Patents

Literature

45results about How to "Fully wound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washings overturned washing method by impeller of washing machine

ActiveCN101851835ASave waterHigh stress frequencyWashing machine with receptaclesTextiles and paperImpellerEngineering

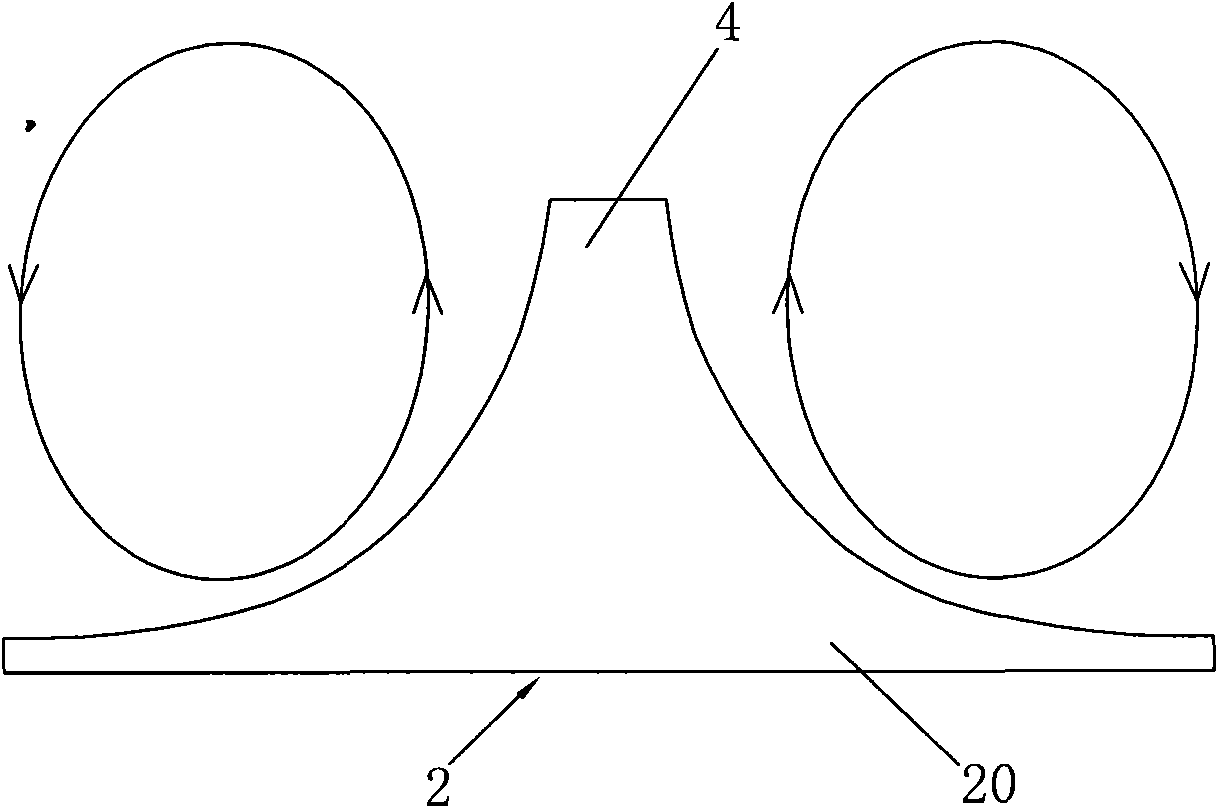

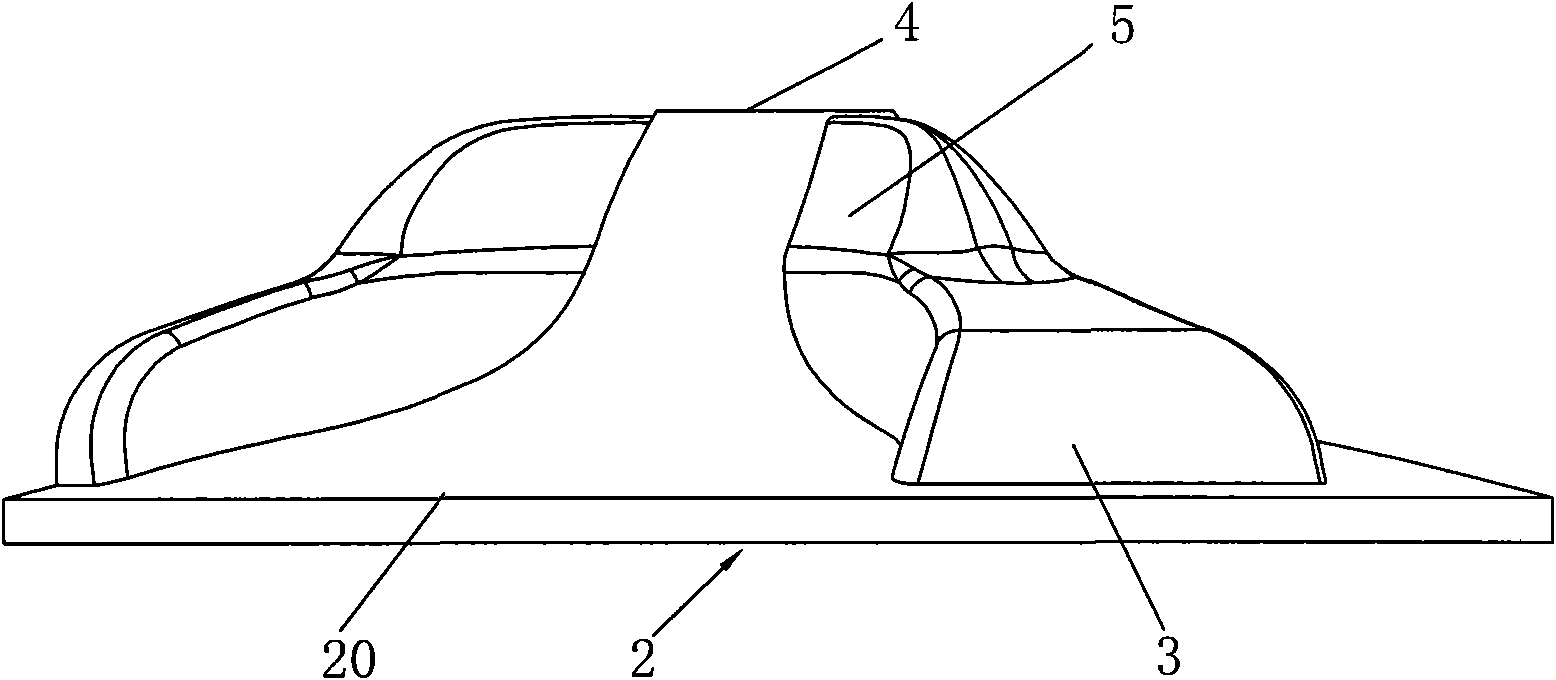

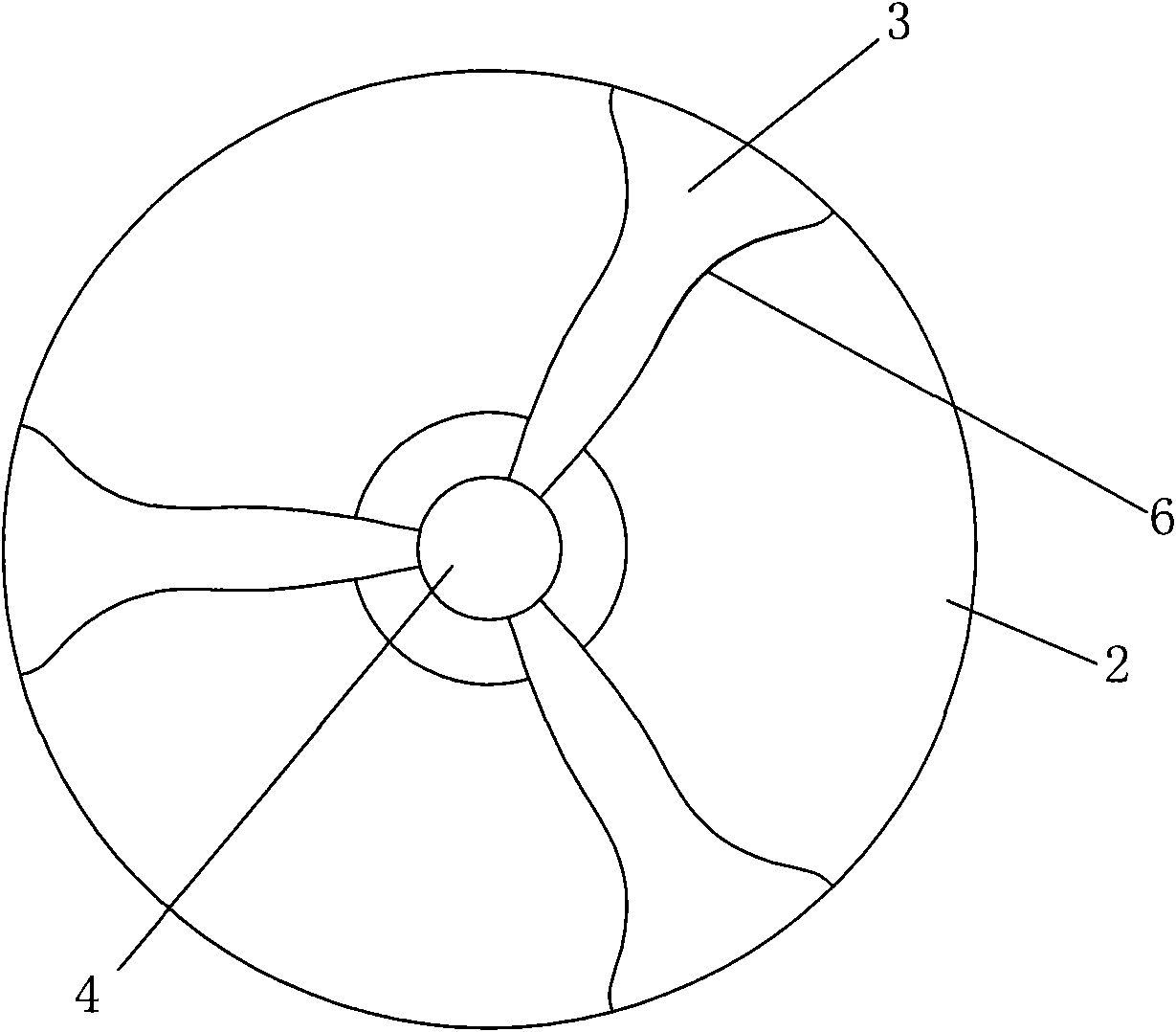

The invention discloses a washings overturned washing method by an impeller of a washing machine. In the method, impeller vanes are arranged on the impeller in the radial direction, and an upward raised impeller neck is arranged on the position of a central axis. The washings overturned washing comprises a forward moving process and a backward moving process: when the washings are on the bottom of an inner barrel and move towards the center of the impeller, the washings moving mode is that washings make spiral ascending motion upwards along the impeller vanes while revolving around the central axis, and move upwards along the impeller vanes to the impeller neck in the center of the impeller; when the washings move to the top of the impeller neck, the washings move upwards due to inertia; after short upcast, the washings make external overturn revolution under the action of centrifugal force and bottom washings until the washings reach the position of inner barrel wall far away from the center of the impeller, and then the washings are pulled downwards by the washings on the bottom and the washings contacted with the impeller until the washings reach the bottom of the barrel; and while the washings move, the washings make overturned motion. The washing method has the characteristics of comprehensiveness, sufficiency, repetition and high efficiency.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Impact-resistant cold-resistant anticorrosive paint

ActiveCN104327670AImprove interface performanceImprove stabilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxySolvent

The invention discloses an impact-resistant cold-resistant anticorrosive paint which is prepared from the following raw materials in parts by weight: 50-55 parts of epoxy resin, 20-24 parts of amino resin, 11-15 parts of alkyd resin, 12-15 parts of nitrile-butadiene rubber 2707, 21-28 parts of modified graphene, 12-15 parts of calcium carbonate, 5-8 parts of zinc oxide, 1.1-1.5 parts of silane coupling agent KH-792, 0.2-0.5 part of preservative, 1.6-2 parts of defoaming agent, 1.5-1.8 parts of leveling agent, 0.8-1.1 parts of mold preventive, 1.1-1.4 parts of dispersing agent, 1.6-1.8 parts of film formation assistant, 1.2-1.5 parts of anti-aging agent OD, 1-3 parts of hydroxyethyl cellulose and 60-64 parts of solvent. The impact-resistant cold-resistant anticorrosive paint has the characteristics of high impact resistance and favorable cold resistance, and is suitable for demands of different occasions.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

