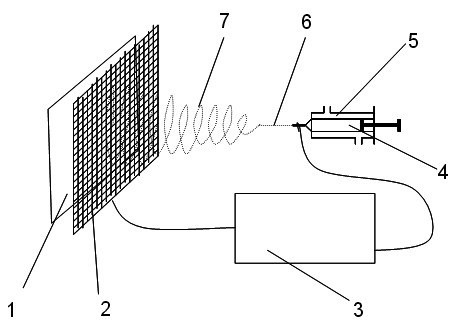

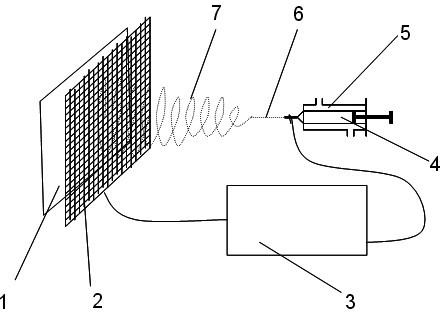

Polyvinyl alcohol nanofiber, and preparation method and device thereof

A technology of nanofibers and polyvinyl alcohol, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems that the breaking strength needs to be improved, so as to improve the spinnability, increase the tensile strength and reduce the viscosity of the system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

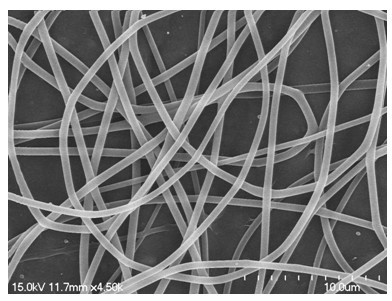

Examples

Embodiment 1

[0020] In this example, the technical scheme of freezing and thawing was adopted to prepare a moderately cross-linked PVA electrospinning solution inside, and the specific steps were as follows:

[0021] 1. Dissolve N,N-bis(2-hydroxyethyl)aminoacetic acid in concentrated hydrochloric acid, raise the temperature to 150°C under reduced pressure, keep the temperature for 4 hours, precipitate, filter with suction, and dry to obtain water-soluble Hydroxyl-terminated hyperbranched polyester;

[0022] 2. Mix PVA particles with a relative molecular weight of 72000 and 1wt% water-soluble hydroxyl-terminated hyperbranched polyester in distilled water, slowly heat to 90°C at a rate of 0.5°C / min from room temperature, and magnetically stir for 4 hours to make it Dissolve fully, obtain the PVA mixed solution that concentration is 6wt%;

[0023] 3. Cool the PVA mixed solution obtained in step 2 to room temperature, and freeze it at -30°C;

[0024] 4. After freezing for 10 hours, take it o...

Embodiment 2

[0030] 1, prepare hydroxyl-terminated hyperbranched polyester according to the technical scheme of embodiment 1;

[0031] 2. Mix PVA particles with a relative molecular mass of 72,000 and 3wt% hydroxyl-terminated hyperbranched polyester in distilled water, slowly heat to 90°C at a rate of 0.5°C / min from room temperature, and magnetically stir for 4 hours to fully dissolve it. The homogeneous PVA solution that obtains concentration is 8wt%;

[0032] 3. Cool the PVA solution obtained in step 2 to room temperature, and freeze it at -50°C;

[0033] 4. After freezing for 10 hours, take it out and place it at room temperature for thawing;

[0034] 5. Repeat steps 3 and 4;

[0035] 6. After 5 times of freezing and thawing, some microcrystals formed in the solution, and an internal micro-crosslinked PVA gel was obtained, which was then placed in a 55°C water bath and heated for half an hour to obtain a spinning solution;

[0036] 7. Put the PVA spinning solution obtained in step 6 ...

Embodiment 3

[0038] 1, prepare water-soluble hydroxyl-terminated hyperbranched polyester with embodiment 1;

[0039] 2. Mix PVA particles with a relative molecular weight of 100,000 and 3wt% hydroxyl-terminated hyperbranched polyester in distilled water, heat slowly from room temperature to 90°C at a rate of 0.5°C / min, and magnetically stir for 4 hours to fully dissolve it. The homogeneous PVA solution that obtains concentration is 6wt%;

[0040] 3. Cool the PVA solution obtained in step 2 to room temperature, and freeze it at -30°C;

[0041] 4. After freezing for 10 hours, take it out and place it at room temperature for thawing;

[0042] 5. Repeat steps 3 and 4;

[0043] 6. After 7 times of freezing and thawing, some microcrystals formed in the solution to obtain an internally cross-linked PVA gel, which was then placed in a water bath at 50°C and heated for half an hour to obtain a PVA spinning solution with a viscosity of 438 mpa. s;

[0044] 7. Put the PVA spinning solution obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com