Patents

Literature

35results about How to "Avoid dulling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

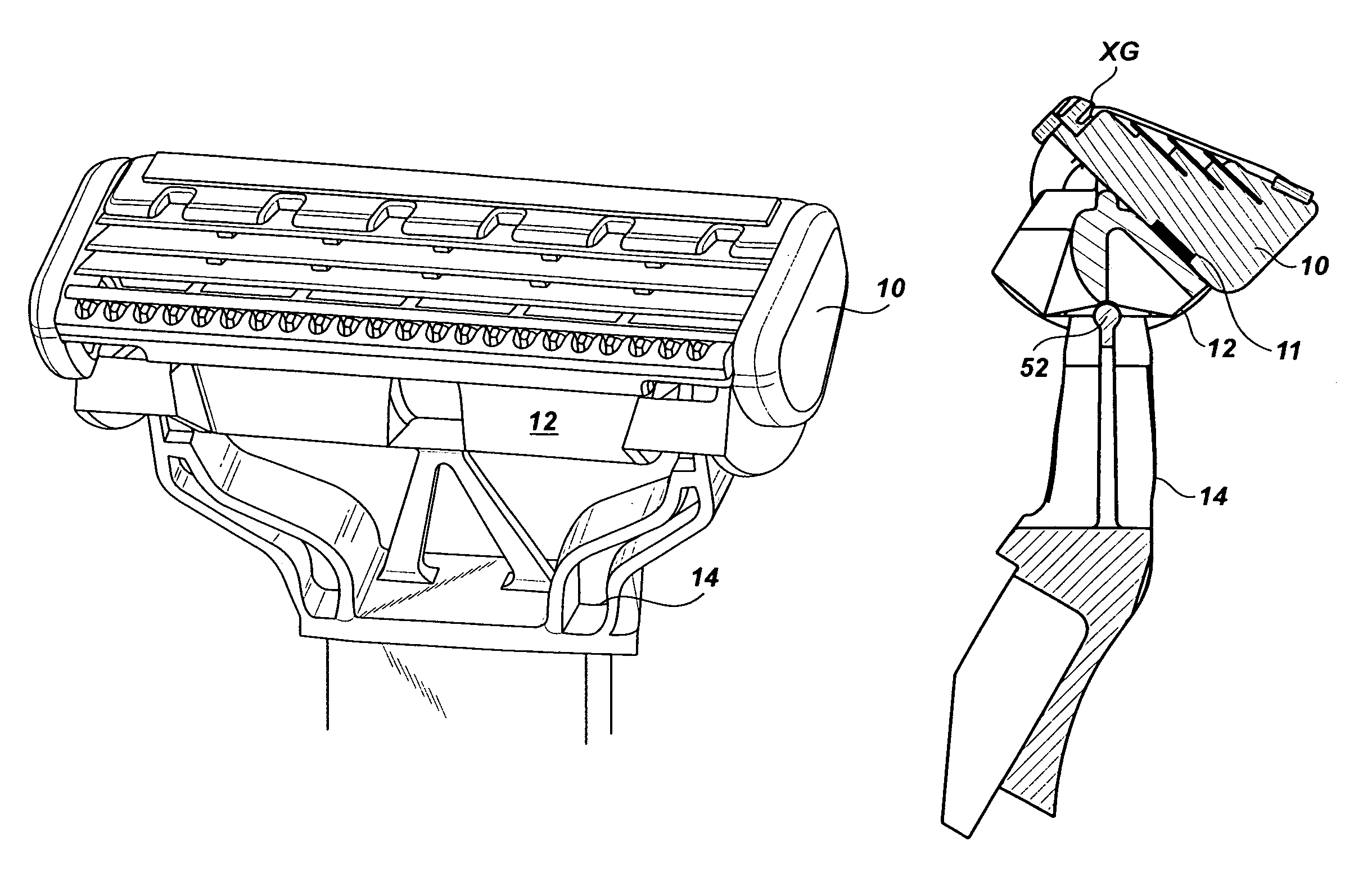

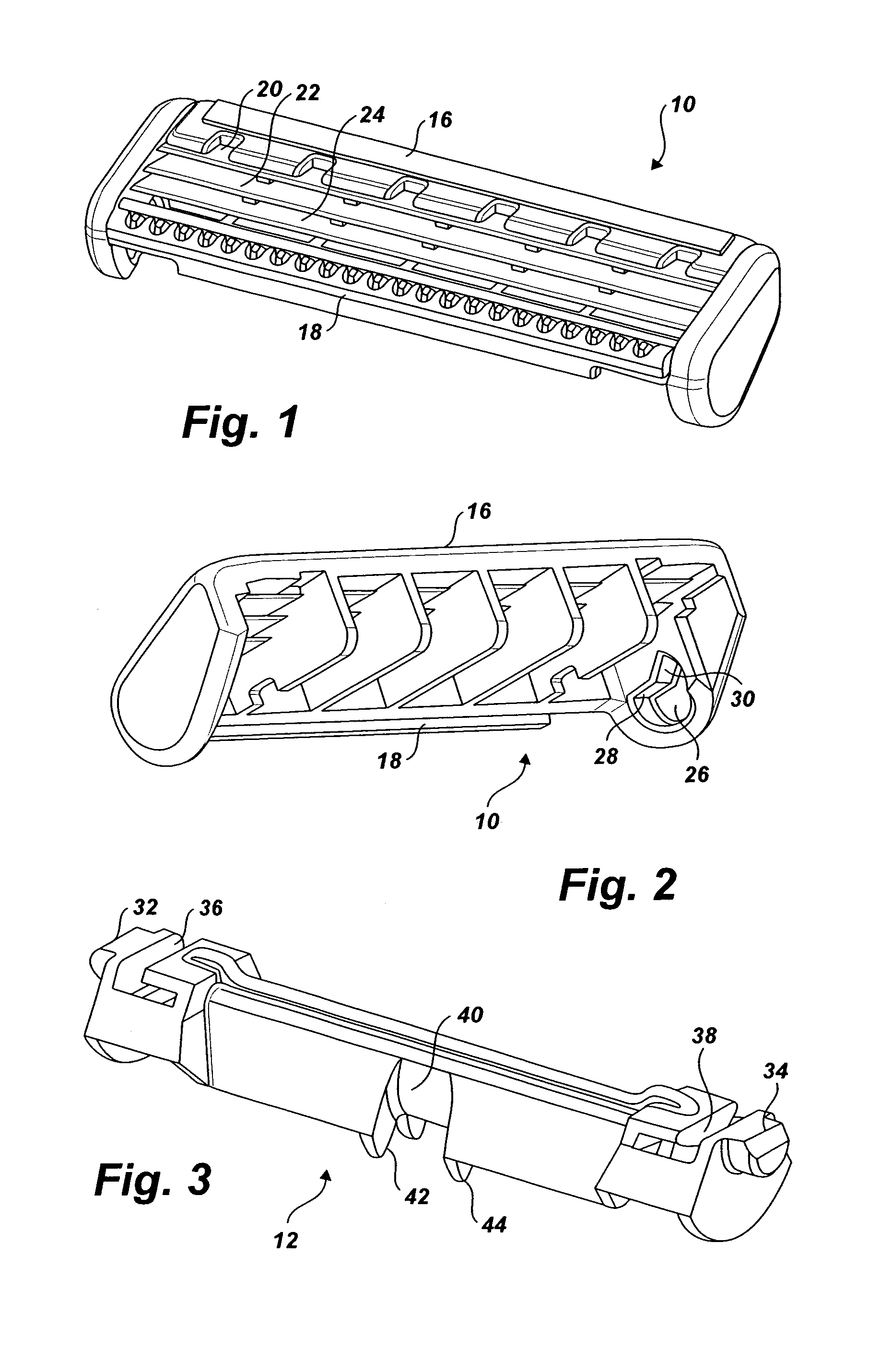

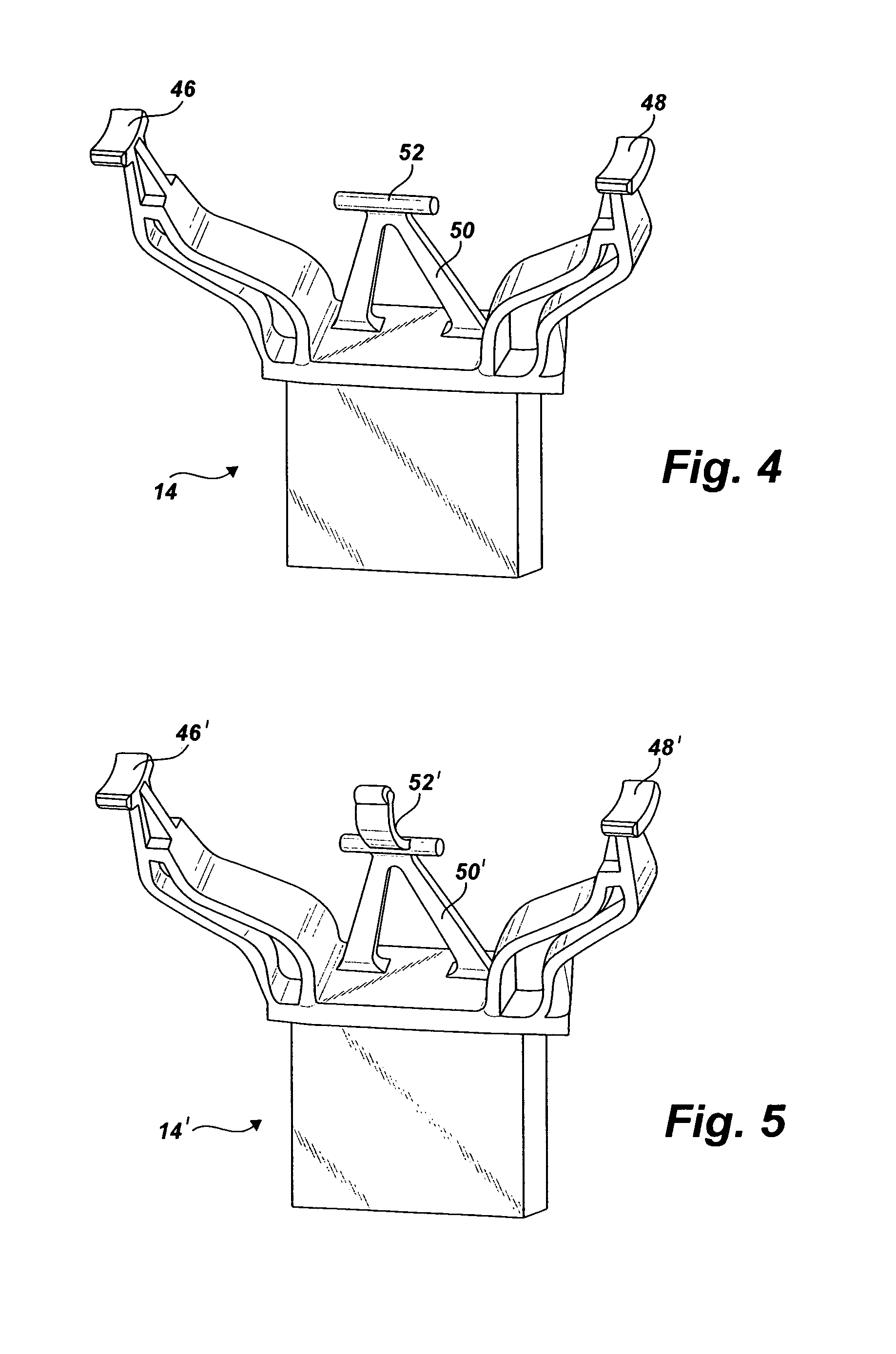

Safety razor with pivot point shift from center to guard-bar under applied load

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

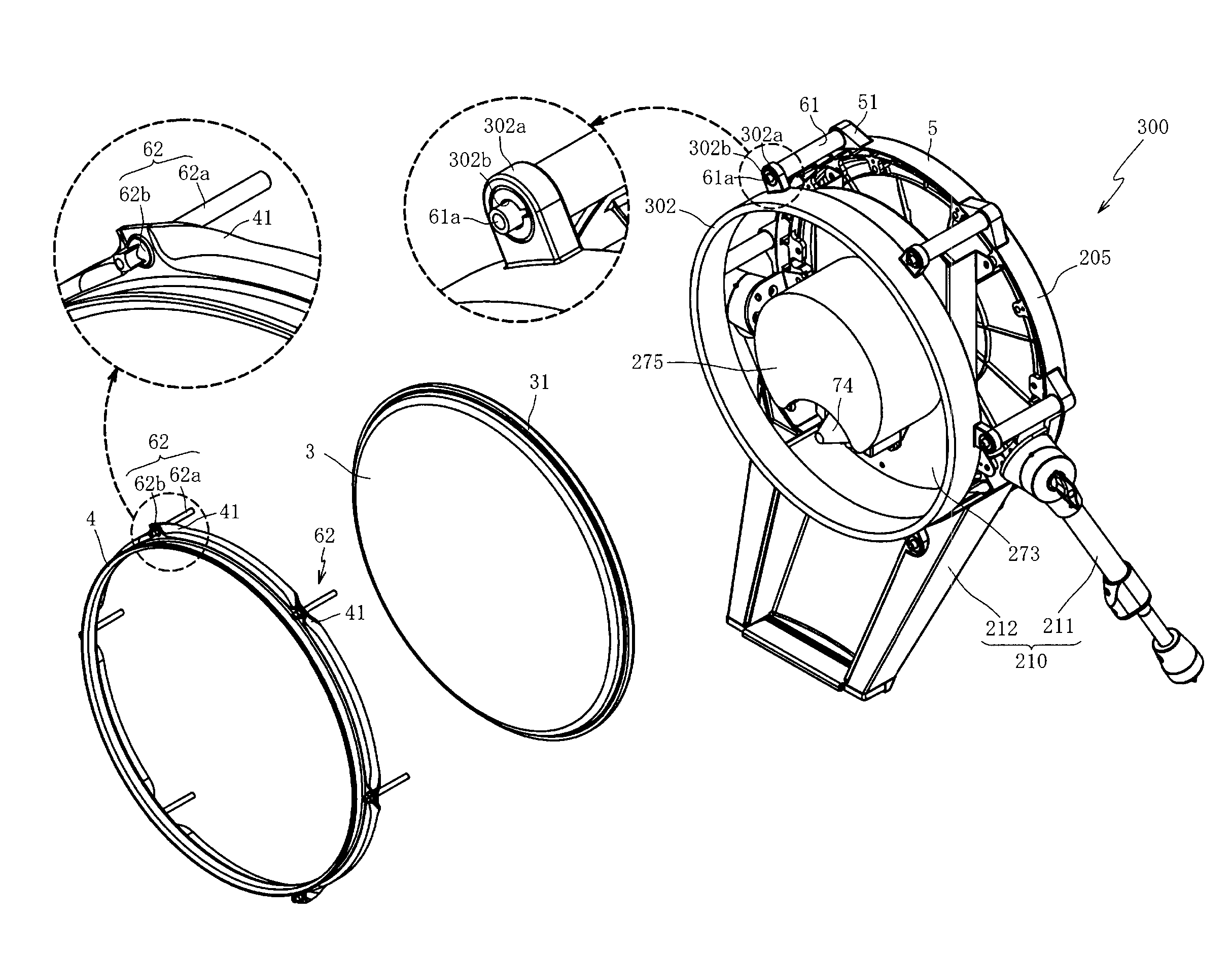

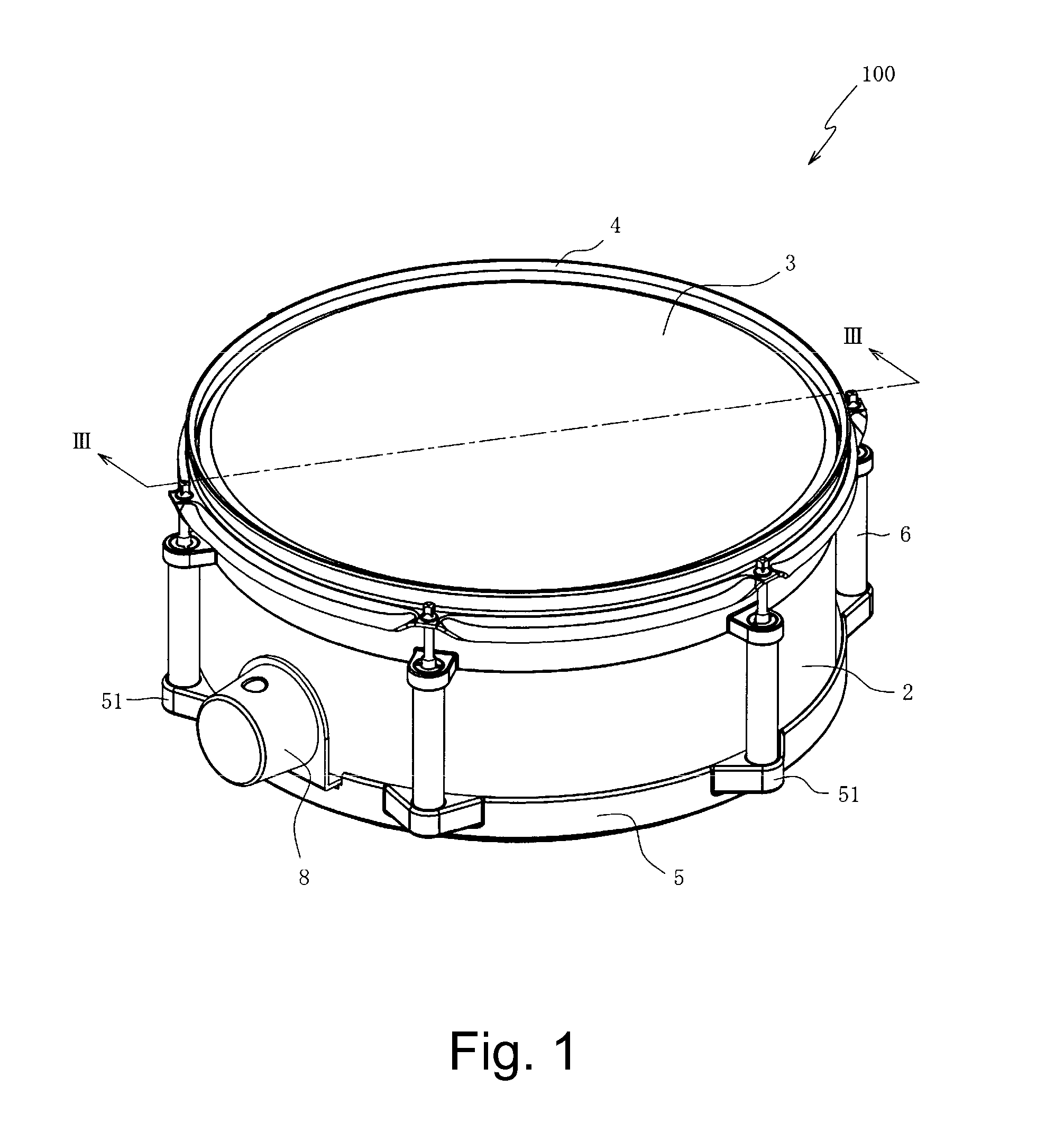

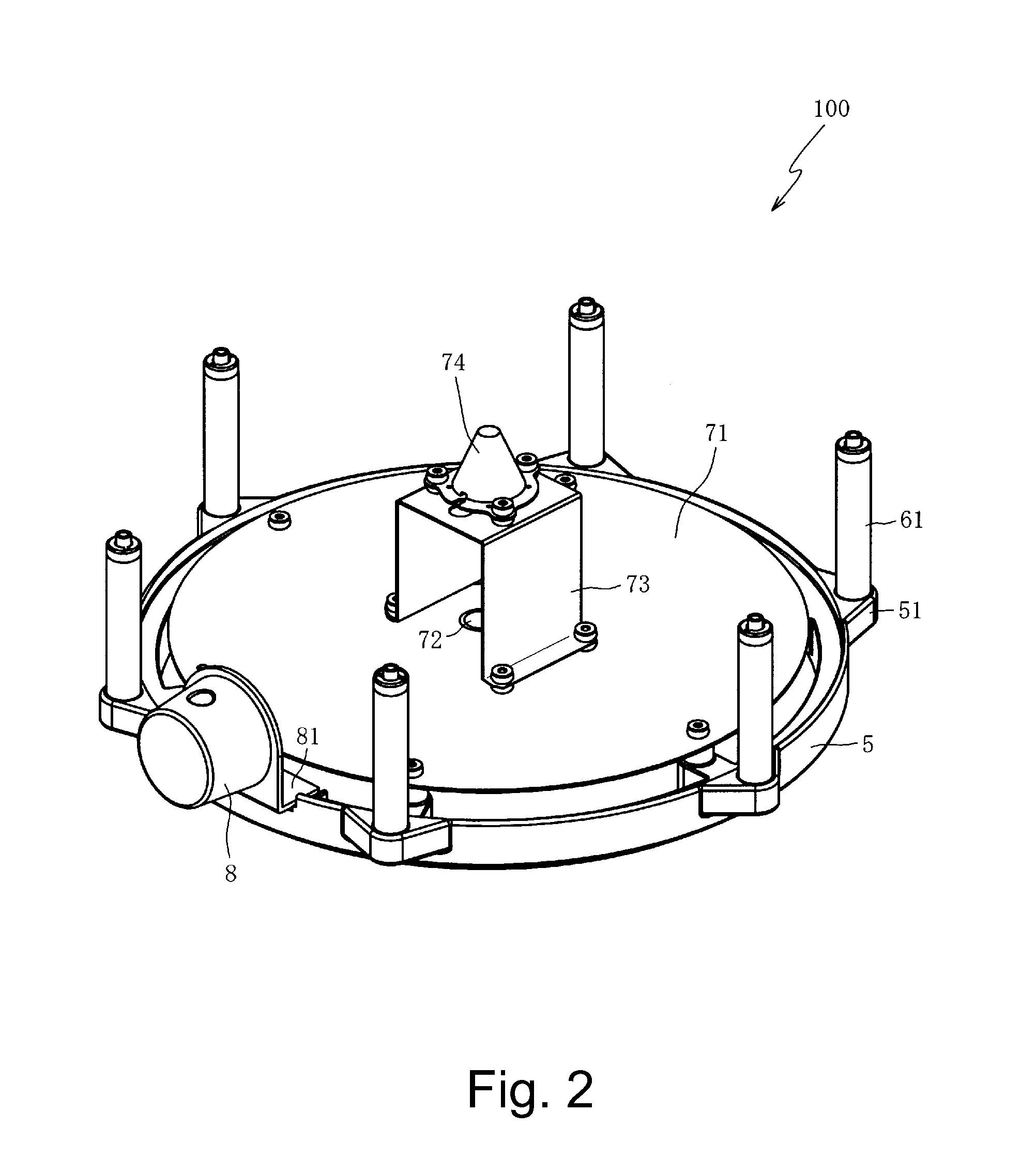

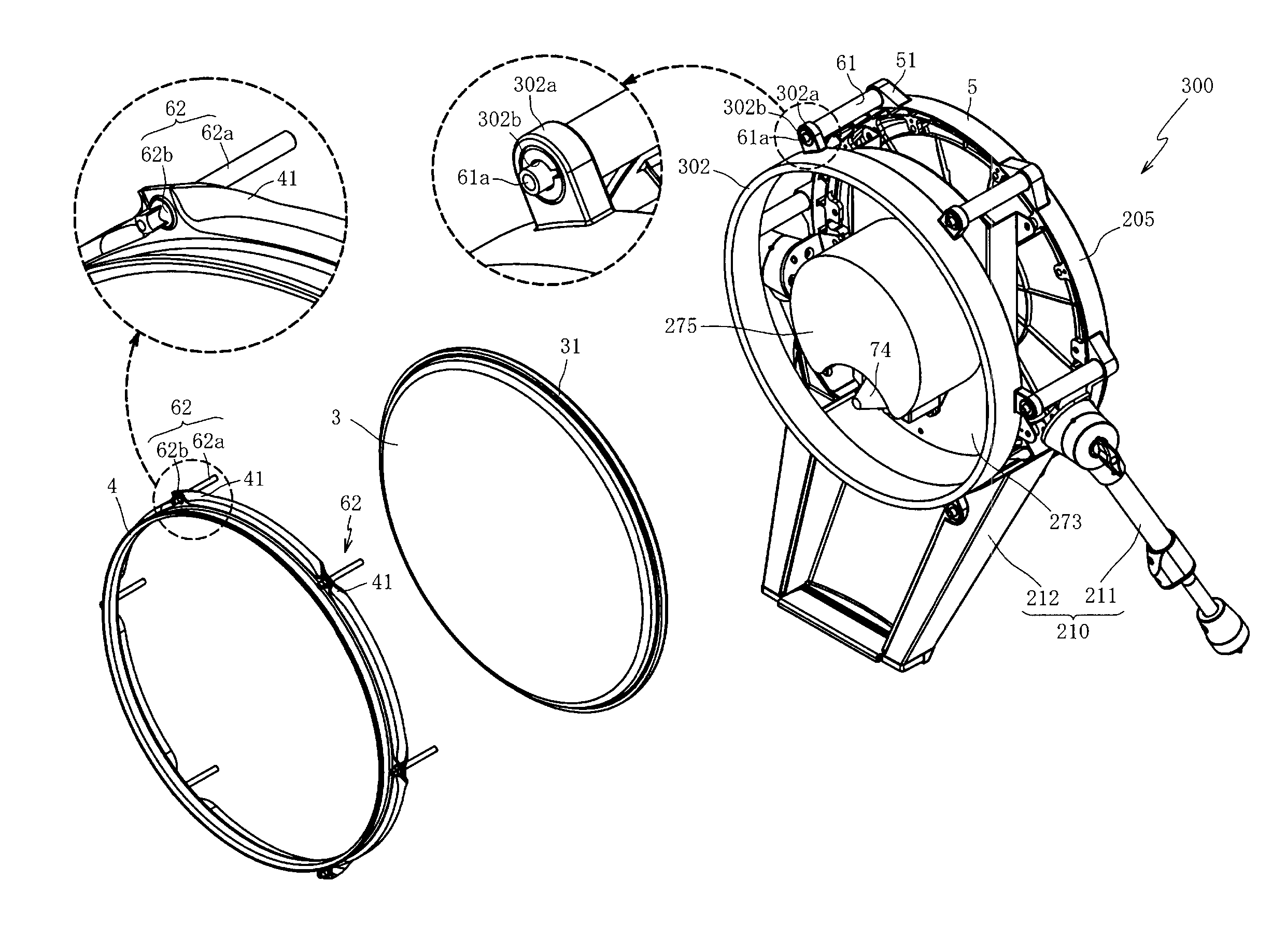

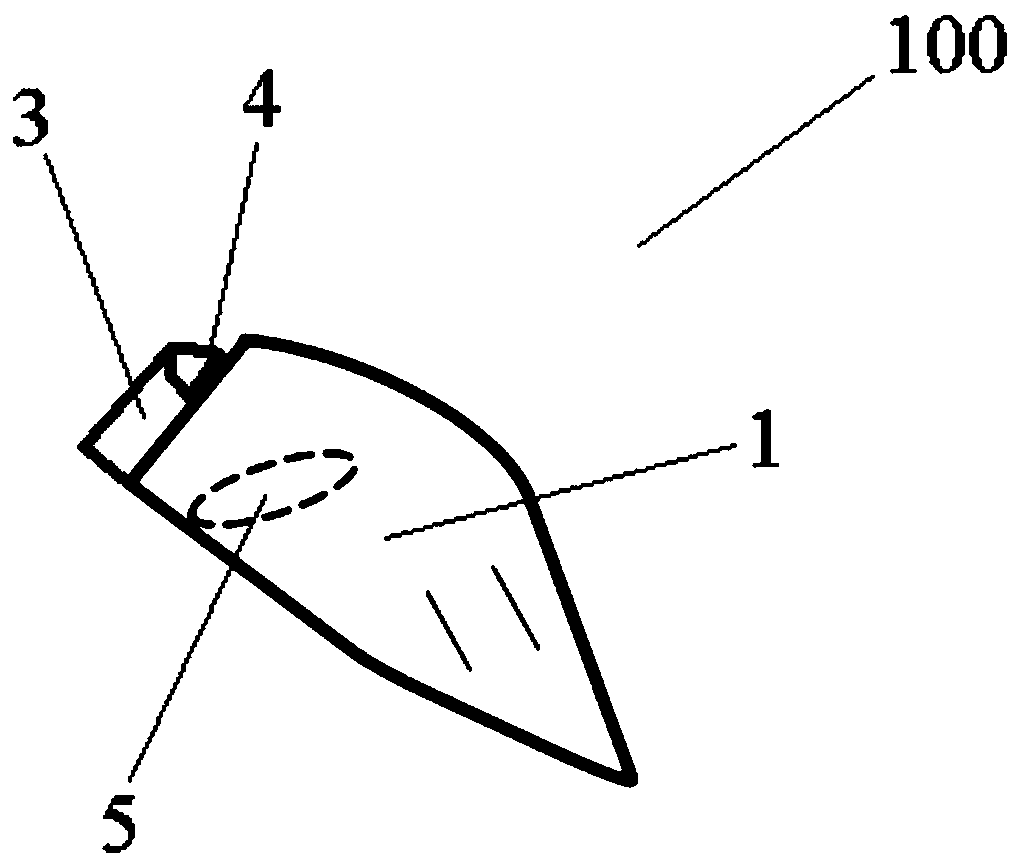

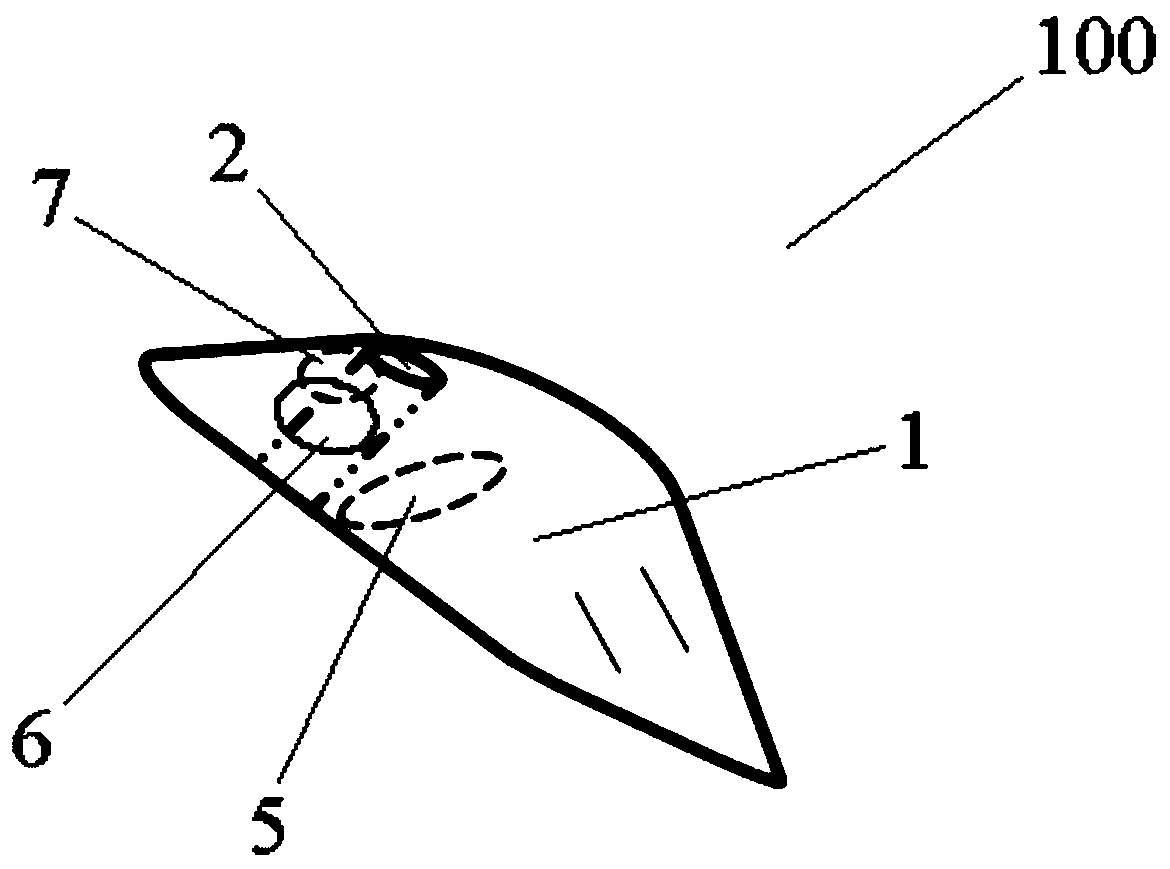

Percussion instrument and method with coupling devices

ActiveUS8431813B2Avoid dullingAbsorption of vibration by another component may be suppressedElectrophonic musical instrumentsElectrical transducersCouplingEngineering