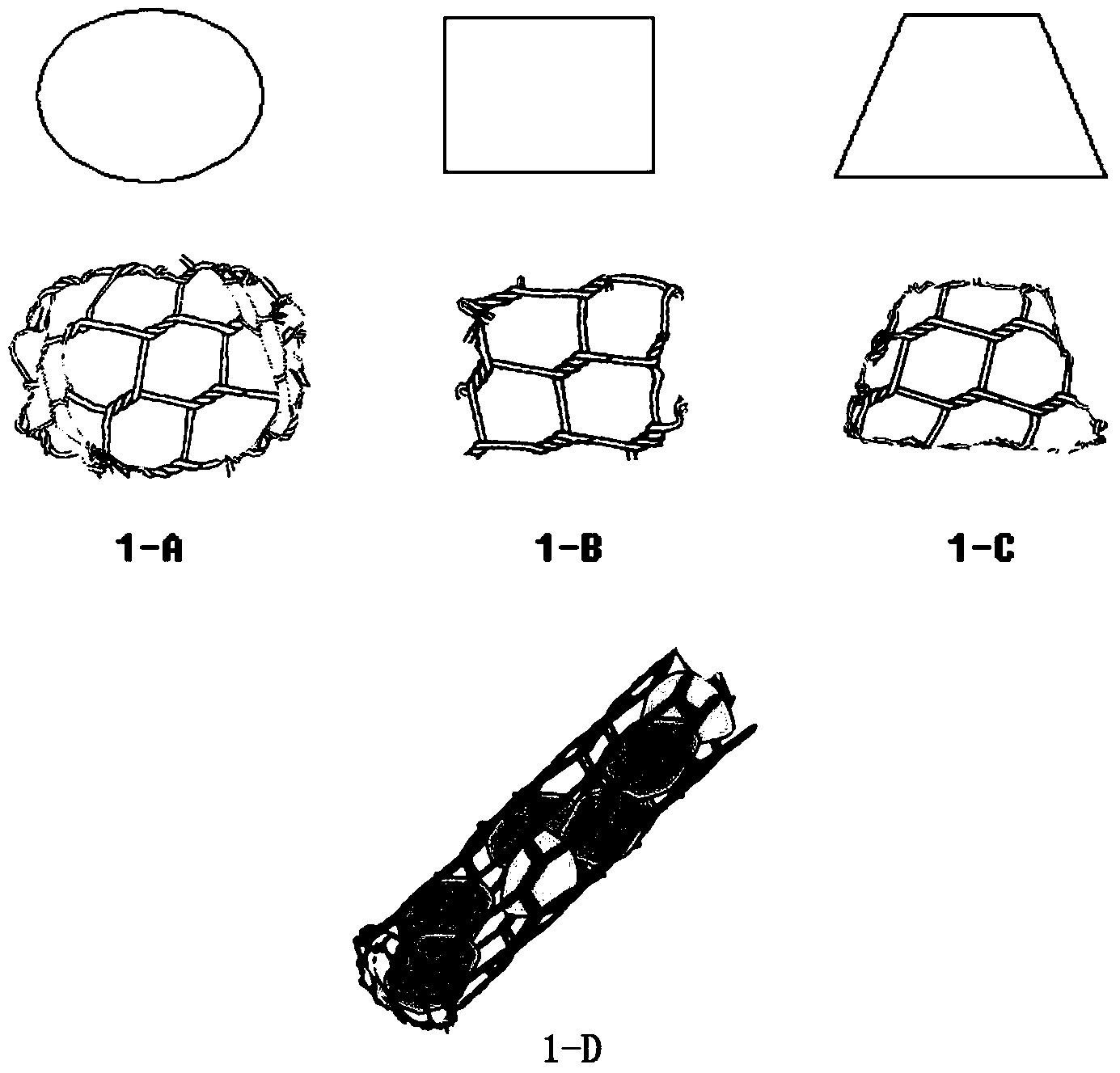

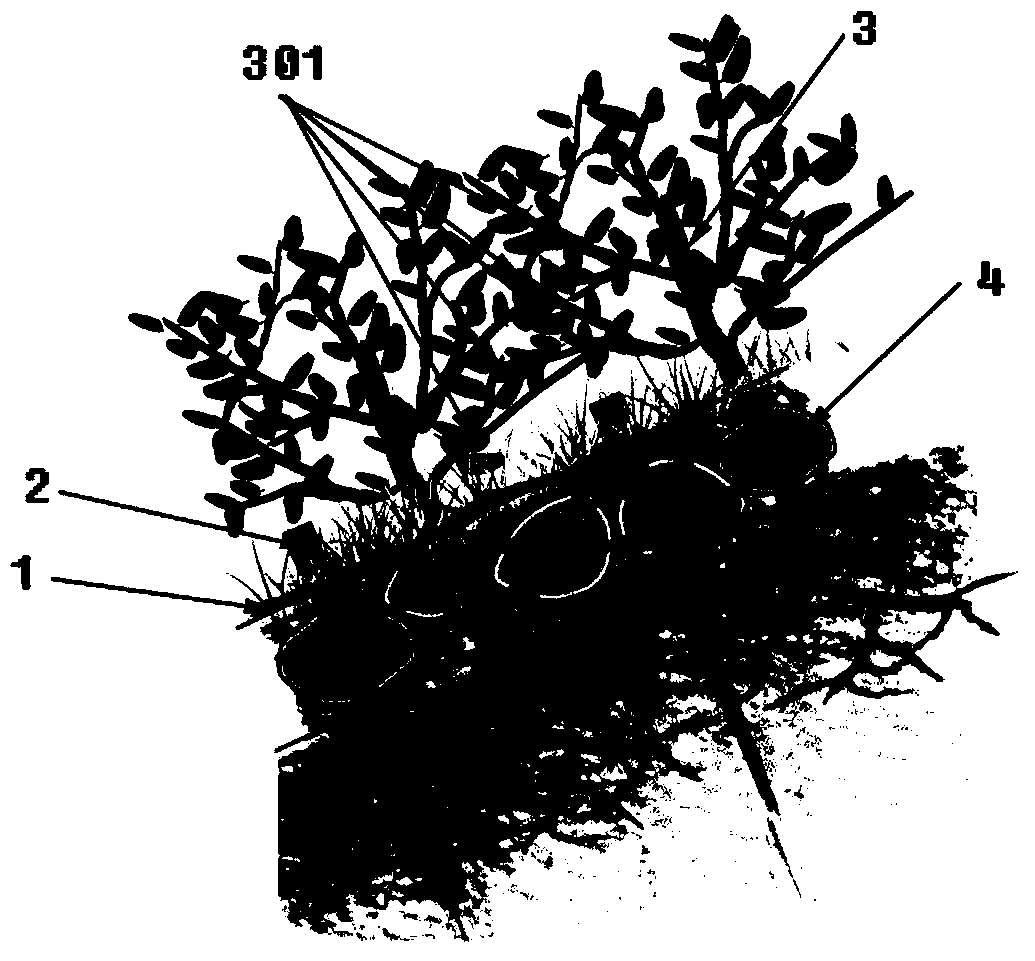

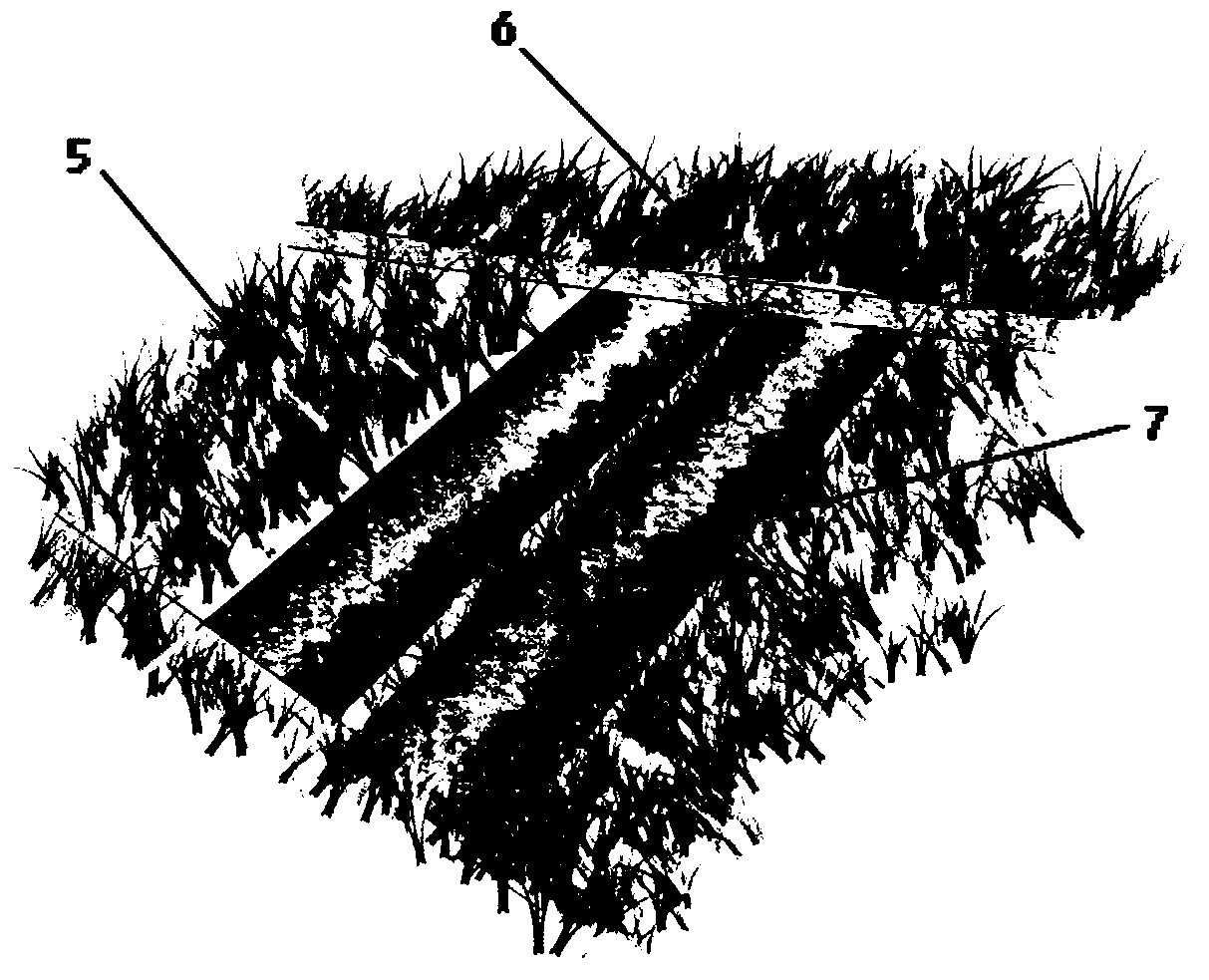

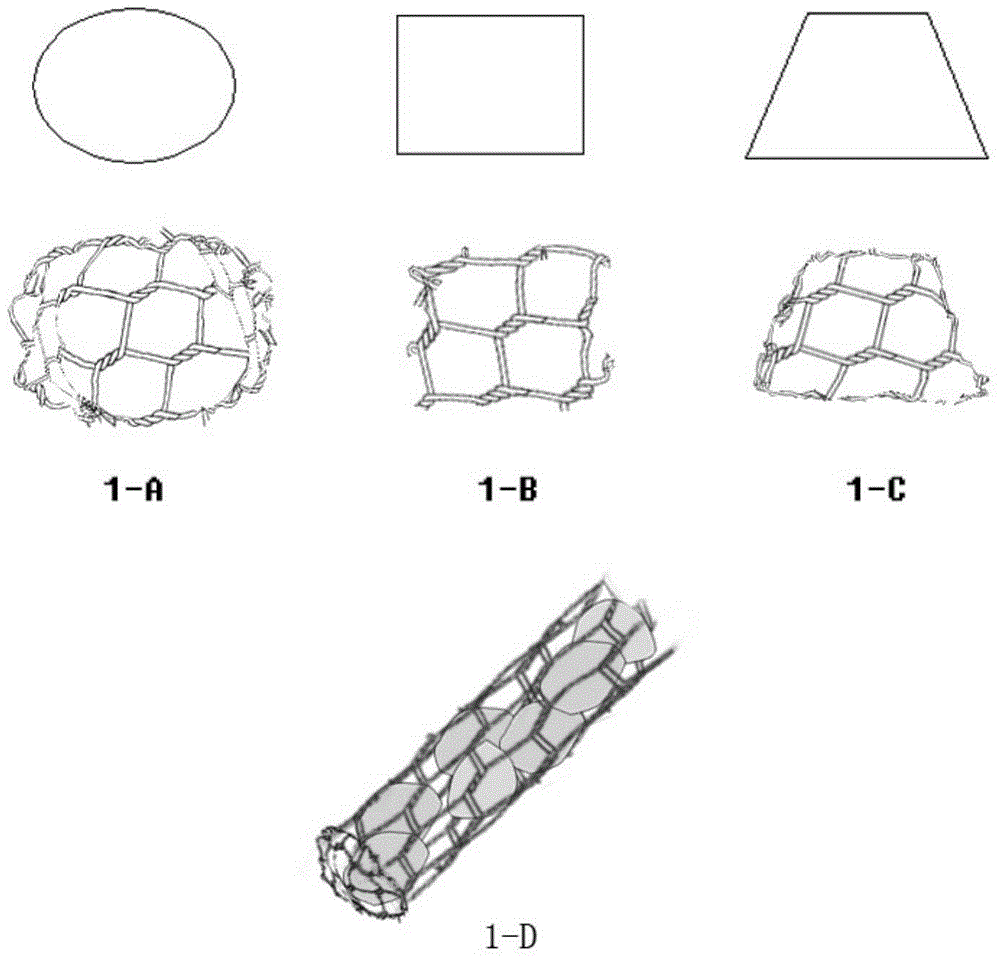

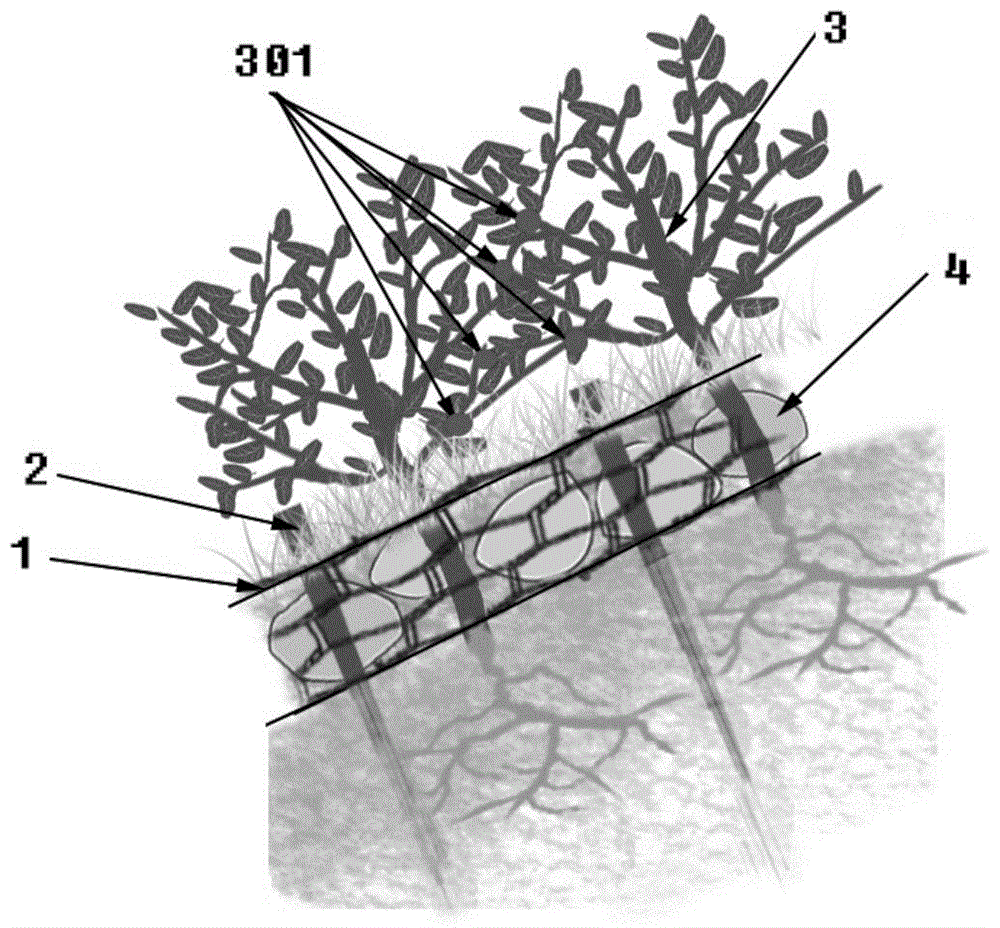

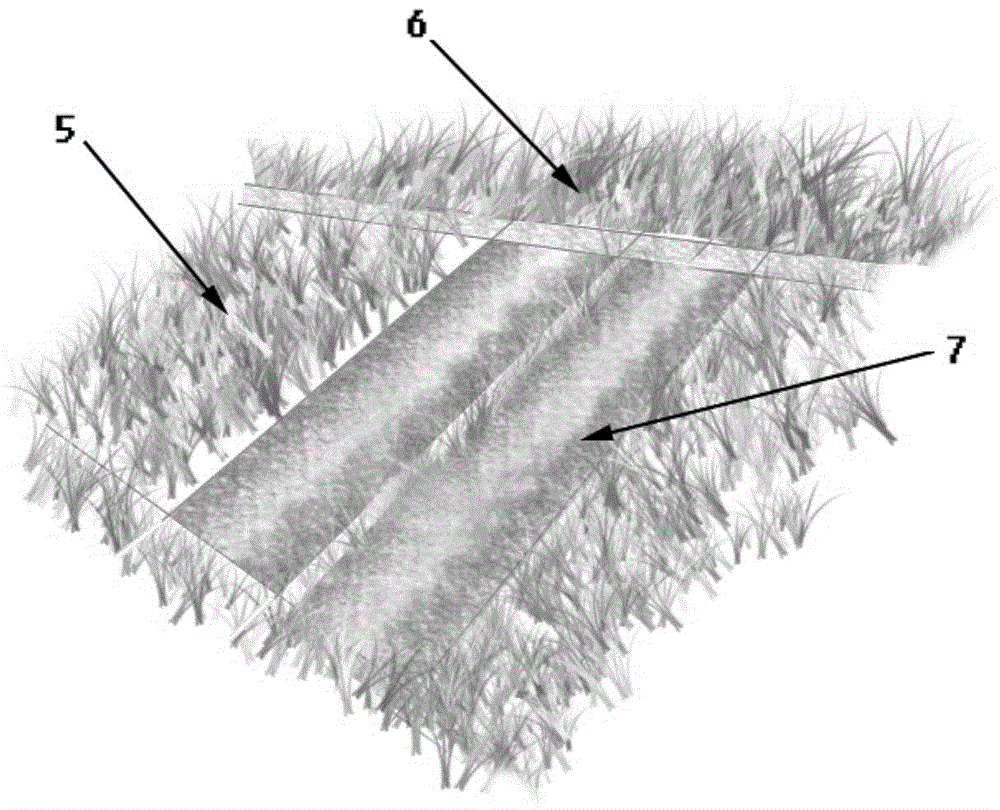

Method for ecological management of hedgerow riverbank revetment

ActiveCN103643654AImprove the landscape effectFully woundCoastlines protectionHorticultureBuffer stripAquatic animal

The invention relates to a method for ecological management of a hedgerow riverbank revetment. The method comprises the steps as follows: ecological gabion revetment grooving, gabion box laying, hedgerow shrub planting, pebble backfilling, shrub grafting and the like. According to the method, a method for fixing gabions through hedgerows formed with a coordinal plant grafting technology is fully used, the revetment is more stable in structure, the water erosion resistance of the revetment is enhanced, and meanwhile, riverbank buffer zones consisting of flooding-resistant shrubs, ground cover herbage and gabion filler can play an important role in filtering non-point source pollutants entering a water body; a