Preparation method of magnesium alloy variable-section cylindrical member by composite extrusion deformation

A composite extrusion, magnesium alloy technology, applied in the direction of metal extrusion dies, etc., can solve the problems of complex process, poor mechanical properties, coarse grains of casting magnesium alloys, etc., to overcome the growth of grains, high material utilization, The effect of increasing the degree of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Determine the magnesium alloy material. According to the use requirements of high-speed aircraft load-bearing parts, AZ80 magnesium alloy with high strength, good corrosion resistance and moderate material cost is selected as the manufacturing material through performance and cost comparative analysis and chemical compatibility analysis;

[0031] Perform homogenization pretreatment on the magnesium alloy blank ①. The treatment temperature is 410°C, and the treatment time is 8 hours;

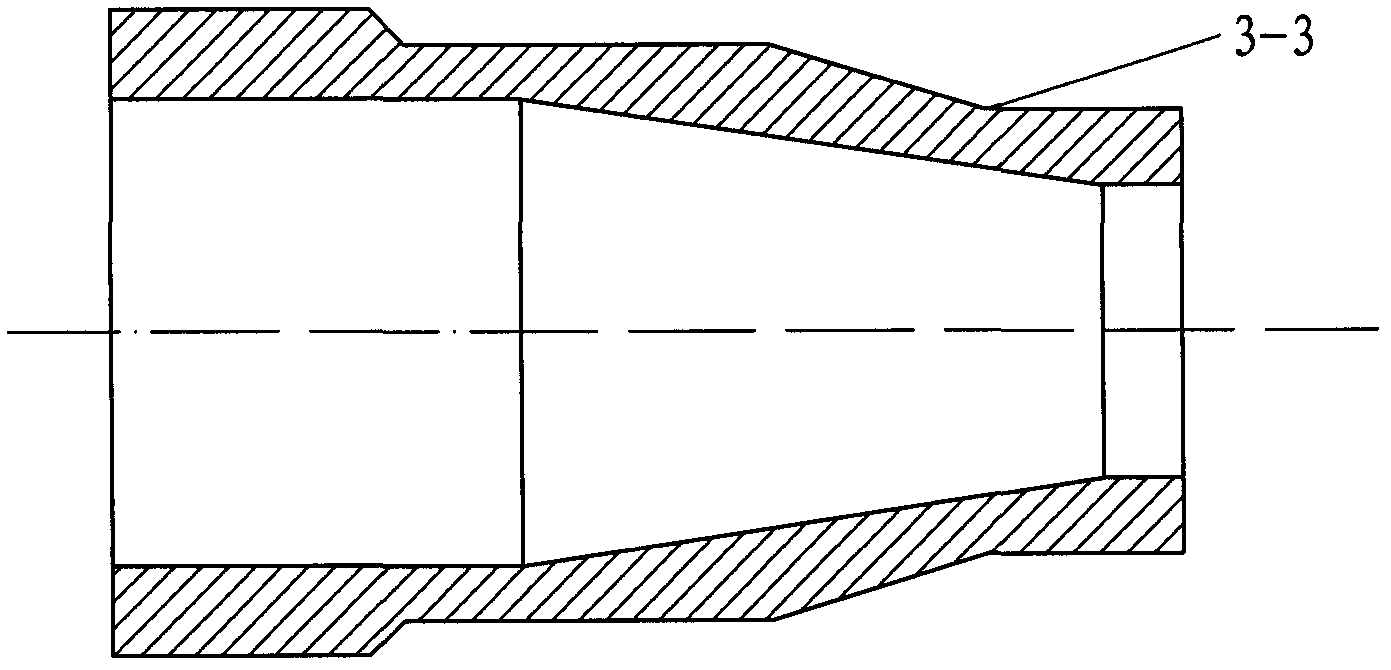

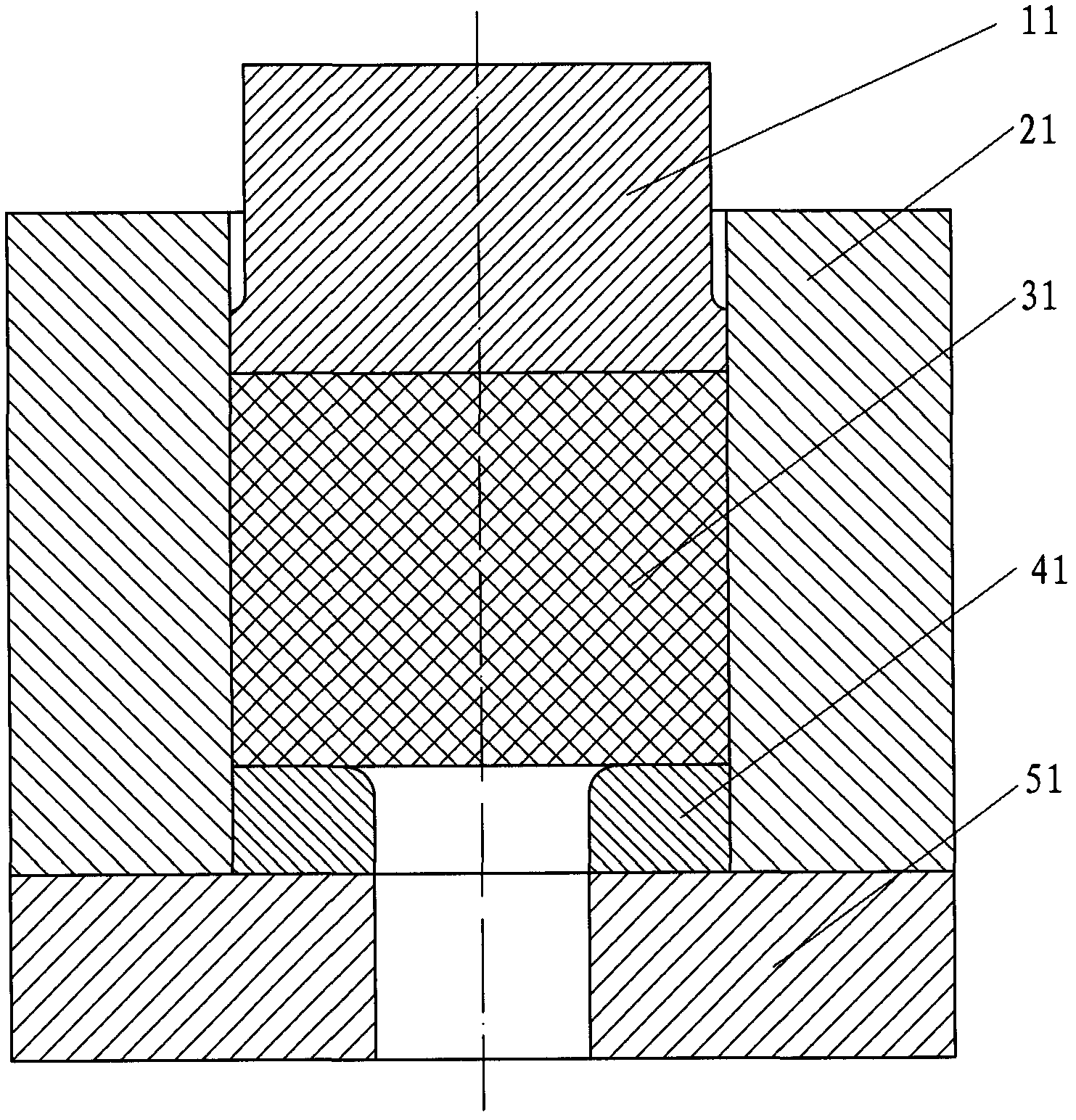

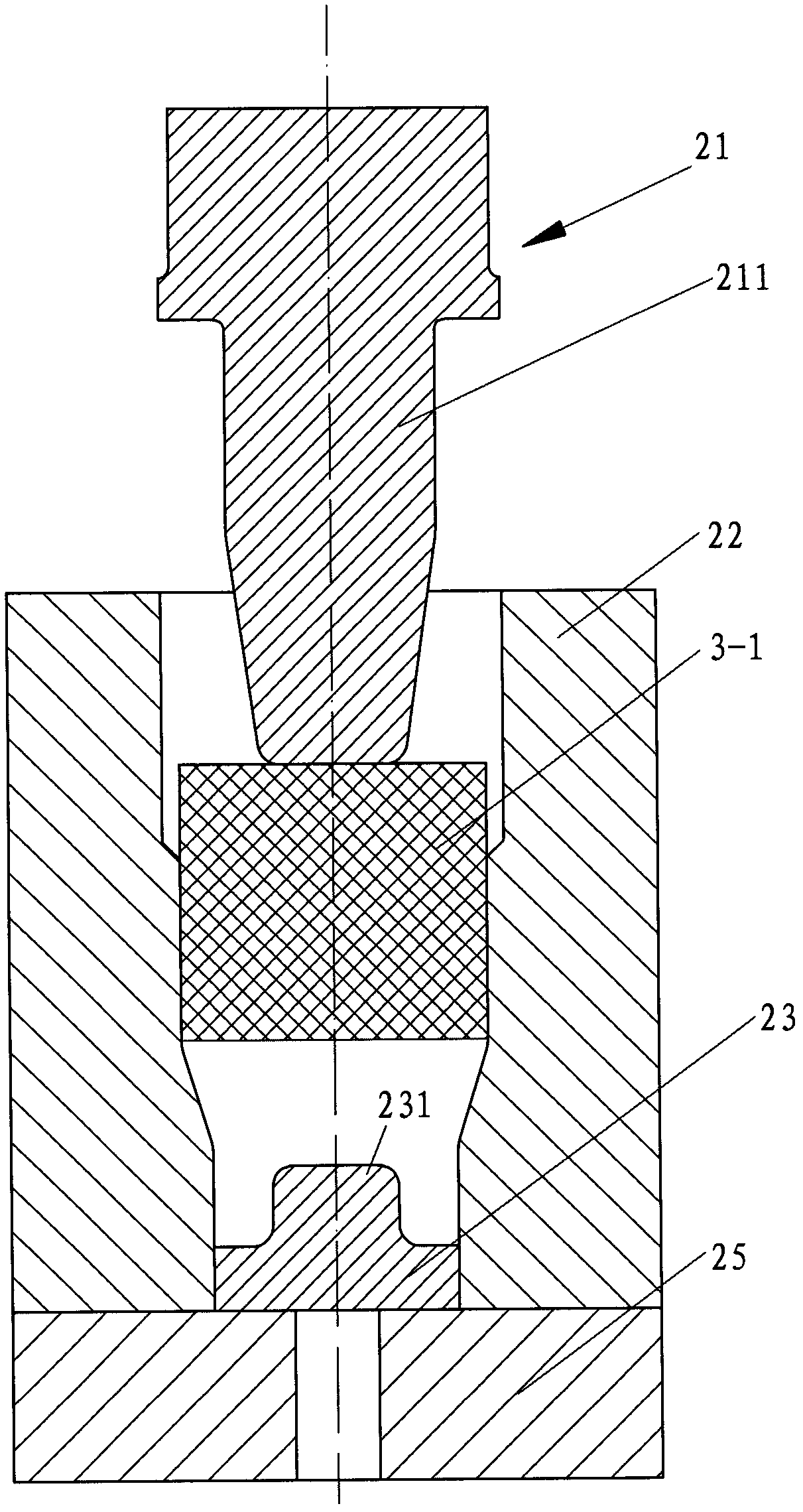