Owner:ROLAND CORP

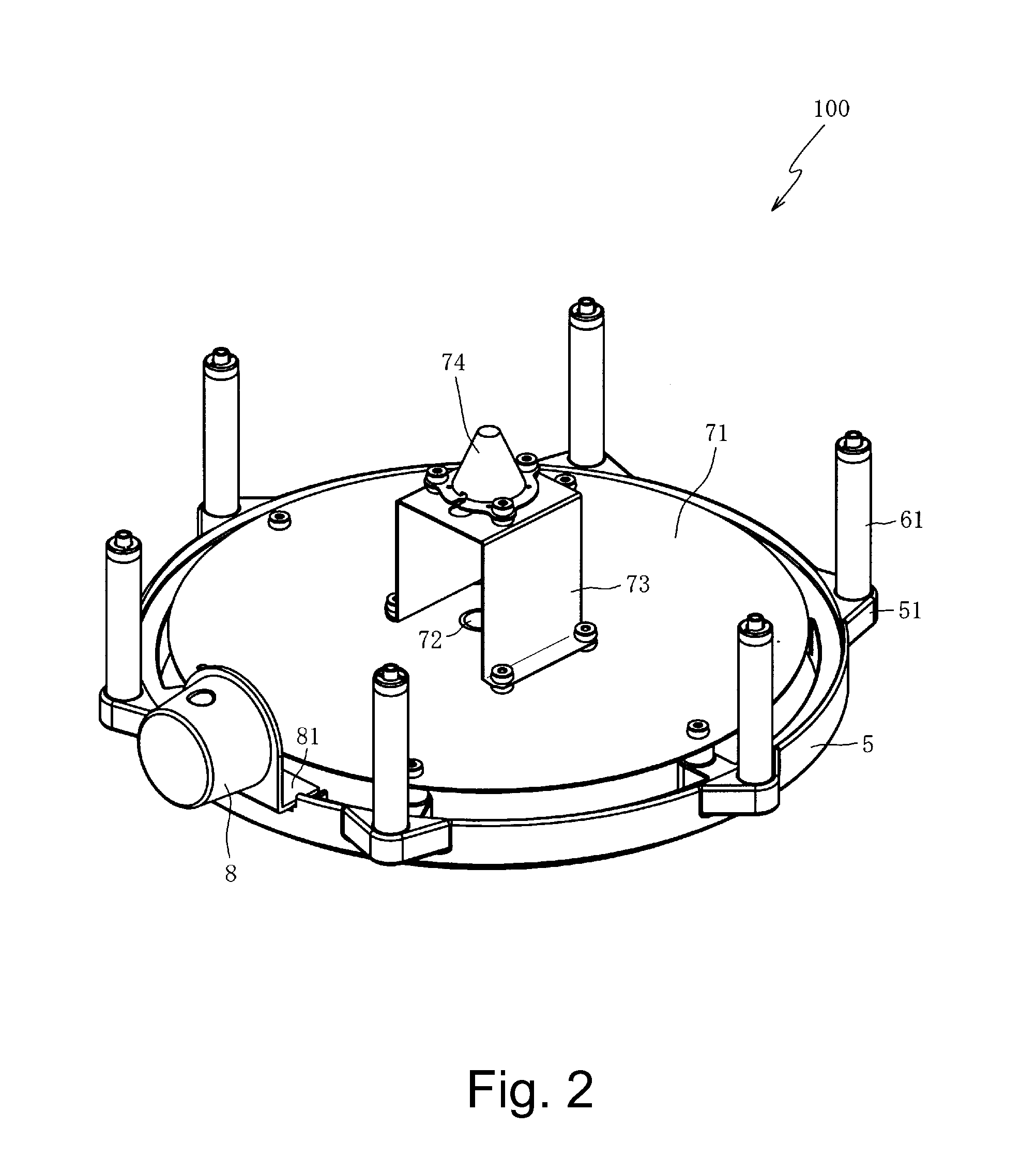

Percussion instrument systems and methods

ActiveUS20100307323A1Avoid dullingAbsorption of vibration by another component may be suppressedElectrophonic musical instrumentsElectrical transducersEngineering

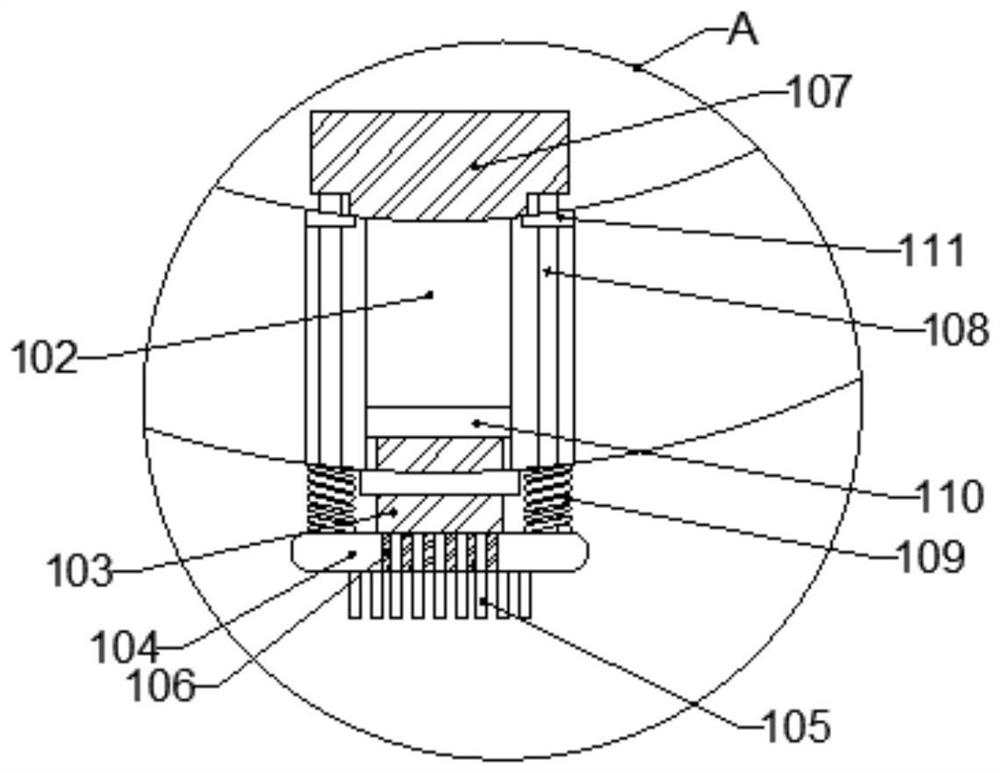

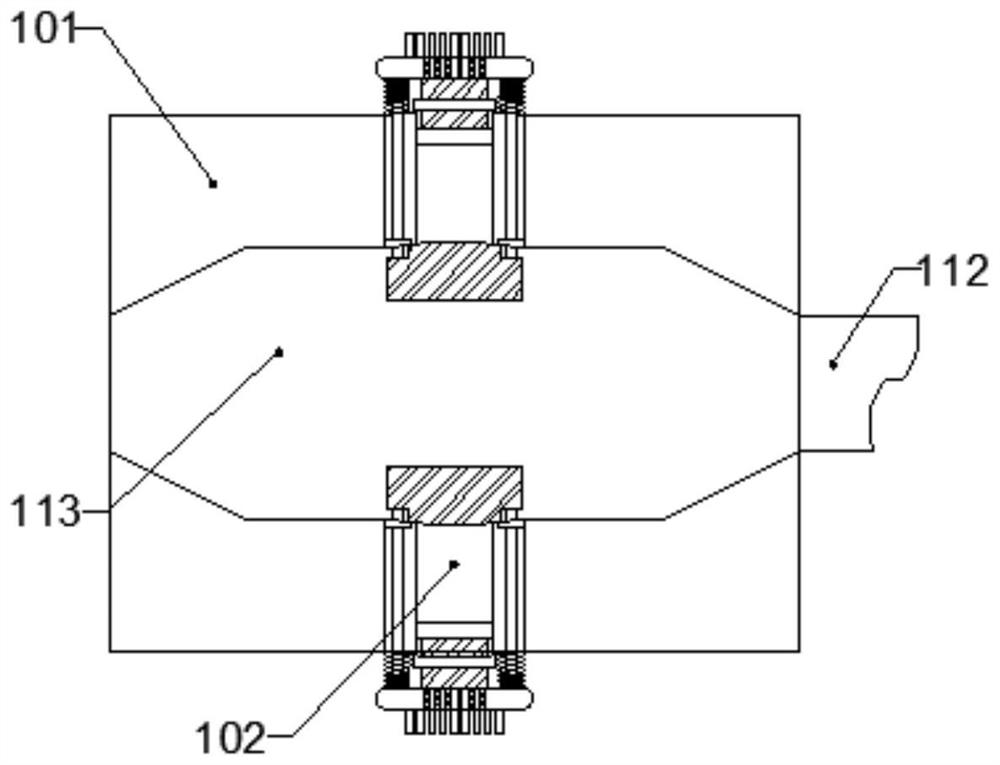

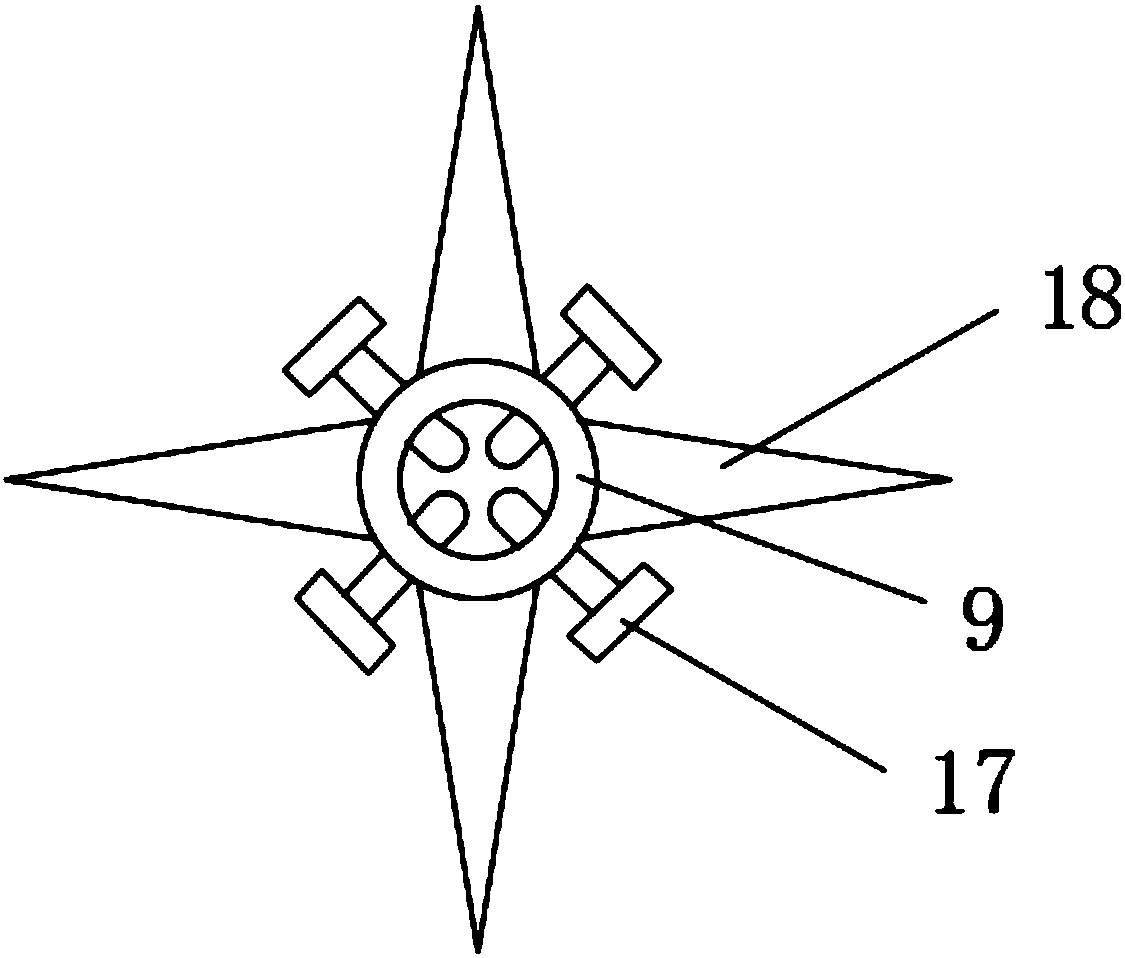

A percussion instrument may include a plurality of coupling device for operatively connecting a first hoop member, which may be configured to hold down a head arranged across a first end of a shell, with a second hoop member, which may be arranged on a second end of the shell. A sensor adjacent the head configured to detect vibration of the head may be operatively connected to the second hoop member.

Owner:ROLAND CORP

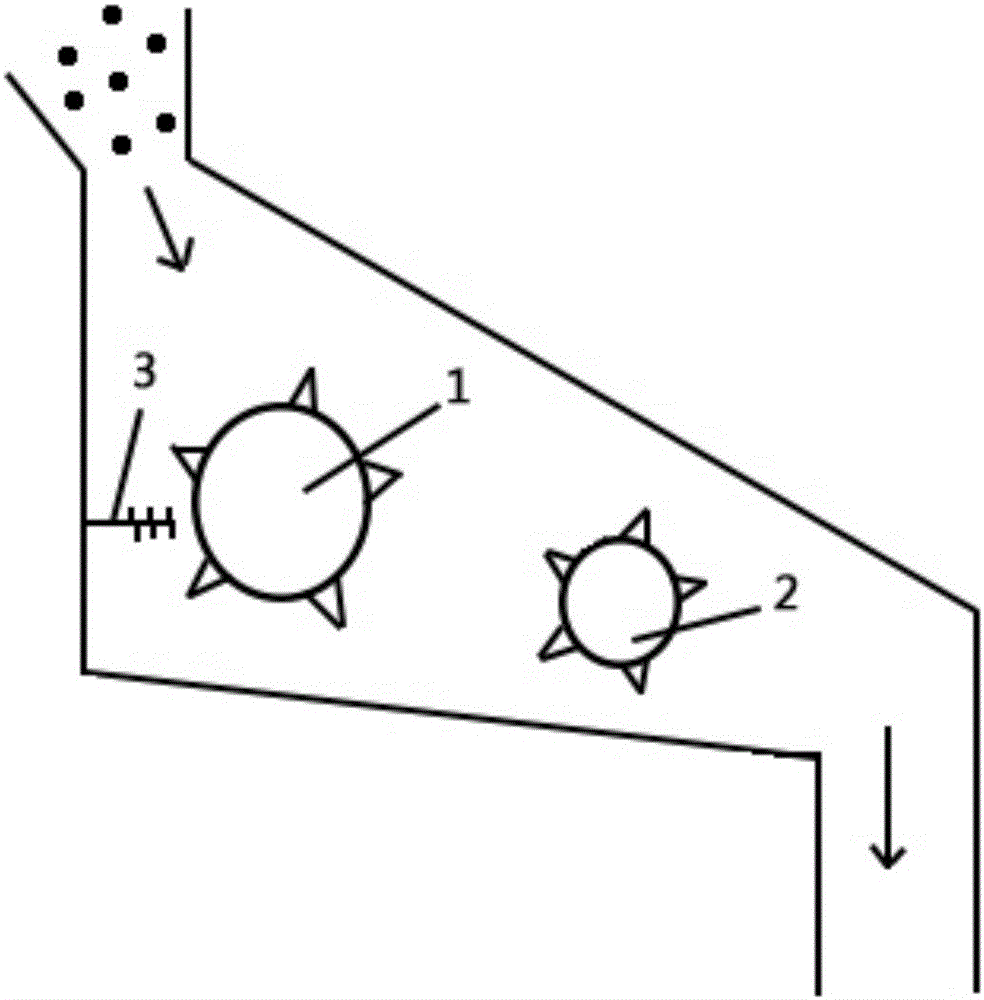

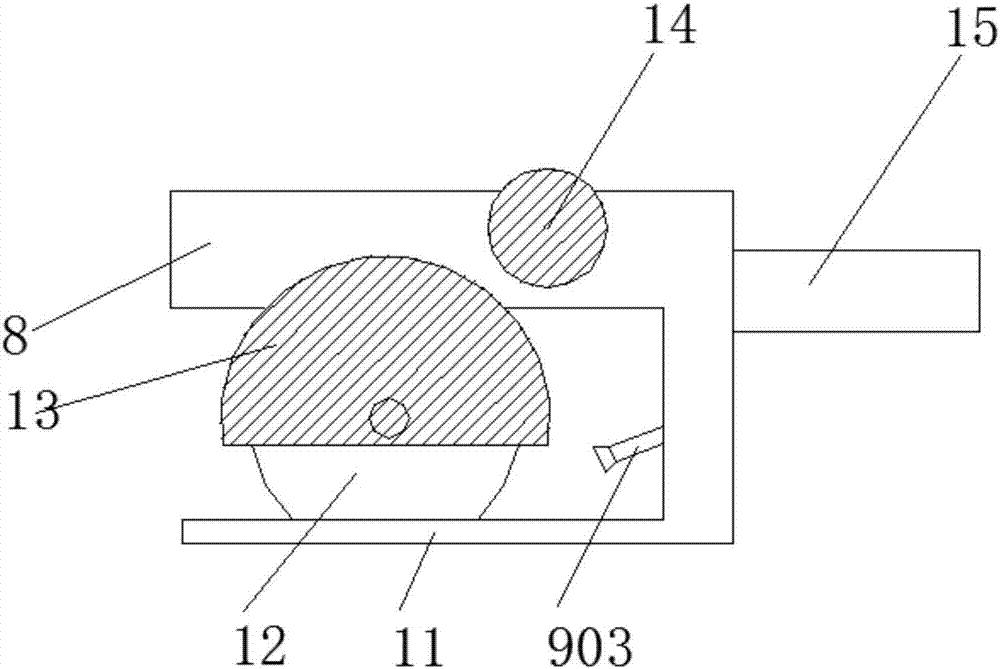

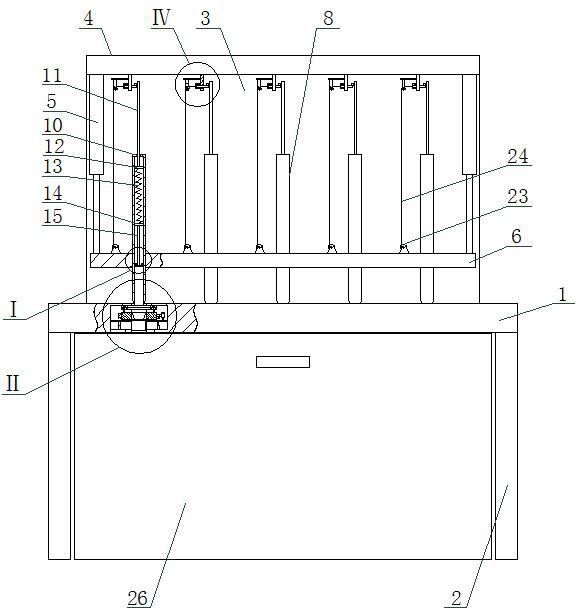

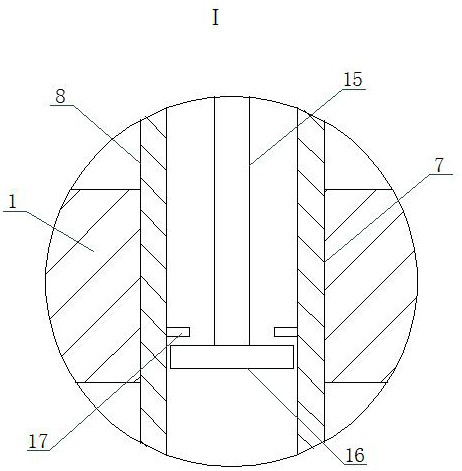

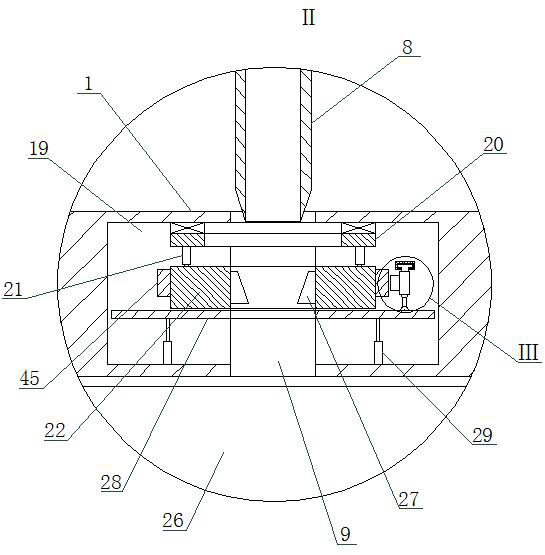

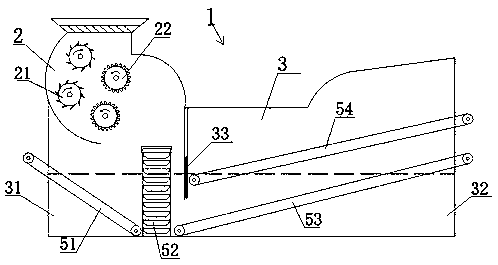

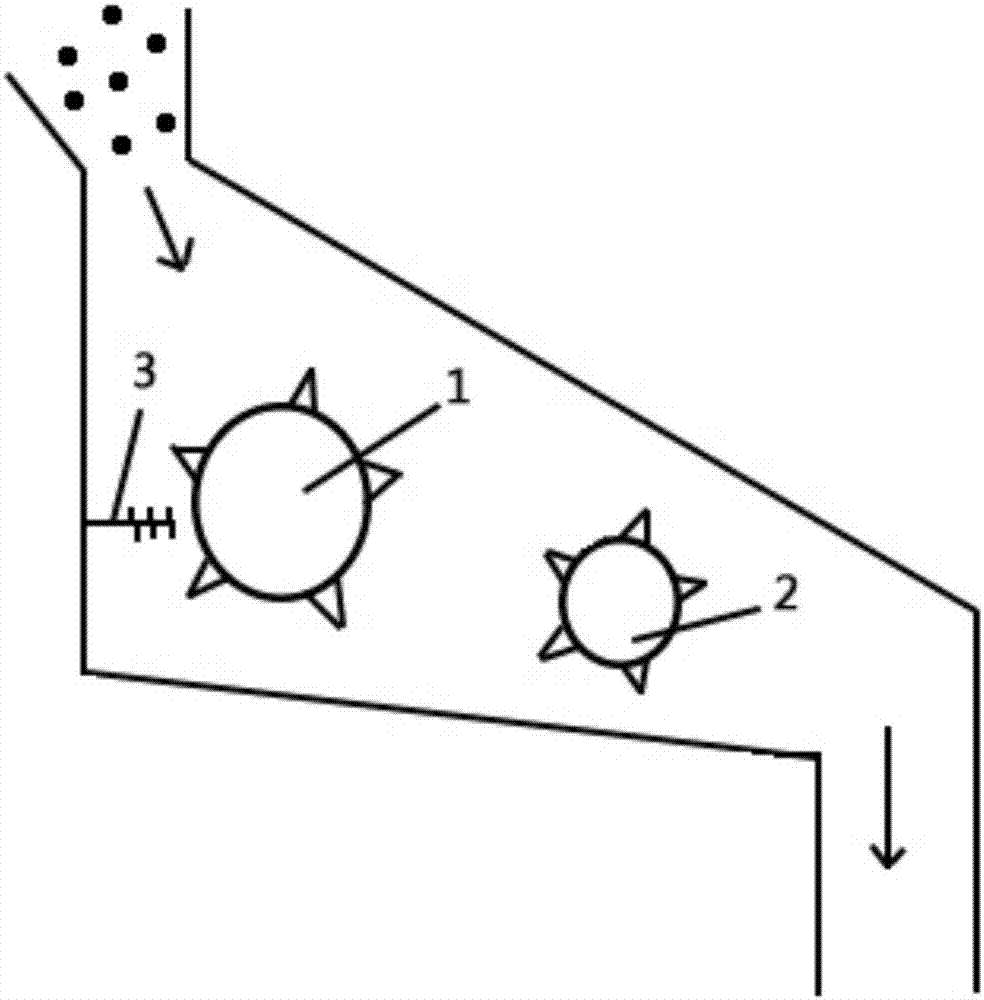

Rotary garbage crushing device

ActiveCN105833957AAvoid dullingGuaranteed smooth outputGrain treatmentsEngineeringMechanical engineering

