Water-flushing degradable non-woven fabric and production method thereof

A production method and technology of non-woven fabrics, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve problems such as high process requirements, inability to clean toilets, and incomplete decomposition, so as to simplify the production process, improve processing efficiency, and speed up production. The effect of decomposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: with reference to attached figure 1 . A water flushing degradable non-woven fabric, comprising a non-woven fabric layer 1; the special-shaped viscose fibers and wood pulp fibers in the non-woven fabric layer 1 are mixed with each other, and entangled with each other; the special-shaped viscose fibers Both viscose and wood pulp fibers are short fibers, and are hydrogen bonded; the ratio of shaped viscose fibers and wood pulp fibers in the non-woven fabric layer 1 is 1:1.

Embodiment 2

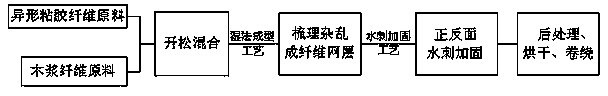

[0018] Embodiment 2: with reference to attached figure 2 . On the basis of embodiment 1, a kind of preparation method of water washing degradable non-woven fabric comprises the following steps:

[0019] ① Using special-shaped viscose fiber and wood pulp fiber as raw materials for opening and mixing;

[0020] ②The fiber raw materials are mixed and carded through the wet forming process to form a fiber mesh layer;

[0021] ③Through the spunlace process, the front and back sides are entangled and reinforced;

[0022] ④ After post-processing (dyeing, etc.), drying, and winding, a water-washed degradable non-woven fabric is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com