richer habitat is provided for aquatic animals and plants by gap structures formed by ecological gabions, so that the stability of a river ecological system is maintained; and the landscape effect of the riverbank revetment can be further improved by planting of shrub vegetation.

Owner:金辛(海南)科技有限公司

Thermal insulation coating with high adhesive force and impact resistance

ActiveCN104312335AGood dispersionEasy to spreadConjugated diene hydrocarbon coatingsAcrylic resinThermal insulation

The invention discloses a thermal insulation coating with high adhesive force and impact resistance. The thermal insulation coating is prepared from the following raw materials in parts by weight: 50-55 parts of acrylic resin, 22-26 parts of nitrile rubber 2707, 18-21 parts of phenolic resin, 1.1-1.4 parts of antioxidant 4010 NA, 23-26 parts of modified graphene, 10-13 parts of talcum powder, 8-11 parts of calcined kaolin, 3-6 parts of cenosphere, 1.1-1.5 parts of silane coupling agent KH-560, 1.4-1.8 parts of a film-forming agent, 2.2-2.5 parts of a dispersant, 1.6-1.9 parts of a defoaming agent, 1-1.5 parts of a thickening agent, 1.8-2.1 parts of a wetting agent, 1.6-2 parts of a flatting agent, 0.3-0.6 part of a preservative, 0.2-0.5 part of a mould inhibitor, and 58-62 parts of a solvent. The thermal insulation coating disclosed by the invention is high in adhesive force and good in impact resistance.

Owner:广州市哲铭油墨涂料有限公司

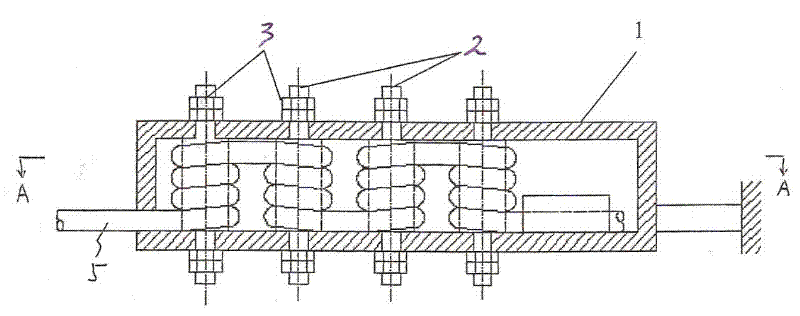

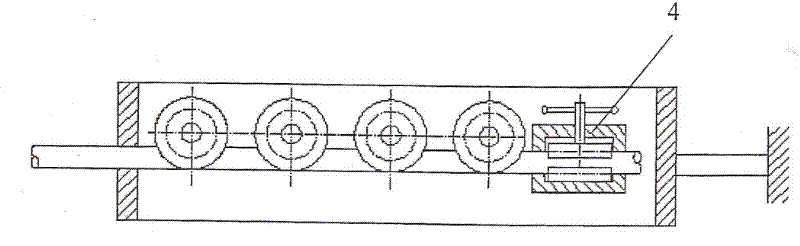

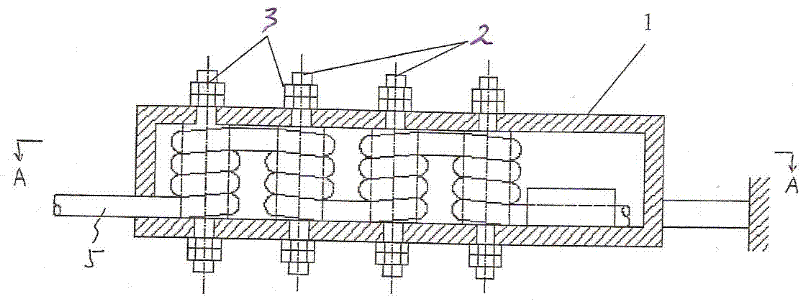

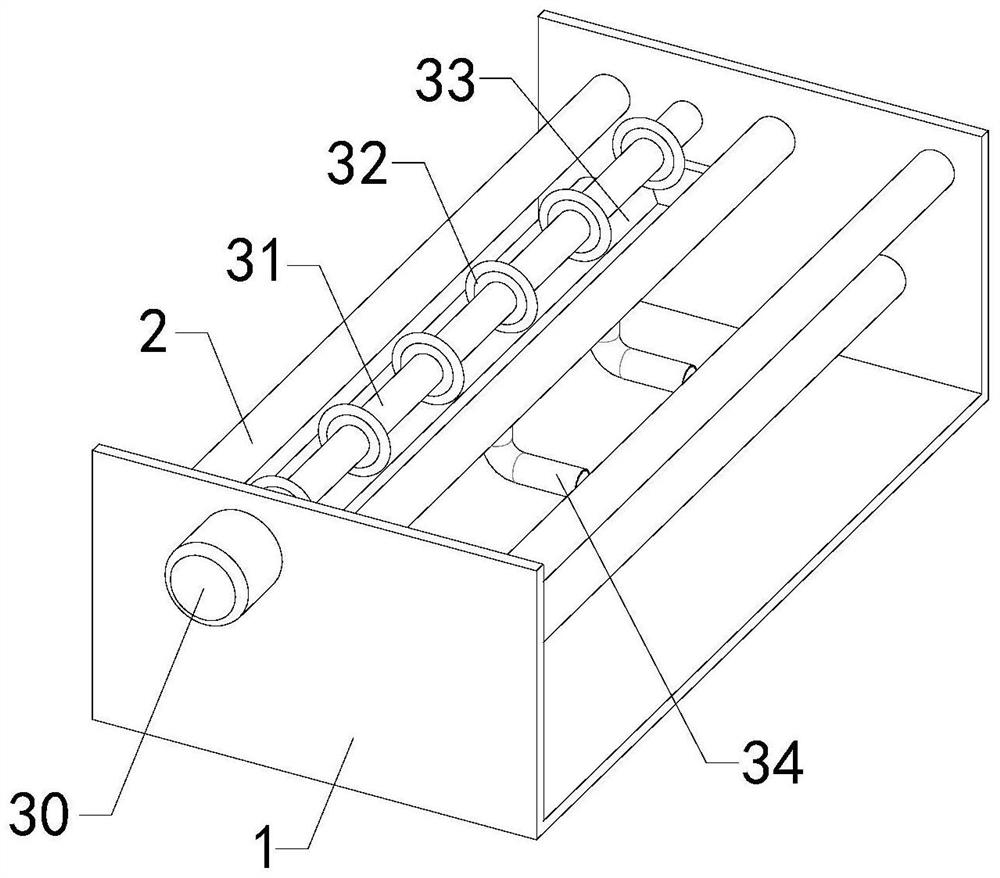

Frictional anchorage device applied to fibre reinforced composite cables

InactiveCN102251474AReasonable structureLarge clamping forceBridge structural detailsEngineeringFiber-reinforced composite

The invention discloses a frictional anchorage device applied to fibre reinforced composite cables. The frictional anchorage device comprises a rack, wherein a plurality of fixed shafts on which fibre reinforced composite cable are wound, and a spiral pressure fastening device used for pressing and fastening the tail ends of the fibre reinforced composite cables is arranged behind the last fixed shaft. The frictional anchorage device has a reasonable structure and is easy for installation and anchoring.