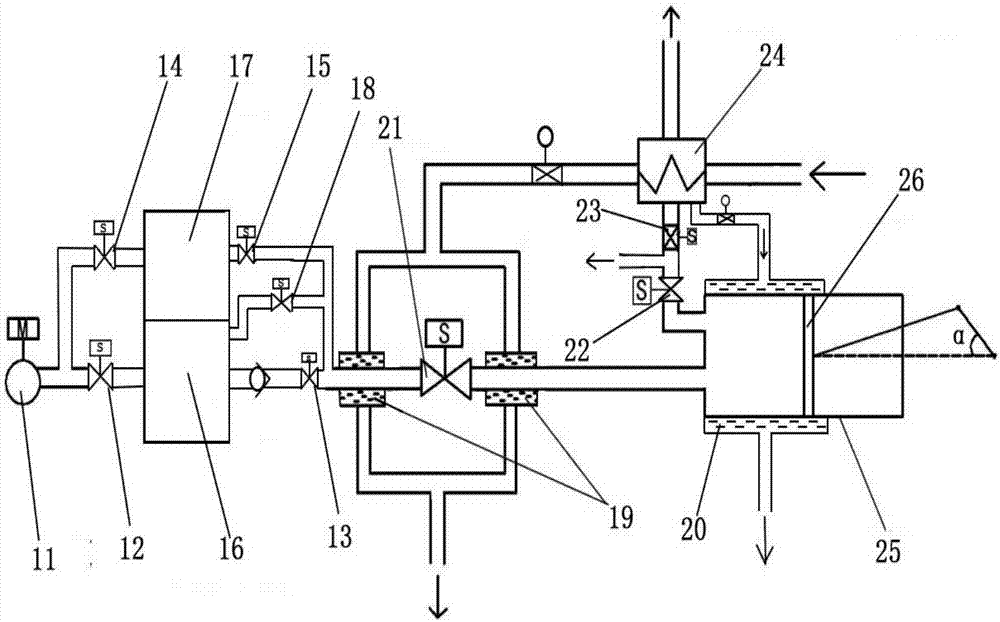

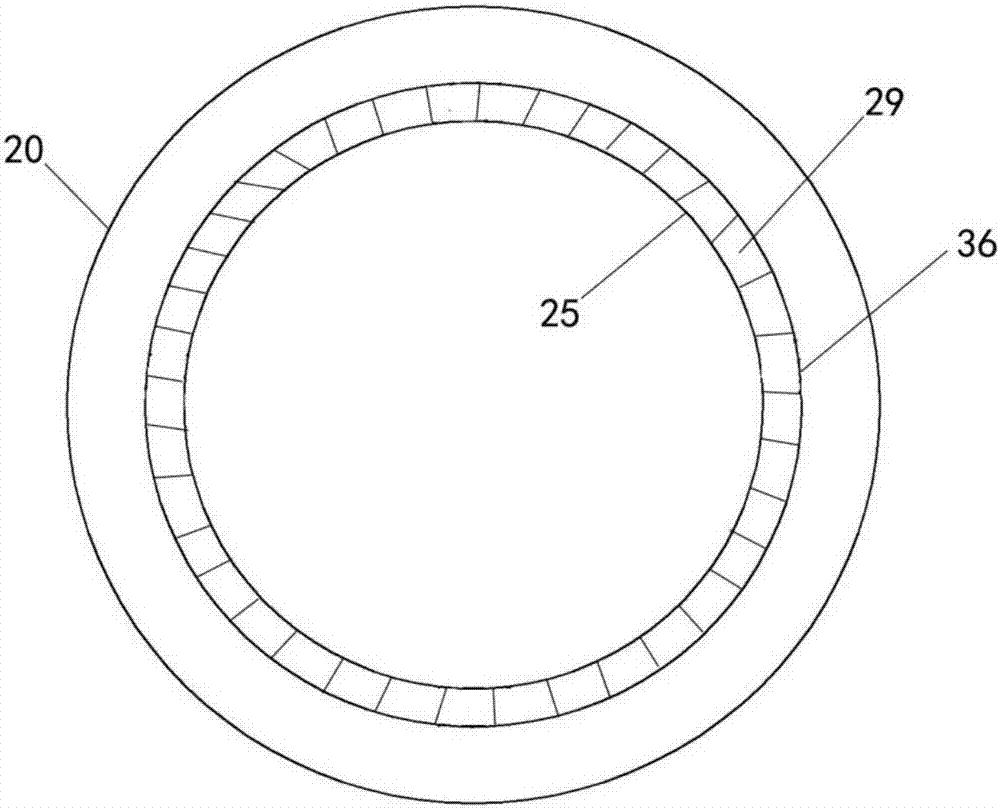

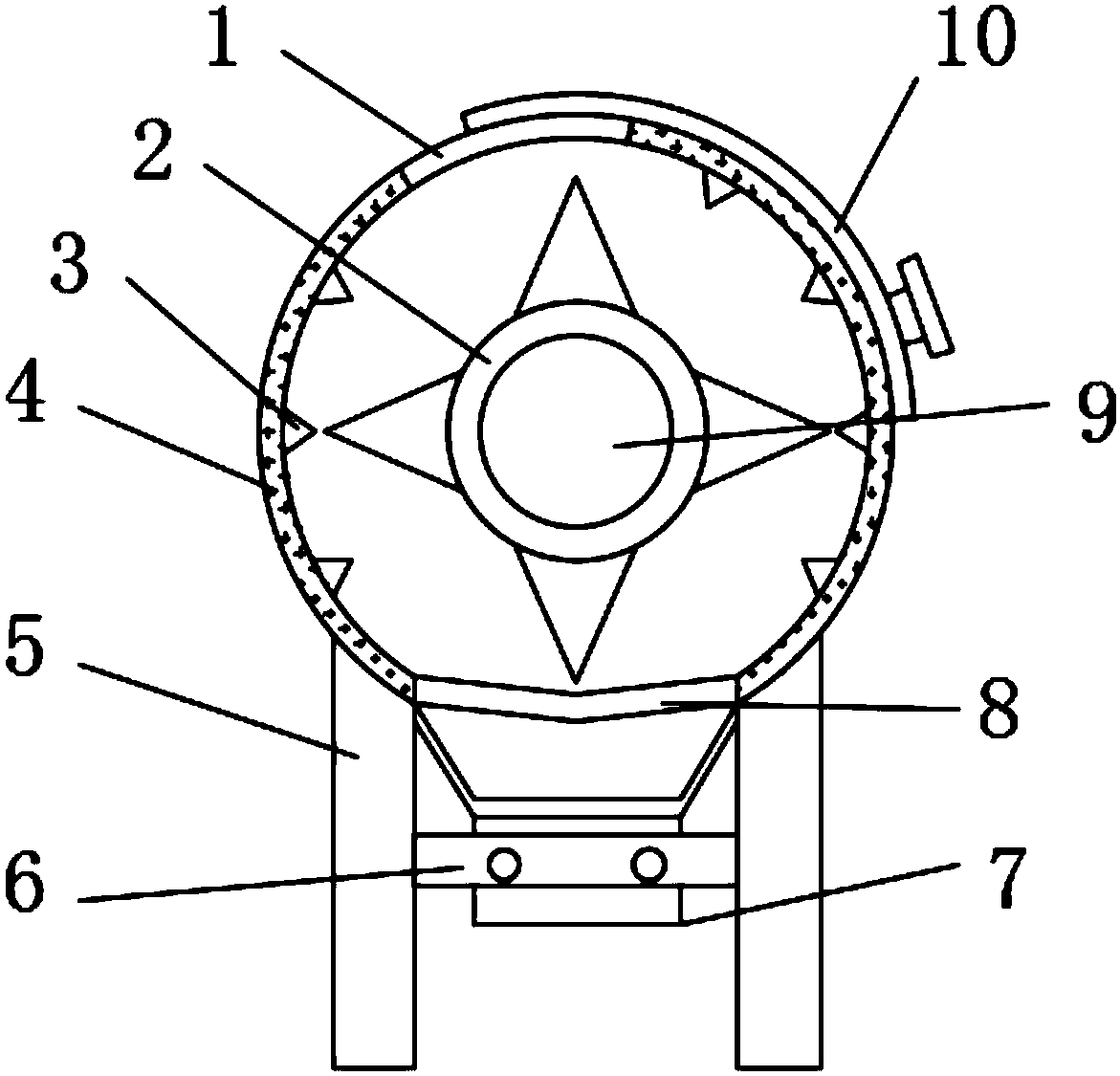

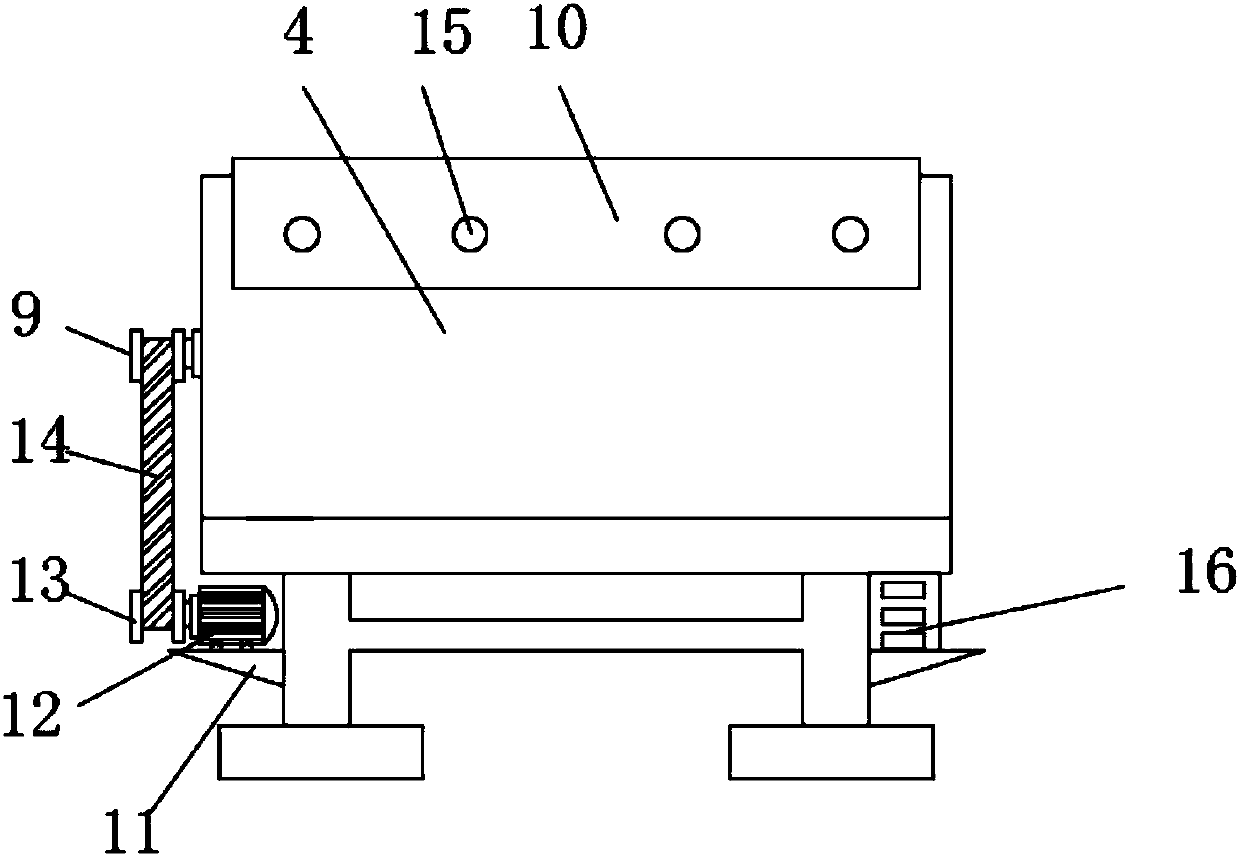

The invention discloses a rotary garbage crushing device, including a first five-knife roller, a second five-knife roller, a soft brush, a shell and an engine system. The garbage crushing device can conduct on-line clearance of flexible materials on the hob through the soft brush, and keep the hob sharp; while a pneumatic engine replaces a traditional motor to drive the roller. The device has the advantages of large output torque, high adjustability and no pollution.

