A kind of lightweight polypropylene micro-foaming composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polymers, can solve the problems of poor foaming performance, restricting the development of polypropylene micro-foaming materials, cell collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of lightweight polypropylene microfoam composite material, comprising the following steps:

[0033] (1) After the sepiolite fiber is purified, it is mixed with an anionic surfactant under water-containing conditions, stirred for 24 to 48 hours, and then washed and dried to obtain surface-activated sepiolite fiber;

[0034] (2) stirring the surface-activated sepiolite fiber and the quaternary ammonium intercalation agent at 60-80°C for 24-48 hours under water-containing conditions, and then washing and drying to obtain organically modified sepiolite fiber;

[0035] (3) Put the organically modified sepiolite fiber, copolymerized polypropylene, compatibilizer, antioxidant, lubricant and auxiliary agent into the twin-screw extruder, melt extrude, and granulate to obtain polypropylene composite materials;

[0036] (4) After uniformly mixing the polypropylene composite material and the foaming agent, perform secondary ...

Embodiment 1

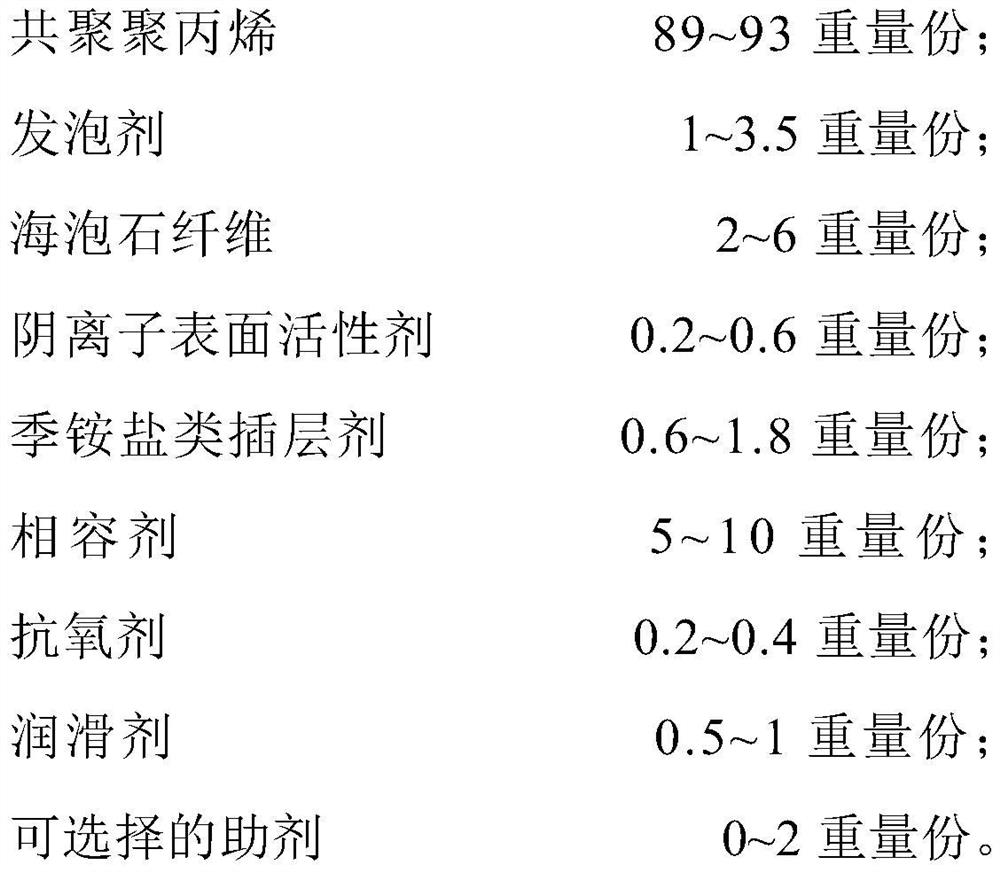

[0042] A lightweight polypropylene micro-foaming composite material is made of the following substances in parts by weight:

[0043]

[0044]

[0045] The preparation method of described lightweight polypropylene microfoam composite material, comprises the following steps:

[0046] (1) Add 2 parts by weight of sepiolite fiber to 200mL of 10wt% hydrochloric acid, then stir at 50°C for 48h, then centrifuge and wash to neutral, and vacuum dry at 50°C for 36h to obtain purified sepiolite fiber ;

[0047] (2) Stir the purified sepiolite fiber and 0.2 parts by weight of sodium dodecylsulfonate in 2000 mL of water at 60°C for 24 hours, then centrifugally wash with deionized water for 3 times, and then vacuum-dry at 50°C for 36 hours , to obtain surface-activated sepiolite fibers;

[0048] (3) Stir the surface-activated sepiolite fibers and 0.6 parts by weight of cetyltrimethylammonium bromide in 200 mL of water at 60°C for 24 hours, then centrifugally wash with deionized wate...

