Cross-linked polyethylene foam material and preparation method thereof

A technology of cross-linked polyethylene and polyethylene, which is applied in the direction of coating, etc., can solve the problems of large amount of addition, self-adhesive products, and inability to store for a long time, and achieve the effects of high adhesion, pollution reduction, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

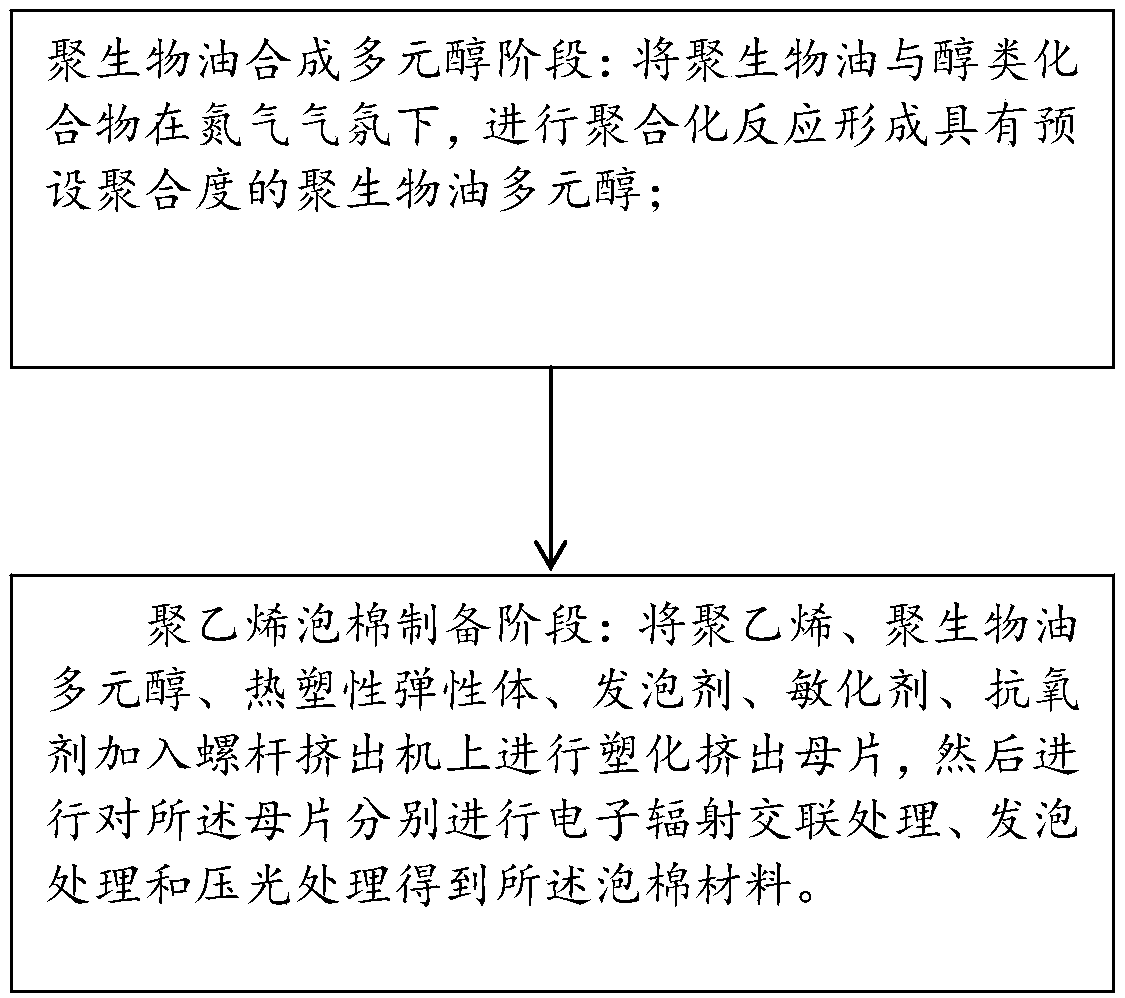

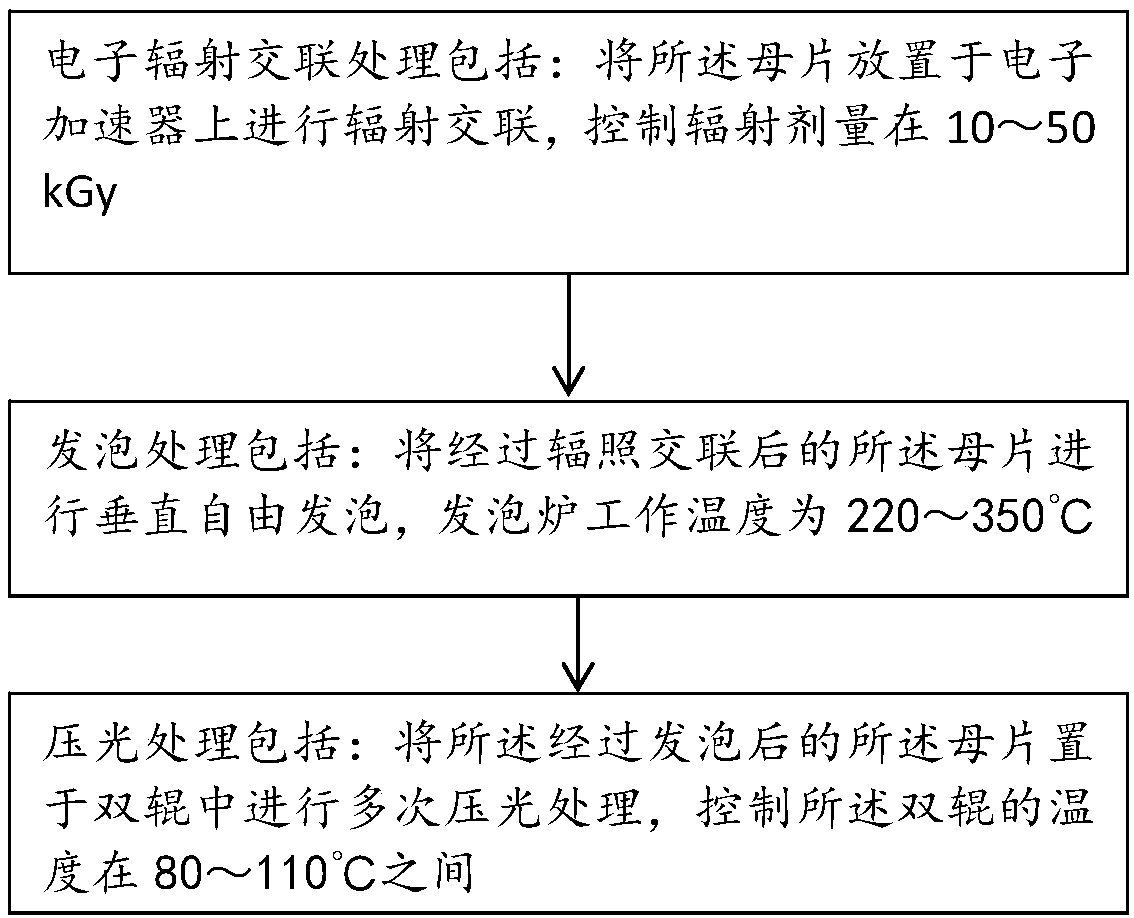

[0039] Such as figure 1 Shown, the preparation method of this cross-linked polyethylene foam material may further comprise the steps:

[0040] The present application also provides a preparation method of the above-mentioned cross-linked polyethylene foam material, the preparation method comprising the following steps:

[0041] (1) Polybio-oil polyol synthesis stage: about 100 parts by weight of poly-bio-oil and 1 to 10 parts by weight of the alcohol compound are formed under a nitrogen atmosphere at 150 to 250° C. for 2 to 12 hours through transesterification reaction The described poly bio-oil polyol;

[0042] (2) Polyethylene foam preparation stage: weigh 65-90 parts by weight of polyethylene, 5-30 parts by weight of polybio-oil polyol, 5-30 parts by weight of thermoplastic elastomer, 0.5-7 parts by weight of foaming agent, 0.5 to 4 parts by weight of sensitizer and 0.5 to 5 parts by weight of antioxidant are added to the screw extruder to plasticize and extrude the maste...

Embodiment 1

[0049] Step 1 Synthesis of polypeanut oil polyol

[0050] 100 parts by weight of peanut oil and 0.5 parts by weight of azobisisobutyronitrile were placed in the reactor, stirred and mixed evenly, and then the air in the reactor was replaced by nitrogen gas. In a nitrogen atmosphere, the reactor was heated to 310°C, and peanut oil and azobisisobutyronitrile were polymerized for 8 hours to obtain polypeanut oil;