Owner:NANTONG UNIVERSITY

Wear-resistant oil-resistant insulating paint

ActiveCN104327720ARich microporous structureGood oil resistanceConjugated diene hydrocarbon coatingsPolyester coatingsPolyesterNitrile rubber

The invention discloses a wear-resistant oil-resistant insulating paint which is prepared from the following raw materials in parts by weight: 40-44 parts of silica gel powder, 26-29 parts of acrylic resin, 18-21 parts of nitrile rubber, 10-15 parts of oxalic polyester, 22-25 parts of modified graphene, 6-10 parts of zinc oxide, 1.6-2 parts of a defoaming agent, 1.5-1.8 parts of a flatting agent, 1.1-1.4 parts of a dispersant, 1.6-1.8 parts of a coalescing agent, 1-1.3 parts of an anti-aging agent 4020, 3-6 parts of a drier, 1.2-1.5 parts of a mildew preventive, 1.5-1.8 parts of an anti-precipitator and 0.6-1 part of an antirust agent. The paint disclosed by the invention has high wear resistance and good oil resistance.

Owner:YANGZHOU LVBAO ARTIFICIAL TURF CO LTD

Waterproofing acid-proofing anti-collision insulating coating

InactiveCN105315820AGood dispersionEasy to spreadConjugated diene hydrocarbon coatingsMicrosphereSolvent

The invention discloses a waterproofing acid-proofing anti-collision insulating coating. The coating is prepared from the following raw materials in parts by weight: 50-55 parts of acrylic polymer emulsion, 22-26 parts of nitrile rubber 2707, 18-21 parts of phenolic resin, 1.1-1.4 parts of a thixotropic agent, 23-26 parts of modified graphene, 10-13 parts of talcum powder, 8-11 parts of calcined kaolin, 3-6 parts of hollow microspheres, 1.1-1.5 parts of a silane coupling agent KH-560, 1.4-1.8 parts of a coalescing agent, 2.2-2.5 parts of a dispersing agent, 1.6-1.9 parts of a defoaming agent, 1-1.5 parts of a thickening agent, 1.8-2.1 parts of a wetting agent, 1.6-2 parts of anti-precipitant, 0.3-0.6 part of preservative, 0.2-0.5 part of mildew preventive and 58-62 parts of solvent. The waterproofing acid-proofing anti-collision insulating coating has high adhesion and good impact resistance.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

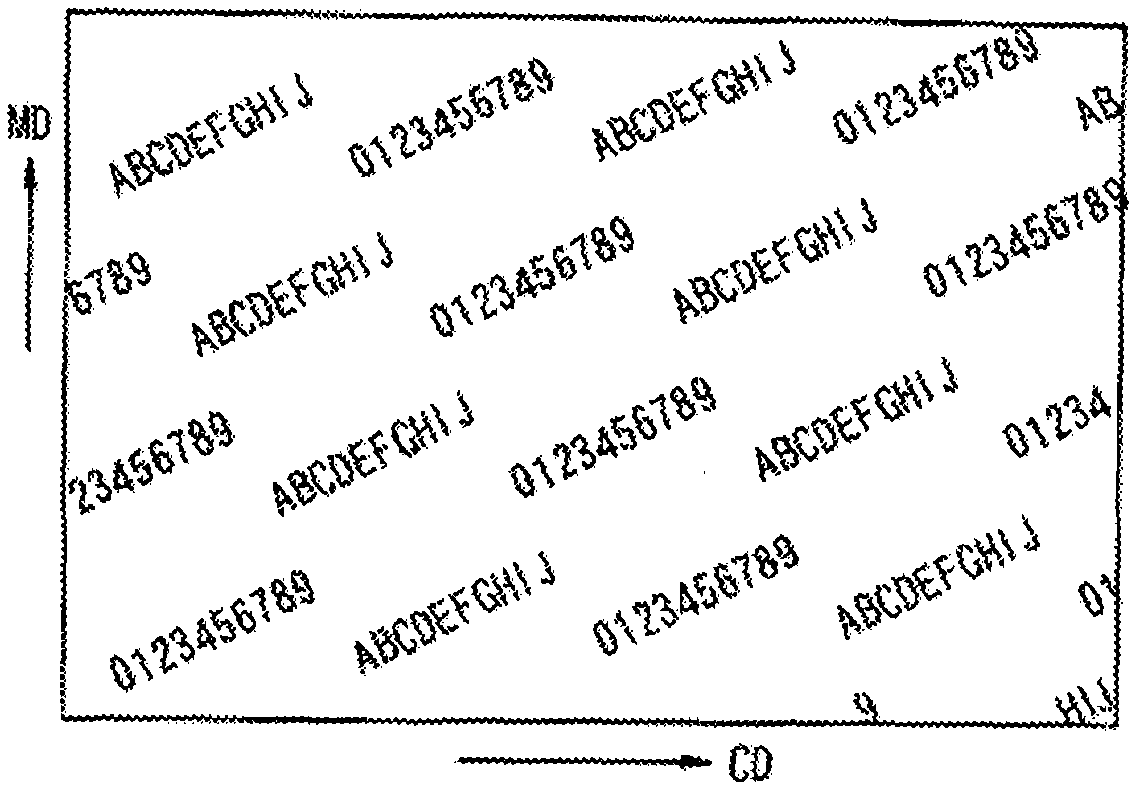

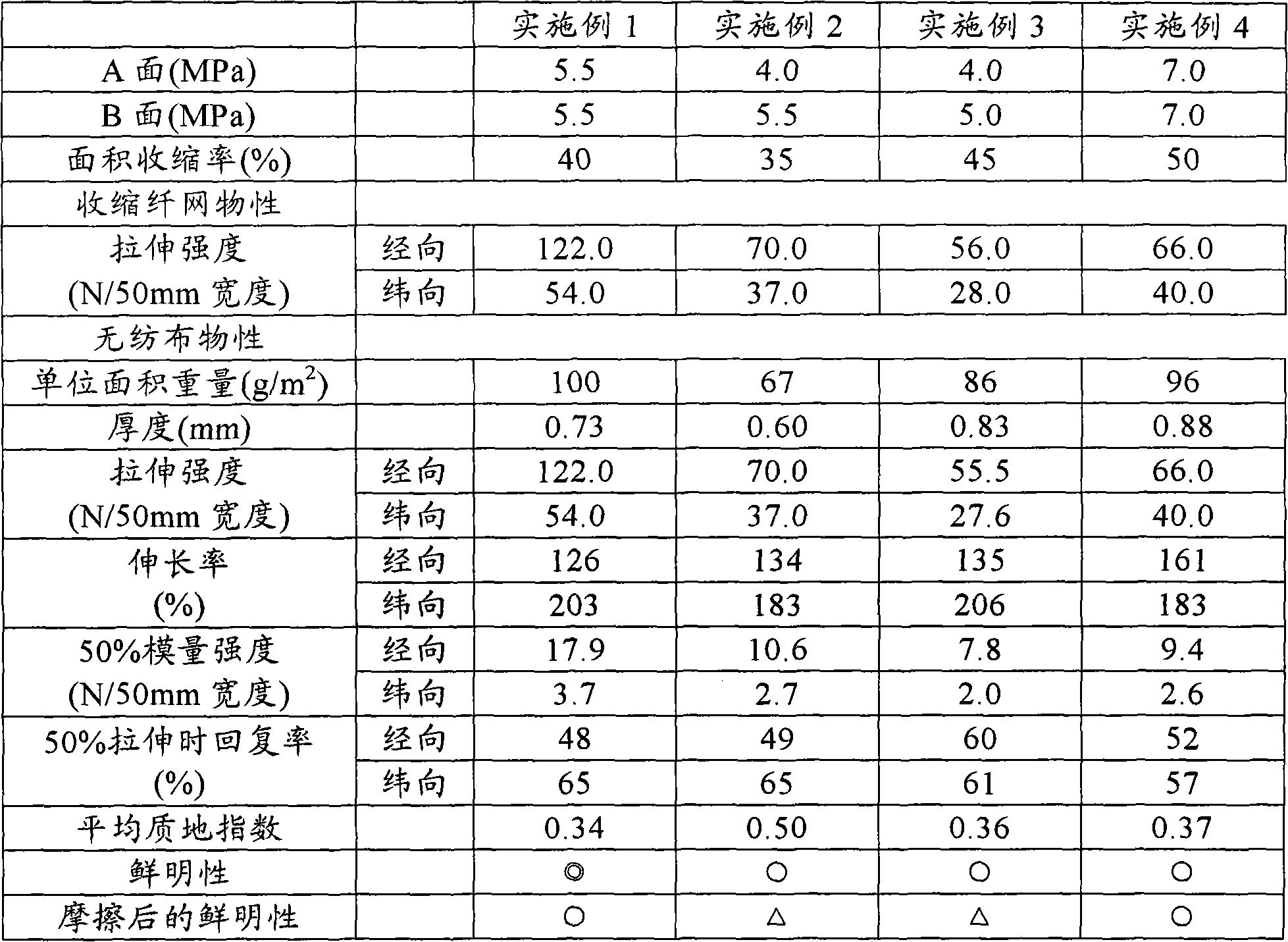

Nonwoven fabric and method for manufacturing same

Provided are an extensible nonwoven fabric on which the source, the medicinal component, a pattern and / or other pieces of information are recognizable not only at beginning of the use of the fabric but also during use; and a method for manufacturing the nonwoven fabric. The nonwoven fabric of the invention is a nonwoven fabric made mainly of highly crimped fibers, partially having a compressed region where no fibers are melted and bonded to each other, and having a tensile strength of 25 N / 5-cm-width or more in both the machine direction and the cross direction. This nonwoven fabric may be manufactured by causing a water jet having a pressure of 5 MPa or more to act onto a fiber web made mainly of a latent crimpable fiber, thereby forming an entangled fiber web, causing heat to act onto the entangled fiber web, thereby crimping the latent crimpable fiber to convert the fiber to a highly crimped fiber and contracting, at the time of the conversion, the area of the entangled fiber web by 30% or more, thereby forming a contracted fiber web, and embossing the contracted fiber web in such a manner that the fibers are not melted and bonded to each other.