Owner:泰兴市城东绿化工程有限公司

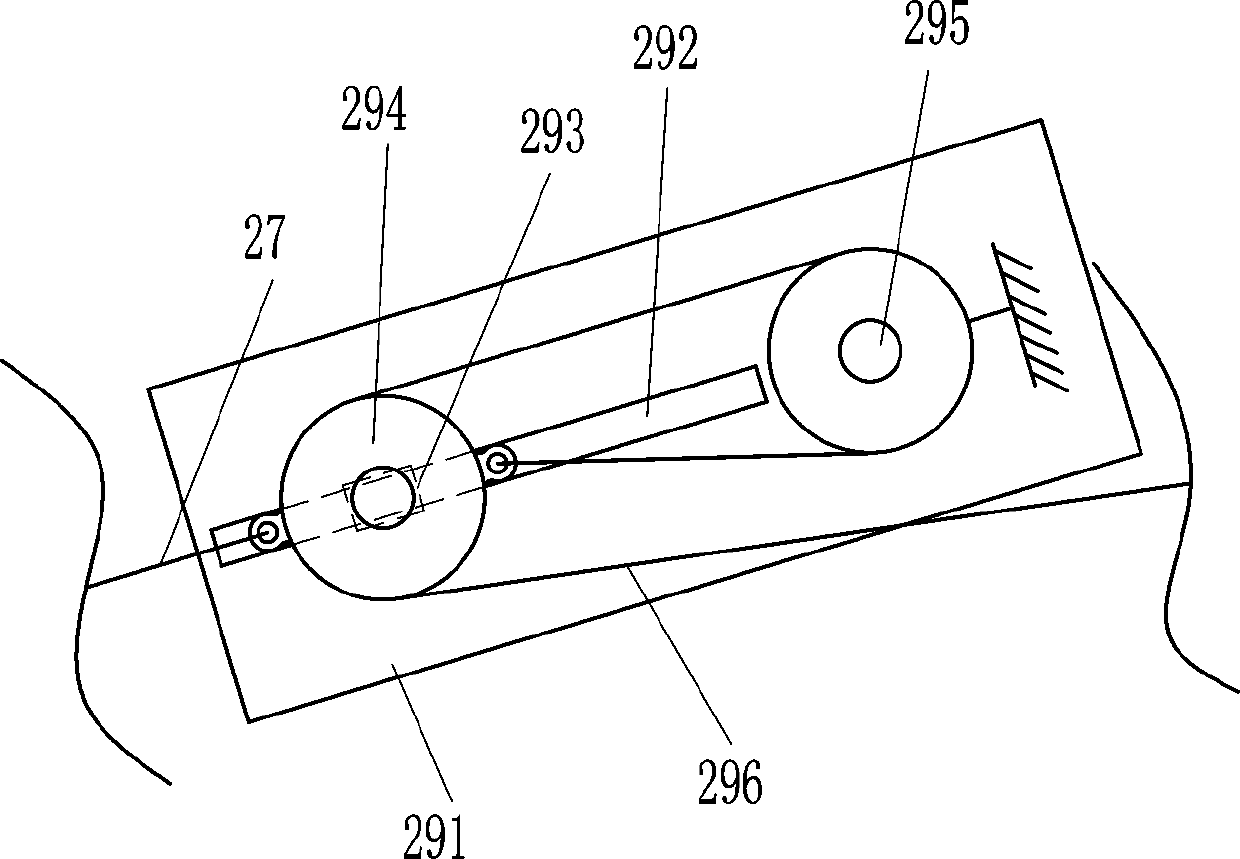

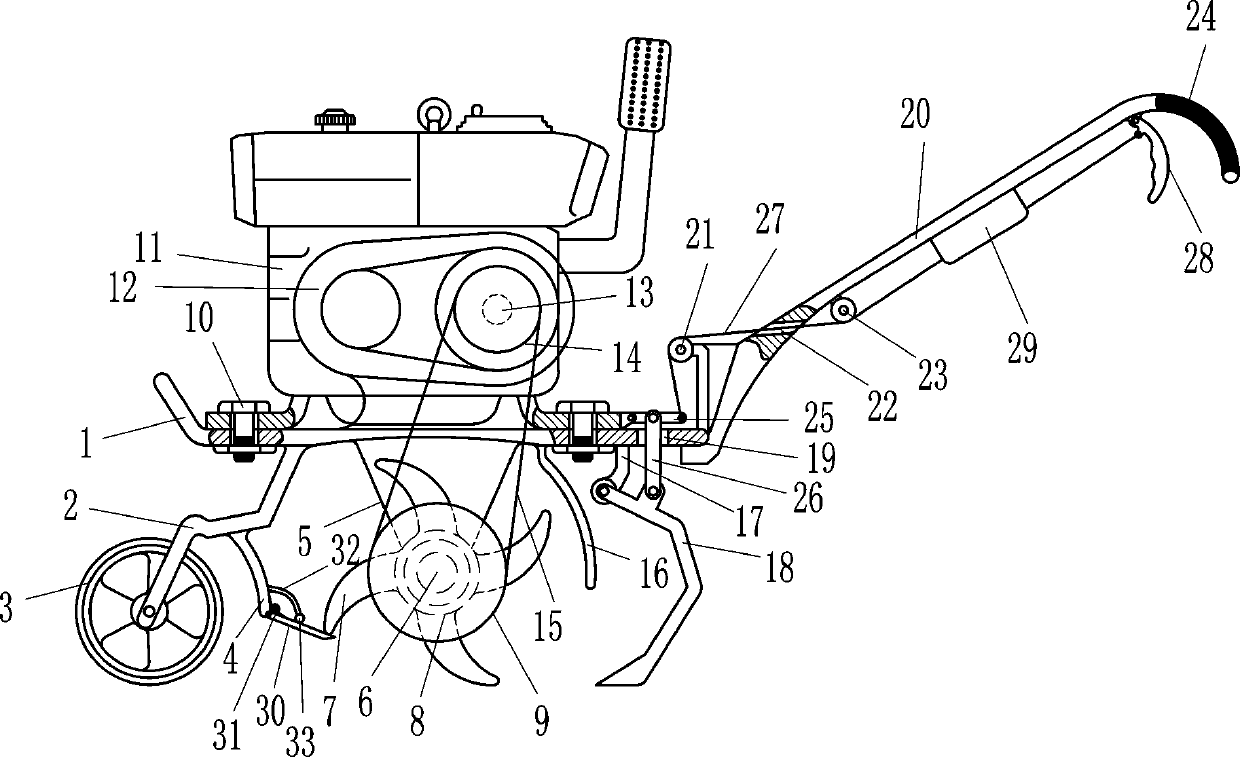

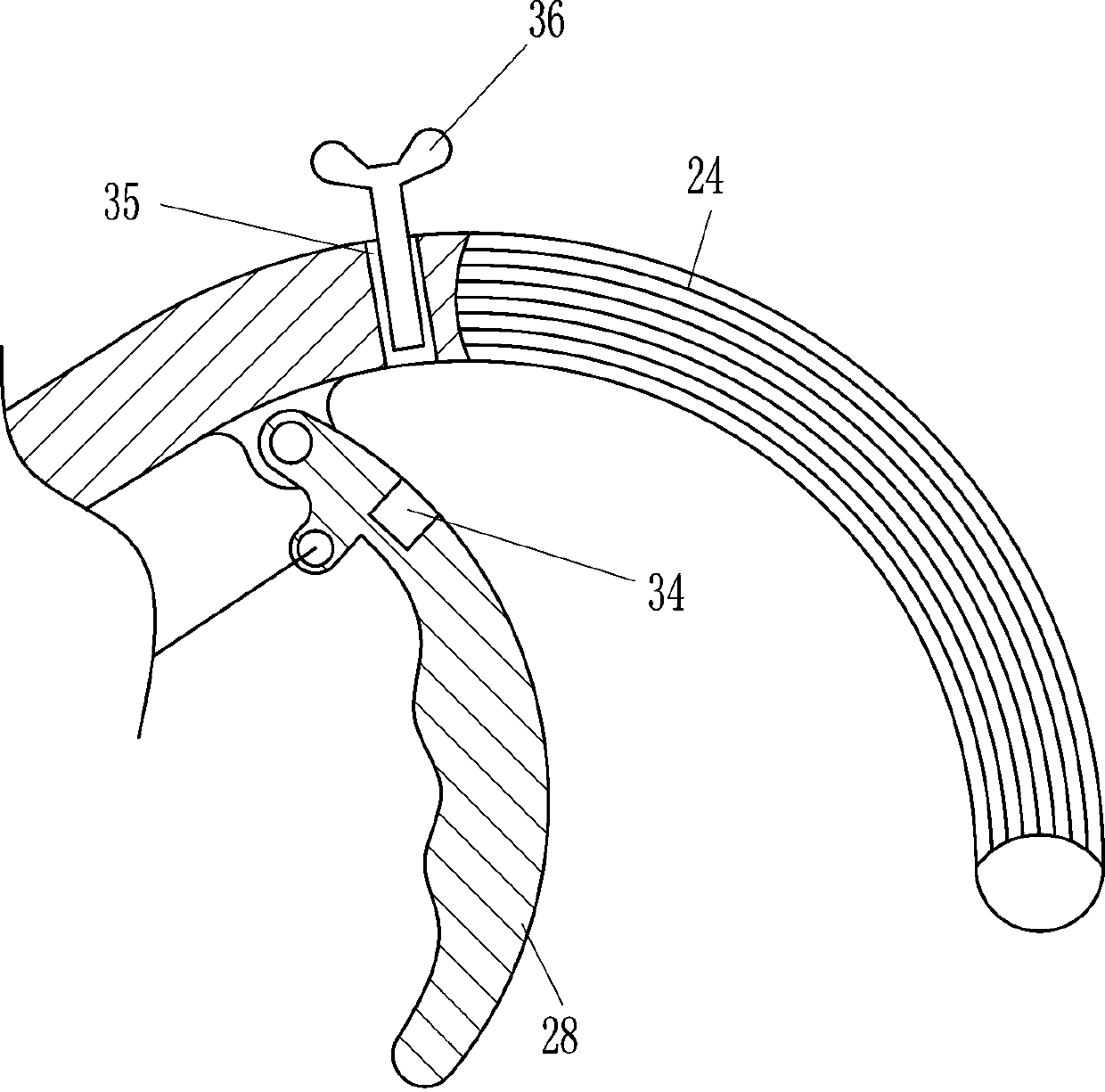

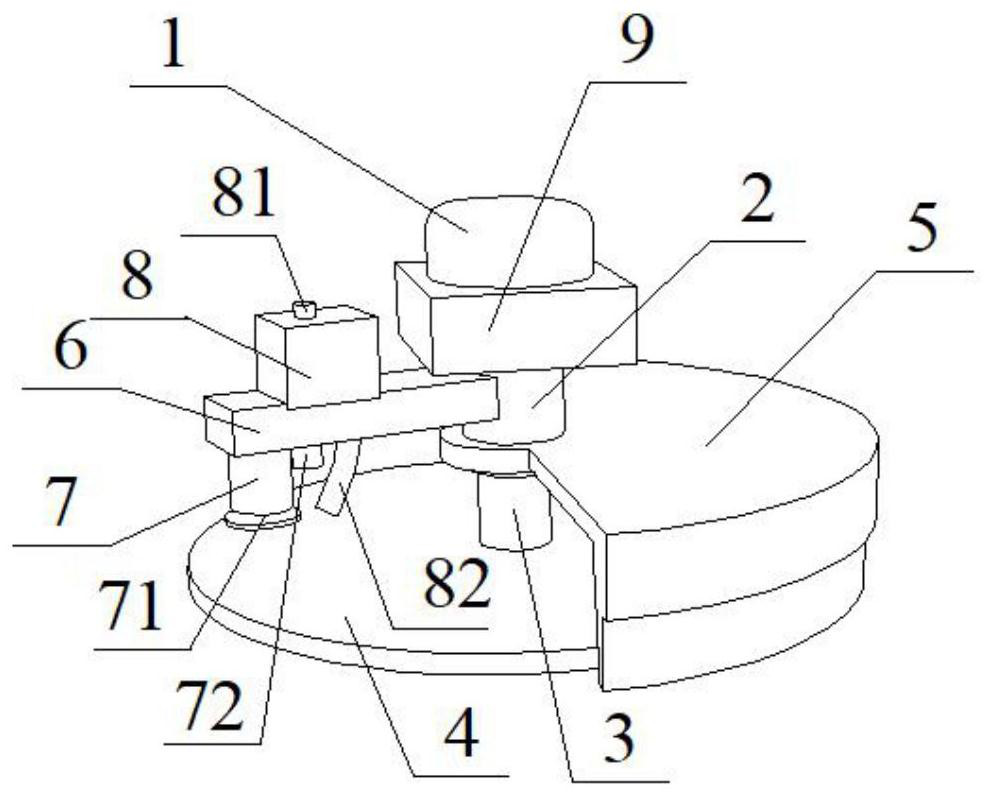

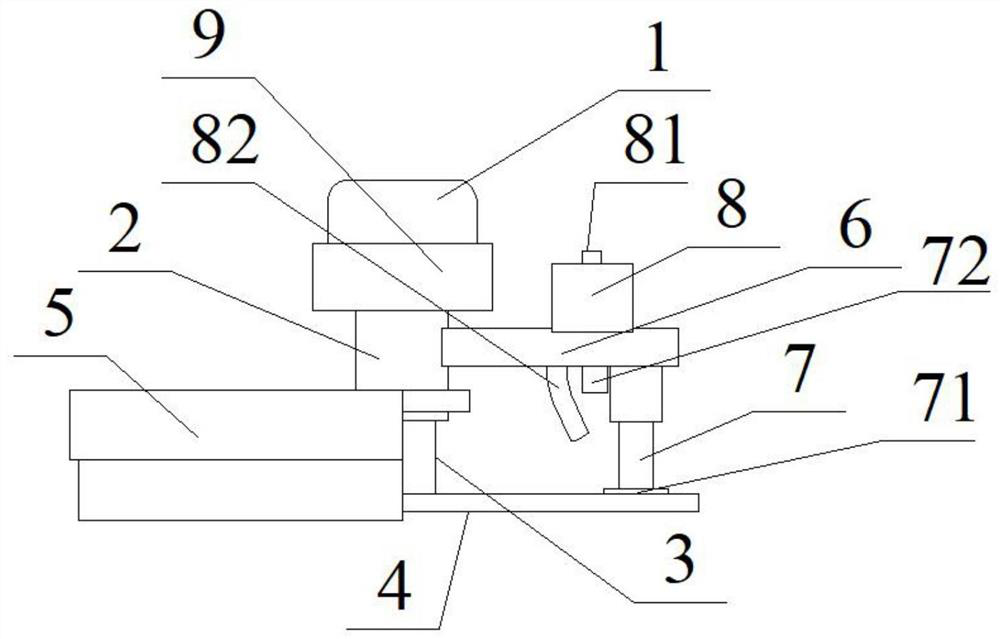

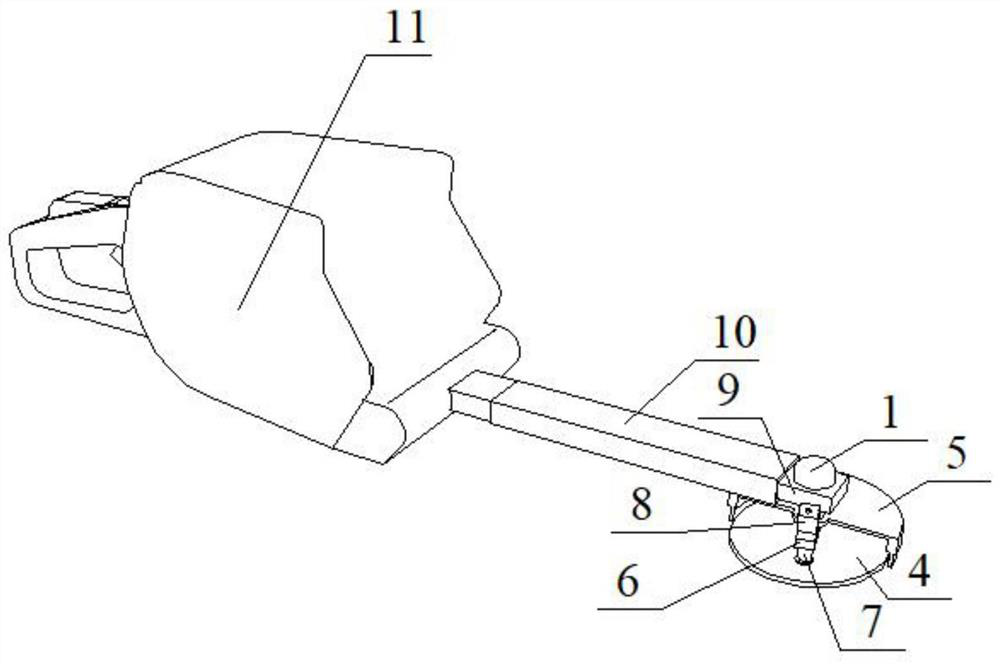

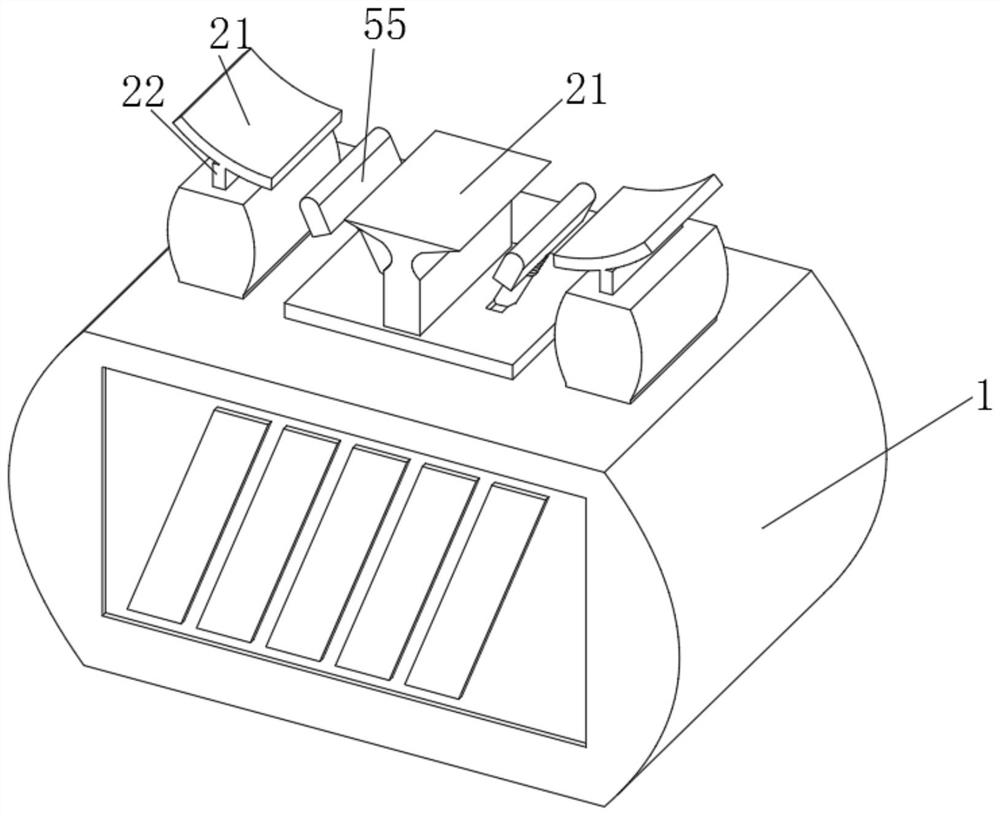

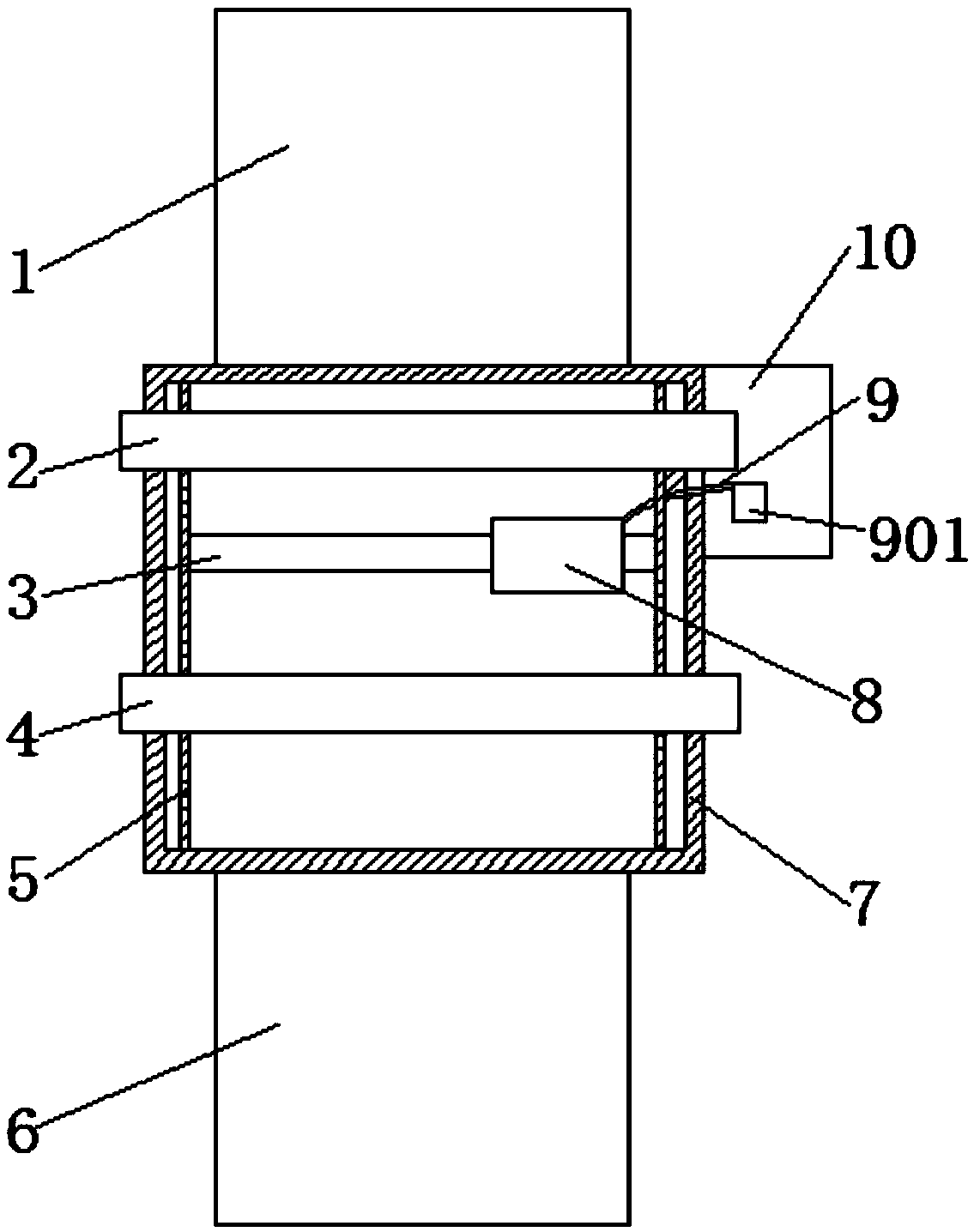

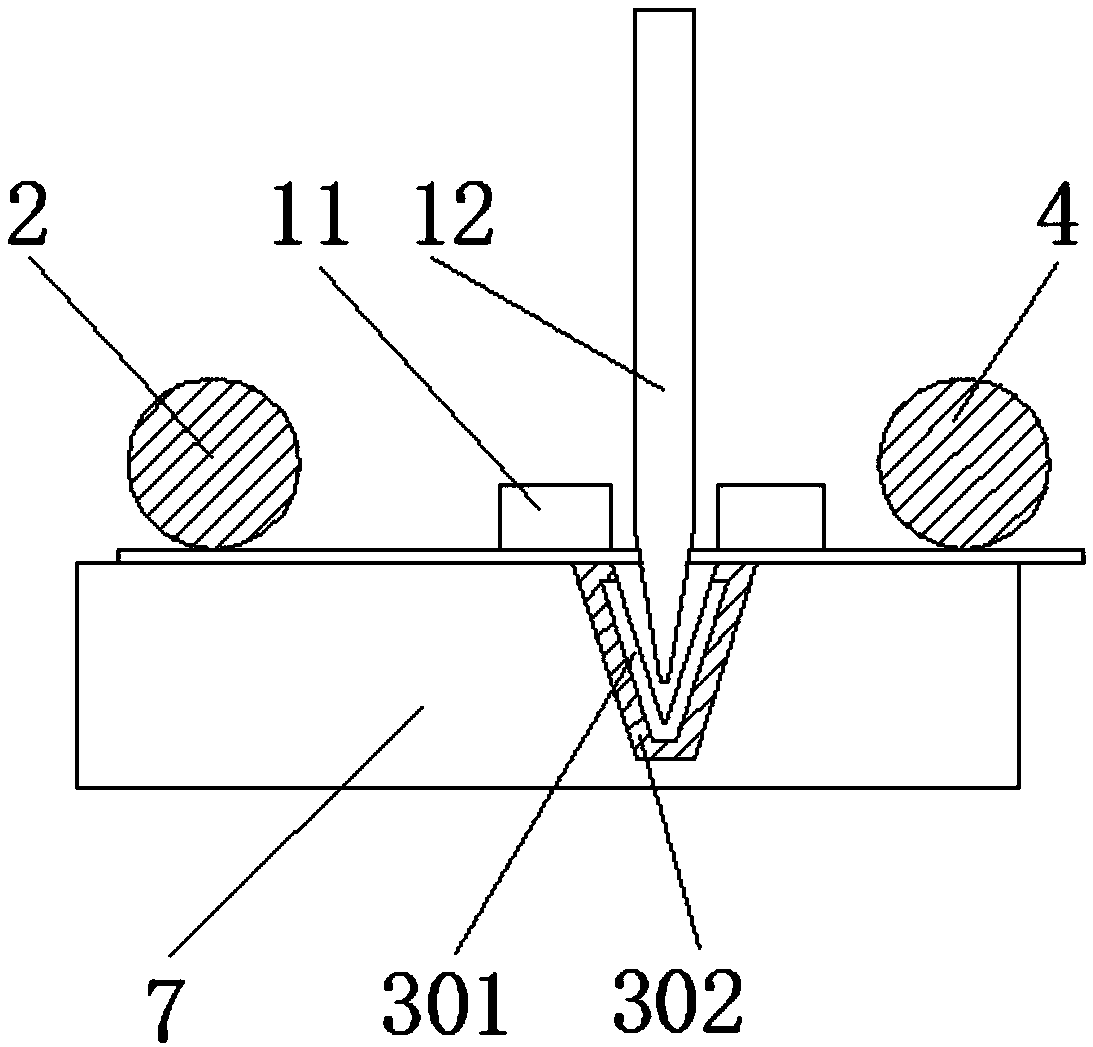

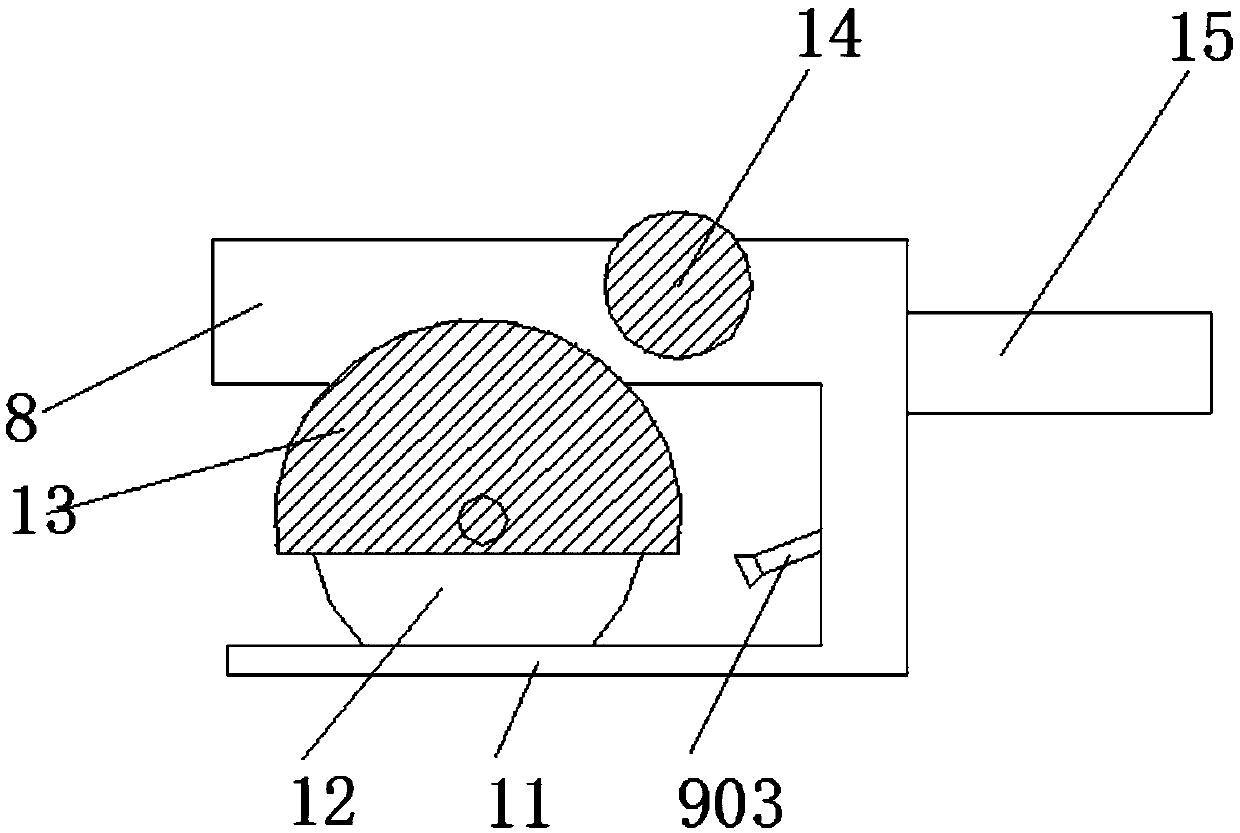

Park soil loosening device

The invention relates to a soil loosening device, in particular to a park soil loosening device. The park soil loosening device achieves the technical purposes that labor force is automatically savedin the soil ploughing process, and the working efficiency is high. According to the technical scheme, the park soil loosening device comprises an installing plate, a first connecting rod, wheels, a front fender, bearing pedestals, a rotating shaft, a scraper knife, a cylinder, a large belt pulley, a fastening bolt, a diesel engine, a speed reducer and the like; the first connecting rod is arrangedat the left side of the bottom of the installing plate, the wheels are rotationally arranged at the lower end of the first connecting rod, the front fender is arranged at the middle of the right sideof the first connecting rod, and the front and rear parts of the middle of the bottom of the installing plate are each provided with one bearing pedestal. By arranging the wheels, the device is moreconvenient to move; by arranging a labor saving device, people can save more labor when soil is loosened; by arranging a diesel engine and a speed reducer, the soil loosening process is automatic; byarranging a swing plate, soil on the scraper knife can be removed, the service life of the scraper knife is prolonged, and the scraper knife is prevented from being blunted.

Owner:李金香

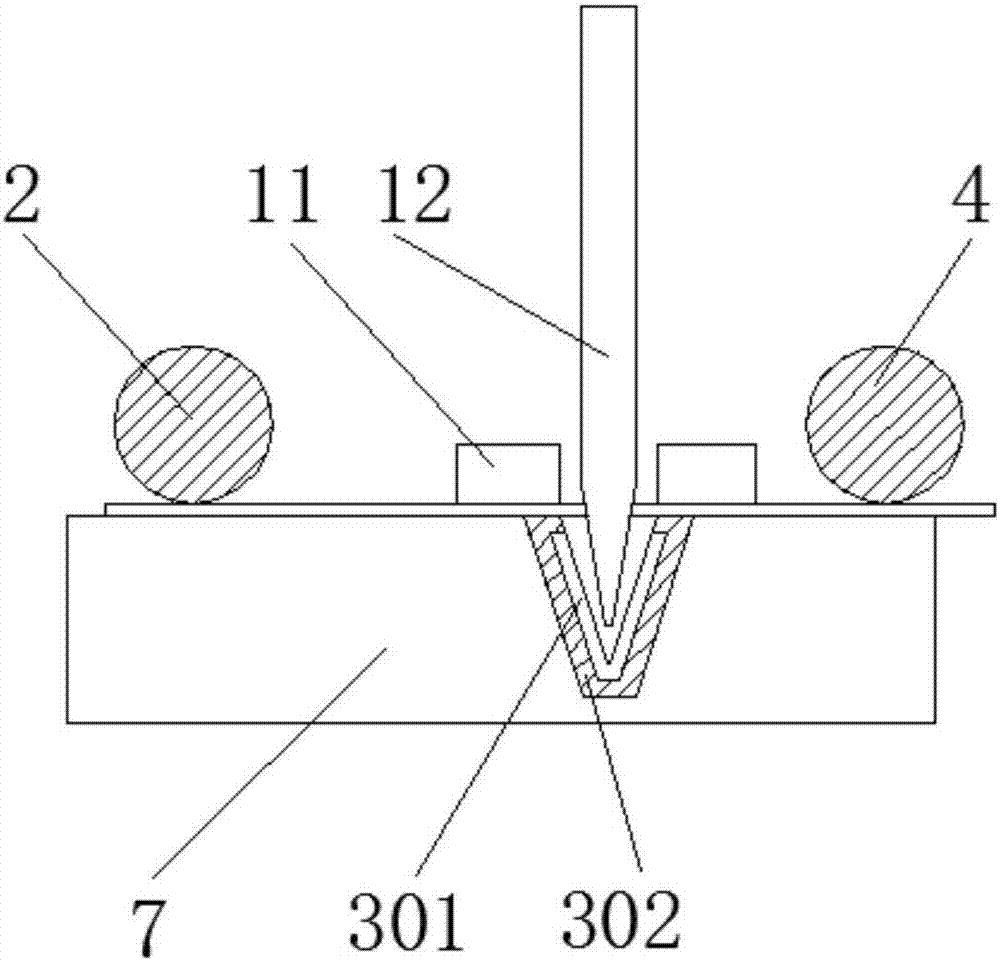

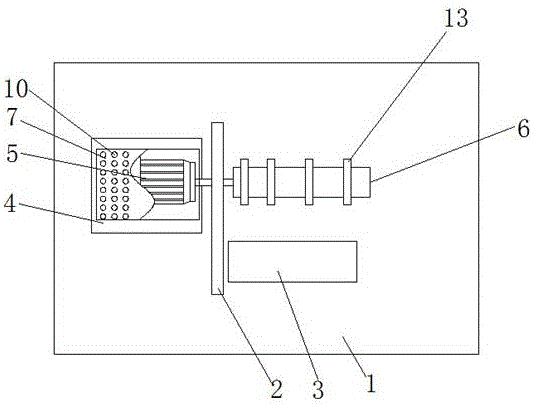

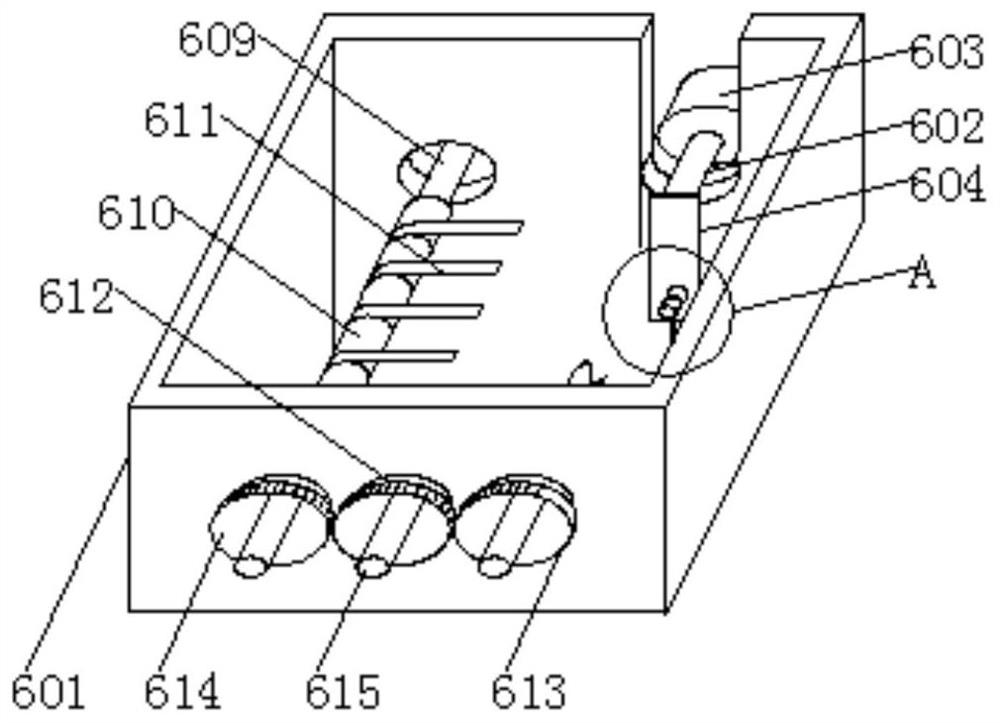

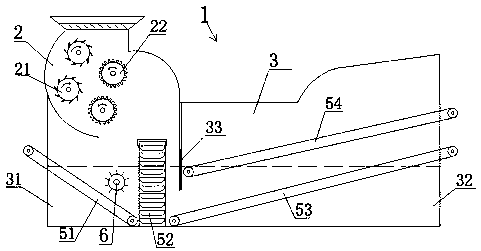

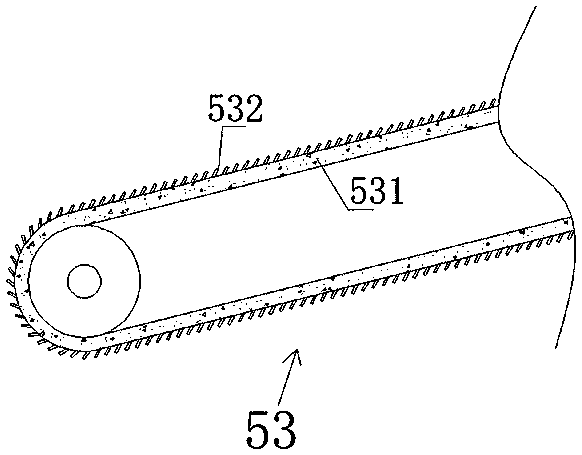

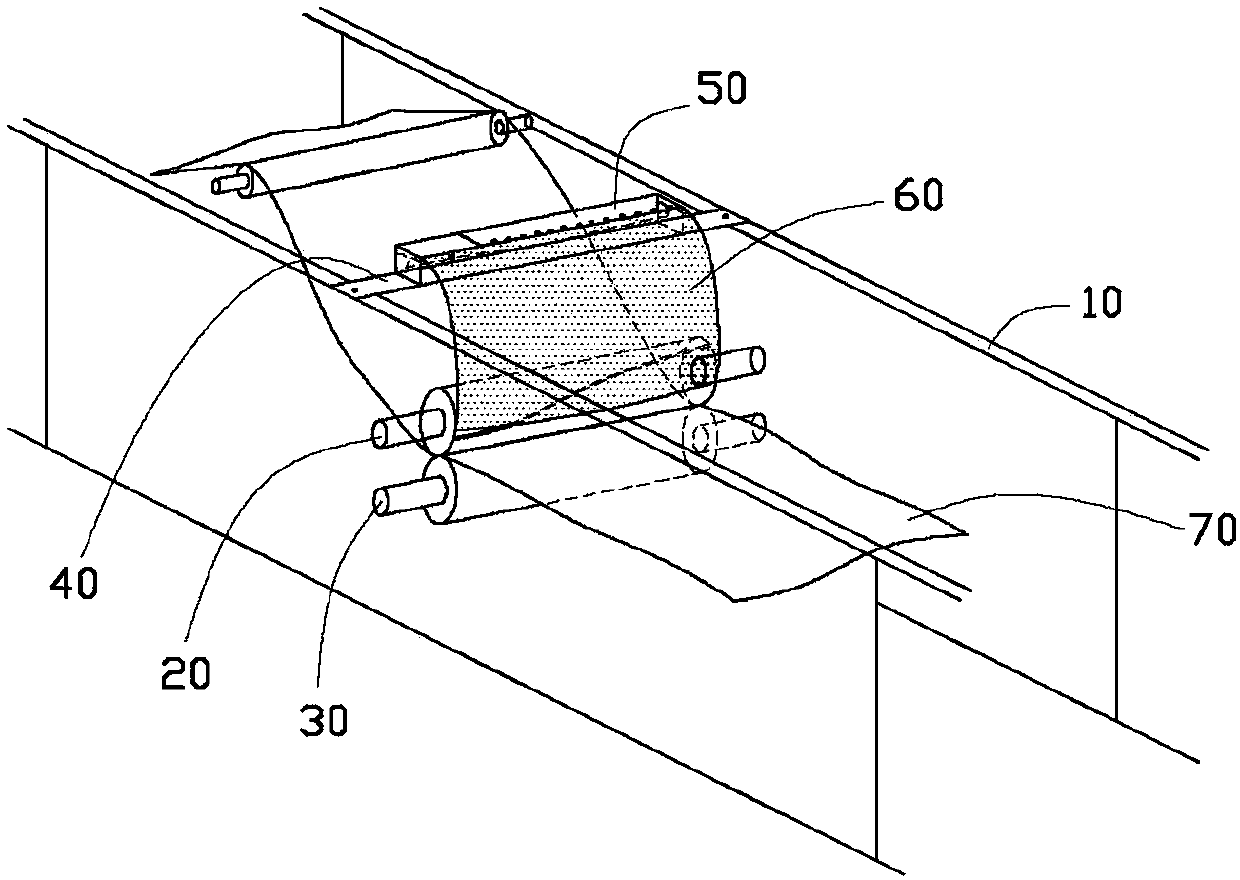

Novel high-precision cloth cutting machine for preventing cloth from moving

ActiveCN107500008AAvoid dullingAvoid sticking to each otherArticle deliveryWebs handlingEngineeringControl switch

The invention discloses a novel high-precision cloth cutting machine for preventing cloth from moving. The novel high-precision cloth cutting machine comprises a feeding conveying belt, a front pressurizing roller, a cutting sliding rail, limiting blocking plates, a discharging conveying belt, a rack, a spray device, a cutting cutter blade, insulation balance iron, a control switch and an electromotor. The cutting sliding rail is arranged on the upper surface of a cutting platform and located between the front pressurizing roller and a back pressurizing roller. The limiting blocking plates are located on the two sides of the cutting platform. The insulation balance iron is located on the left side of the rack. The control switch is located at the tail end of the rack. The electromotor is located on the right side of the rack and connected with the cutting cutter blade. According to the novel high-precision cloth cutting machine for preventing the cloth from moving, the cutting sliding rail is arranged, the cutting sliding rail comprises a cutter grinding device and a sliding rail groove, arranging of the cutter grinding device can grind the cutting cutter blade while the cutting cutter cuts the cloth, and the fact that a cutter edge is blunt, and the cloth can not be effectively and fast cut due to the fact that the cutting cutter blade is not ground for a long time is prevented.

Owner:江苏优恩服饰辅料有限公司

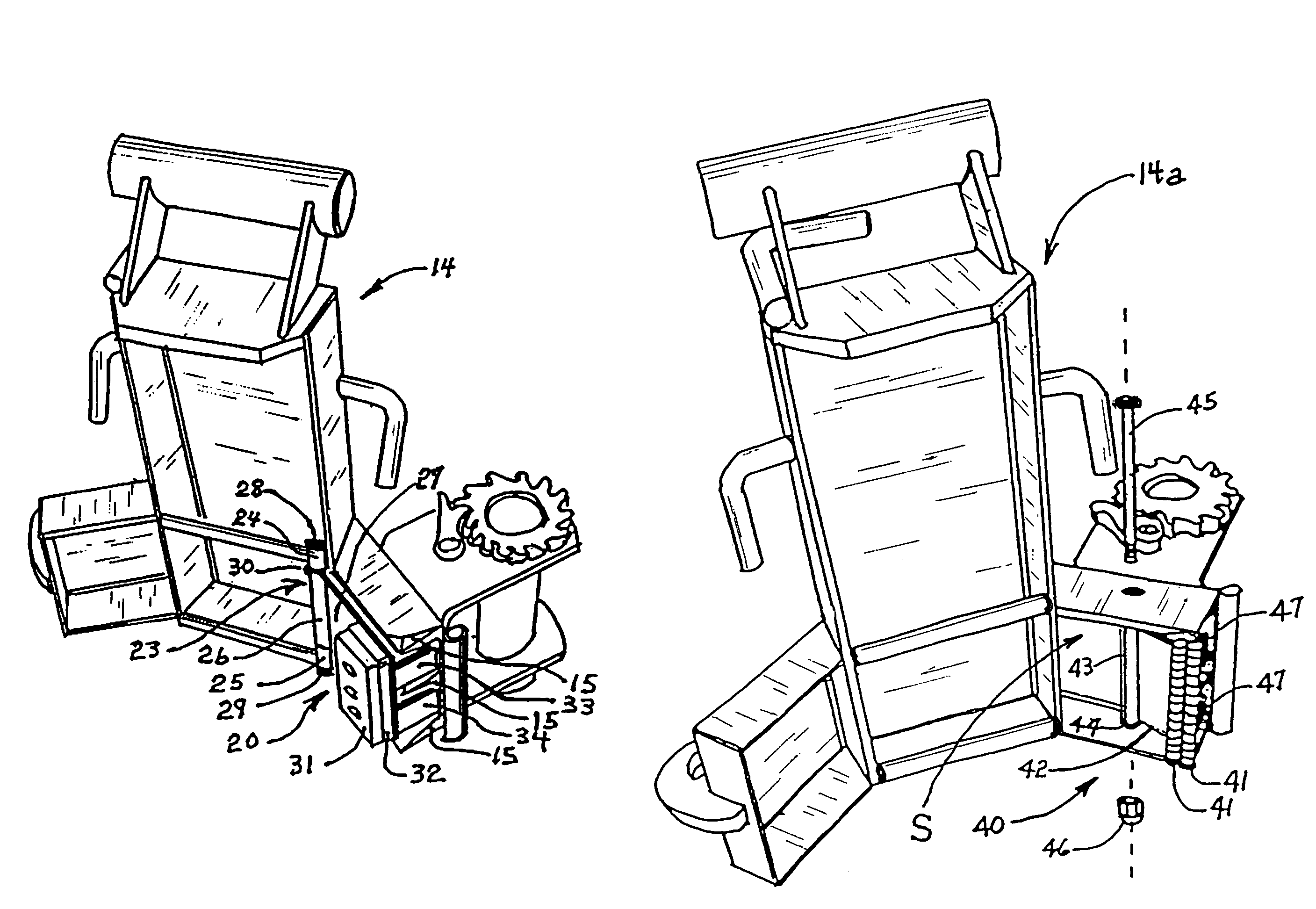

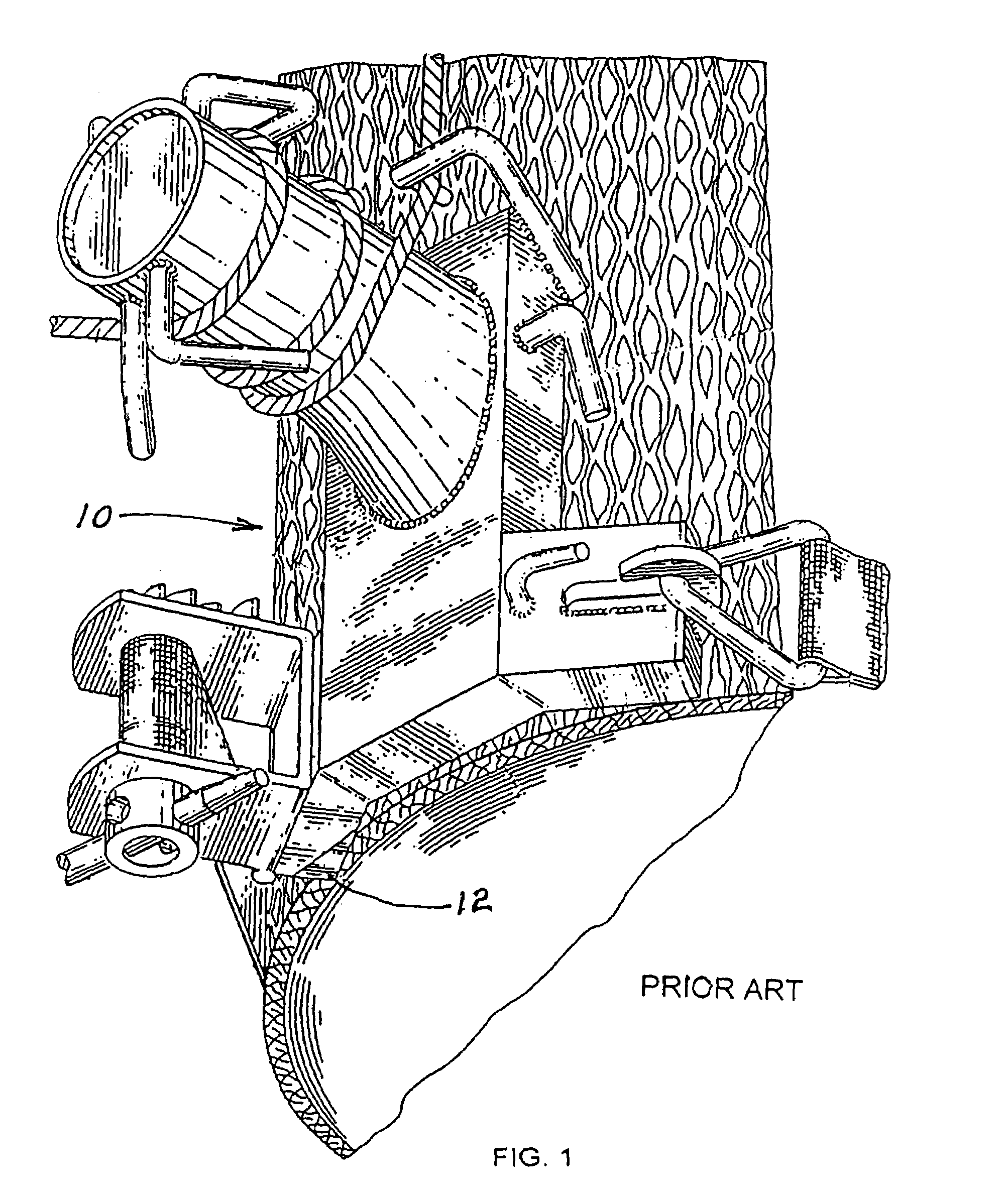

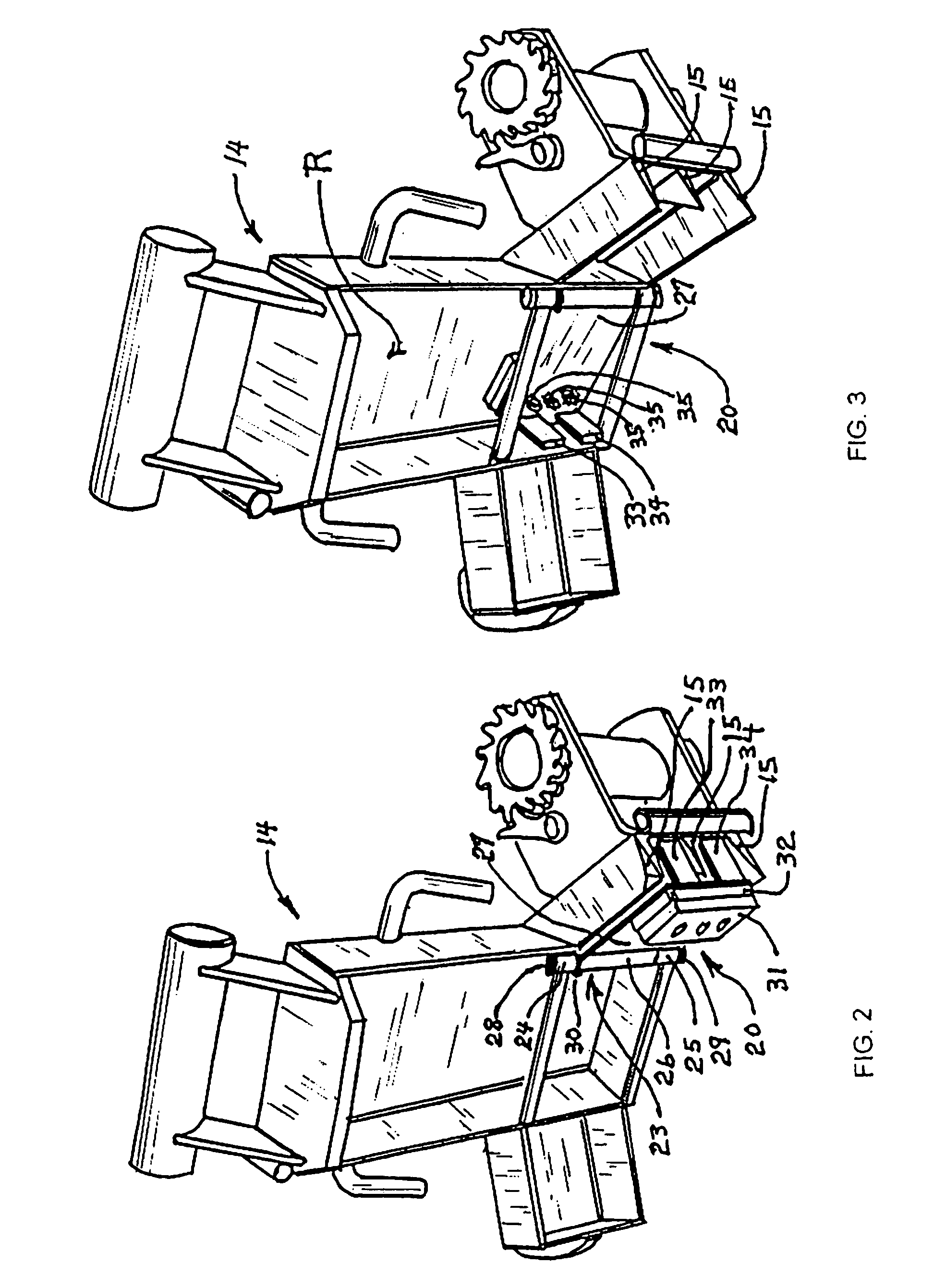

Flip-out function converter for tree-mounted frame apparatus used in arbor rigging procedures

InactiveUS7556068B1Increase the number ofImprove efficiencyMulti-purpose machinesForestryEngineeringLiving tree

A flip-out function converter apparatus is attached to and functions in combination with a tree-mountable frame apparatus for use by arborists in handling loads in a wide variety of arbor rigging procedures. When positioned in its operational mode, the function converter apparatus enables additional functional rigging procedures to be performed which could not be effectively and efficiently performed with the original frame apparatus. When the function converter apparatus is positioned in its stowed mode in an unused recessed region of the frame apparatus, the frame apparatus can be used in its original application mode without interference from the function converter. In an embodiment of a frame apparatus with spikes, the function converter in its operational position enables the frame apparatus to be used in rigging procedures on live trees without the frame spikes producing damage to the bark and cambium layer of the live trees.

