Rotary garbage crushing device

A crushing device and rotary technology, applied in grain processing and other directions, can solve the problems of dull hob, insufficient output torque, pollution, etc., to achieve smooth output, large output torque, and prevent excessive threshold fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

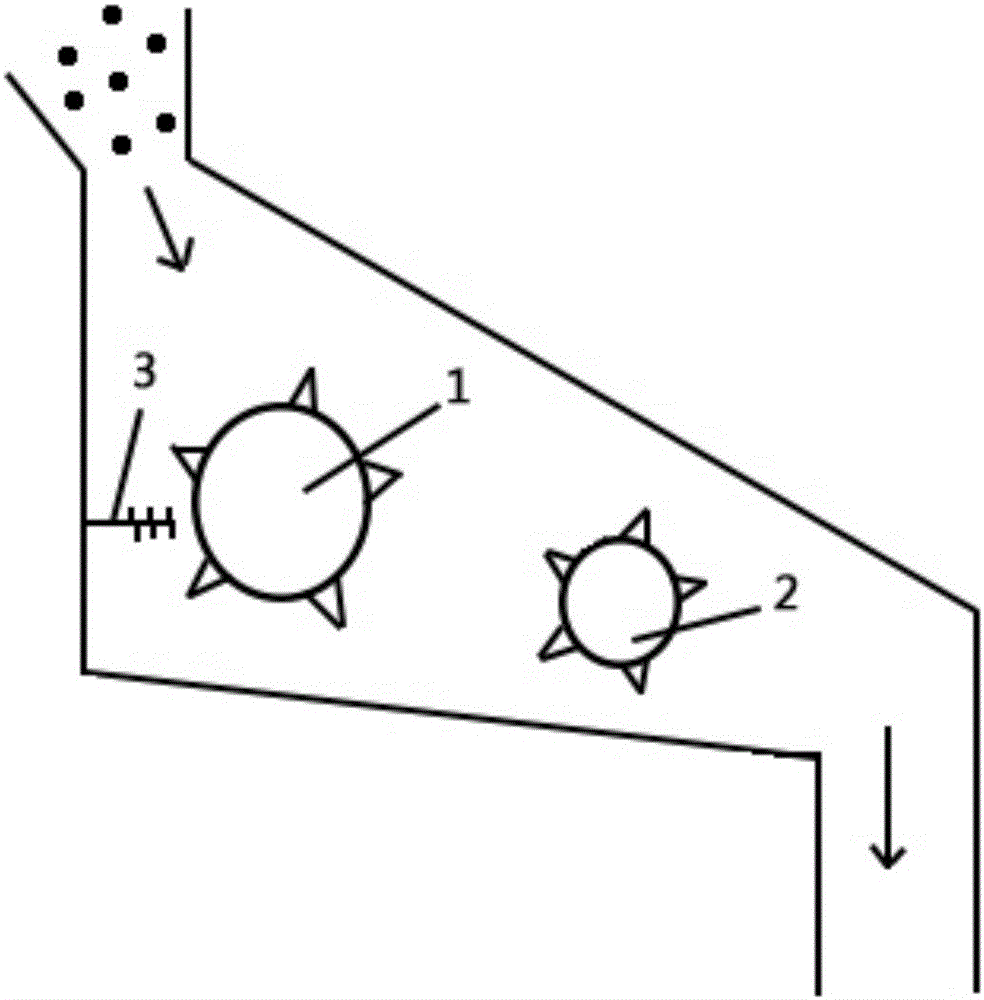

[0022] Such as figure 1 The rotary garbage crushing device shown includes the first five-knife roller 1, the second five-knife roller 2, a soft brush 3, a housing and an engine system; unbroken garbage enters from the entrance above the housing inside the housing, and successively pass through the first five-knife roller 1 and the second five-knife roller 2 for crushing, and then discharge from the outlet below the housing; the soft brush 3 is arranged on the left side of the first five-knife roller 1 The side is used to clean the flexible objects on the hob of the first five-blade roller 1, and the engine system drives the first five-blade roller 1 and the second five-blade roller 2 to rotate through a crankshaft connection;

