High-welding-strength polypropylene composition as well as preparation method and application thereof

A technology of polypropylene composition and welding strength, which is applied in the field of modified plastics, can solve the problems of insufficient product structural strength and sealing, limited improvement, low melt strength, etc., and achieve molecular chain movement ability and orientation degree reduction, Effects of increased molecular chain entanglement and excellent interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0023] See Table 1 for specific raw materials used, their grades and manufacturers.

[0024] Adopt table 1 raw material to prepare composition described in the application and comparative example composition, its preparation method is as follows:

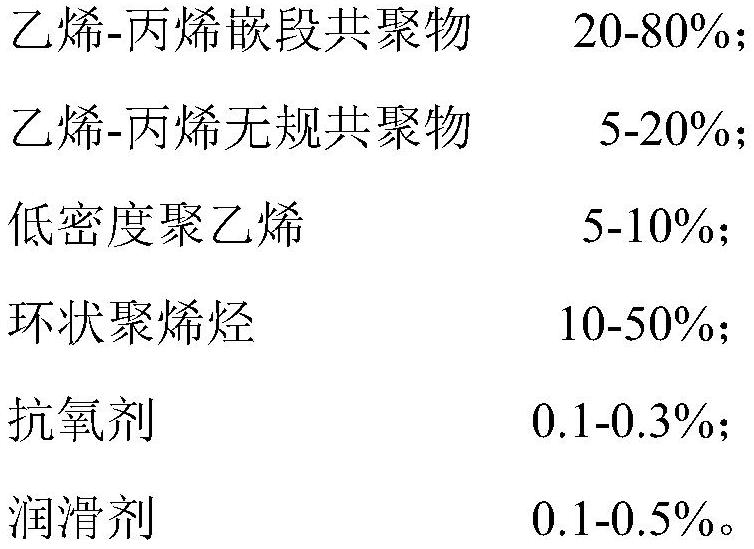

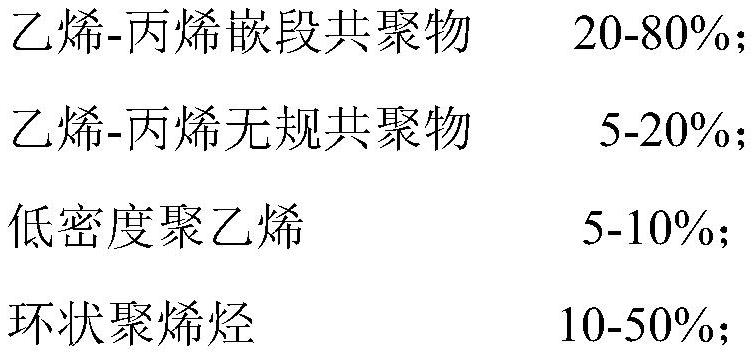

[0025] Step 1: take each component according to the proportioning (weight ratio) in Table 2;

[0026] Step 2: ethylene-propylene block copolymer, ethylene-propylene random copolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com