Owner:JOHNSON KENT H

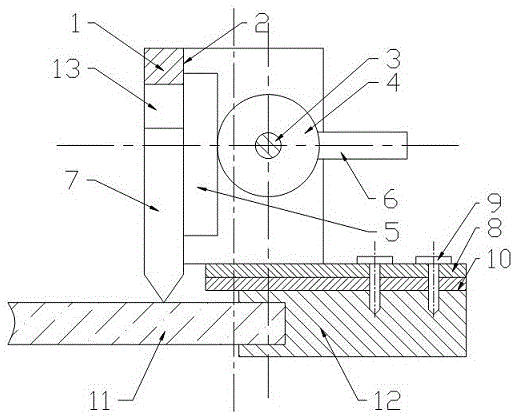

Gear rack type automotive glass crusher

InactiveCN105459942AIncrease pressureEasy to fixPedestrian/occupant safety arrangementEngineeringCrusher

The invention discloses a gear rack type automotive glass crusher. The crusher comprises a support seat in the shape of a cuboid. A guide groove is formed in the support seat in the direction parallel to the axis. A rack is connected in the guide groove in a sliding mode. A rotary shaft is fixed in the guide groove. A gear is hinged to the rotary shaft. The gear meshes with the rack. A push handle is fixed to the gear in the direction perpendicular to the axis of the gear. The axis of the push handle is perpendicular to the axis of the support seat. The bottom face of the guide groove is provided with a sliding groove parallel to the axis of the support seat. The sliding groove is a through groove. A thimble is fixed to the reverse side of the rack in the direction parallel to the sliding direction of the rack. The thimble is connected in the sliding groove in a sliding mode. The top of the thimble is conical. A connection plate is fixed to the bottom face of the support seat and perpendicular to the axis of the support seat. Threaded holes are evenly distributed in the connection plate. Bolts matched with the threaded holes are arranged in the threaded holes respectively. Through the gear rack type automotive glass crusher, automotive glass is convenient to crush.

Owner:重庆天和玻璃有限公司

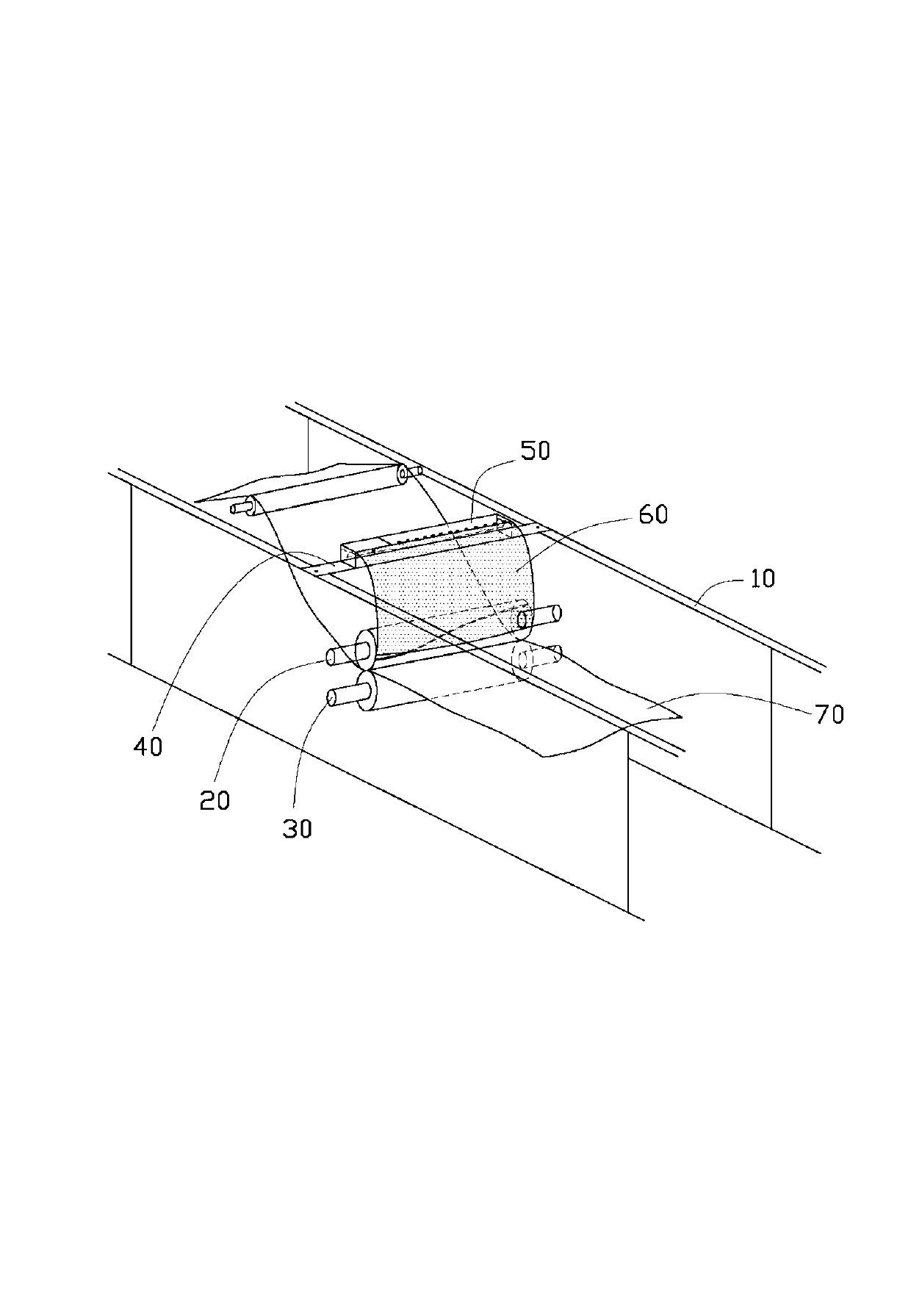

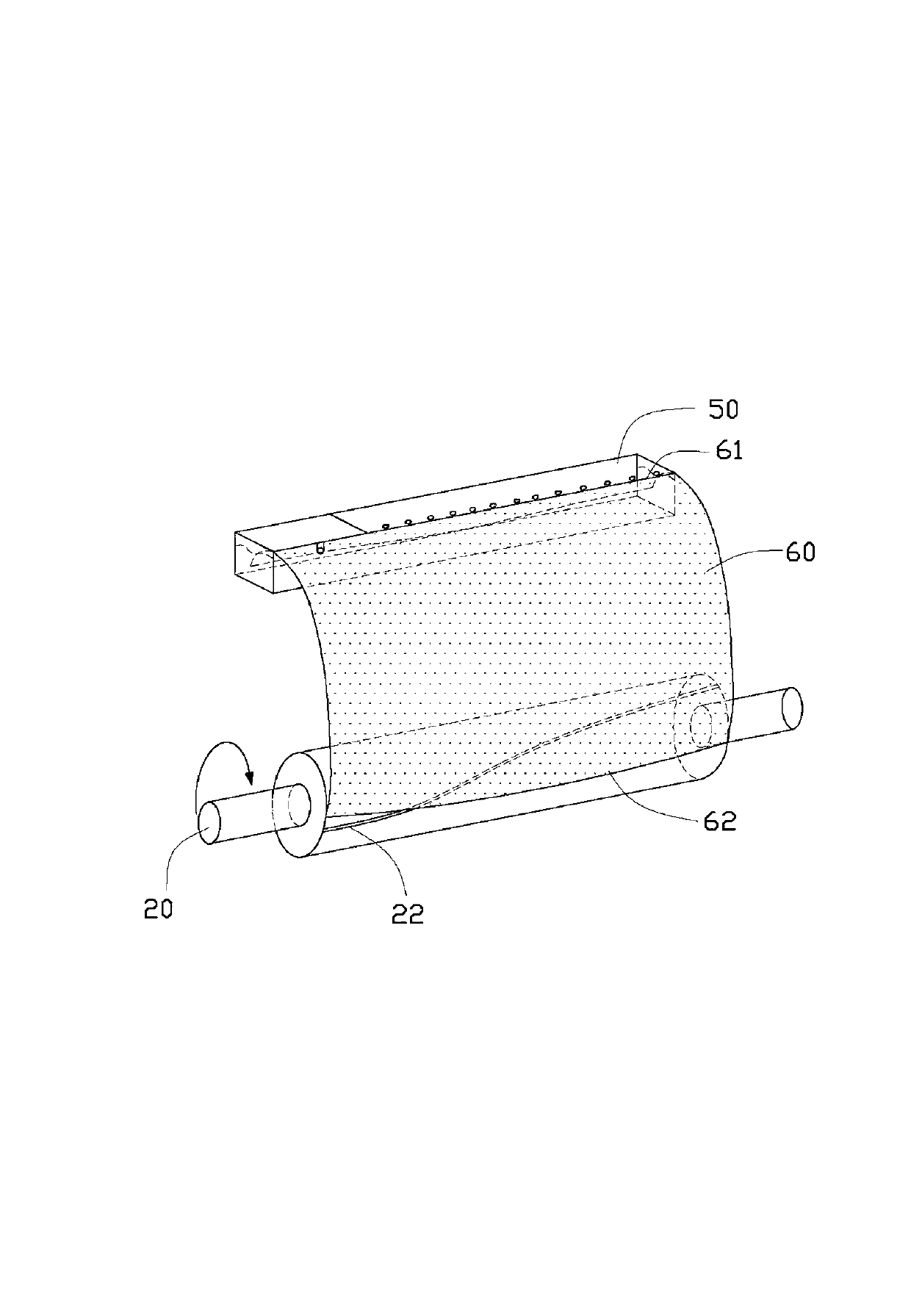

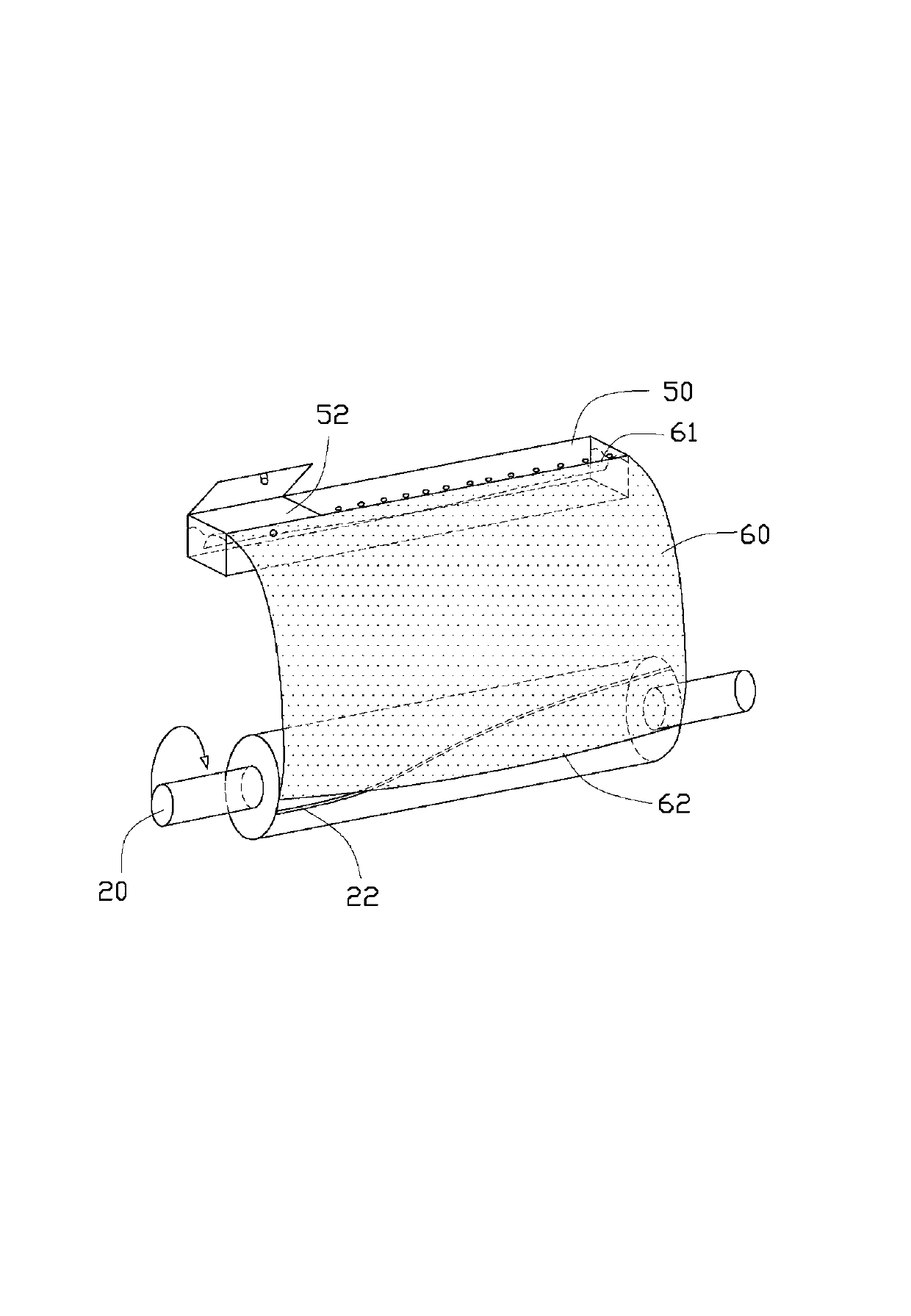

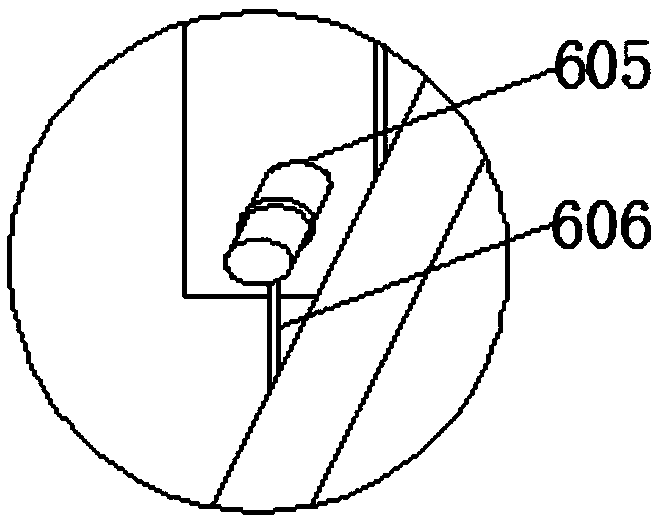

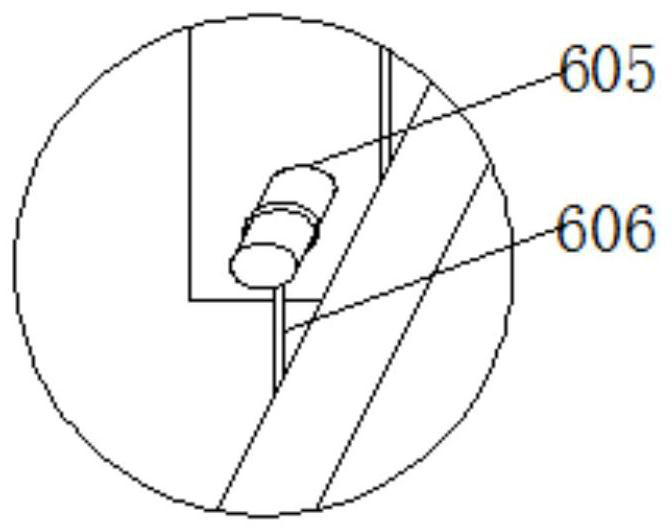

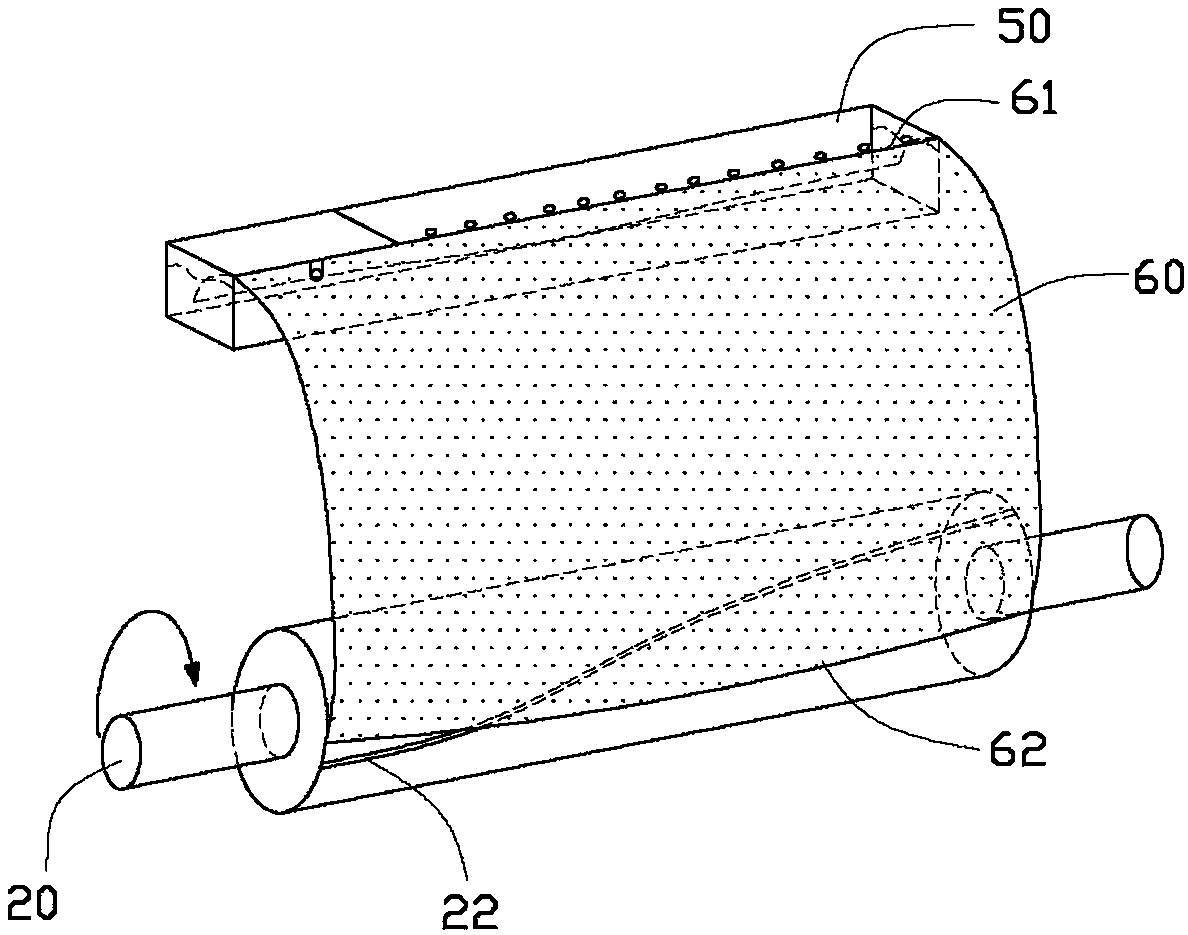

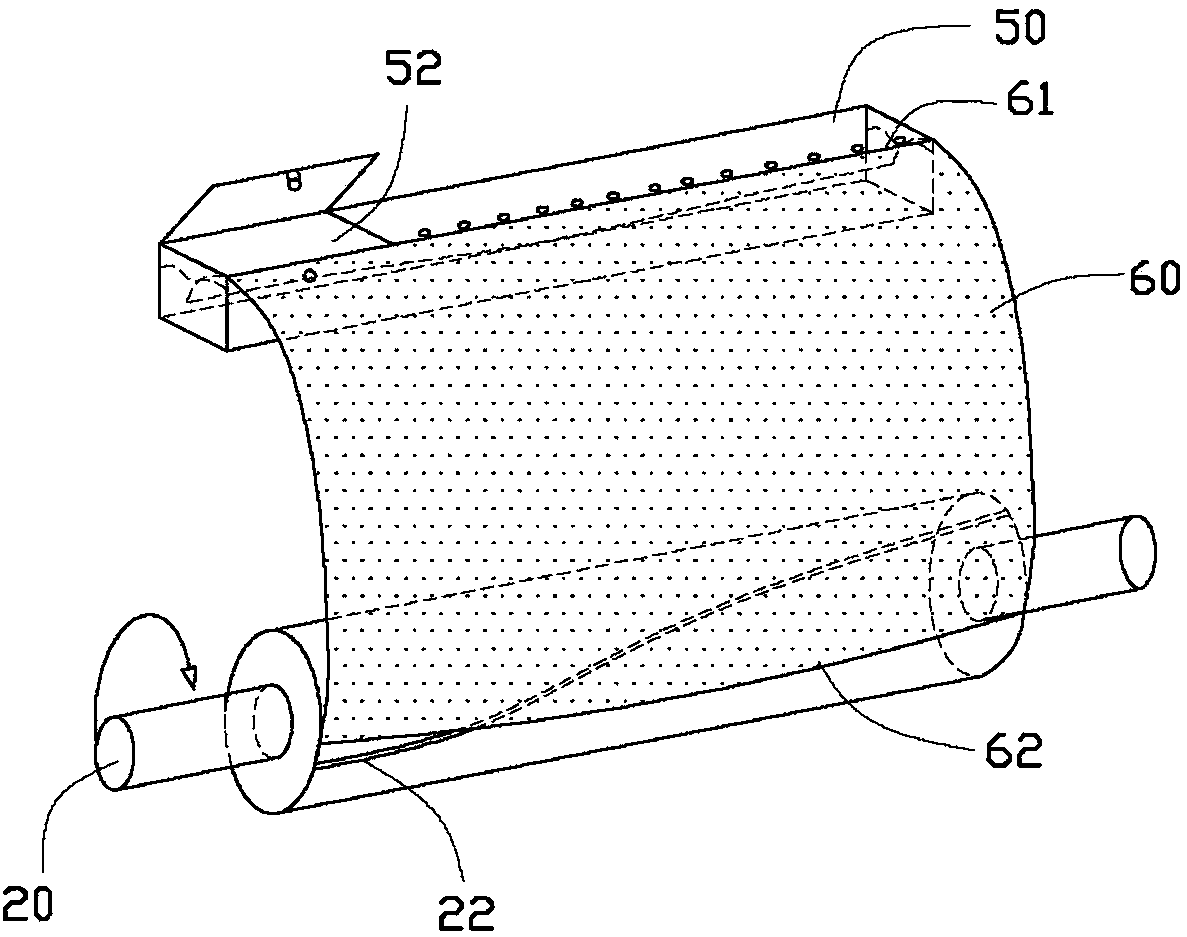

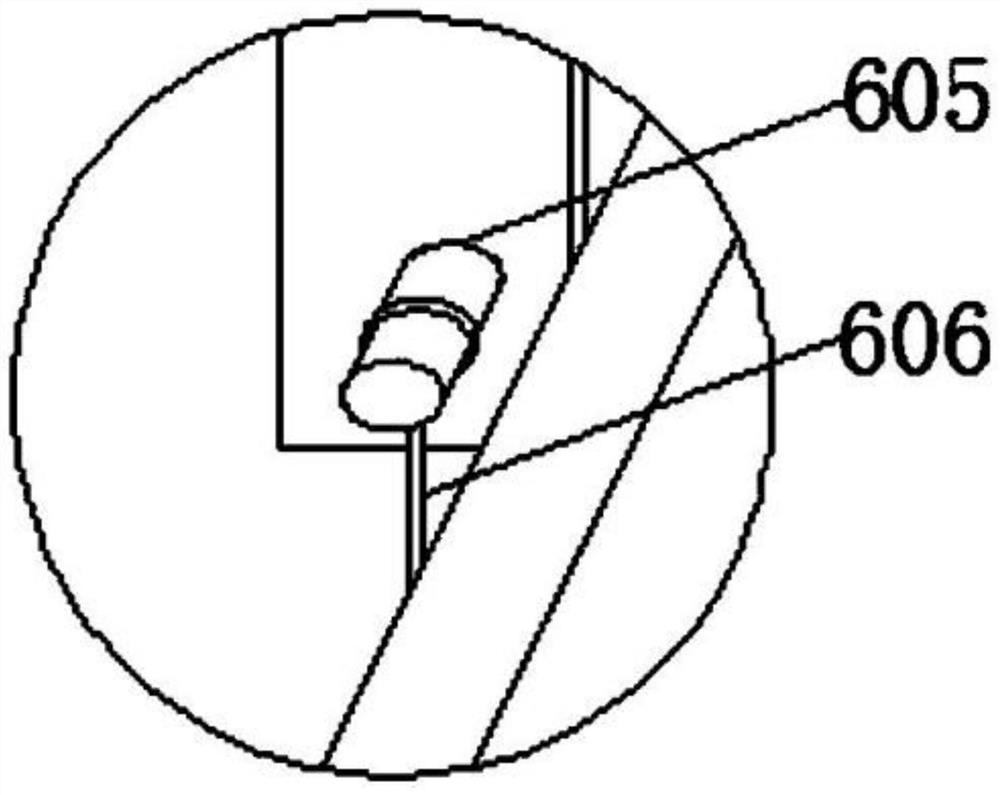

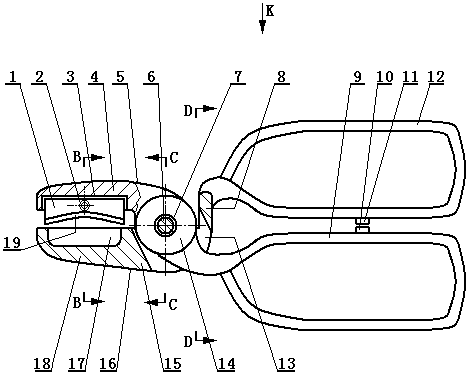

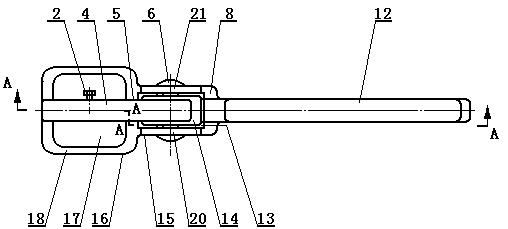

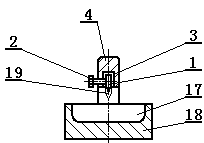

Dotted cutting device and cutting roll cleaning device thereof

A cutting roll cleaning device is used for cleaning a cutter of a cutting roll and comprises a fixing plate, an oil storage tank and a cleaner. The oil storage tank is arranged on the fixing plate, a first end of the cleaner is fixed on the fixing plate and immersed into the oil storage tank, and a second end, which is opposite to the first end, of the cleaner, extends to a roll surface of the cutting roll and is used for cleaning the cutter of the cutting roll. The invention further provides a dotted cutting device with the cutting roll cleaning device. The cutter of the cutting roll of the dotted cutting device can be cleaned on line by the cutting roll cleaning device rather than being disassembled while stopping the device, and production efficiency is guaranteed, meanwhile, dusts adhered to the cutter can be eliminated by the cleaning device, the cutter is avoided to be blunt, and dusts are prevented from falling off on a product to influence the product quality.

Owner:海南金红叶纸业有限公司 +1

Non-crimping protective film splitting and winding integrated device

InactiveCN106695927APrevents sections from dullingAvoid curlMetal working apparatusWebs handlingKnife bladesEngineering

The invention discloses a non-crimping protective film splitting and winding integrated device which comprises a base; a fixing block and a support plate are fixedly mounted at the top of the base from left to right; a splitting device is mounted the top of the base and on the side, far away from the fixing block, of the support plate; a motor is fixedly mounted at the top of the fixing block; and the output shaft of the motor passes through the support plate and is fixedly connected at one end of a rotating rod. According to the cooperation of the base, the support plate, the splitting device, the motor, the rotating rod and a rotating shaft bearing, a protective film is split and wound; and due to the cooperation of a base plate, a top plate, a buckle, a clamping rod, a cutting blade, a pressing block, a blind hole, a spring, a limiting plate, a pressing rod, a pressing plate and a limiting block, the edges of the protective film are extruded while being split. When an edge of the protective film is cut, as the protective film passes through an edge of a blade fast, the phenomenon that the protective film crimps due to friction between the blade and the cut edge is avoided.

