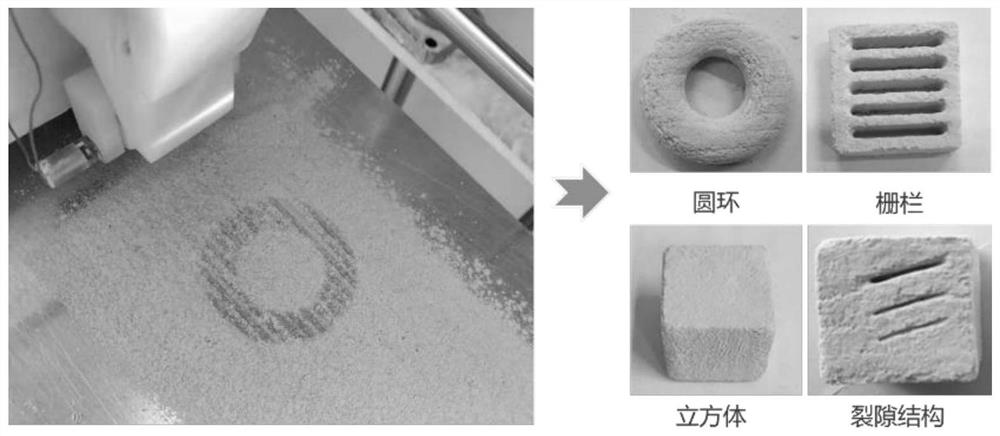

Material for powder 3D printing test model and preparation method thereof

A test model, 3D printing technology, applied in the direction of additive processing, etc., can solve the problem of unable to make a three-dimensional complex geological structure model, and achieve the effect of high printing accuracy and apparent accuracy, and good molding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Dry and ball mill 25% of the quartz sand at a speed of 1100r for 20 minutes, pass through a 200-mesh sieve for later use; ball mill dead-burned magnesia and ammonium dihydrogen phosphate at a speed of 1100r, and mill for 20 minutes. Pass through a 150-mesh sieve for later use;

[0052] Mix the dead-burned MgO passed through a 150-mesh sieve with ammonium dihydrogen phosphate according to the mass ratio of 59:41 and add it to the mixer, and stir for 3 minutes; then, add 25% quartz sand and 5% fly ash and 5% % of 200 mesh polyvinyl alcohol powder, and continue to stir for 2 minutes; finally, add 0.1% of carbon nanotubes, and stir for 3 minutes to obtain the powder material for the powder 3D printing test model.

[0053] Liquid material: Add the weighed 1,2 propylene glycol and glycerin into distilled water and vibrate with 50Hz ultrasonic wave for 3min;

[0054] Add the powder material for the powder 3D printing test model prepared above into the powder feeding bin of th...

Embodiment 2

[0056] Each part of this embodiment is the same as that of Embodiment 1, except that the addition of fly ash is 10% (wt).

Embodiment 3

[0058] The parts of this embodiment are the same as those of Embodiment 1, except that the amount of carbon nanotubes added is 0.3% (wt).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com