Nonwoven fabric and method for manufacturing same

A technology of non-woven fabrics and fibers, which is applied in the direction of textiles, papermaking, textiles, and non-woven fabrics. Clear and other problems, to achieve the effect of high fiber density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

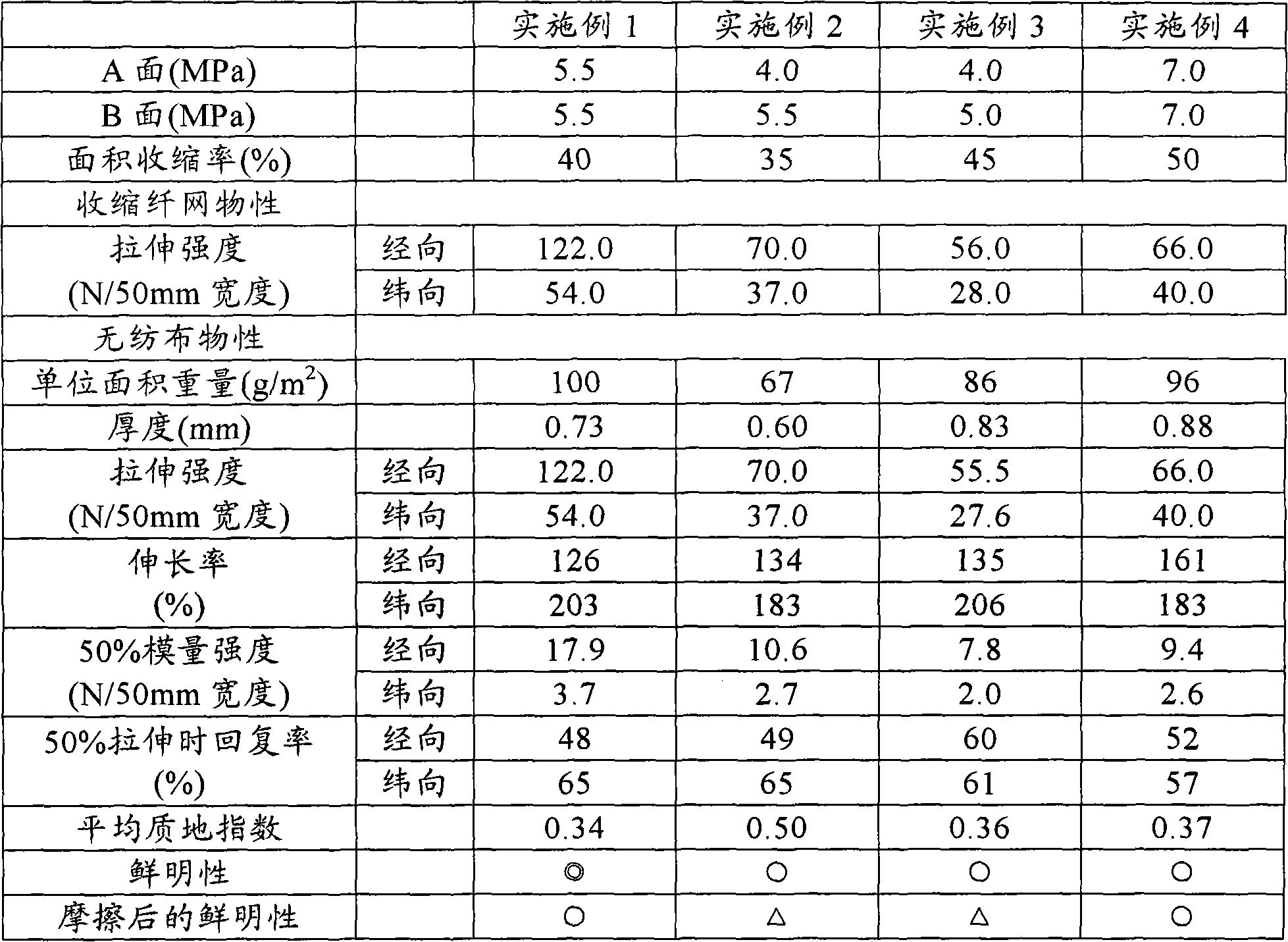

Embodiment 1

[0083] Use 100% by mass of latent crimped fibers (fineness 2.2dtex, fiber length 51mm) of a combination of polyester (melting point: 250°C) / low-melting point polyester (melting point: 230°C), using a carding machine Opening, and then use a cross lapper to form a cross web (weight per unit area: 60g / m 2 ), conveyed with a 90-mesh polyester twill net (support body) and entangled with water flow at the same time to form a hydroentangled web. The conditions for hydroentangling are as follows.

[0084] 1. Sprinkler: 0.1MPa (record one side as "A side")

[0085] 2. 5.5 MPa (side A) from a nozzle plate with a nozzle diameter of 0.13 mm and a nozzle spacing of 0.6 mm

[0086] 3. 5.5 MPa from a nozzle plate with a nozzle diameter of 0.13 mm and a nozzle pitch of 0.6 mm (the opposite side of A side, hereinafter referred to as "B side")

[0087] Next, after drying the hydroentangled fiber web at 110°C, for the hydroentangled fiber web that is overfed in the warp direction without rest...

Embodiment 2

[0096] Change the hydroentanglement conditions as follows, and set the temperature of the hot air dryer when the latently crimped fibers are crimped to form highly crimped fibers at 185°C, so that the area of the hydroentangled web is in the warp direction and Except that the weft direction was shrunk by 35% in total, it carried out similarly to Example 1, and produced the nonwoven fabric. The crimped portion of the nonwoven fabric was not welded.

[0097] 1. Sprinkler: 0.1MPa (side A)

[0098] 2. Nozzle plate 4.0MPa (side A) with a nozzle diameter of 0.13mm and a nozzle spacing of 0.6mm

[0099] 3. Nozzle plate 5.5MPa (side B) with a nozzle diameter of 0.13mm and a nozzle spacing of 0.6mm

Embodiment 3

[0101] Change the hydroentangling conditions as follows, and set the temperature of the hot air dryer to 185°C when the latently crimped fibers are crimped to form highly crimped fibers, so that the area of the hydroentangled web shrinks by 45%, Other than that, it carried out similarly to Example 1, and produced the nonwoven fabric. The crimped portion of the nonwoven fabric was not welded.

[0102] 1. Sprinkler: 0.1MPa (side A)

[0103] 2. Nozzle plate 4.0MPa (side A) with a nozzle diameter of 0.13mm and a nozzle spacing of 0.6mm

[0104] 3. Nozzle plate 5.0MPa (side B) with a nozzle diameter of 0.13mm and a nozzle spacing of 0.6mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com