Cutting-open device suitable for cutting open chestnut shell notch at home

A shell and chestnut technology, applied in the field of kitchen utensils, can solve the problems of high price, unsuitable use, large volume, etc., and achieve the effect of simple structure and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment.

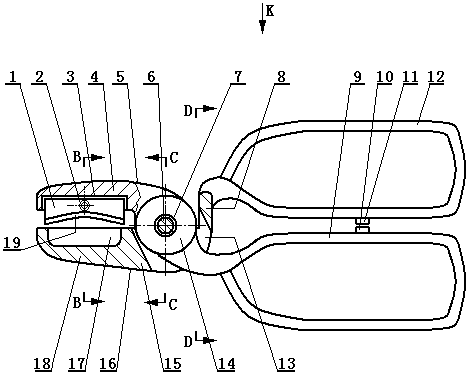

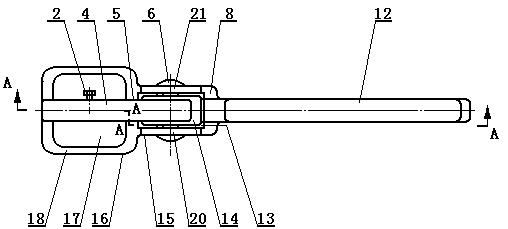

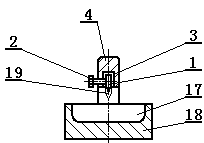

[0027] Embodiment: As shown in the accompanying drawings, design and manufacture a kind of cutter that is suitable for cutting the gap of the chestnut shell at home, including blade 1, bolt 2, upper shear body 5, rivet 6 and lower shear body 16, the cutter The left end of upper scissor body 5 is provided with integral structure, elongated knife seat 4, and the center of front and back width of knife seat 4 lower ends is provided with long knife groove 3, is provided with in the long knife groove 3 and is used for cutting open chestnut shell. The blade 1 of breach, the lower end of blade 1 is provided with sharp circular arc blade 19, and the left end of the lower scissors body 16 of scissors is provided with integral structure, square storage table 18, and the upper end of storage table 18 is provided with for cutting. Place the square concave hole 17 of chestnut when the chestnut sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com