Owner:JAPAN VILENE CO LTD

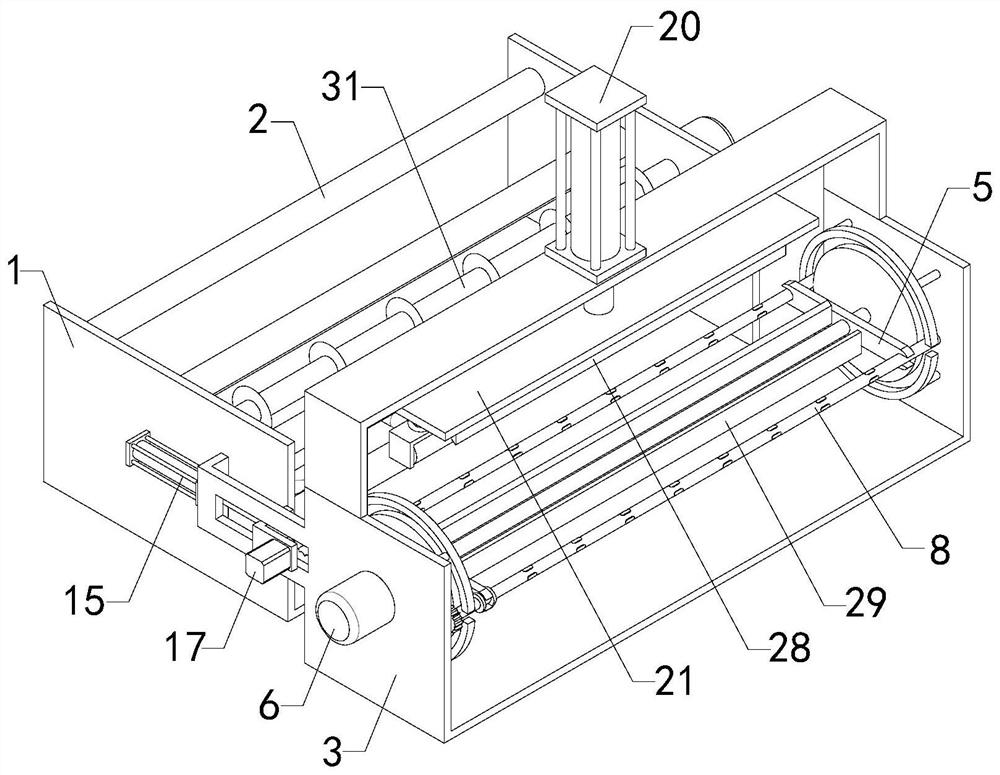

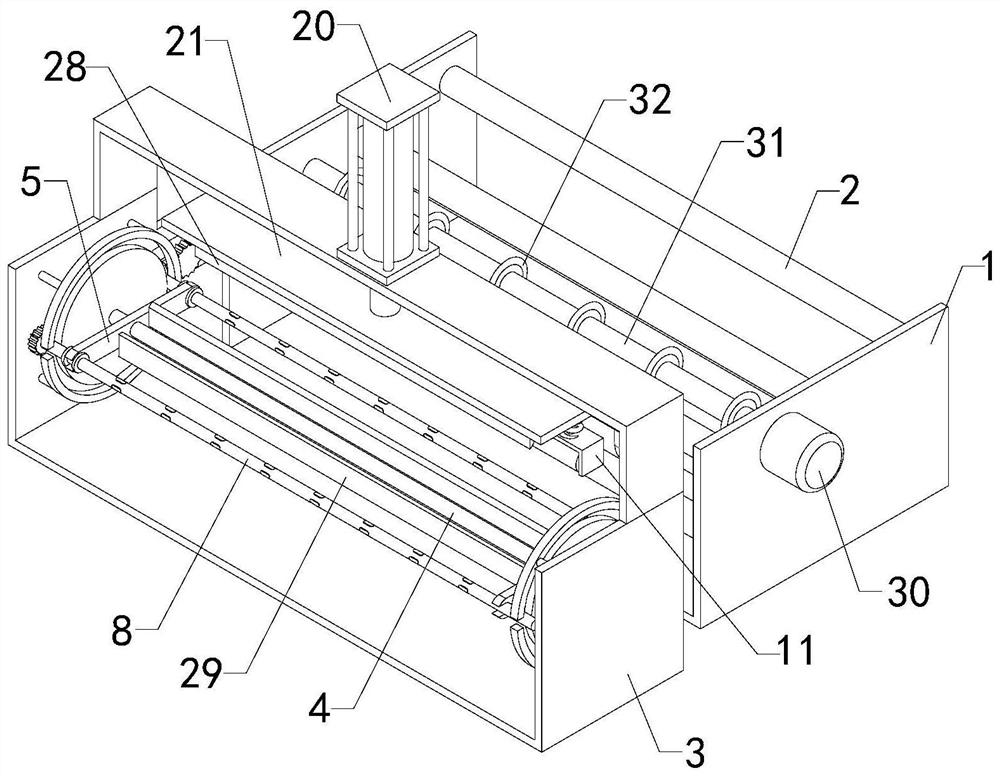

Electrostatic spinning and spunlacing consolidation composite membrane-making device

ActiveCN102061571AImproved strength and thickness distributionHigh strengthFilament/thread formingNon-woven fabricsElectrospinningWoven fabric

The invention relates to an electrostatic spinning and spunlacing consolidation composite membrane-making device comprising a stand and an annular supporting web band, wherein the annular supporting web band is rotationally arranged in a vertical plane; the front side of the stand is provided with a receiving device used for receiving cellosilk generated by an electrostatic spinning device; the annular supporting web band is provided with a segment of cellosilk receiving stroke used for intercepting the cellosilk at the front side of the receiving device; and the cellosilk receiving stroke of the annular supporting web band is downstream provided with at least one spunlacing head. The electrostatic spinning and spunlacing consolidation composite membrane-making device combines an electrostatic spinning technology with a spunlacing consolidation membrane-forming technology, intercepts and receives the cellosilk generated by the electrostatic spinning device by adopting the rotational annular supporting web band, can enable the cellosilk to be sufficiently orientated and form a fiber web because the annular supporting web band rotates towards one direction during work and then twine the cellosilk of the fiber web into a membrane by utilizing the spunlacing consolidation membrane-forming technology, thereby greatly improving the intensity and the thickness distribution of an obtained non-woven fabric membrane.

