Polyamide composition with good appearance

A polyamide composition, thermoplastic polyamide technology, applied in the field of modified polyamide composition, can solve the problems of lack of molecular weight, molecular structure, sag melt, cracking and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

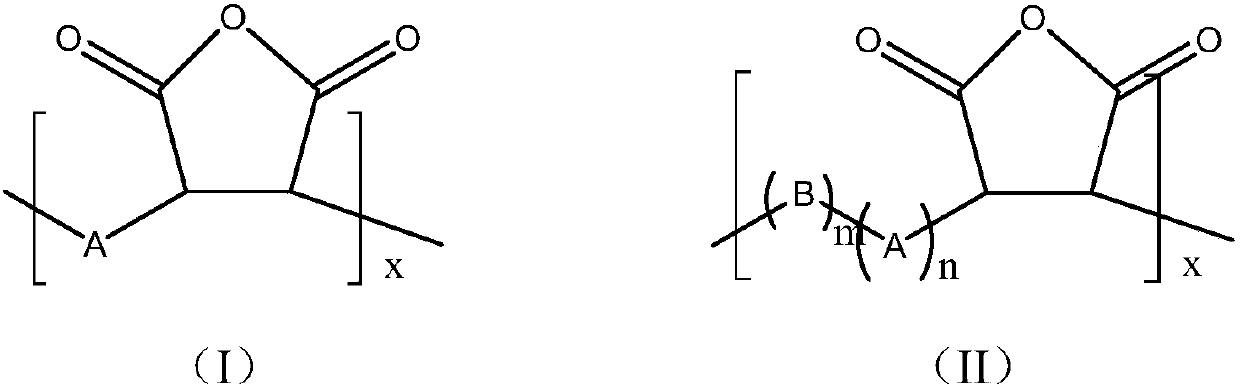

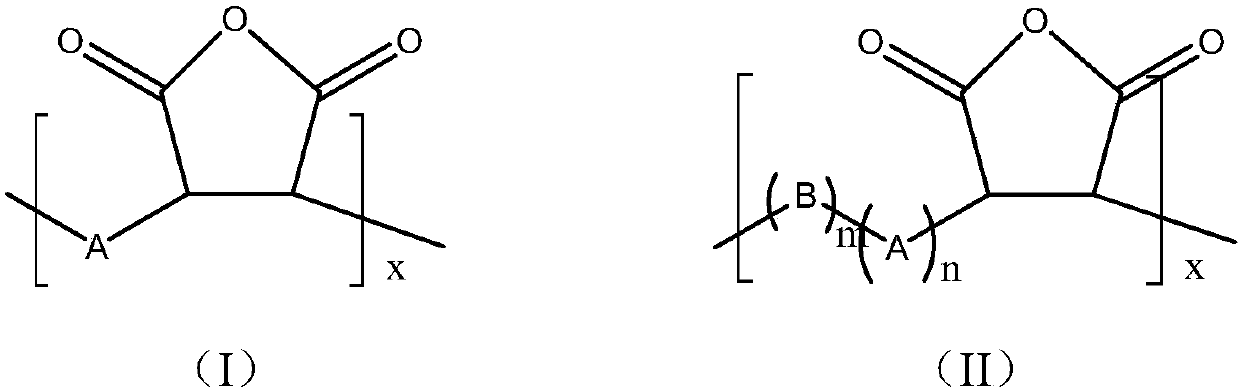

Image

Examples

specific Embodiment E1-E14

[0059] The polyamide compositions with good appearance in specific examples E1-E14 were prepared from the components in columns E1-E14 in Tables 1-2, respectively. The preparation method is as follows: before extrusion, the thermoplastic polyamide resin pellets are dried until the moisture content is lower than 1500ppm, and then the ingredients (except glass fiber) are blended in proportion and put into the main feed of the twin-screw extruder. The feeder is extruded and granulated by twin-screw. The processing conditions are: the temperature of the first zone is 240°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 260°C, and the temperature of the sixth zone is 270°C , The temperature in the seventh zone is 270°C, the temperature in the eighth zone is 275°C, and the temperature in the ninth zone is 280°C; the speed of the host is 350 rpm. Glass fiber is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Low temperature impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com