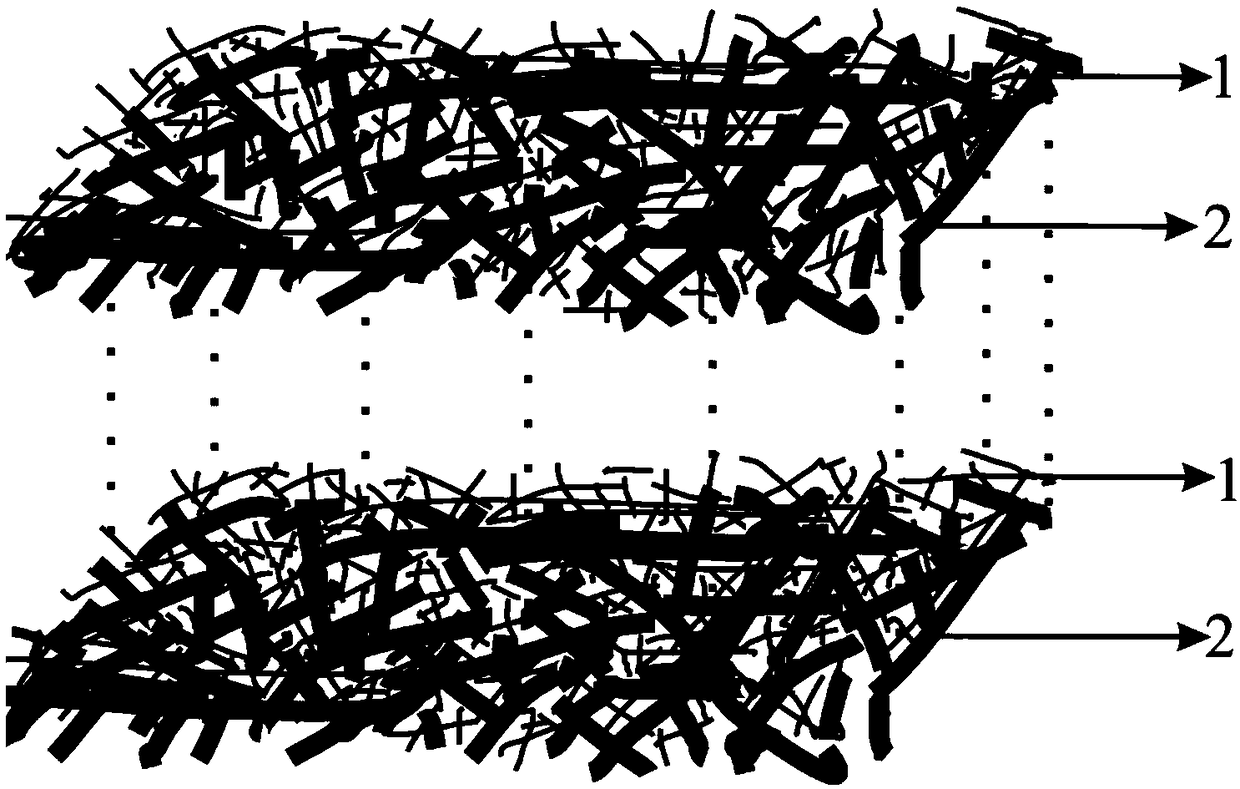

Micrometer/nanometer fiber composite filtering material and preparation method thereof

A nanofiber and composite filtration technology, applied in filtration separation, membrane filter, separation method, etc., can solve the problems of loss of filtration effect, easy damage, high resistance, etc., achieve increased specific surface area, simple production process, and ensure stable size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention simultaneously provides a kind of preparation method (abbreviation method) of micro / nano fiber composite filter material, it is characterized in that the method comprises the following steps:

[0035] Step 1, preparing a uniform electrospinning solution with a mass concentration of 5-40%;

[0036] The electrospinning solution includes all solutions capable of forming nanofibers through electrospinning technology, specifically polyester solutions, polyvinyl chloride solutions, polyvinyl alcohol solutions, polyetherimide solutions, polyamide solutions, polyethylene oxide At least one of solution, polystyrene solution, polyacrylonitrile solution, polylactic acid solution, polyamic acid solution, polytetrafluoroethylene solution or polysulfone solution;

[0037] Step 2, making the micron-scale fiber into a single-layer fluffy micron fiber net, and transporting it to the mesh conveyor curtain;

[0038] The micron-scale fiber forming method adopts dry-l...

Embodiment 1

[0048] Step 1. Dissolve 30 g of dry polyacrylonitrile (PAN) powder in 200 ml of N,N-dimethylformamide solvent to prepare an electrospinning solution with a mass concentration of 15%, and stir it magnetically for 12 hours at room temperature;

[0049] Step 2. The polyacrylonitrile fibers with a fiber length of 51 mm and a diameter of 13 μm are mixed, opened, and carded into a web with a grammage of 10 g / m 2 Single-layer fluffy micron fiber net, and conveyed to the mesh conveyor curtain;

[0050] Step 3, start spinning, use the electrospinning liquid obtained in step 1, set the single-hole injection volume to 3ml / h, and evenly spray single or bundled PAN from 6 rows of 36 needle-type electrospinning nozzles The single-layer fluffy microfibrous web that step 2 obtains on the conveying screen of nanofibers forms a grammage of 10.25g / m 2 A single-layer micro / nano fiber composite network;

[0051] The spinning temperature is 25°C, the relative humidity is 45%, the spinning voltage...

Embodiment 2

[0063] Step 1. Dissolve 30 g of dry thermoplastic polyurethane particles in 200 ml of N,N-dimethylformamide solvent to prepare an electrospinning solution with a mass concentration of 15%, and stir it magnetically for 10 hours at room temperature.

[0064] Step 2. Polyester fibers with a fiber length of 38 mm and a diameter of 10 μm are mixed, opened, and carded into a grammage of 5 g / m 2 Single-layer fluffy micron fiber web, and conveyed to the mesh conveyor curtain with mesh.

[0065] Step 3, start spinning, use the electrospinning liquid obtained in step 1, set the single-hole injection volume to 1.2ml / h, and evenly spray a single or bundle from 3 rows of 18 needle-free electrospinning nozzles Polyurethane nanofibers are transported to the single-layer fluffy micron fiber web on the mesh curtain that step 2 obtains, forming a grammage of 5.05g / m 2 A single-layer micro / nano fiber composite network;

[0066] The spinning temperature is 30°C, the relative humidity is 45%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com