Owner:无锡祁龙胶粘制品有限公司

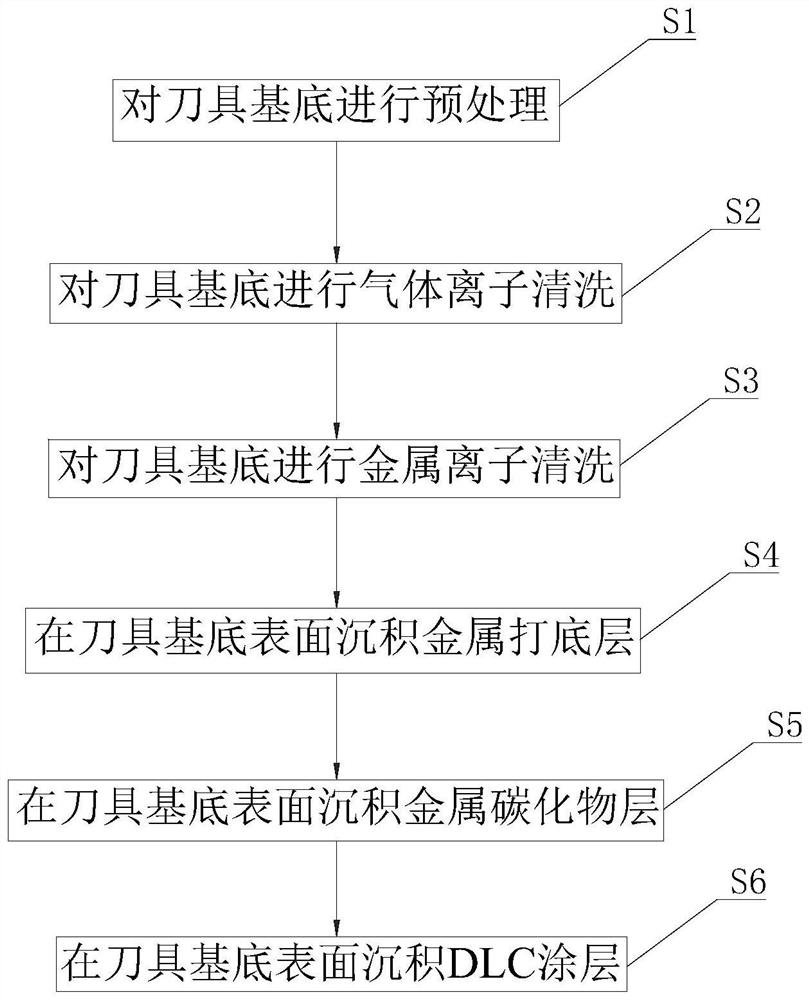

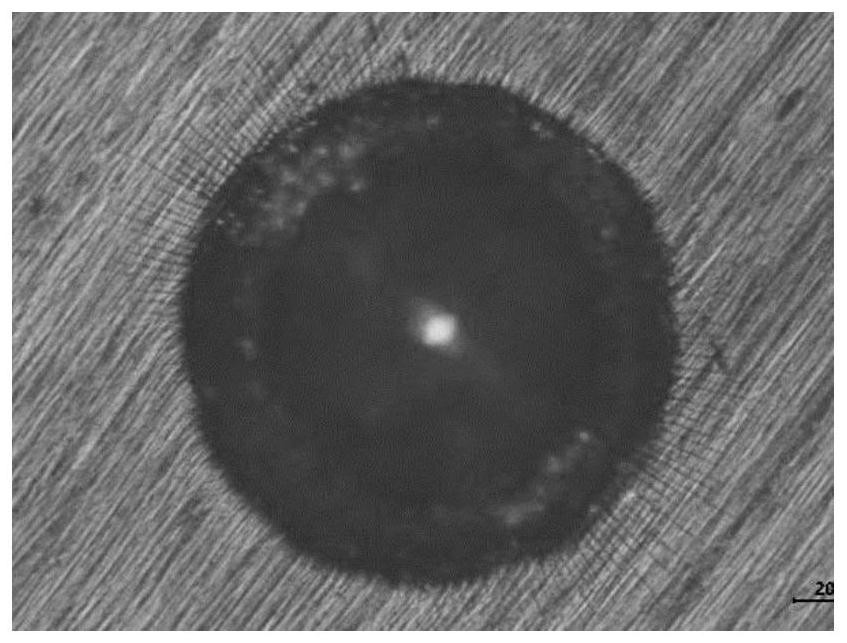

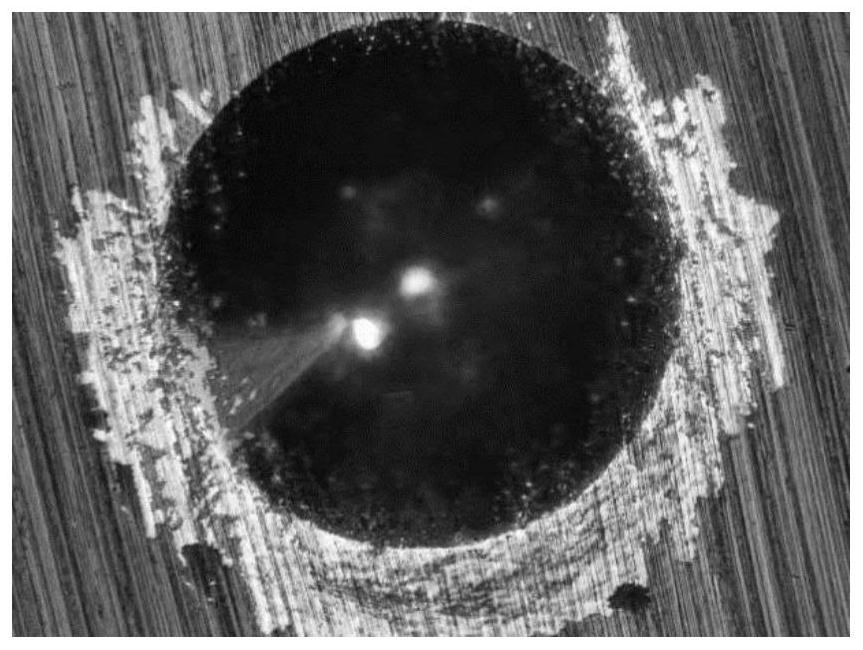

Cutter coating process and equipment

PendingCN114293144AImprove bindingReduce thicknessVacuum evaporation coatingSputtering coatingCarbon filmSputtering

The invention provides a cutter coating process and equipment, and relates to the field of metal surface treatment. The cutter coating process comprises the following steps: pretreating a cutter substrate; performing gas ion cleaning on the tool substrate; carrying out magnetron sputtering on the metal target material by adopting a high-energy pulse magnetron sputtering technology to form metal ions, and carrying out etching cleaning on the tool substrate by matching with the pulse control metal ions of the pulse bias; and a metal carbide layer and a carbon film layer are sequentially deposited on the surface of the tool substrate, and the thickness of the metal carbide layer is not larger than 500 nm. After the tool substrate is subjected to gas ion cleaning, the tool substrate is subjected to metal ion etching cleaning, the binding force between the tool substrate and the carbon film layer can be effectively increased, and therefore the thickness of a metal carbide layer is reduced on the premise that it is guaranteed that the tool substrate and the carbon film layer are stably combined, the thickness of the metal carbide layer is not larger than 500 nm, and the tool substrate is not prone to being damaged. The cutting edge is prevented from being blunt due to over-thickness, and the sharpness of the cutting edge is ensured.

Owner:SONGSHAN LAKE MATERIALS LAB

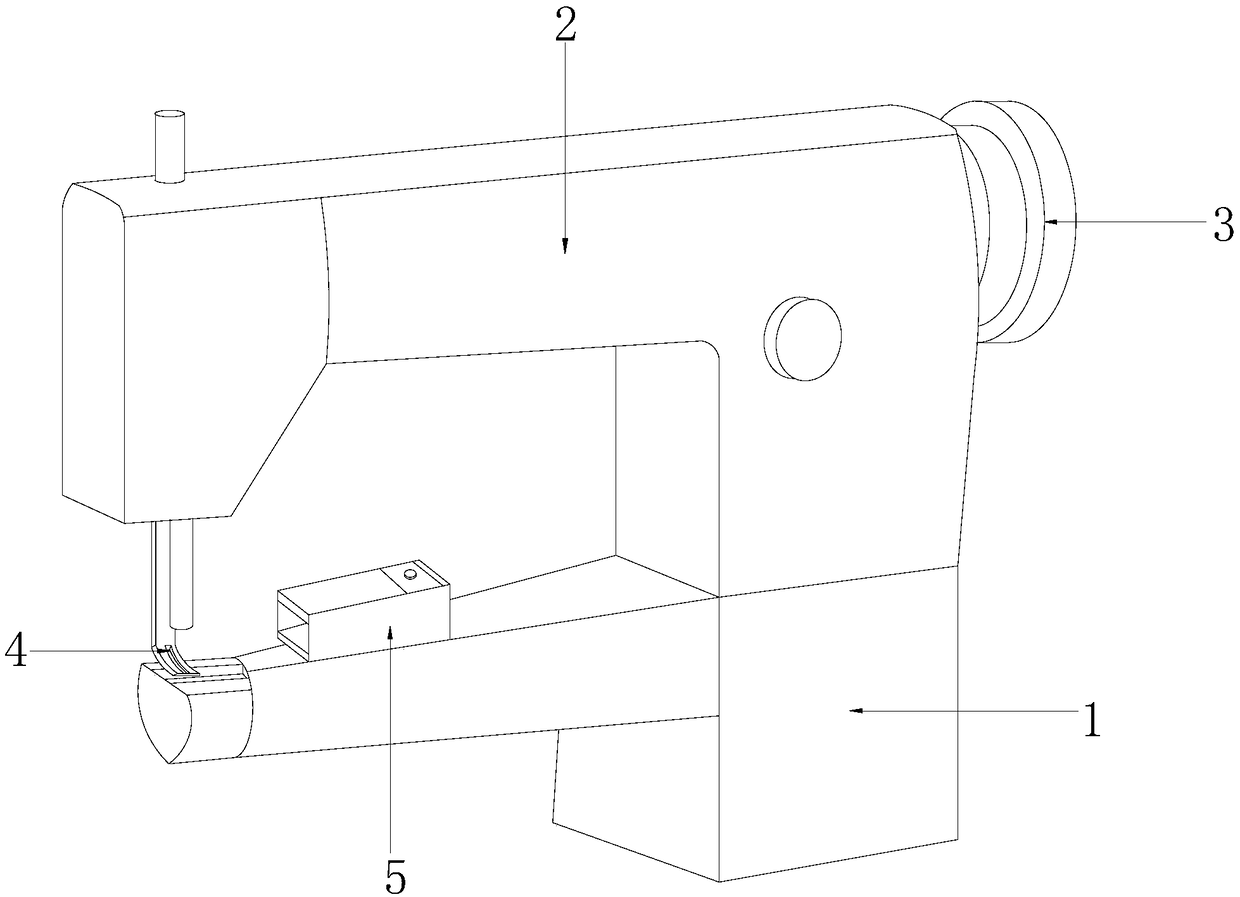

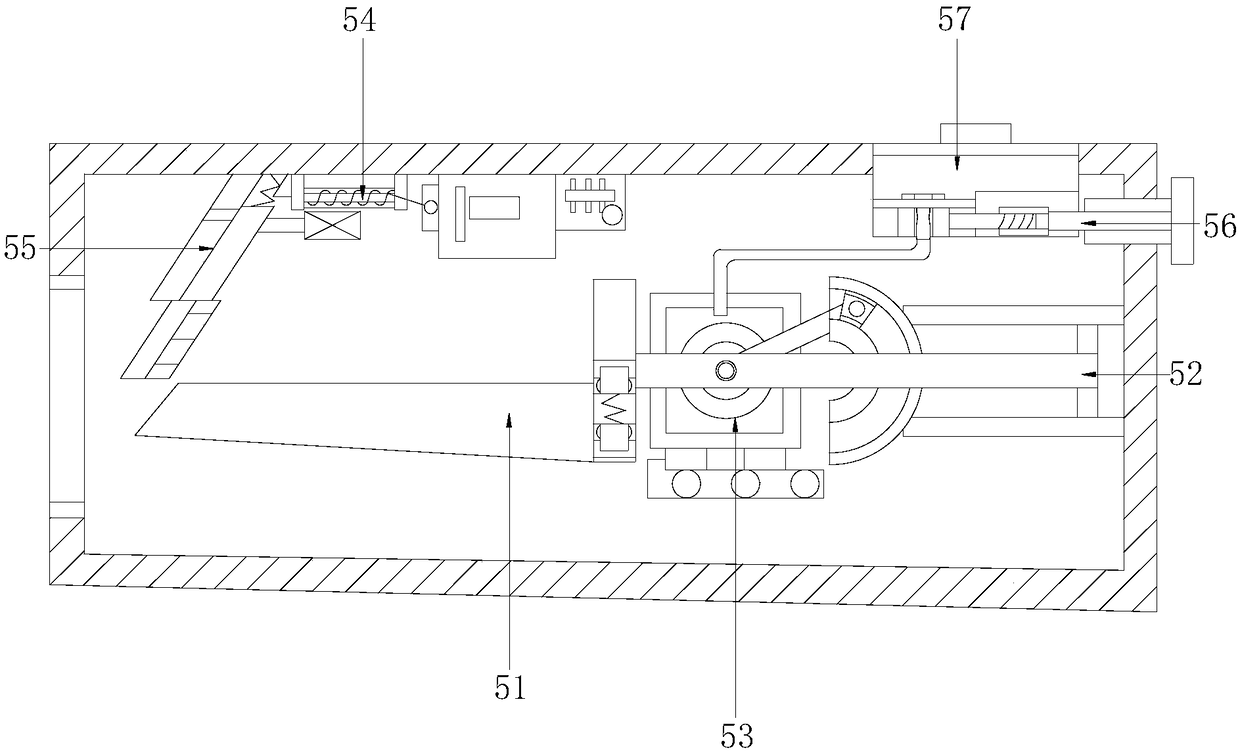

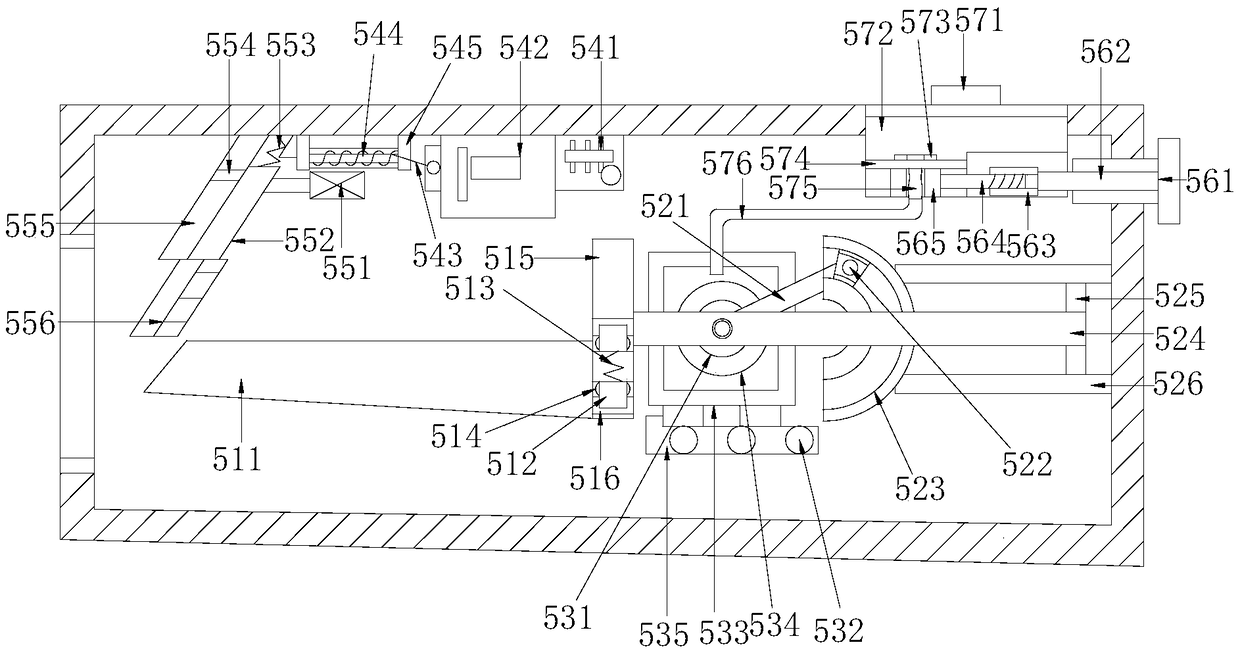

Efficient integrated edge covering and cutting sewing machine

The invention discloses an efficient integrated edge covering and cutting sewing machine. The efficient integrated edge covering and cutting sewing machine structurally comprises a device base, a device shell, a driving wheel, a binder and a polishing and cutting moisture-proof device, wherein the top of the device base is connected with the bottom of the device shell, the driving wheel is embedded into the surface of the right side of the device shell, the binder is arranged under the device shell, and the binder is arranged above the device base. The efficient integrated edge covering and cutting sewing machine has the advantages that a timing chip carries out timing, a cutter is used for a certain time, an inner polishing stone can move up and down repeatedly by itself, the cutter thatdoes not work is polished to avoid the situation that the cutting cutter rusts and cuts cloth incompletely, the integrated edge covering and cutting sewing machine can pour butter into an oil accumulating box, adjust a gap of a hose, so that the butter flows out little by little at a constant speed, and a shaft of a drive motor is lubricated to avoid the situation that the force pushing out the cutter is insufficient.

Owner:湖州周鼎纺织品有限公司

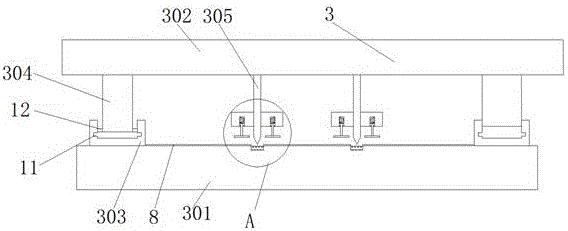

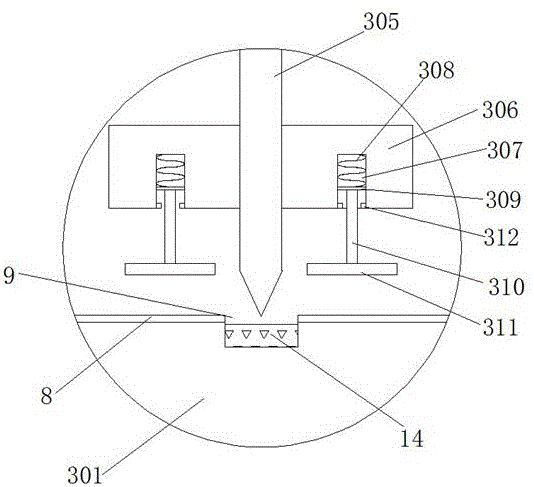

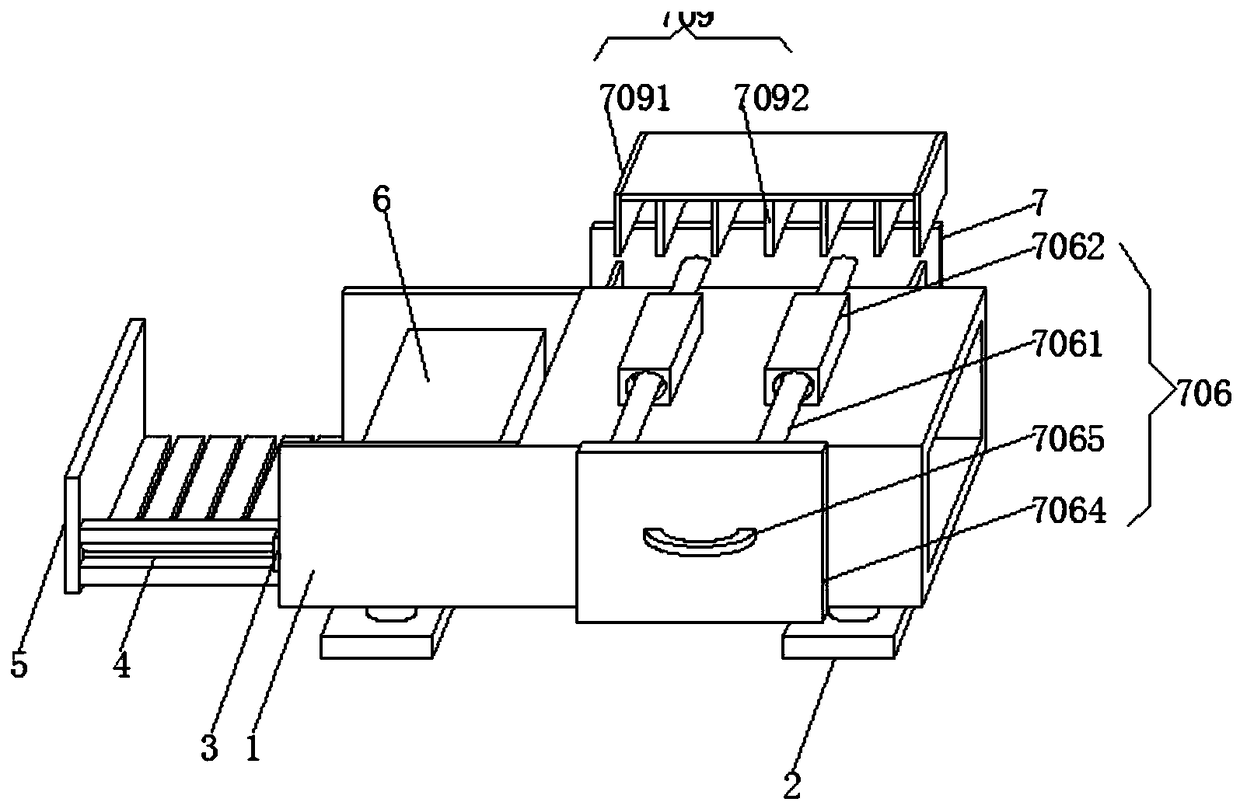

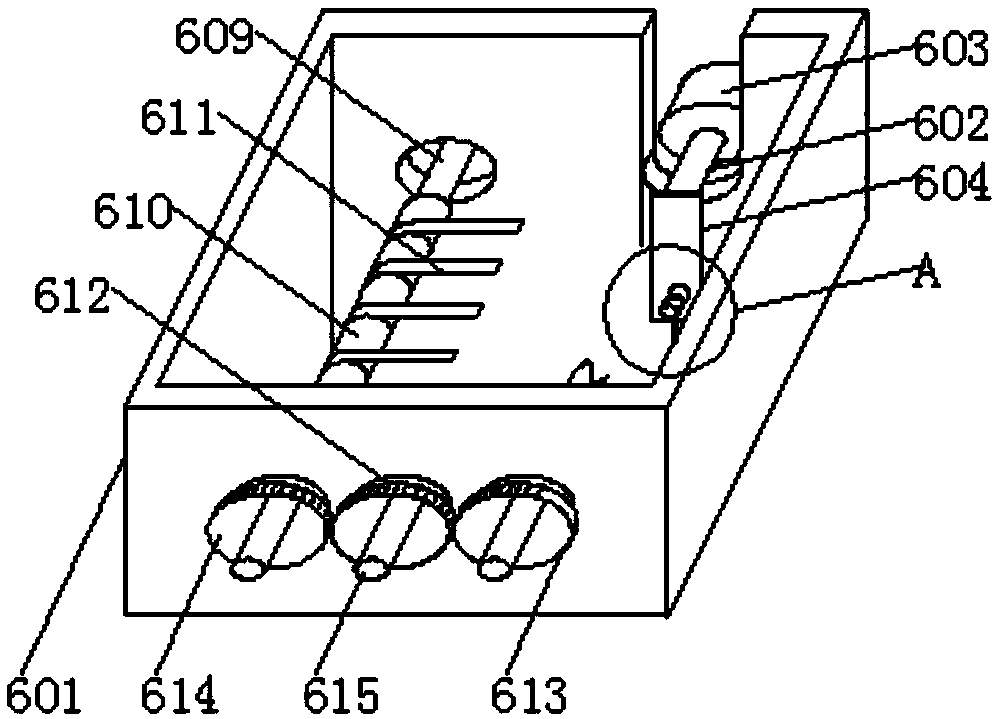

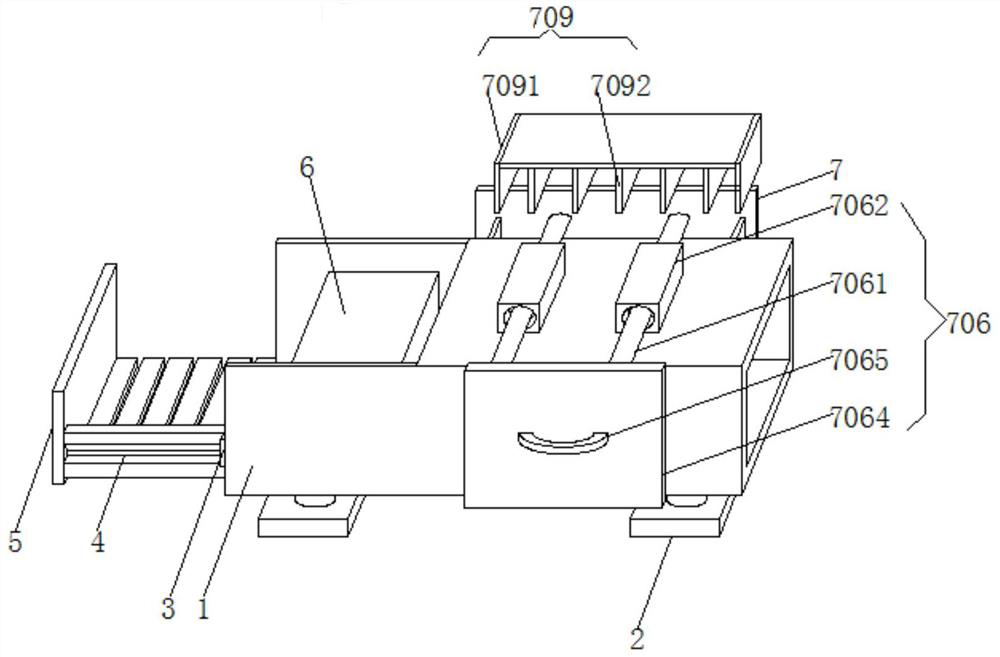

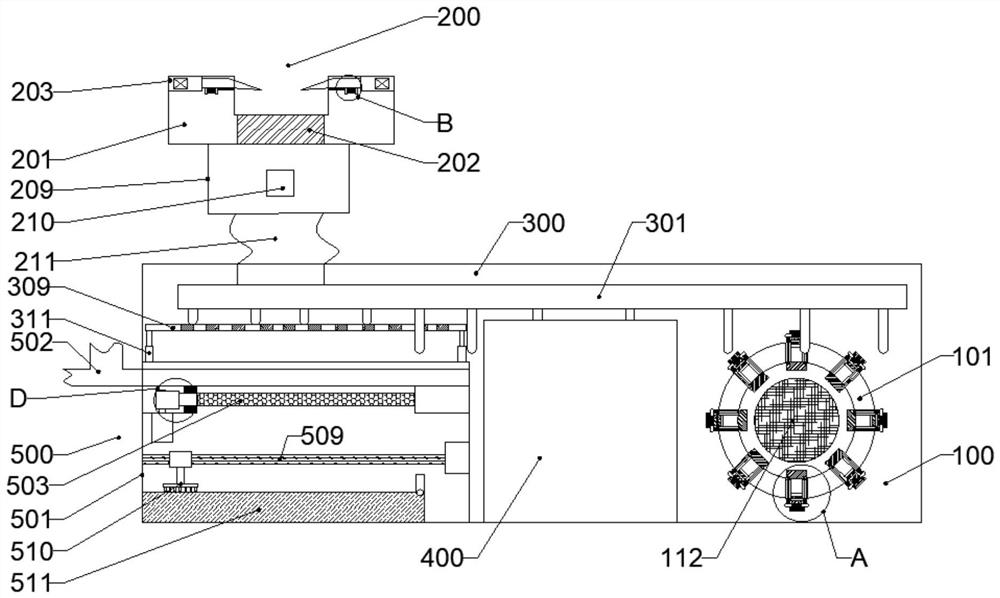

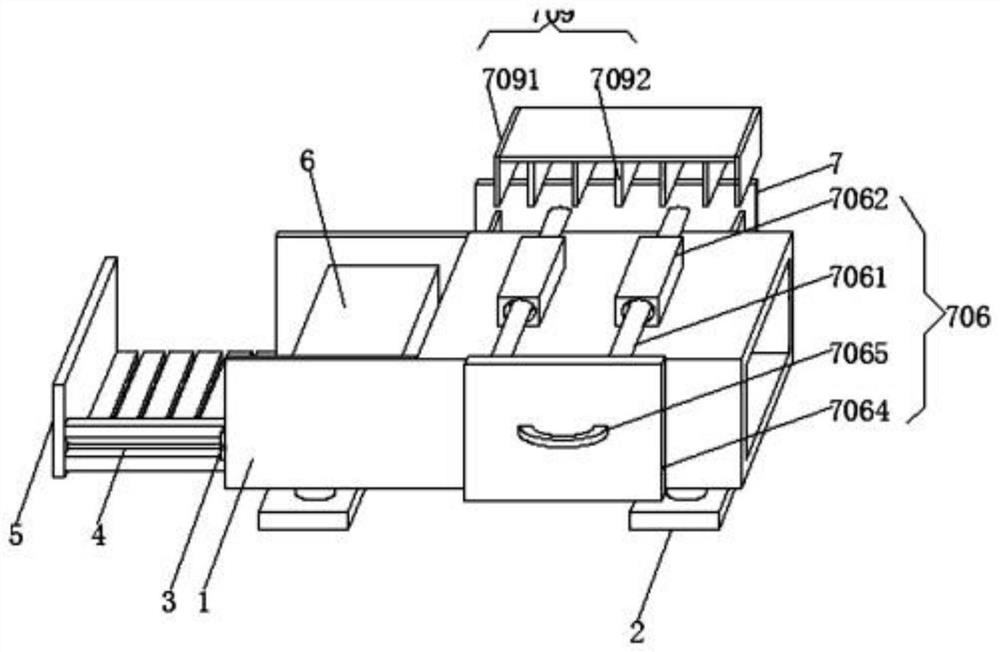

Sparerib block cutting equipment capable of shortening cooking time in auxiliary way

ActiveCN108967494AReduce cooking timeGuaranteed sizeOther manufacturing equipments/toolsMeat processing devicesEngineeringNoise reduction

The invention discloses sparerib block cutting equipment capable of shortening the cooking time in an auxiliary way. The equipment comprises an accommodating box, wherein support feet are arranged atthe two sides of the bottom of the accommodating box; a guide slide rail is arranged at the front side of the inner wall of the accommodating box; a guide slide stirp is clamped and connected in an inner cavity of the guide slide rail in an interactive way; a segmentation box is fixedly connected onto one side, far away from the guide slide rail, of the guide slide strip; a penetration mechanism is arranged at the front side of the top of the inner wall of the accommodating box; a block cutting device is arranged at the back side of the accommodating box. The retreatment through time expandingdue to kitchen environment pollution caused by blood liquid and other liquid sputtering in all positions during the block chopping can be avoided; a conventional cutter chopping mode is used for performing block cutting treatment; the noise reduction function is achieved; the penetration mechanism has the main purpose of performing hole puncture piercing treatment on the spareribs; on one hand, the block cutting can be smoother; on the other hand, during the subsequent cooking, the spareribs can be cooked at a higher speed; the seasoning effect is better; the effect of saving fuel indirectlyis achieved.