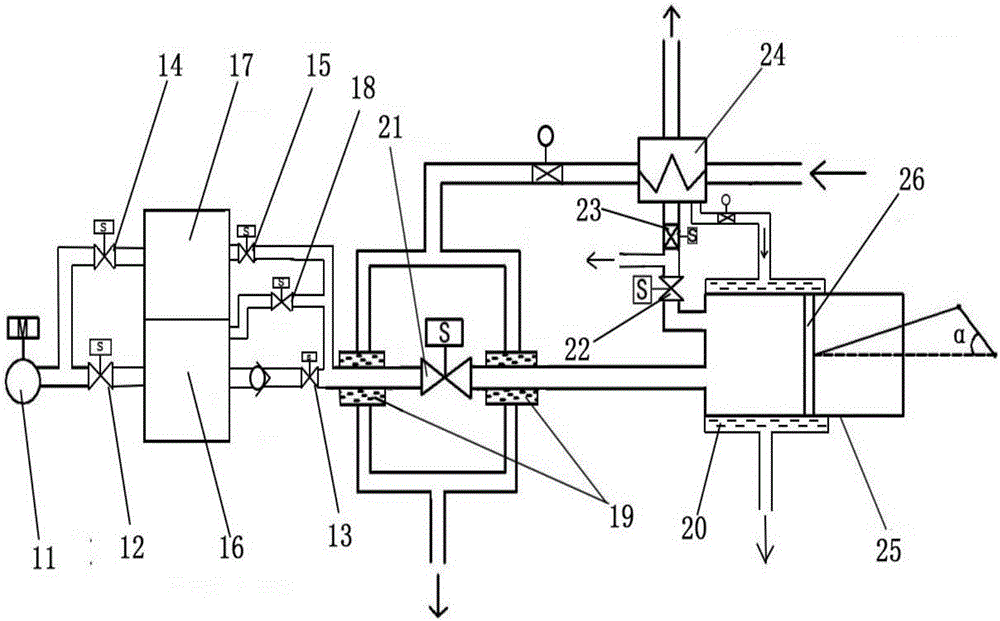

[0023] Such as figure 2As shown, the engine system includes an air compression pump 2, a compressed air tank, an intake solenoid valve 21, an engine, an exhaust solenoid valve 22, a heat exchange system and a control system, and the inside of the comp...

Embodiment 2

[0033] Such as figure 1 The rotary garbage crushing device shown includes the first five-knife roller 1, the second five-knife roller 2, a soft brush 3, a housing and an engine system; unbroken garbage enters from the entrance above the housing inside the housing, and successively pass through the first five-knife roller 1 and the second five-knife roller 2 for crushing, and then discharge from the outlet below the housing; the soft brush 3 is arranged on the left side of the first five-knife roller 1 The side is used to clean the flexible objects on the hob of the first five-blade roller 1, and the engine system drives the first five-blade roller 1 and the second five-blade roller 2 to rotate through a crankshaft connection;

[0034] Such as figure 2 As shown, the engine system includes an air compression pump 2, a compressed air tank, an intake solenoid valve 21, an engine, an exhaust solenoid valve 22, a heat exchange system and a control system, and the inside of the com...

Embodiment 3

[0044] Such as figure 1 The rotary garbage crushing device shown includes the first five-knife roller 1, the second five-knife roller 2, a soft brush 3, a housing and an engine system; unbroken garbage enters from the entrance above the housing inside the housing, and successively pass through the first five-knife roller 1 and the second five-knife roller 2 for crushing, and then discharge from the outlet below the housing; the soft brush 3 is arranged on the left side of the first five-knife roller 1 The side is used to clean the flexible objects on the hob of the first five-blade roller 1, and the engine system drives the first five-blade roller 1 and the second five-blade roller 2 to rotate through a crankshaft connection;

[0045] Such as figure 2 As shown, the engine system includes an air compression pump 2, a compressed air tank, an intake solenoid valve 21, an engine, an exhaust solenoid valve 22, a heat exchange system and a control system, and the inside of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com