[0032] Perform thermomechanical extrusion pre-deformation on the magnesium alloy billet 31 after step ①. The preheating temperature of the magnesium alloy billet is 340°C, the temperature of the hot extrusion die is 200°C, and the extrusion speed is 3mm / s to obtain a magnesium alloy rod with a diameter of 150mm, see figure 2 As shown, the hot extrusion die includes a hot extrusion punch 11, a hot extrusion die 21, a hot extrusion new film 41 and a workbench 51;

[0033] Cutting the pre...

Embodiment 2

[0039] Determine the magnesium alloy material. According to the use requirements of high-speed aircraft load-bearing parts, AZ80 magnesium alloy with high strength, good corrosion resistance and moderate material cost is selected as the manufacturing material through performance and cost comparative analysis and chemical compatibility analysis;

[0040] Perform homogenization pretreatment on the magnesium alloy blank ①. The treatment temperature is 400°C, and the treatment time is 12h;

[0041] The magnesium alloy treated in step ① is subjected to thermomechanical extrusion pre-deformation. The preheating temperature of the magnesium alloy billet is 360°C, the temperature of the hot extrusion die is 200°C, and the extrusion speed is 3mm / s to obtain a magnesium alloy rod with a diameter of 160mm;

[0042] Machining the pre-deformed magnesium alloy in step ② to obtain a pre-deformed blank. The size of the pre-deformed blank is calculated based on the size of the bearing part ...

Embodiment 3

[0048] Determine the magnesium alloy material. According to the use requirements of high-speed aircraft load-bearing parts, AZ80 magnesium alloy with high strength, good corrosion resistance and moderate material cost is selected as the manufacturing material through performance and cost comparative analysis and chemical compatibility analysis;

[0049] Perform homogenization pretreatment on the magnesium alloy blank ①. The treatment temperature is 400°C, and the treatment time is 12h;

[0050] The magnesium alloy treated in step ① is subjected to thermomechanical extrusion pre-deformation. The preheating temperature of the magnesium alloy billet is 380°C, the temperature of the hot extrusion die is 220°C, the speed of the extrusion rod is 3mm / s, and a magnesium alloy rod with a diameter of 170mm is obtained;

[0051] Machining the pre-deformed magnesium alloy in step ② to obtain a pre-deformed blank. The size of the pre-deformed blank is calculated based on the size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com