Method for directly preparing phosphor magnesium fertilizer with by-product mine tailing of phosphorus ore floatation

A technology for flotation of tailings and phosphate rock is applied in the field of preparing industrial-grade phosphorus-magnesium fertilizers, which can solve the problems of occupying a large amount of land resources, ecological environment, inputting large processing costs, changes, etc., and achieving good social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

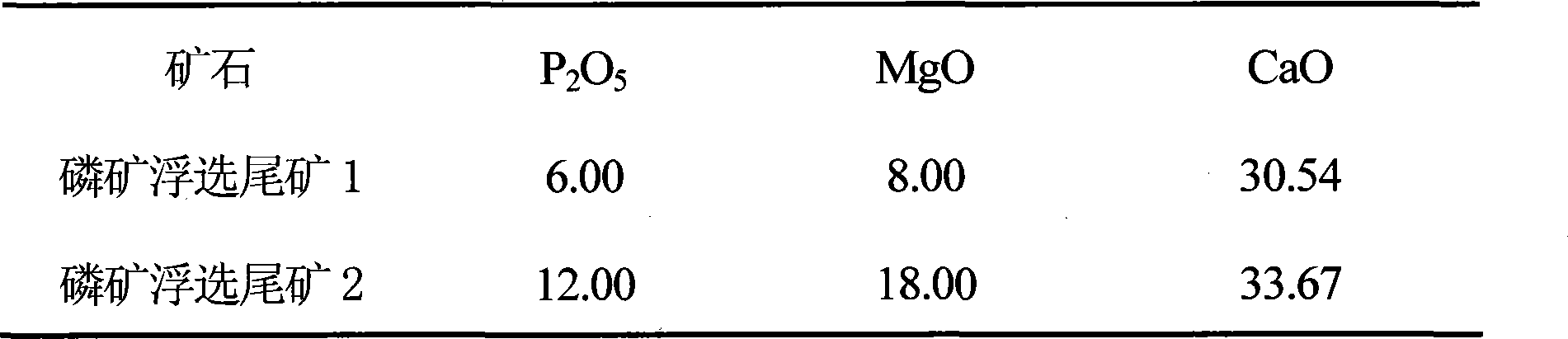

[0023] The typical chemical composition of the phosphate rock flotation tailings used is:

[0024]