Owner:焦作伴侣纳米材料工程有限公司

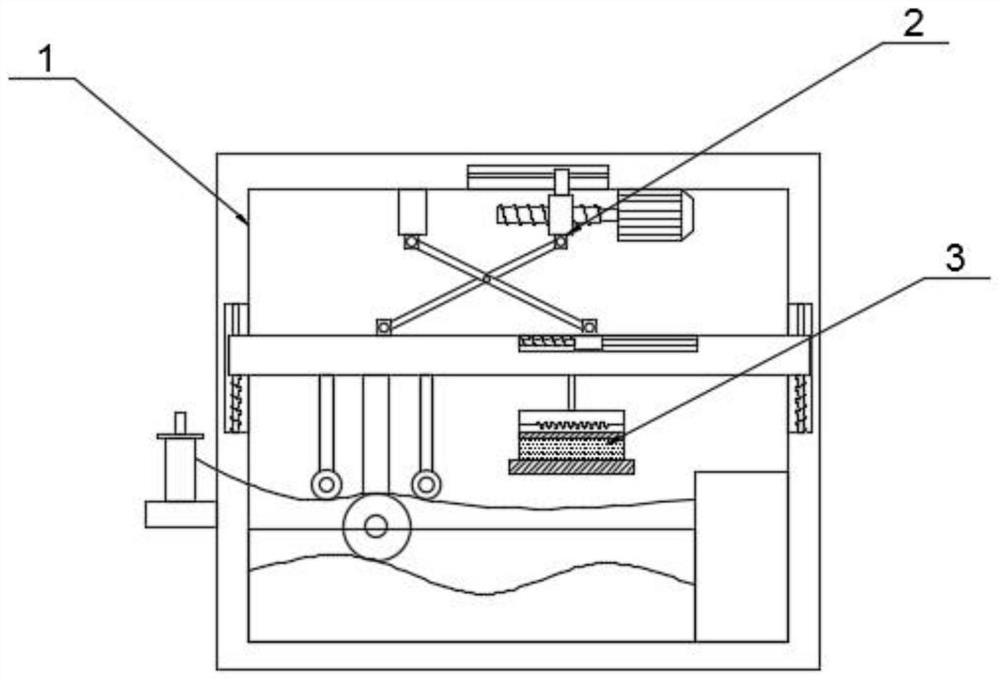

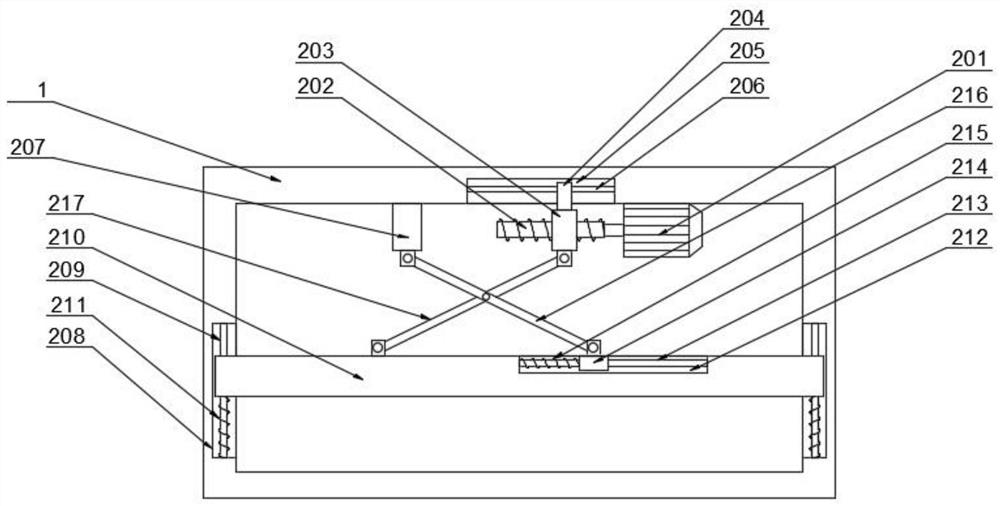

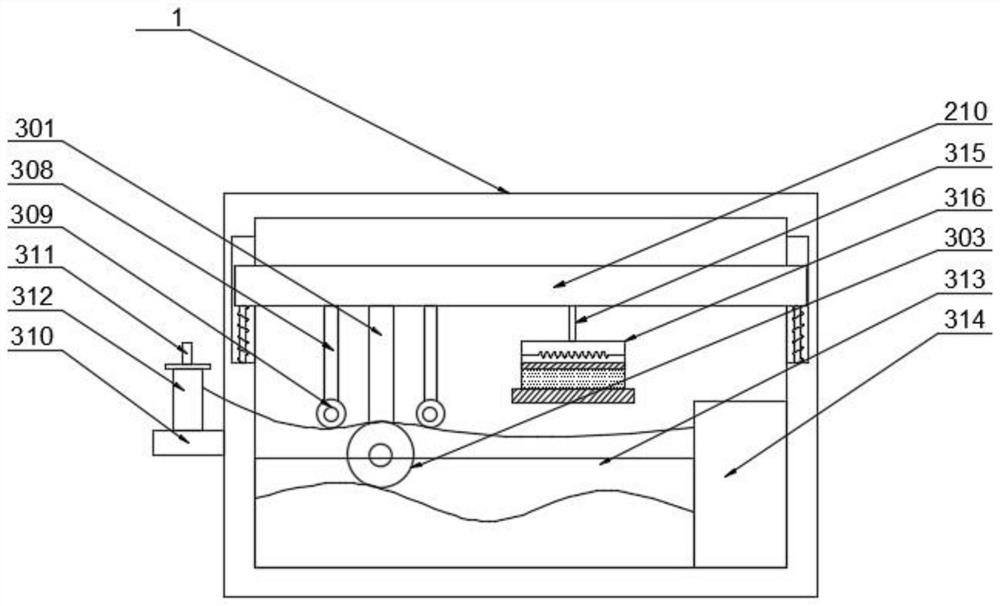

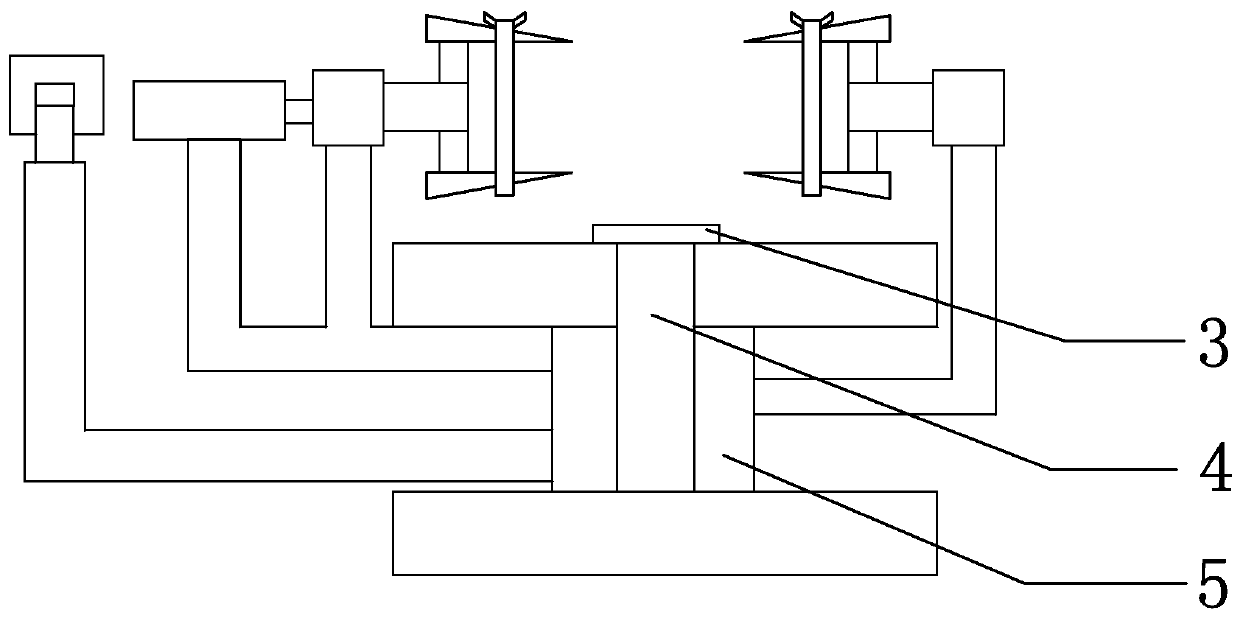

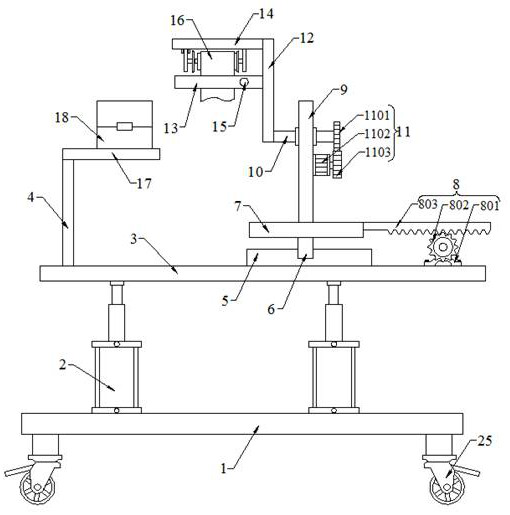

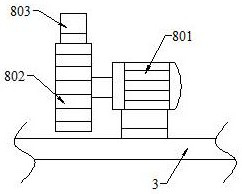

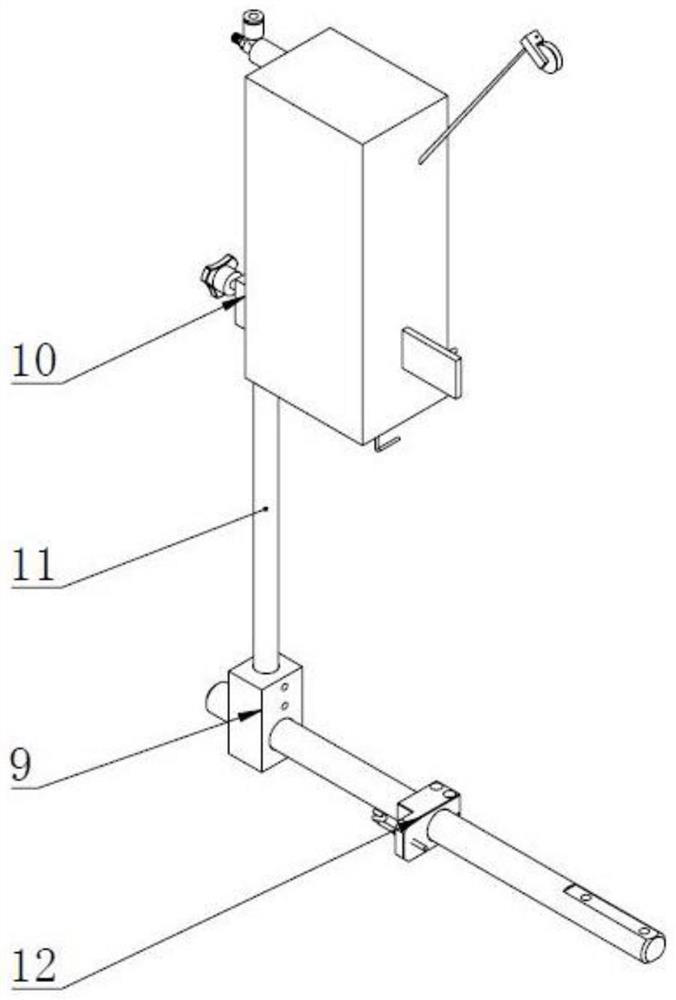

Glass fiber battery separator winding and cutting device

PendingCN113697552AEasy to disassembleImprove work efficiency and use reliabilityWebs handlingContinuous productionStructural engineering

The invention relates to the technical field of glass fiber battery separator processing accessory devices, in particular to a glass fiber battery separator winding and cutting device. The glass fiber battery separator winding and cutting device comprises a machine frame and a winding mechanism, and further comprises a transverse moving mechanism, a driving mechanism, a lifting mechanism, pressing mechanisms and a cutting mechanism, a plurality of guiding and conveying shafts and a slitting mechanism are arranged on the machine frame, the winding mechanism comprises a fixing frame and a servo motor, a rotating shaft is arranged on the inner side of the fixing frame in a rotating mode, a rotating material frame is arranged on the outer side of the rotating shaft, arc-shaped clamping grooves are formed in the left end and the right end of the rotating material frame correspondingly, winding air swelling shafts are movably arranged at the arc-shaped clamping grooves, guide plates are arranged at the front end and the rear end of the fixing frame correspondingly, annular guide holes are formed in the guide plates, and pick-and-place openings communicating with the annular guide holes are formed in the right ends of the guide plates. According to the glass fiber battery separator winding and cutting device, winding sleeves can be fed and discharged conveniently, in the feeding and discharging process, shutdown is not needed, continuous production operation is achieved, and the working efficiency and the use reliability are improved.