[0051] Next, 100 parts by weight of poly-peanut oil and 5 parts by weight of glycerin were placed in the reactor for stirring and mixing, and then the air in the reactor was replaced by nitrogen gas. The polypeanut oil polyol was obtained after heating to about 200° C. for transesterification reaction in a nitrogen atmosphere for about 8 hours.

[0052] Step 2 Polyethylene Foam Preparation

[0053] Weigh raw materials according to the following parts by weight:

[0054] 75 parts by weight of low-density polyethylene;

[0055] 10 parts by weight of poly-peanut oil p...

Embodiment 2

[0065] Step 1 Poly-Rapeseed Polyol Synthesis

[0066] 100 parts by weight of rapeseed oil and 0.8 parts by weight of azobisisobutyronitrile were placed in the reactor, stirred and mixed evenly, and then the air in the reactor was replaced by nitrogen gas. In a nitrogen atmosphere, the reactor was heated to 320°C, and rapeseed oil and azobisisobutyronitrile were polymerized for 18 hours to obtain poly-rapeseed oil;

[0067] Next, 100 parts by weight of rapeseed oil and 7 parts by weight of trimethylolpropane were placed in the reactor for stirring and mixing, and then the air in the reactor was replaced by nitrogen gas. After heating to about 220° C. for about 10 hours for transesterification reaction in a nitrogen atmosphere, the poly-rapeed oil polyol was obtained.

[0068] Step 2 Polyethylene Foam Preparation

[0069] Weigh raw materials according to the following parts by weight:

[0070] 70 parts by weight of low-density polyethylene;

[0071] 15 parts by weight of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com