Proparation technology of conductive polyaniline

A conductive polyaniline technology, which is applied in the field of preparation of conductive polyaniline, can solve the problems of poor adhesion, low mechanical strength of polyaniline coating, and neglect of the mechanical properties of polyaniline materials, so as to increase the degree of entanglement, Good mechanical strength and adhesion, good solubility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

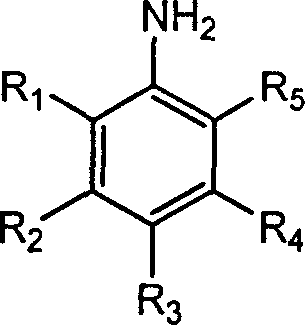

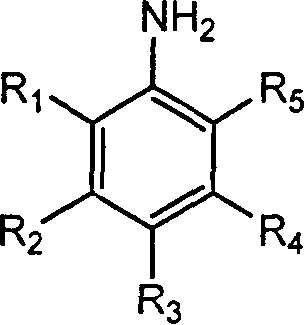

Method used

Image

Examples

Embodiment 1

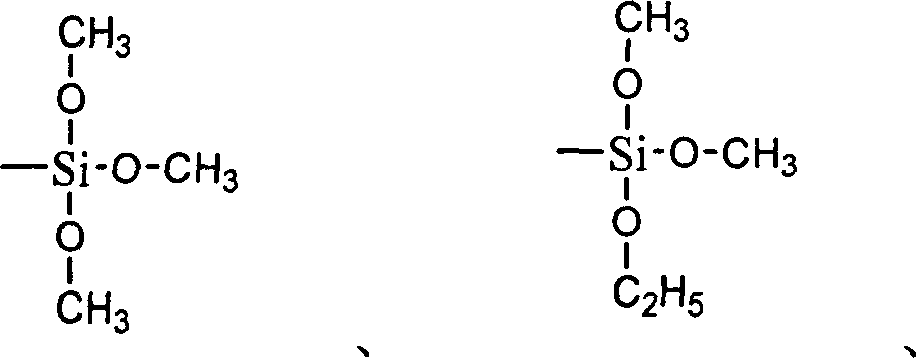

[0031] Place the three-necked flask in a water bath at 5°C, add a certain amount of macromolecular protonic acid dodecylsulfonic acid to 150.0ml ethanol, adjust the pH value to about 0.5, and then add monomer A7.3g m- (5-Hydroxybutylthio)aniline, monomer B 10.0 g m-(3-trimethoxysilylethylthio)aniline. Dissolve 9.9g of the oxidant potassium persulfate in absolute ethanol, and slowly add it dropwise to the three-necked flask under nitrogen protection and stirring. The dropwise addition is completed within half an hour. React at room temperature for 15 hours. Suction filtration was performed after the reaction was completed, and then dried at room temperature for 2 hours to obtain conductive polyaniline. The obtained conductive polyaniline was dissolved in a mixed solvent of xylene:butanol=60:40, sprayed and dried at 60° C. to form a film.

Embodiment 2

[0033] Place the three-necked flask in a 5°C water bath, add a certain amount of macromolecular protonic acid octylsulfonic acid to 150.0ml n-propanol to adjust the pH value to about 0.5, and then add monomer A9.7g m-(5 -Hydroxybutylthio)aniline, monomer B 6.7 g m-(2-dimethoxyethoxysilylethylthio)aniline. Dissolve 19.7g of oxidant potassium persulfate in anhydrous n-propanol, and slowly add it dropwise to a three-necked flask under nitrogen protection and stirring. The dropwise addition is completed within half an hour. After the dropwise addition, keep it at 5°C for 4 hours. , reacted at room temperature for 15 hours. Suction filtration was performed after the reaction was completed, and then vacuum-dried at room temperature for 2 hours to obtain conductive polyaniline. The obtained conductive polyaniline was dissolved in a mixed solvent of xylene:butanol=60:40, sprayed to form a film, and then dried at 60° C. to form a film.

Embodiment 3

[0035] Place the three-necked flask in an ice-water bath, add a certain amount of macromolecular protonic acid heptanesulfonic acid in 150.0ml of isopropanol to adjust the pH value to about 0.5, and then add monomer A9.4g m-(9 -Hydroxyoctylthio)aniline, monomer B 10.5g m-(4-dimethoxyethoxysilylbutylthio)aniline. Dissolve 19.8g of the oxidant potassium persulfate in anhydrous isopropanol, and slowly add it dropwise to the three-necked flask under nitrogen protection and stirring. The dropwise addition is completed within half an hour. After the dropwise addition, keep it at 0°C for 4 hours. , reacted at room temperature for 20 hours. Suction filtration was performed after the reaction was completed, and the filter residue obtained by suction filtration was vacuum-dried at room temperature for 5 hours to obtain conductive polyaniline. The obtained polyaniline was dissolved in a mixed solvent of xylene:butanol=60:40, sprayed and dried at 60°C to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com