Tungsten steel blade anti-blunt device

A blade and tungsten steel technology, applied in the field of tungsten steel blade anti-dulling device, to prevent blade passivation, improve cutting operation efficiency, and prevent dullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

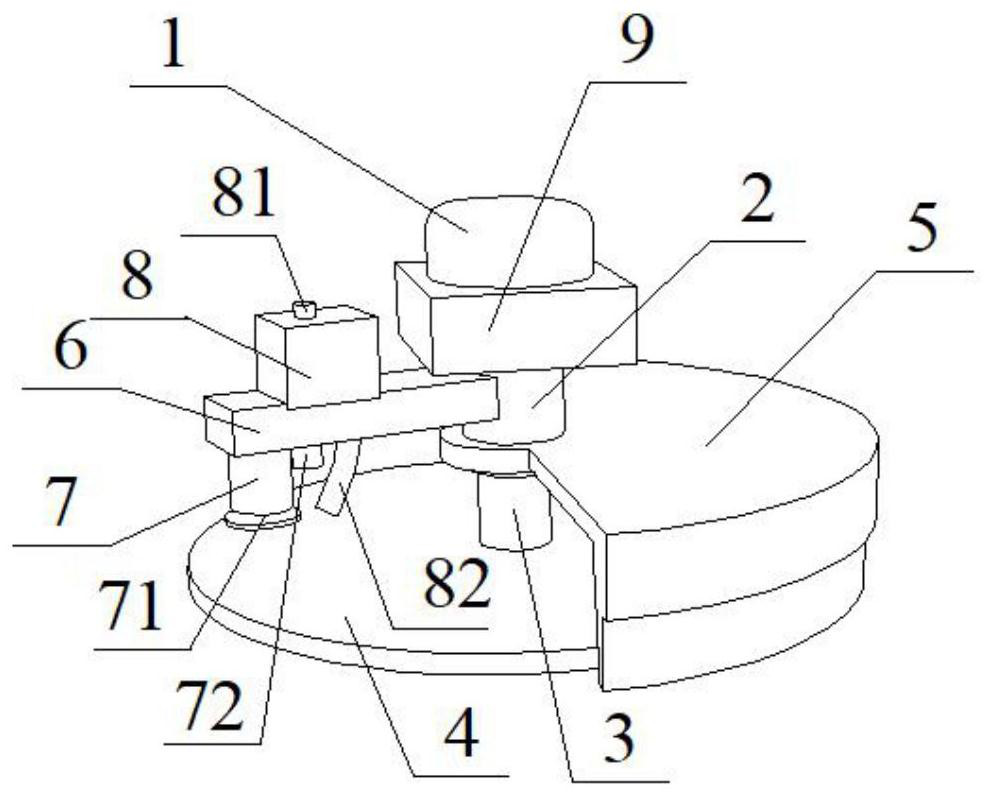

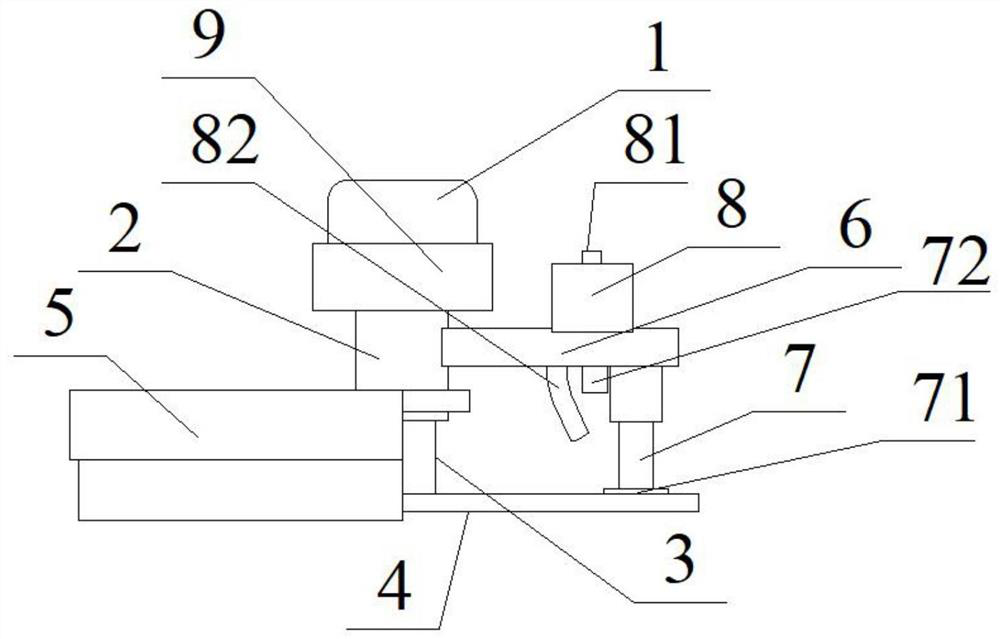

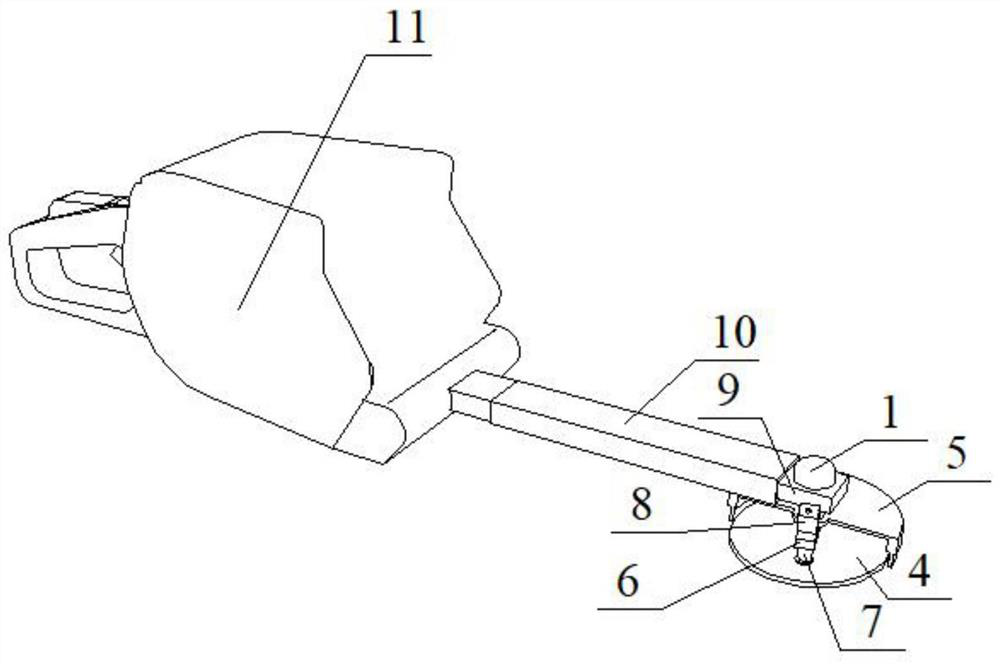

[0035] as attached figure 1 to attach Figure 4 As shown, the present invention provides a tungsten steel blade anti-blunt device, including a motor 1, a connecting rod 2, a rotating shaft 3, a tungsten steel blade 4, a protective cover 5, a connecting block 6, a grinding telescopic rod 7, a polishing liquid tank 8, a control Module 9, connection handle 10, host 11.

[0036] The lower part of the motor 1 is provided with a connecting rod 2; the lower part of the connecting rod 2 is equipped with a tungsten steel blade 4; the side of the connecting rod 2 is fixedly connected with a connecting block 6; Polishing fluid tank 8.

[0037] as attached figure 1 to attach figure 2 As shown, in the above embodiment, specifically, the lower part of the motor 1 is fixedly connected with the rotating shaft 3; the lower part of the rotating shaft 3 is fixedly installed with the tungsten steel blade 4.

[0038] In the above embodiment, specifically, the side of the connecting rod 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com