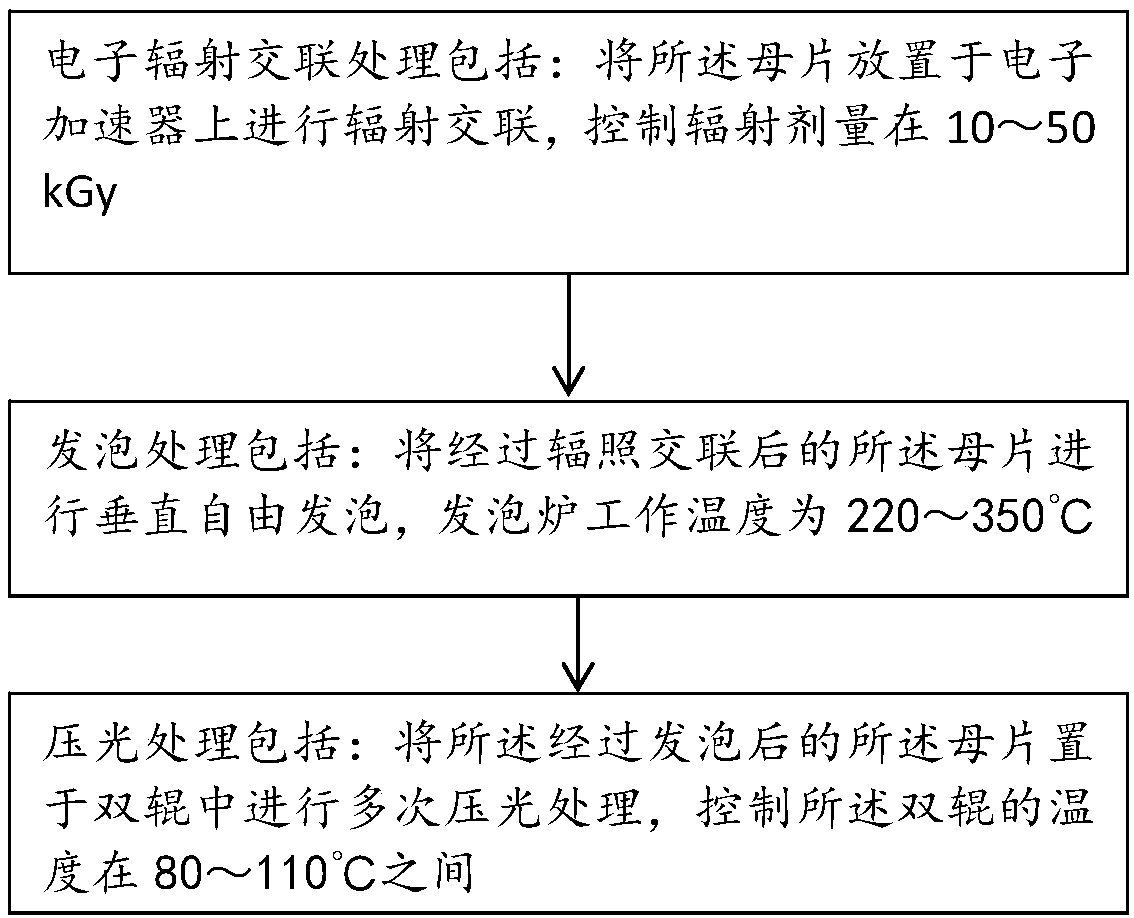

Cross-linked polyethylene foam material and preparation method thereof

The invention provides a cross-linked polyethylene foam material. The foam material is prepared from the following materials: 65-90 parts by weight of polyethylene, 5-30 parts by weight of a polybiologicaloilpolyol, 5-30 parts by weight of a thermoplastic elastomer, 0.5-7 parts by weight of a foaming agent, 0.5-4 parts by weight of a sensitizer, and 0.5-5 parts by weight of an antioxidant. According to the invention, the longitudinal tensile strength of the foam material is greater than 3MPa, the longitudinal elongation is greater than 190%, the transverse tensile strength is greater than 1MPa, the transverse elongation is greater than 300%, the 25% compression ratio is 80KPa or less, and the surface tension is 40mN / m or more; and meanwhile the foam material has an apparent density of 0.2-0.5g / cm<3>. The polyethylene foam can be applied to sealing buffer of a view window and a touch screen of an electronic product or a basic material of an adhesive tap.

Owner:ZHEJIANG WANLI NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com