Owner:善讯智能科技(杭州)有限公司

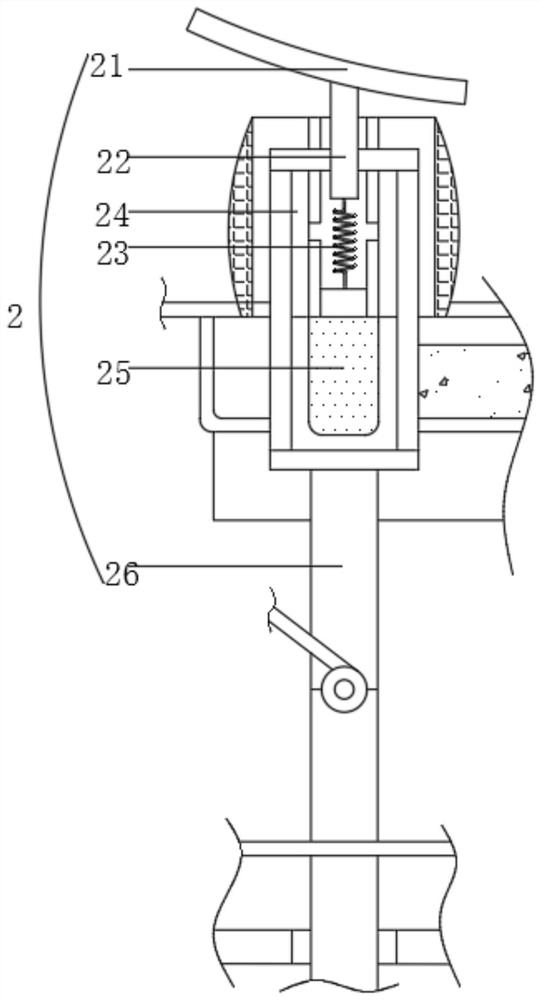

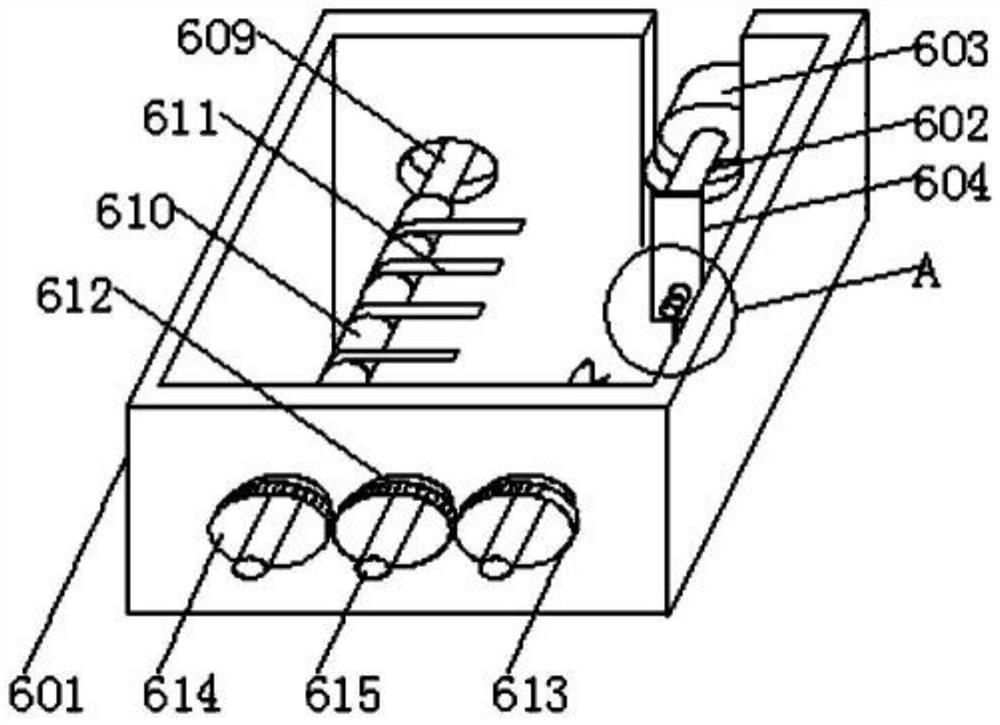

Tungsten steel blade anti-blunt device

InactiveCN112372724AAvoid passivationAvoid dullingMetal working apparatusGrinding/polishing apparatusMetallurgyElectric machinery

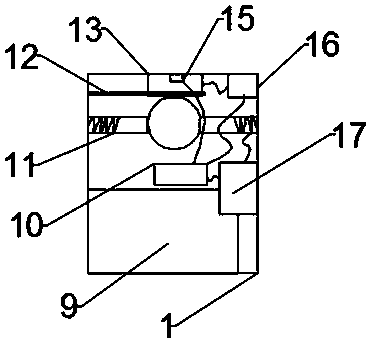

The invention provides a tungsten steel blade anti-blunt device, and belongs to the field of tungsten steel blade equipment. The device comprises a motor, a connecting rod, a tungsten steel blade, a connecting block, a grinding telescopic rod and a polishing solution box; the connecting rod is arranged at the lower part of the motor; the tungsten steel blade is mounted at the lower part of the connecting rod; the side surface of the connecting rod is fixedly connected with the connecting block; the grinding telescopic rod is fixedly mounted at the lower part of the connecting block; and the polishing solution box is fixedly arranged at the upper part of the connecting block. According to the device, starting and stopping of the grinding telescopic rod can be intermittently controlled through a control module, intermittent grinding operation during tungsten steel blade cutting operation is achieved, and the tungsten steel blade is prevented from becoming blunt; and meanwhile, due to thearrangement of the automatic polishing solution spraying, the tungsten steel blade grinding effect is improved.

Owner:邵阳县华锐合金工具有限公司

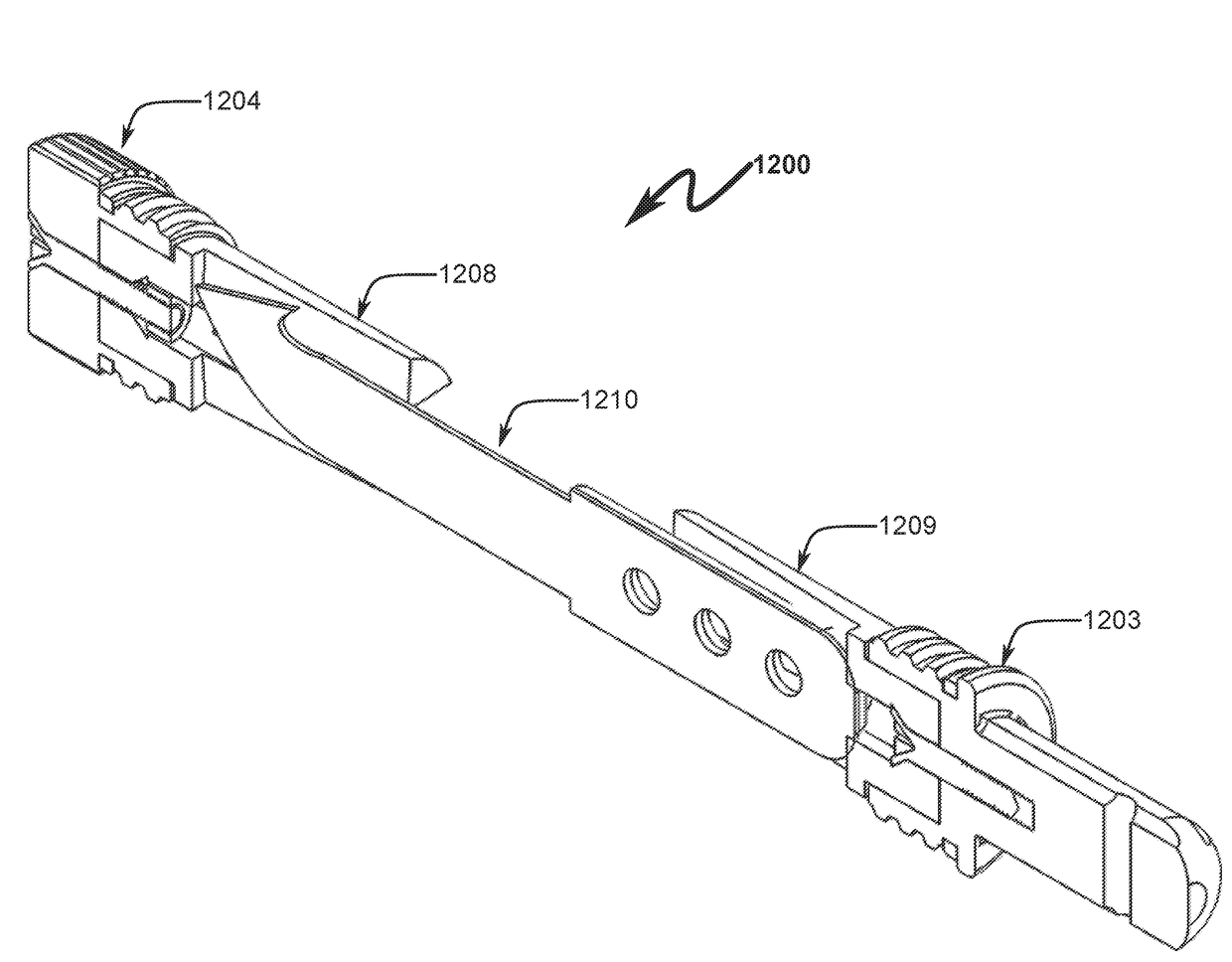

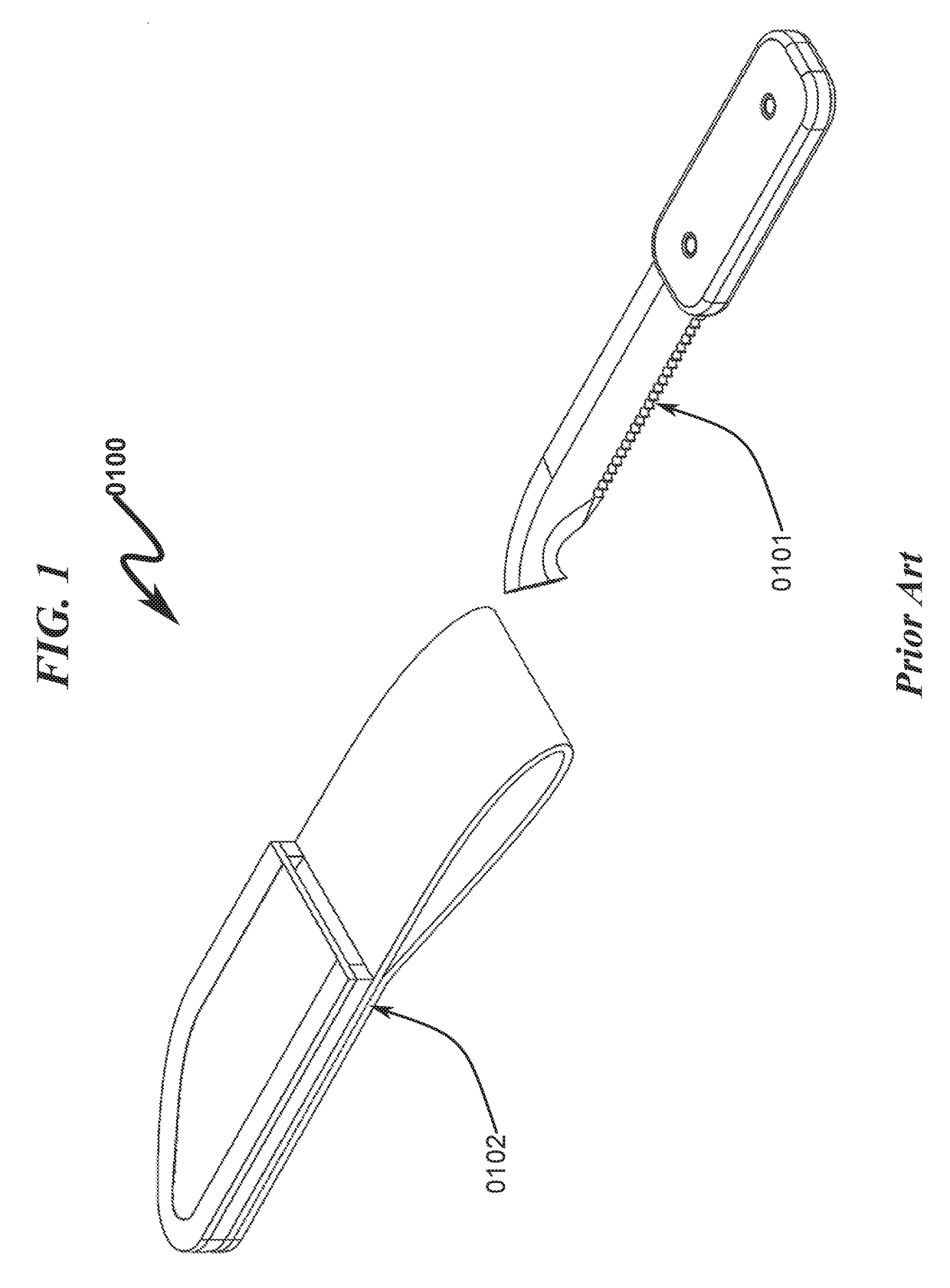

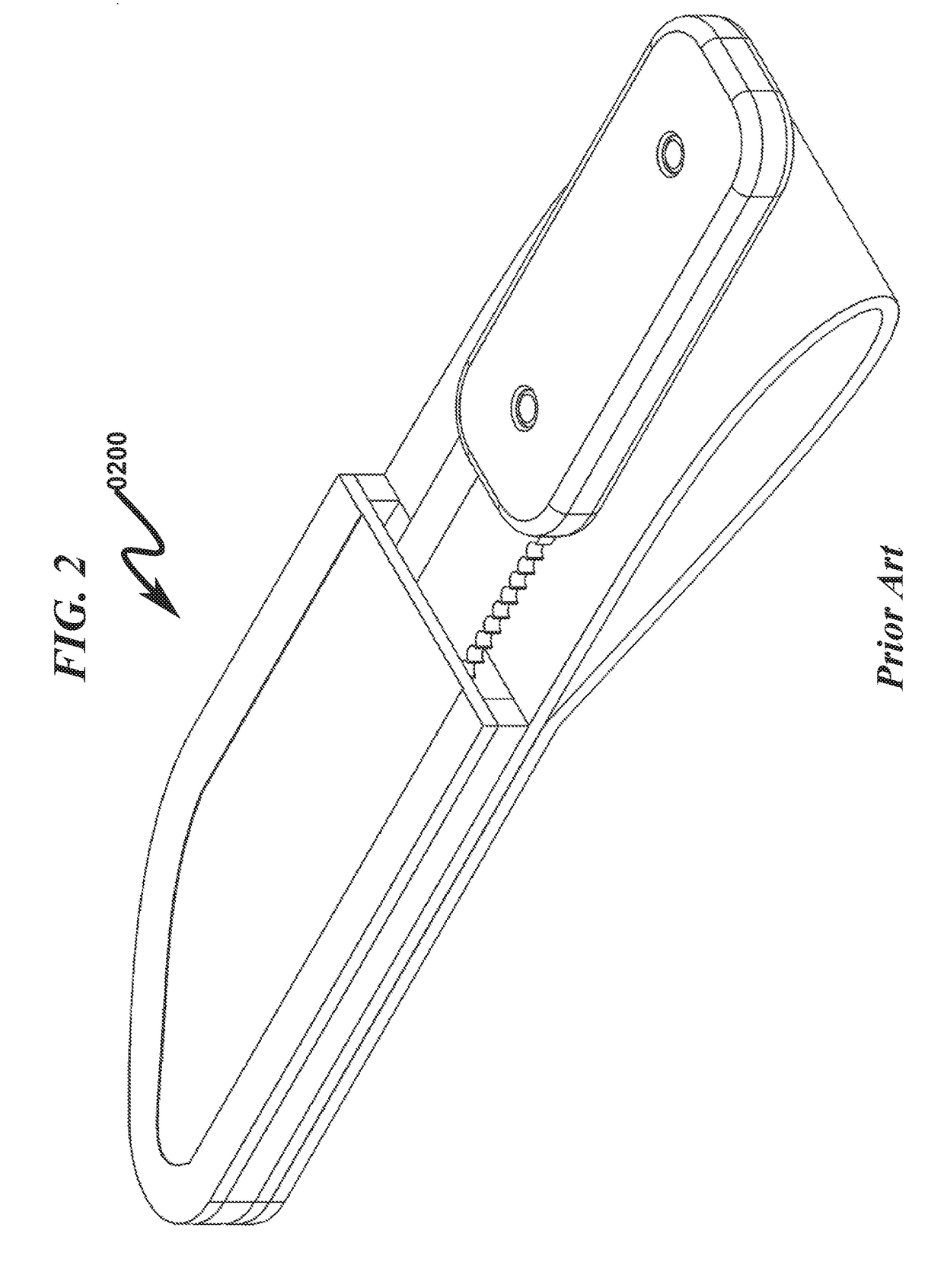

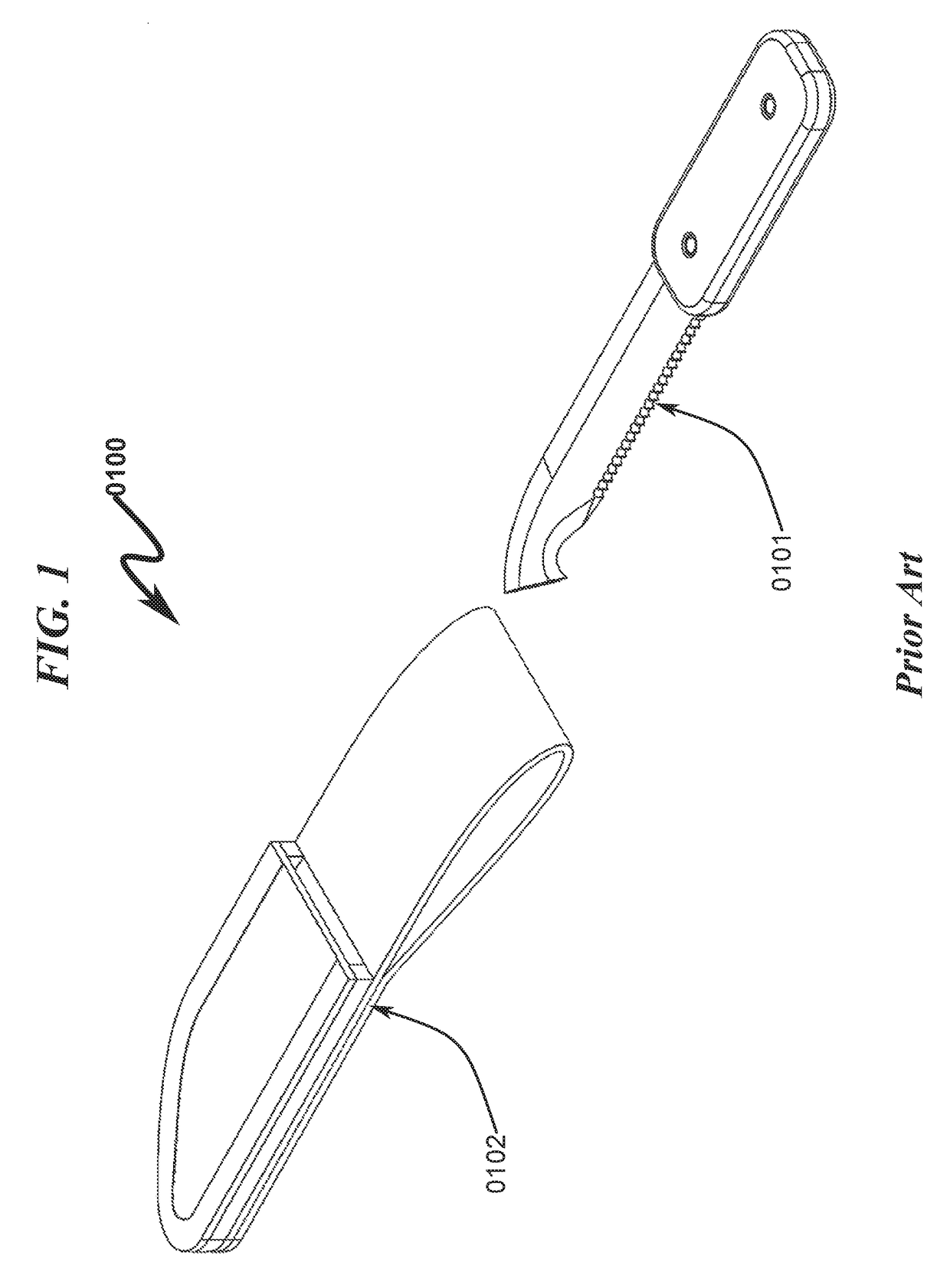

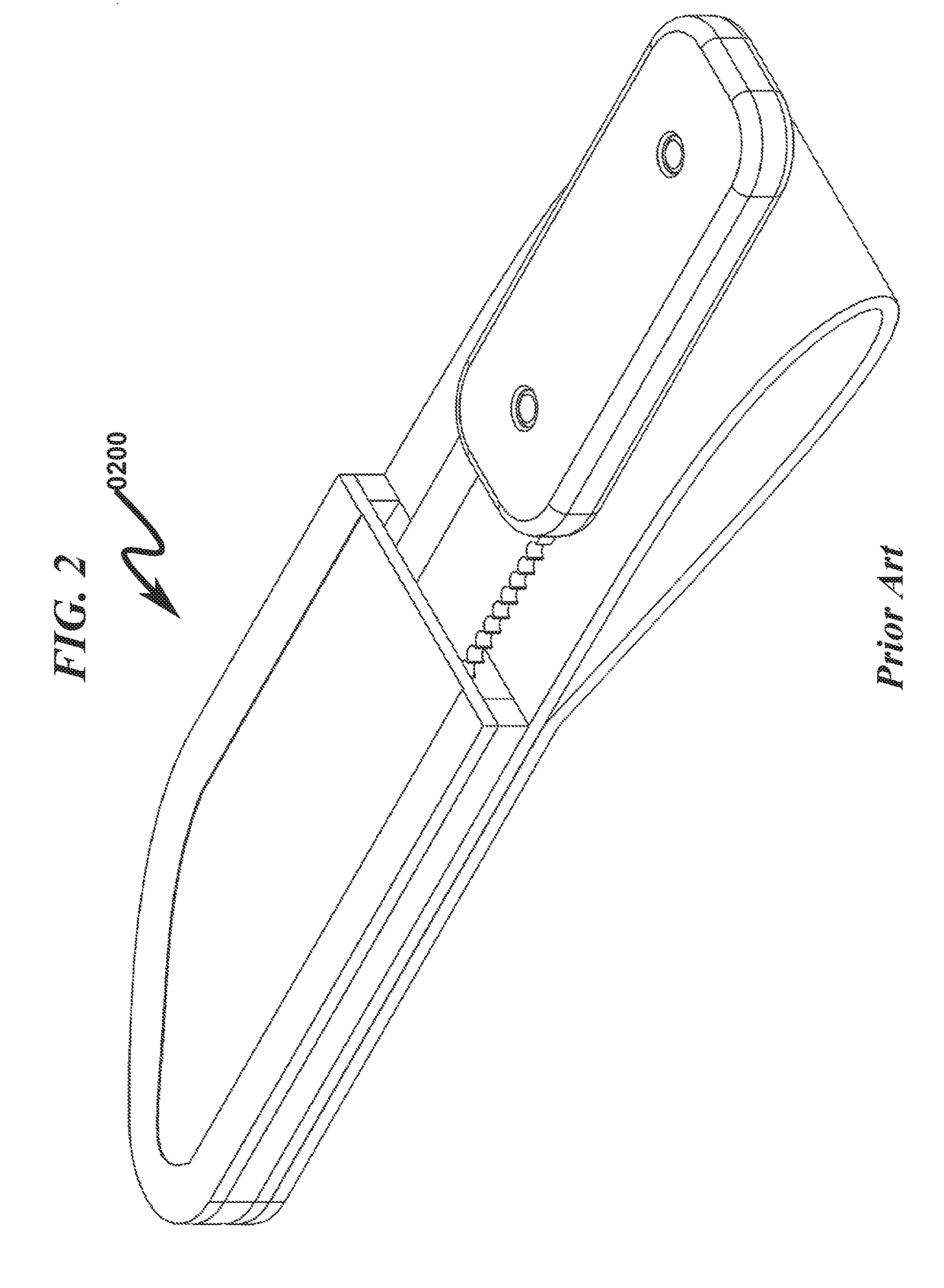

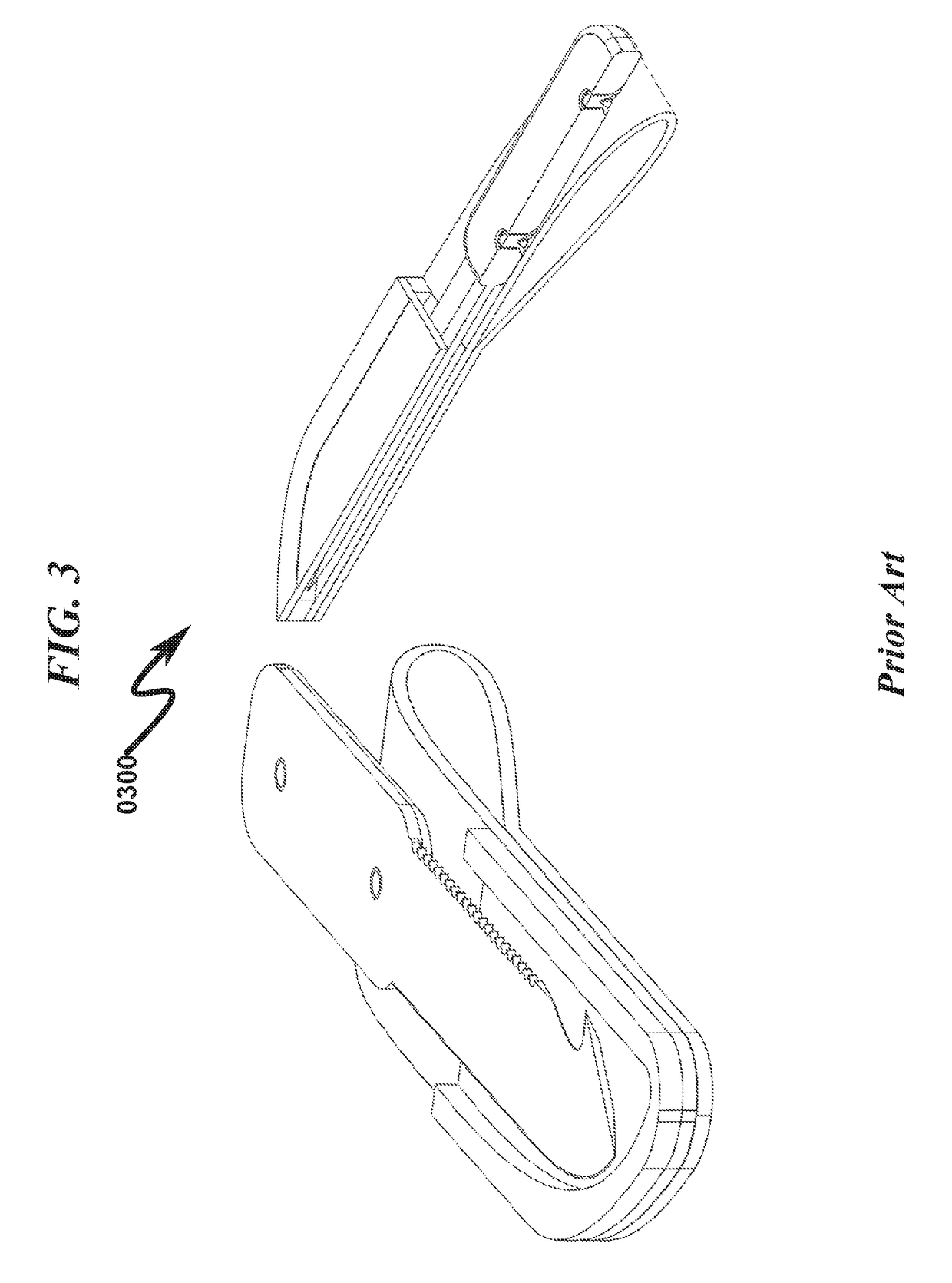

Knife storage system and method

ActiveUS20170355057A1Easy to cleanEasy to disassembleOther manufacturing equipments/toolsMetal working apparatusEngineeringContamination

A knife storage system and method is disclosed. The system and method utilize a resealable tube with retractable end-caps to safely store a hunting knife that may be contaminated with blood residue from a game animal that has been field dressed. The end-caps are configured with grooved cylinders to safely restrain a hunting knife so as to prevent dulling of the knife edge while simultaneously providing a fluid seal to the resealable tube to prevent contamination of the tube exterior with blood or other animal residue. Removal of both end-caps permits the tube and end-caps to be cleaned of game residue. Incorporated within the end-caps are integrated knife sharpening inserts comprised of ceramic and tungsten carbide to allow the knife to be safely sharpened in the field.

