Film with high tensile strength and production method

A high-tensile, thin-film technology, used in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as irregularities in items, mechanical properties, film breakage, and inability to use normally. Tensile effect, increased tensile strength, good tensile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

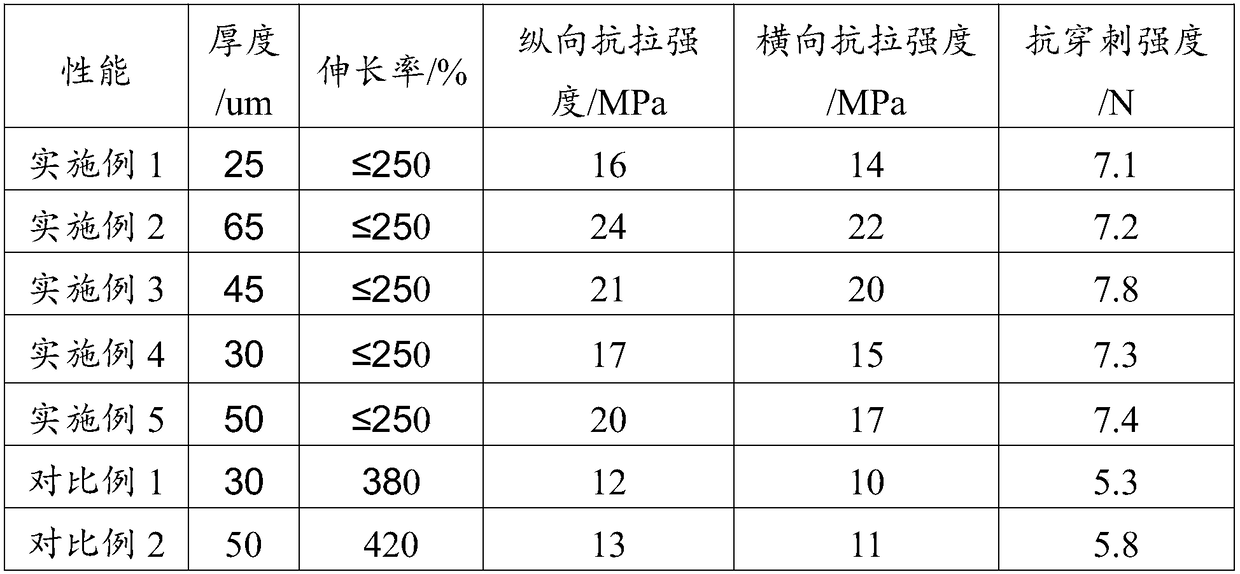

Examples

Embodiment 1

[0035] Starting from the film cross section and going from outside to inside include:

[0036] The first layer is A layer, its composition is metallocene linear low density polyethylene and ethylene modified PET blend modified resin, the melt index is 3.3g / 10min, and the density is 0.93g / cm 3 ; The amount of metallocene polyethylene accounts for 35wt% of the total amount of the blended modified resin; the thickness of the A layer is 10 μm;

[0037] The second layer is B layer, its composition is graphene oxide modified low-density polyethylene, the melt index is 3.0g / 10min, and the density is 0.91g / cm 3 ; The thickness of the B layer is 5 μm; the graphene oxide is hydroxylated graphene, and the hydroxyl content is 15at%;

[0038] The third layer is C layer, its composition is maleic anhydride grafted low-density polyethylene, the melt index is 1.5g / 10min, and the density is 0.89g / cm 3 ; The graft ratio of the maleic anhydride grafted polyethylene is 2.5%; the thickness of th...

Embodiment 2

[0051] Starting from the film cross section and going from outside to inside include:

[0052] The first layer is A layer, its composition is metallocene linear low density polyethylene and ethylene modified PET blend modified resin, the melt index is 3.8g / 10min, and the density is 0.9337g / cm 3 ; The amount of metallocene polyethylene accounts for 40wt% of the total amount of the blended modified resin; the thickness of the A layer is 20 μm;

[0053] The second layer is B layer, its composition is graphene oxide modified low-density polyethylene, the melt index is 3.6g / 10min, and the density is 0.9124g / cm 3 ; The thickness of the B layer is 8 μm; the graphene oxide is hydroxylated graphene, and the hydroxyl content is 20at%;

[0054] The third layer is C layer, its composition is maleic anhydride grafted low-density polyethylene, the melt index is 1.8g / 10min, and the density is 0.8927g / cm 3 ; The graft ratio of the maleic anhydride grafted polyethylene is 4%; the thickness o...

Embodiment 3

[0067] Starting from the film cross section and going from outside to inside include:

[0068] The first layer is layer A, which is composed of metallocene linear low density polyethylene and ethylene-modified PET blend modified resin, with a melt index of 4.6g / 10min and a density of 0.94g / cm 3 ; The amount of metallocene polyethylene accounts for 45wt% of the total amount of the blended modified resin; the thickness of the A layer is 30 μm;

[0069] The second layer is B layer, its composition is graphene oxide modified low-density polyethylene, the melt index is 4.4g / 10min, and the density is 0.92g / cm 3 ; The thickness of the B layer is 10 μm; the graphene oxide is hydroxylated graphene, and the hydroxyl content is 16at%;

[0070] The third layer is C layer, its composition is maleic anhydride grafted low-density polyethylene, the melt index is 2.1g / 10min, and the density is 0.90g / cm 3 The graft ratio of the maleic anhydride grafted polyethylene is 5%; the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com