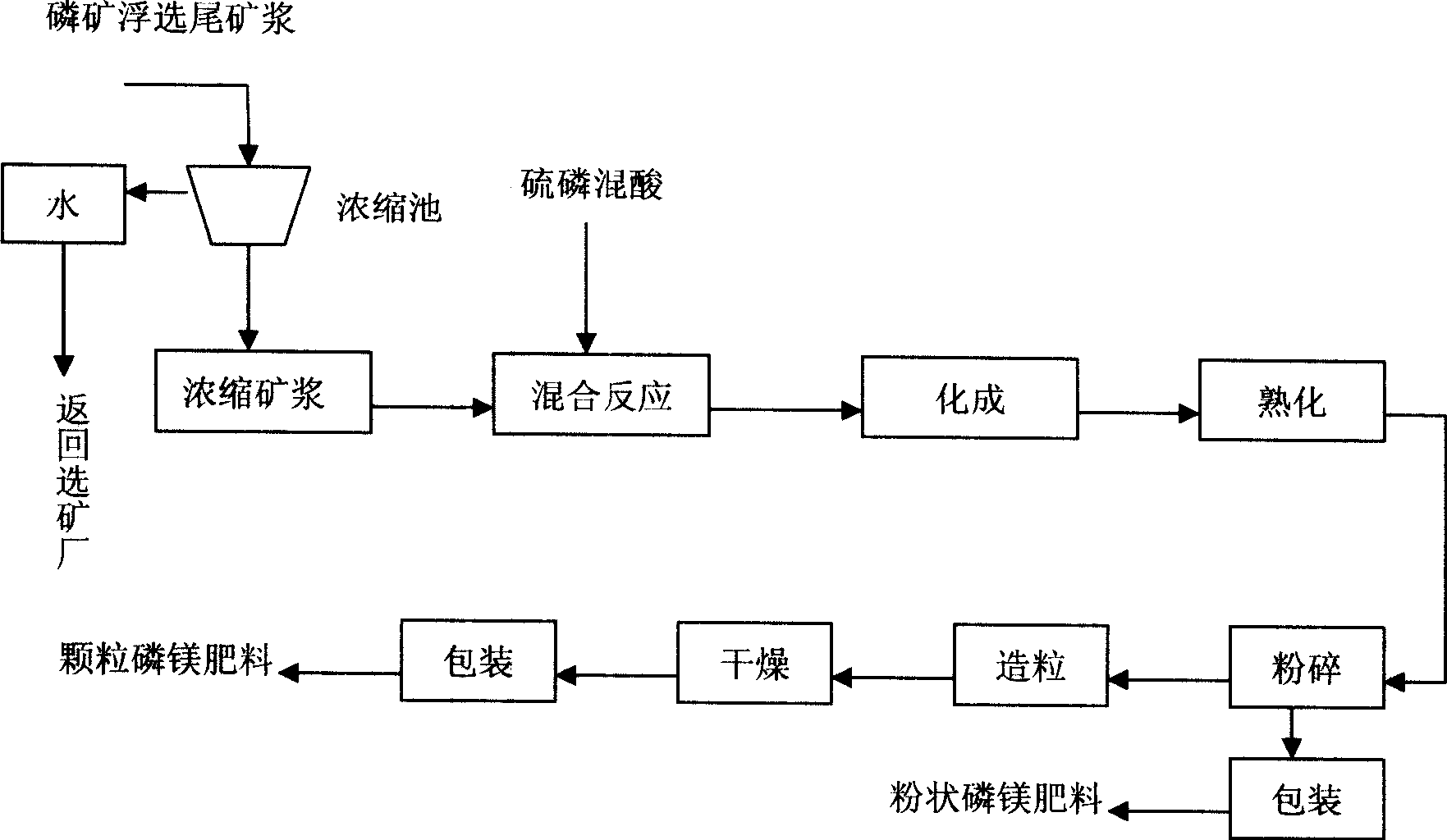

[0025] Continuous production, the process such as figure 1 , including phosphate ore flotation tailings pretreatment, mixing, aging, crushing, granulation, and drying processes.

[0026] (1) Pretreatment

[0027] The purpose of pretreatment is to concentrate the phosphate ore flotation tailings slurry through a thickener, control the tailings moisture at about 40%-45%, and provide tailings raw materials with a water content of about 40%-45% for the production of phosphorus and magnesium fertilizers.

[0028] (2) mixed into

[0029] As a mixed chemical process for the production of phosphorus and magnesium fertilizers, the weight ratio of W phosphate ore flotation tailings: W concentrated sulfuric acid: W concentrated phosphoric acid is 3.34: 2.00: 1.00 and added to the mixer, and the stirring speed is controlled at 400r / min. The time is controlled at 45 minutes to make it...

Embodiment 2

[0037] The typical chemical composition of the phosphate rock flotation tailings used is:

[0038]

[0039] Continuous production, the process such as figure 1 , including pretreatment, mixing, aging and neutralization, granulation and drying.

[0040] The process steps used in this example are all the same as in Example 1.

[0041] Typical process conditions for this example are:

[0042]

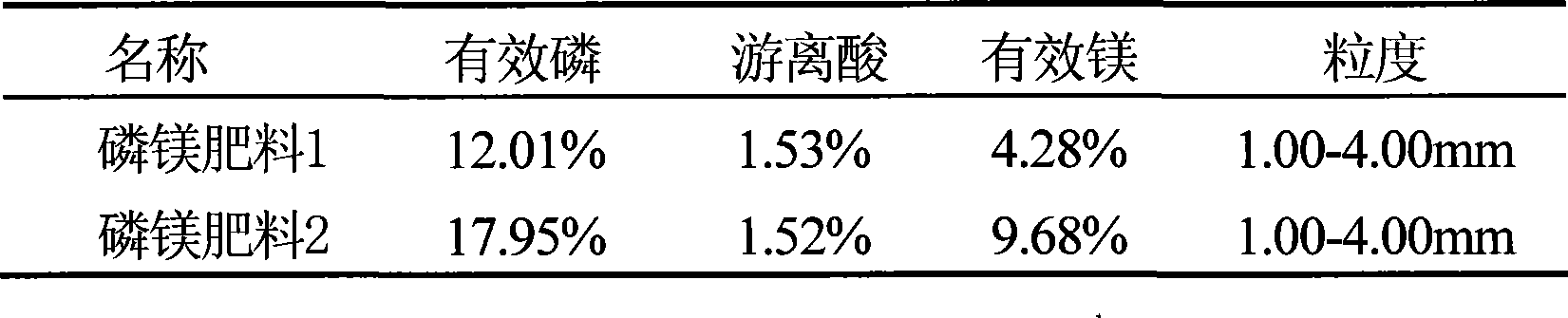

[0043] The economic indicators of the industrial grade phosphorus and magnesium fertilizer prepared by this example are as follows:

[0044]

Embodiment 3

[0046] The typical chemical composition of the flotation phosphorous tailings used is:

[0047]

[0048] Continuous production, the process such as figure 1 , including pretreatment, mixing, aging and neutralization, granulation and drying.

[0049] The process steps used in this example are all the same as in Example 1.

[0050] Typical process conditions for this example are:

[0051]

[0052] The economic indicators of the industrial grade phosphorus and magnesium fertilizer prepared by this example are as follows:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com