High-strength polylactic acid bone fixation material and preparation method thereof

A polylactic acid bone and fixation material technology, applied in medical science, surgery, etc., can solve the problems of poor viscoelasticity, limited stretching ratio, difficult mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

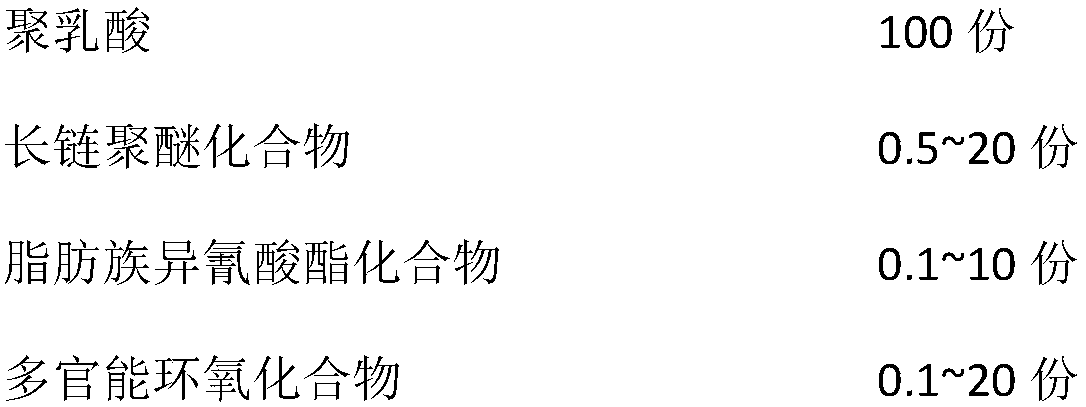

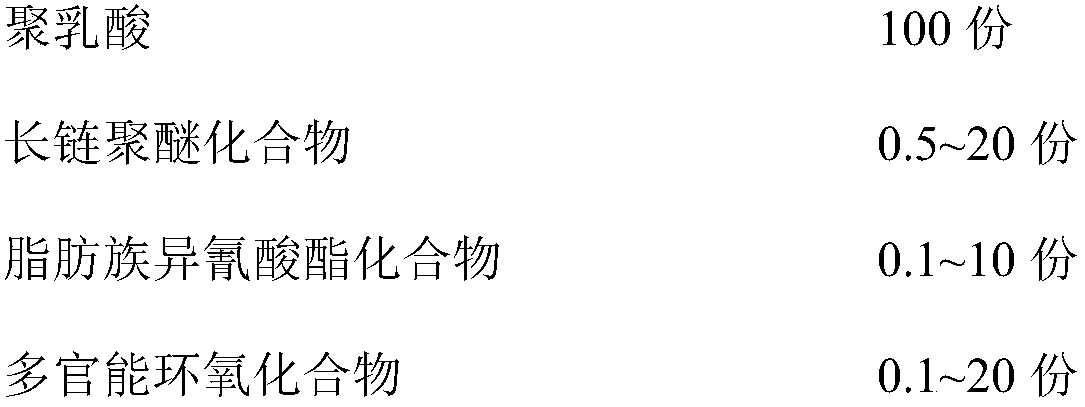

Method used

Image

Examples

Embodiment 1

[0023] Put 0.5 parts of 1,6-hexamethylene diisocyanate into the reactor, then slowly add 2 parts of amino-terminated polyoxyethylene ether (molecular weight 2000g / mol) dropwise therein at -5°C, and react for 20 minutes to obtain polyether-isocyanate Multifunctional long-chain flexible branching agent;

[0024] Add 3 parts of long-chain flexible branching agent, 3 parts of 1,4-butanediol diglycidyl ether and 100 parts of dry polylactic acid into the internal mixer, and react at 170°C for 10 minutes to obtain a multi-arm structure Long chain branched polylactic acid biocompatible material;

[0025] Compress the obtained polylactic acid material into a size of 50×50×4mm 3 The sample, pressing temperature: 170°C, pressing pressure 10MPa, then fix the polylactic acid sample on a temperature-controllable and speed-adjustable biaxial stretching device, keep the temperature at 70°C for 20min, and then stretch it along the longitudinal direction and the transverse direction at the sam...

Embodiment 2

[0028] Put 5 parts of 4,4'-dicyclohexylmethane diisocyanate into the reactor, then slowly add 10 parts of amino-terminated polyoxypropylene ether (molecular weight 3000g / mol) dropwise at 20°C, and react for 40 minutes to obtain poly Ether-isocyanate polyfunctional long-chain flexible branching modifier;

[0029] Add 5 parts of long-chain flexible branching agent, 5 parts of glycerol triglycidyl ether and 100 parts of dry polylactic acid into the internal mixer, and react at 200°C for 30 minutes to obtain long-chain branched Polylactic acid biocompatible material;

[0030] Compress the obtained polylactic acid material into a size of 50×50×4mm 3 The sample, pressing temperature: 200°C, pressing pressure 7MPa, then fix the polylactic acid sample on a temperature-controllable and speed-adjustable biaxial stretching device, keep the temperature at 90°C for 40min, and then stretch it along the longitudinal direction and the transverse direction at the same time Perform stretching...

Embodiment 3

[0033] Put 10 parts of isophorone diisocyanate into the reactor, then slowly drop 10 parts of hydroxyl-terminated polyoxypropylene ether (molecular weight 4000g / mol) into it at 30°C, and react for 60 minutes to obtain polyether-isocyanate polyfunctional Long chain flexible branching modifier;

[0034] Add 10 parts of long-chain flexible branching agent, 10 parts of pentaerythritol tetraglycidyl ether and 100 parts of dry polylactic acid into the internal mixer, and react at 220°C for 40 minutes to obtain long-chain branched polylactic acid with multi-arm structure biocompatible materials;

[0035] Compress the obtained polylactic acid material into a size of 50×50×4mm 3 The sample, pressing temperature: 210°C, pressing pressure 15MPa, then fix the polylactic acid sample on a temperature-controllable and speed-adjustable biaxial stretching device, keep the temperature at 100°C for 60min, and then stretch it along the longitudinal direction and the transverse direction at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com