Method using epoxy resin liquid crystal to modifying nylon performance

A technology of epoxy resin and modified nylon, which is applied in the performance field of liquid crystal epoxy resin modified nylon, can solve various problems, and achieve the effects of improving high temperature resistance, reducing costs, and reducing processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Liquid crystal epoxy bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethoxybiphenyl‐4,4'‐diester with nylon 66 The mixture was weighed in proportion and mixed uniformly, wherein the amount of liquid crystal epoxy resin accounted for 5% by mass of the mixture. The structural formula of bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethoxybiphenyl‐4,4'‐diester is:

[0028]

[0029] Step 1: first mix bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethoxybiphenyl‐4,4'‐diester and nylon 66 is called according to the mass percentage of bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethoxybiphenyl‐4,4'‐diester at 5% Mix well and dry in a blast oven at 70°C for 24 hours. Dry in a forced air oven at 70°C for 24 hours. Dry in a blast oven at 60°C for 20 hours

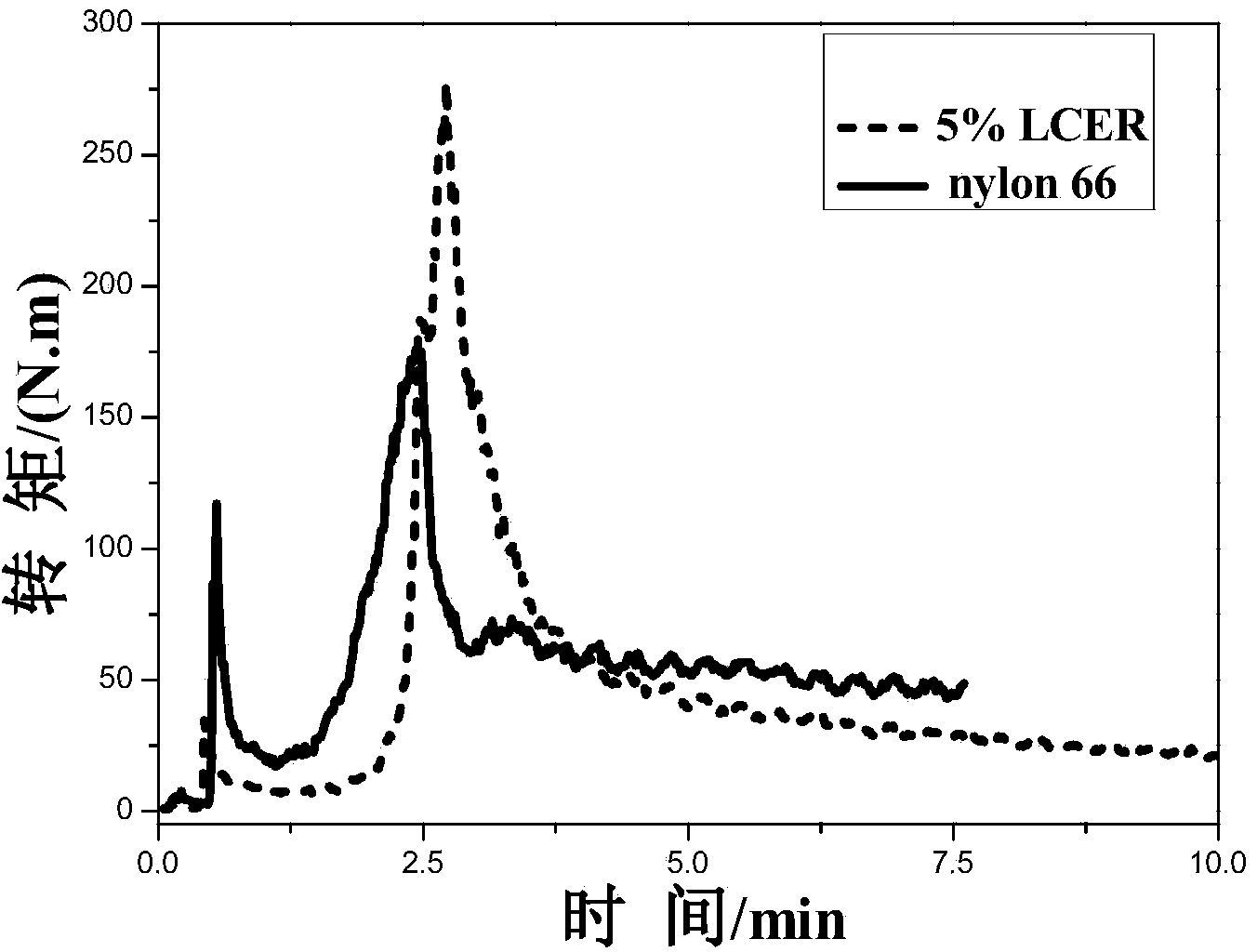

[0030] Step 2: Put the blend into Haake rheometer (HAAKE400P) for banburying. The banburying temperature is 265°C. When the material starts to be added into the mixing chamber of the rheometer, it is ...

Embodiment 2

[0037] Liquid crystal epoxy bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethylbiphenyl‐4,4'‐diester and nylon 66 mixture Weigh and mix uniformly according to the proportion, wherein the amount of liquid crystal epoxy resin is respectively 10% by mass. The structural formula of bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethylbiphenyl‐4,4'‐diester is:

[0038]

[0039]In step 1, bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethylbiphenyl‐4,4'‐diester and nylon 66 are prepared according to the Bis(4‐(2,3‐glycidoxy)benzoic acid)‐3,3',5,5'‐tetramethylbiphenyl‐4,4'‐diester mass percentage 3%‐10% Mix well and dry in a blast oven at 70°C for 24 hours. Dry in a blast oven at 60°C for 20 hours

[0040] Step 2: Put the blend into Haake rheometer (HAAKE 400P) for banburying. The banburying temperature is 260°C. When the material starts to be added into the mixing chamber of the rheometer, it is observed that the torque gradually rises and a sharp torque peak appe...

Embodiment 3

[0047] Liquid crystal epoxy resin N,N'‐di(4‐(2,3‐glycidoxy)‐phenylmethylene)‐2,2,3,3',5,5',6,6' The mixture of ‐octafluorobiphenyl‐4,4'‐diamine and nylon 66 is weighed and mixed uniformly in proportion, and the amount of liquid crystal epoxy resin is 7% by mass. N,N'‐bis(4‐(2,3‐glycidoxy)‐phenylmethylene)‐2,2,3,3',5,5',6,6'‐octafluorobi The structural formula of benzene‐4,4'‐diamine is:

[0048]

[0049] Step 1: First N,N'-bis(4-(2,3-glycidoxy)-phenylmethylene)-2,2,3,3',5,5',6,6 '‐octafluorobiphenyl‐4,4'‐diamine and nylon 66 according to N,N'‐di(4‐(2,3‐glycidoxy)‐phenylmethylene)‐2,2, The mass fraction of 3,3',5,5',6,6'-octafluorobiphenyl-4,4'-diamine is 7%, weighed, mixed evenly and dried in a blast oven at 60°C for 20 hours.

[0050] Step 2: Put the blend into Haake rheometer (HAAKE 400P) for banburying. The banbury temperature is 270°C. When the material starts to be added into the mixing chamber of the rheometer, it is observed that the torque gradually rises and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com