Owner:OWENS III WILLIAM THOMAS

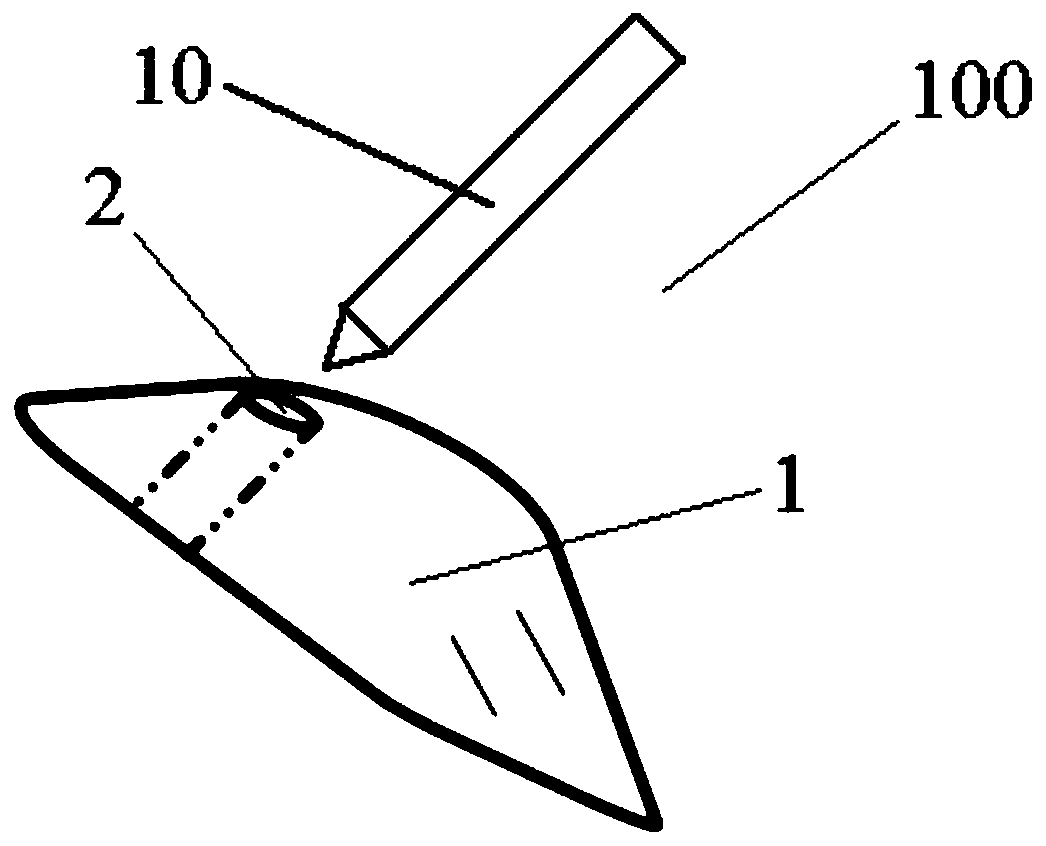

Manufacturing device and manufacturing method of grip aid for pen

ActiveCN108357239BKeep stableOvercome the problem of small holding force and unable to hold the pen stablyWriting connectorsHand sizeBiomedical engineering

Owner:高卓

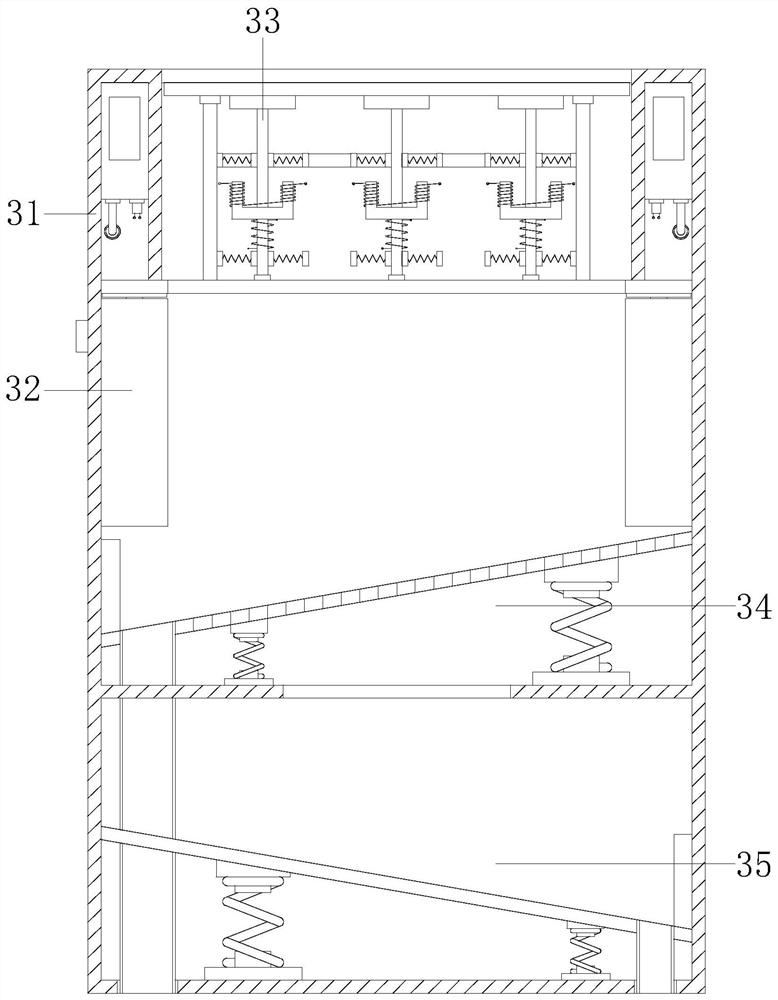

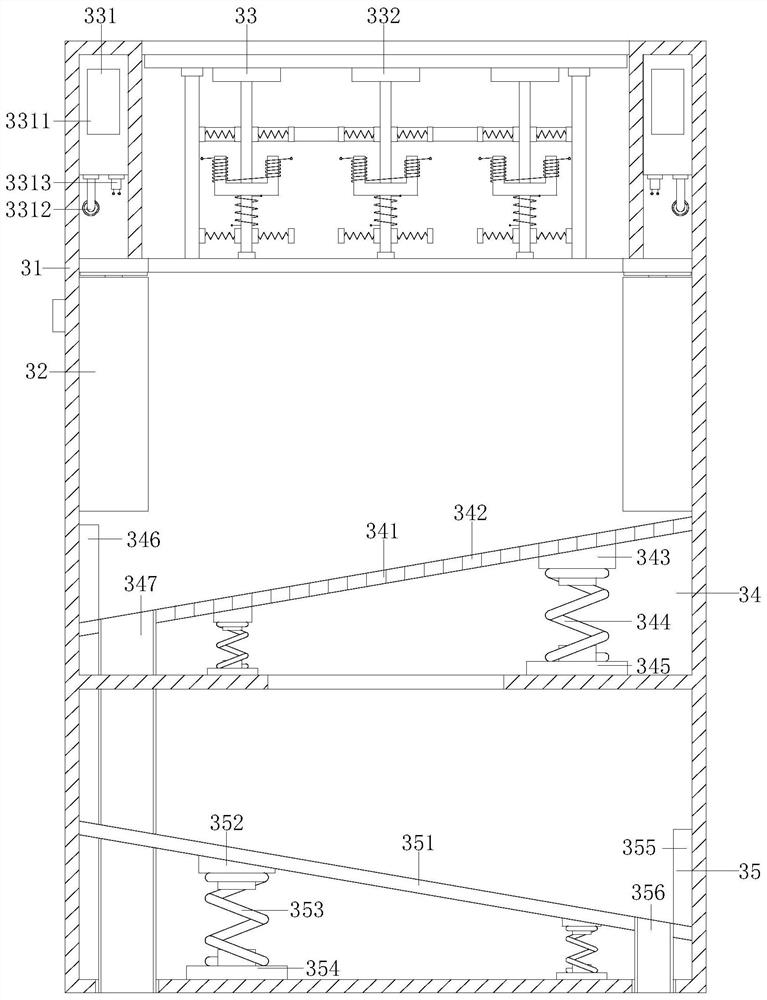

An automatic test paper binding device

An automated complete book binding device for test papers, including a workbench, the four corners of the bottom of the workbench are respectively fixed with table legs, the rear of the top of the workbench is fixedly connected to a vertical board, the upper part of the front of the vertical board is fixedly connected to the back of a horizontal board, and the bottom of the horizontal board The two sides of the two sides are respectively fixedly connected to the upper end of the electric push rod, and the lower end of the electric push rod is fixedly connected to the top surface of the horizontal plate. A row of several first through holes is opened on the top surface of the horizontal plate, and the bottom surface of the first through hole is respectively fixed and installed. Open vertical cylinder, the lower end of the vertical cylinder is an annular knife edge, and the front side of the top surface of the workbench is provided with several second through holes, and the grinding device capable of grinding the bottom of the corresponding vertical cylinder is provided in the second through holes. When the device is punching holes, it can realize the automatic cleaning of the vertical tube, and discharge the paper scraps in the vertical tube out of the vertical tube, which is convenient for the user to clean and collect the paper scraps, avoids the blockage of the vertical tube, and improves the reliability of the vertical tube. To ensure the punching effect of the vertical cylinder.

Owner:咸阳天裕印务有限公司

A spare rib cutting device capable of assisting in shortening the cooking time

ActiveCN108967494BReduce cooking timeGuaranteed sizeOther manufacturing equipments/toolsMeat processing devicesMedicineEngineering

The invention discloses a pork rib cutting equipment capable of assisting in shortening the cooking time, which comprises a storage box, the two sides of the bottom of the storage box are provided with supporting feet, and the front of the inner wall of the storage box is provided with a guide slide rail, the guide The inner cavity of the slide rail is interactively engaged with a guide slide bar, and the side of the guide slide bar away from the guide slide rail is fixedly connected with a segmented box, and the front of the top of the inner wall of the storage box is provided with a penetration mechanism, and the storage box There is a cutting device on the back of the cutting block. This invention avoids splashing of blood and other liquids when chopping blocks, causing the kitchen environment to be polluted, and it takes time to process it again. It replaces the traditional knife chopping method to cut it into blocks, which plays a role in noise reduction. The main purpose of the penetration mechanism is to pre-pierce and penetrate the ribs. On the one hand, it can make the cutting more smooth, and on the other hand, it can make the subsequent cooking faster and taste better. to save fuel.

Owner:SHANXUN INTELLIGENT TECH (HANGZHOU) CO LTD

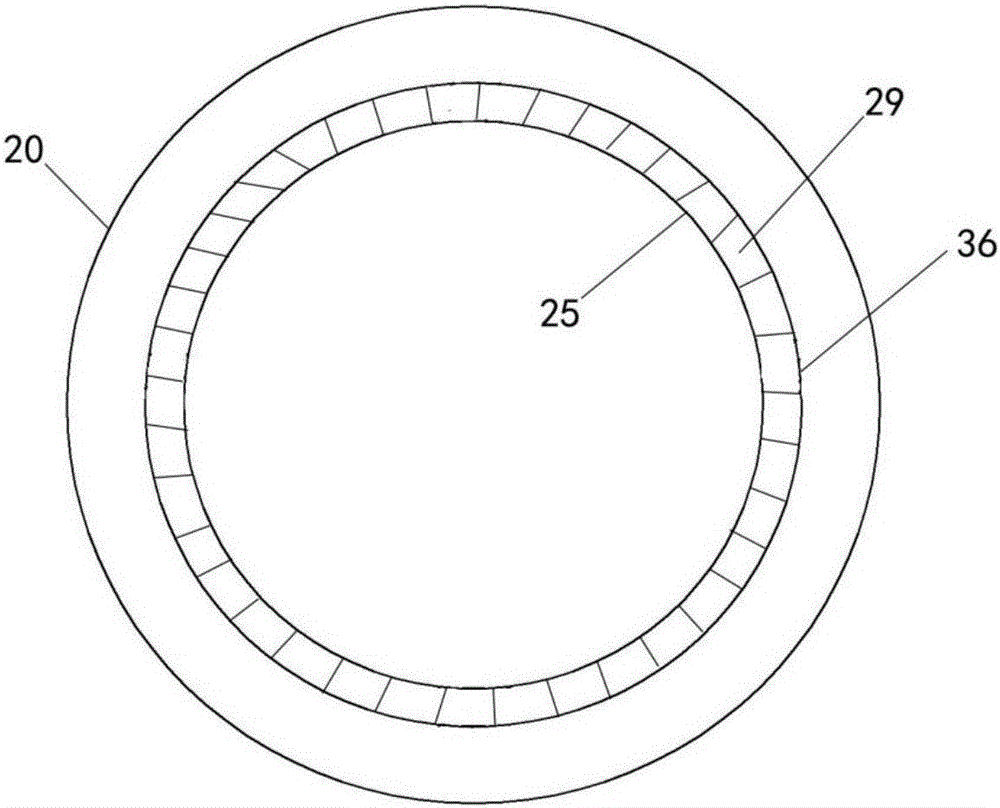

Household waste classifying device

PendingCN110449238AQuick classificationHighly integratedCleaning using gasesCleaning using liquidsSprayerClassification methods

The invention relates to a household waste classifying device which comprises a machine body, wherein a crushing cavity and a separating cavity are formed in the machine body up and down separately and communicate with each other; a crushing device is arranged in the crushing cavity; a separating device is arranged in the separating cavity; the crushing device comprises a plurality of steel kniferolling shafts and a plurality of rubber rolling shafts corresponding to the steel knife rolling shafts; and a plurality of high-pressure water sprayers are arranged in the crushing cavity and flush the corresponding steel knife rolling shafts and / or rubber rolling shafts in central symmetry distribution. The household waste classifying device can quickly, simply, conveniently and effectively classify household waste, is different from the existing classifying standard and method, realizes classification according to weight, hydrophilia, density and other features of waste after the preliminary crushing of waste, is simple, high in integration level and convenient to operate, and can ensure the sorting effect to certain degree.

Owner:九江绿谷源农业科技有限公司

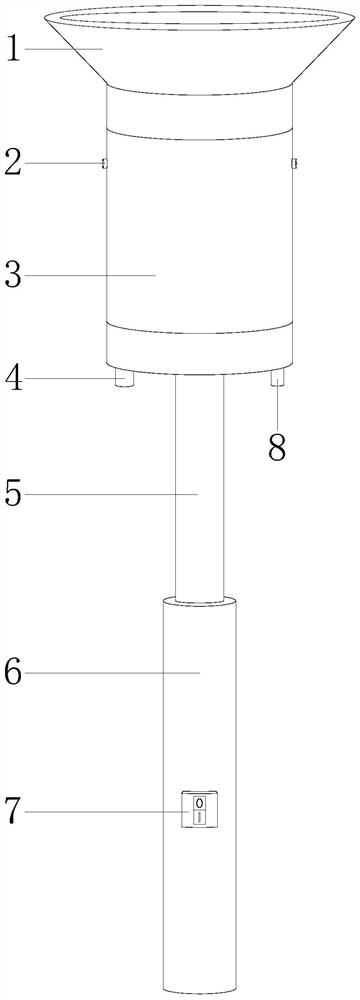

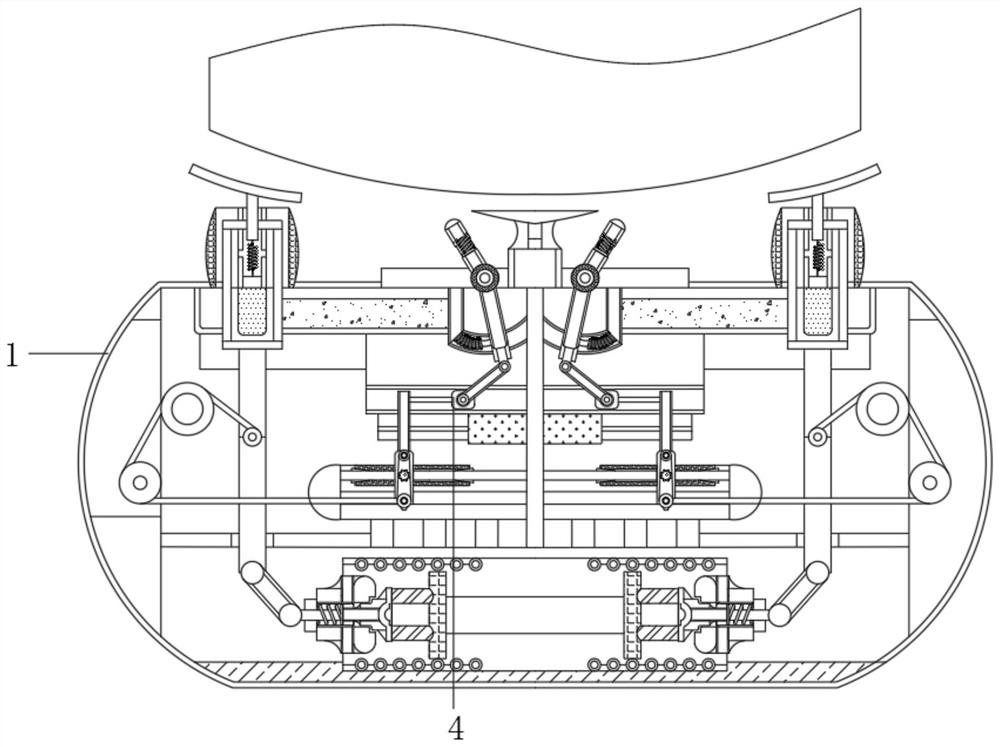

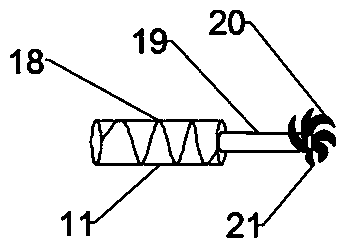

Intelligent apricot pollen collector

The invention discloses an intelligent apricot pollen collector which comprises a collecting mechanism, a picking mechanism, an arranging mechanism, a cutting mechanism, a drying mechanism and a box body. The collecting mechanism is located at the outlet end of the cutting mechanism and located on one side of the interior of the box body, the picking mechanism is located at the top of the box body, and the arranging mechanism is located at the top of the interior of the box body and located at the tops of the collecting mechanism, the cutting mechanism and the drying mechanism; according to the device, a brush makes contact with the interior of a flower, so that anther is collected into a negative pressure channel through anther holes to be collected, meanwhile, under the action of a telescopic spring, when the brush makes contact with the flower, a sealing cover and the negative pressure channel are separated from sealing connection, then external impurities can be prevented from entering the device, the drawing force is larger when the anther is collected, and the anther collecting effect is improved. And the collected anther is purer and more convenient to collect, the phenomena that petals fall and water is squeezed out are prevented, the situation that impurities are broken and difficult to separate is prevented, and separation of the anther is more convenient.

Owner:中国林业科学研究院经济林研究所

Knife storage system and method

ActiveUS10173294B2Easy to cleanEasy to disassembleOther manufacturing equipments/toolsMetal working apparatusEngineeringContamination

A knife storage system and method is disclosed. The system and method utilize a resealable tube with retractable end-caps to safely store a hunting knife that may be contaminated with blood residue from a game animal that has been field dressed. The end-caps are configured with grooved cylinders to safely restrain a hunting knife so as to prevent dulling of the knife edge while simultaneously providing a fluid seal to the resealable tube to prevent contamination of the tube exterior with blood or other animal residue. Removal of both end-caps permits the tube and end-caps to be cleaned of game residue. Incorporated within the end-caps are integrated knife sharpening inserts comprised of ceramic and tungsten carbide to allow the knife to be safely sharpened in the field.

Owner:OWENS III WILLIAM THOMAS

Agricultural plum harvesting device

ActiveCN109220222BGuaranteed movement trackAvoid dullingSievingScreeningAnimal scienceAgricultural science

The invention discloses a plum collection device for agriculture. Its structure includes a collection port, an adjustment button, a collection host, a first-stage outlet pipe, a lifting rod, a handle, a switch, and a second-stage outlet pipe. It is installed inside the collection host by embedding and adopts clearance fit. The top of the first-stage outlet pipe is installed inside the bottom of the collection host by embedding. The top of the lifting rod is fixedly installed in the middle of the bottom of the collection host. The handle is fixedly connected to the bottom of the lifting rod. The vibration potential energy is transmitted to the plum branches through the excitation mechanism, effectively vibrating the plums from the branches, changing the previous method of cutting the branches with a knife to collect plums, avoiding the problem of blunt knives, and collecting a large number of plums. The plum collection mechanism and the small plum collection mechanism can effectively avoid plums from being bruised. By classifying plums according to their size, there is no need to classify them in the future, which reduces the labor cost of plum collection.

Owner:泉州台商投资区一创工业设计有限公司

Shoe production-based shoe sole processing trimming device and method

ActiveCN113977680AImprove cooling effectImprove trimming efficiencyMetal working apparatusStructural engineeringContact mechanism

The invention relates to the technical field of shoe sole manufacturing, and discloses a shoe production-based shoe sole processing trimming device which comprises a shell, a contact mechanism is movably connected to the interior of the shell, a transmission mechanism is movably connected to the side, away from the inner wall of the shell, of the contact mechanism, a sliding block is fixedly connected to the top of the transmission mechanism and the top of the sliding block is movably connected with a cutting mechanism. When a shoe sole is trimmed by a cutter, one scraper block is used for preventing excessive leftover materials from being adhered to the bottom of the cutter, when the shoe sole leaves from the top of the shell, the arc plate moves upwards, the scraper blocks move towards the side away from the cutter through the connection relation of the internal structure, due to the elastic force effect of an anti-resistance spring, when the scraper blocks move, the bottom of the cutter can be scraped, meanwhile, the cutter can be polished, the edge of the cutter is prevented from being blunt, and therefore the effects of automatically cleaning leftover materials attached to the cutter and polishing the cutter at the same time when the edge of the shoe sole is cut are achieved.

Owner:保定步康宇鞋服有限公司

A rotary garbage crushing device

The invention discloses a rotary garbage crushing device, including a first five-knife roller, a second five-knife roller, a soft brush, a shell and an engine system. The garbage crushing device can conduct on-line clearance of flexible materials on the hob through the soft brush, and keep the hob sharp; while a pneumatic engine replaces a traditional motor to drive the roller. The device has the advantages of large output torque, high adjustability and no pollution.

Owner:泰兴市城东绿化工程有限公司

Wood chip crusher

InactiveCN107890924AIncrease the scope of applicationEasy to install and removeWood working apparatusGrain treatmentsPulverizerTransverse plane

A wood chip pulverizer, comprising a pulverizer body, a feeding port is opened above the pulverizer body, a sealing plate is fixed above the feeding port by positioning bolts, a fixed knife is welded on the inner wall of the pulverizer body, the A main bracket is arranged below the pulverizer body, a horizontal plate is arranged inside the main bracket, a controller is fixed on one side of the main bracket through a fixing plate, and a motor is fixed on the other side of the main bracket through a fixing plate. The device is fixed with a sealing plate through positioning bolts above the feeding port, and the width of the feeding port can be changed by moving the sealing plate, so that the device can be applied to the crushing of wood chips of various thicknesses, which improves the scope of application of the device In this device, the crushing roller is fixed on the outer wall of the driven shaft through positioning pins, so that the installation and disassembly of the crushing roller is convenient, and it is convenient to replace it, which can effectively prevent the moving knife from becoming blunt due to long-term use, and improve the crushing efficiency of the device.

Owner:利川隆祥生物科技有限公司

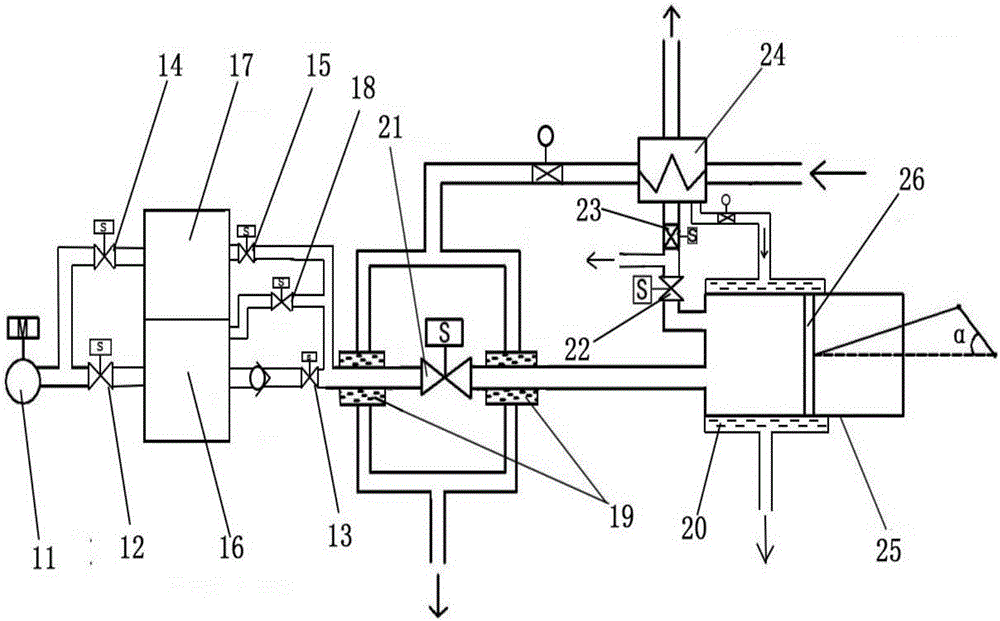

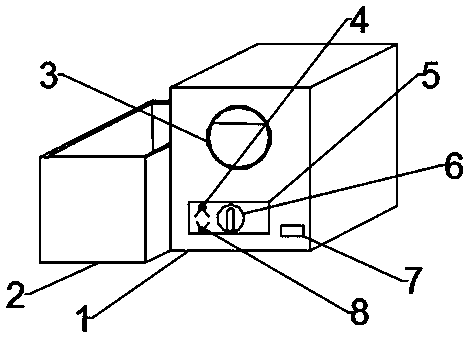

A small automatic peeling machine according to the curvature of sugarcane

The invention discloses a small-sized automatic peeler capable of peeling a sugarcane according to the bending degree. The small-sized automatic peeler comprises a peeler housing, wherein a container is welded with the left side of the peeler housing; a sugarcane inlet is formed in the peeler housing; a control button is mounted on the front side of the peeler housing; an acceleration button and a deceleration button are mounted on the left side of the control button; the acceleration button is arranged above the deceleration button; a turn-on knob is mounted in the middle of the control button; a charging port is mounted at the right side of the control button; and a storage battery is welded on the inner side of the charging port. According to the small-sized automatic peeler, as the container is arranged, the automatic peeler can be cleaned every once in a while, knife edges are prevented from getting dull, and residual sugarcane skin on the cleaned knife edges are cleaned to avoid contaminating the next sugarcane; and as the acceleration button is arranged, together with the deceleration button, a user can control the peeling speed according to the number of purchasing personnel on site, and accordingly, the peeling speed can match up with the user.

Owner:上海中道糖业有限公司

A new type of high-precision cloth cutting machine that prevents cloth from moving

ActiveCN107500008BAvoid dullingAvoid sticking to each otherArticle deliveryWebs handlingEngineeringControl switch

The invention discloses a novel high-precision cloth cutting machine for preventing cloth from moving. The novel high-precision cloth cutting machine comprises a feeding conveying belt, a front pressurizing roller, a cutting sliding rail, limiting blocking plates, a discharging conveying belt, a rack, a spray device, a cutting cutter blade, insulation balance iron, a control switch and an electromotor. The cutting sliding rail is arranged on the upper surface of a cutting platform and located between the front pressurizing roller and a back pressurizing roller. The limiting blocking plates are located on the two sides of the cutting platform. The insulation balance iron is located on the left side of the rack. The control switch is located at the tail end of the rack. The electromotor is located on the right side of the rack and connected with the cutting cutter blade. According to the novel high-precision cloth cutting machine for preventing the cloth from moving, the cutting sliding rail is arranged, the cutting sliding rail comprises a cutter grinding device and a sliding rail groove, arranging of the cutter grinding device can grind the cutting cutter blade while the cutting cutter cuts the cloth, and the fact that a cutter edge is blunt, and the cloth can not be effectively and fast cut due to the fact that the cutting cutter blade is not ground for a long time is prevented.

Owner:江苏优恩服饰辅料有限公司

Virtual cutting device and its knife roller cleaning device

A cutting roll cleaning device is used for cleaning a cutter of a cutting roll and comprises a fixing plate, an oil storage tank and a cleaner. The oil storage tank is arranged on the fixing plate, a first end of the cleaner is fixed on the fixing plate and immersed into the oil storage tank, and a second end, which is opposite to the first end, of the cleaner, extends to a roll surface of the cutting roll and is used for cleaning the cutter of the cutting roll. The invention further provides a dotted cutting device with the cutting roll cleaning device. The cutter of the cutting roll of the dotted cutting device can be cleaned on line by the cutting roll cleaning device rather than being disassembled while stopping the device, and production efficiency is guaranteed, meanwhile, dusts adhered to the cutter can be eliminated by the cleaning device, the cutter is avoided to be blunt, and dusts are prevented from falling off on a product to influence the product quality.

Owner:海南金红叶纸业有限公司 +1

Spareribs cutting device and cutting method capable of assisting in shortening cooking time

InactiveCN111771948AReduce cooking timeGuaranteed sizeOther manufacturing equipments/toolsMeat processing devicesStructural engineeringMechanical engineering

The invention discloses a spareribs cutting device and a cutting method capable of assisting in shortening cooking time. The spareribs cutting device includes a holding box, two sides of the bottom ofthe holding box are provided with supporting feet, the front side of the inner wall of the holding box is provided with guide slide rails, the inner cavities of the guide slide rails are interactively clamped with guide slide bars, the sides of the guide slide bars far away from the guide slide rails are fixedly connected with a segmenting box, the front side of the top of the inner wall of the holding box is provided with a penetrating mechanism, and the back side of the holding box is provided with a cutting device. The invention avoids the contamination to the kitchen environment caused bythe splashing of bloody water and other liquids in all directions while chopping, thus there is no need to take time to process the kitchen environment again. The spareribs cutting device, instead ofthe traditional chopping method, has an effect of noise reduction. The main purpose of the penetrating mechanism is to carry out pre-piercing and penetrating treatment on the spareribs. On one hand,the penetrating mechanism can make the cutting more smooth; and on the other hand, the penetrating mechanism can make the spareribs faster in cooking and better in taste when cooking the spareribs subsequently, which can play a role in saving fuels in a disguise way.

Owner:南京溧水高新产业股权投资有限公司

Cutting-open device suitable for cutting open chestnut shell notch at home

InactiveCN107913003AAvoid dullingExtended service lifeKitchen equipmentAgricultural engineeringNotching

The invention discloses a scissors suitable for cutting the gaps of chestnut shells at home. The main features are: the left end of the upper scissor body of the scissors is provided with a long knife seat with an integral structure, the center of the front and rear widths of the lower end of the knife seat is provided with a long knife groove, and there is a knife groove in the long knife groove for scissors. The blade for opening the gap in the chestnut shell, the lower end of the blade is provided with a sharp circular arc blade, the left end of the lower scissors of the scissors is provided with an integral structure, a square storage table, and the upper end of the storage table is provided with for cutting the chestnut shell gap. The chestnut is placed in the square concave hole; the knife seat of the upper scissors body passes through the oblique oblique hole of the riveting seat of the lower scissors body, and corresponds to the top and bottom of the storage table of the lower scissors body, and the rivets respectively pass through the front and rear of the oblique oblique hole The front through hole and the rear through hole on the hole wall plate and the riveting hole on the central axis of the riveting column rivet the upper shear body and the lower shear body together. The invention can simply, easily and quickly cut the gap of the chestnut shell, and has a simple, small and exquisite structure, and is economical and practical.

Owner:詹七云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com