Embodiment 2

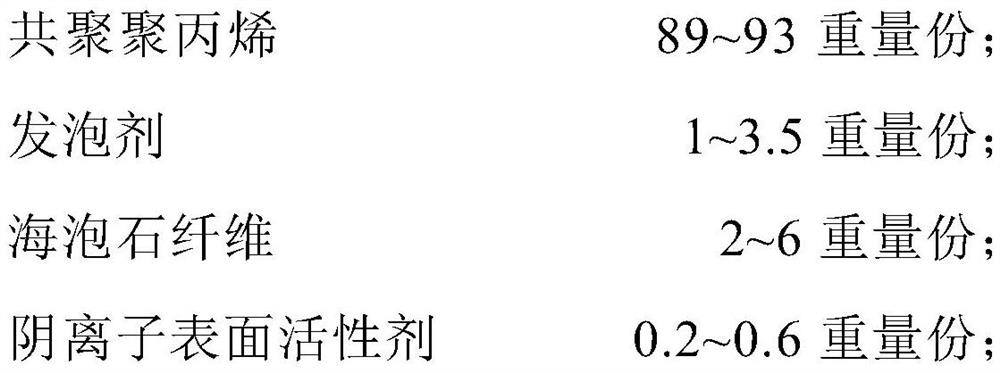

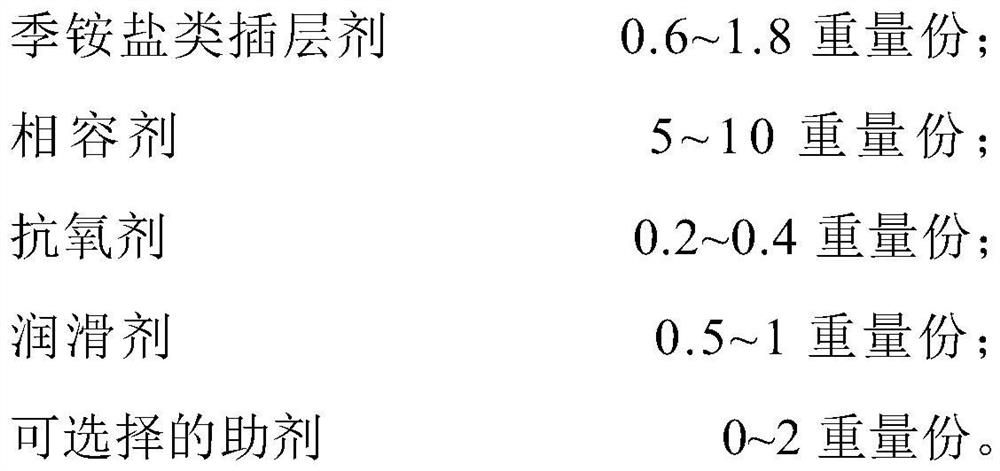

[0052] A lightweight polypropylene micro-foaming composite material is made of the following substances in parts by weight:

[0053]

[0054]

[0055] The preparation method of described lightweight polypropylene microfoam composite material, comprises the following steps:

[0056] (1) Add 4 parts by weight of sepiolite fiber to 200mL of 10wt% hydrochloric acid, then stir at 60°C for 24h, then centrifuge and wash to neutral, and vacuum dry at 50°C for 36h to obtain purified sepiolite fiber ;

[0057] (2) Stir the purified sepiolite fiber and 0.4 parts by weight of sodium dodecylbenzenesulfonate in 2000 mL of water at 80°C for 48 hours, then centrifugally wash with deionized water for 3 times, and then vacuum-dry at 50°C 36h, obtain the sepiolite fiber of surface activation;

[0058] (3) Stir the surface-activated sepiolite fiber and 1.2 parts by weight of octadecyltrimethylammonium bromide in 200 mL of water at 80°C for 48 hours, then centrifugally wash with deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com