Owner:天长市永昌玻纤制品有限公司

Method for ecological management of hedgerow riverbank revetment

ActiveCN103643654BImprove the landscape effectFully woundCoastlines protectionHorticultureBuffer stripAquatic animal

The invention relates to a method for ecological management of a hedgerow riverbank revetment. The method comprises the steps as follows: ecological gabion revetment grooving, gabion box laying, hedgerow shrub planting, pebble backfilling, shrub grafting and the like. According to the method, a method for fixing gabions through hedgerows formed with a coordinal plant grafting technology is fully used, the revetment is more stable in structure, the water erosion resistance of the revetment is enhanced, and meanwhile, riverbank buffer zones consisting of flooding-resistant shrubs, ground cover herbage and gabion filler can play an important role in filtering non-point source pollutants entering a water body; a richer habitat is provided for aquatic animals and plants by gap structures formed by ecological gabions, so that the stability of a river ecological system is maintained; and the landscape effect of the riverbank revetment can be further improved by planting of shrub vegetation.

Owner:金辛(海南)科技有限公司

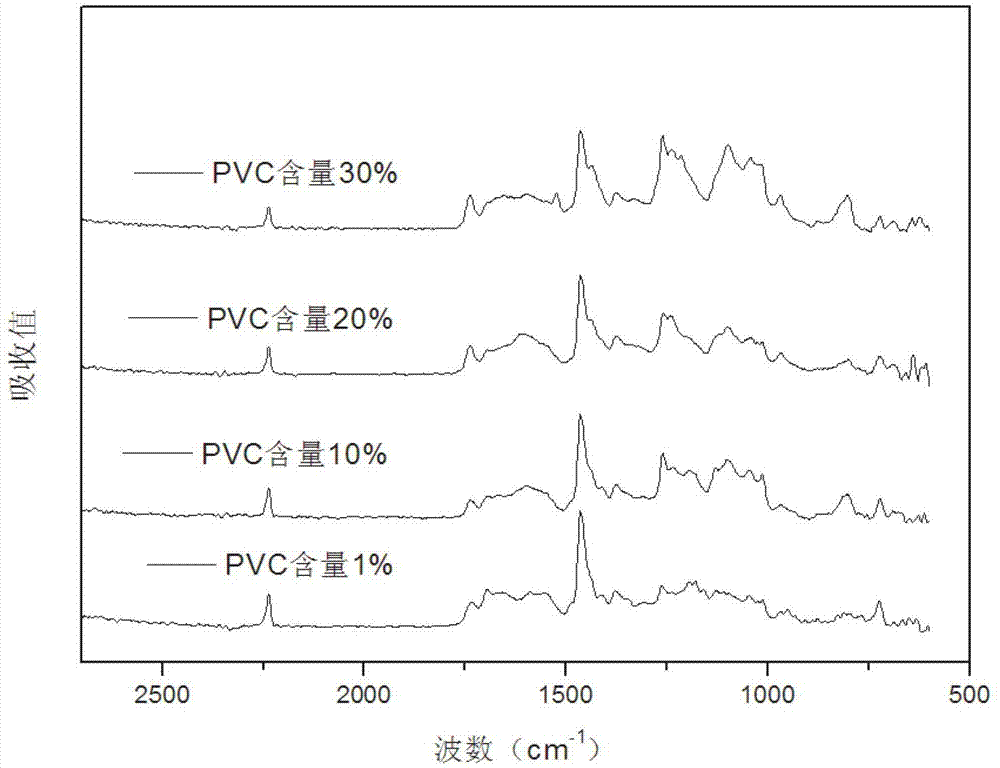

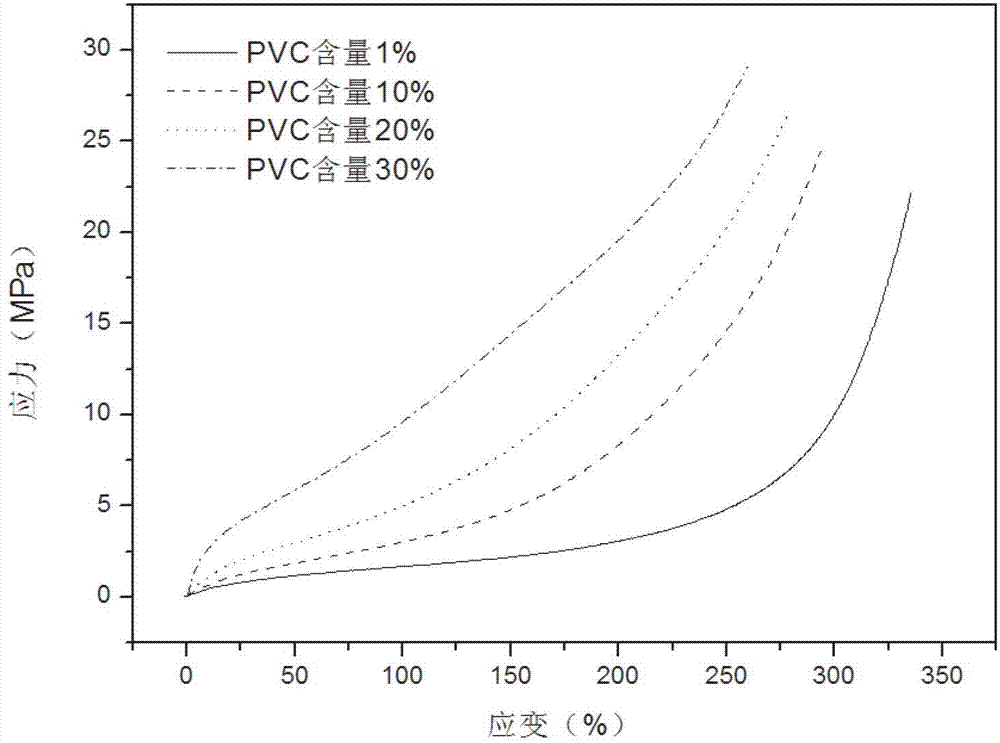

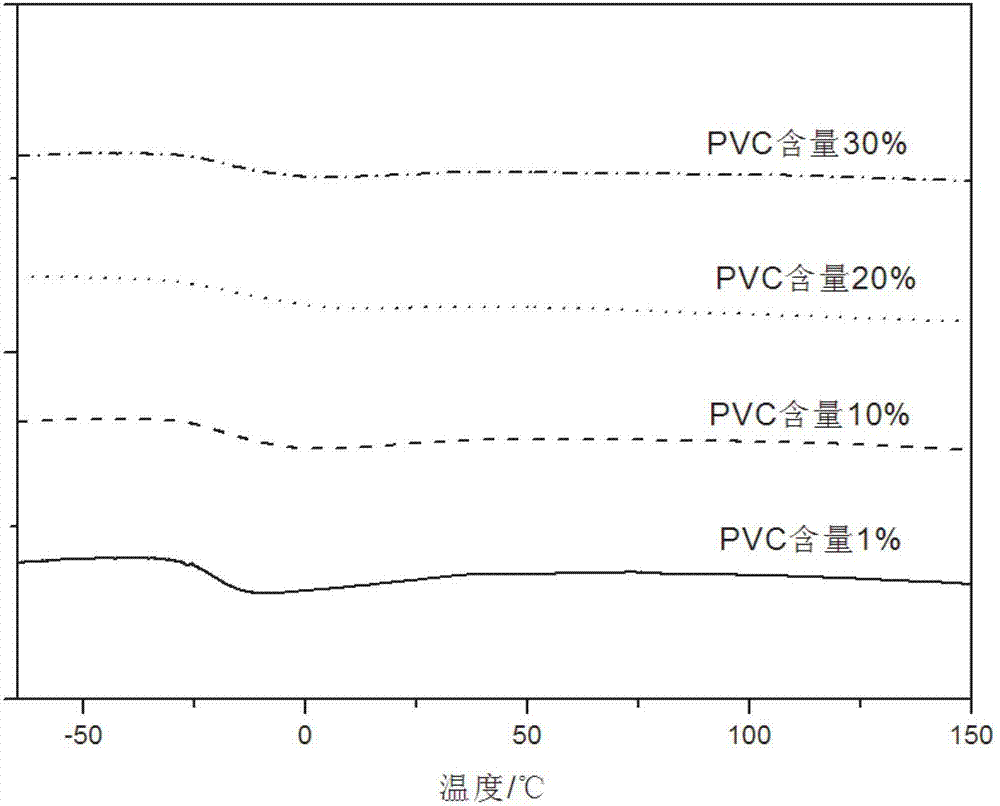

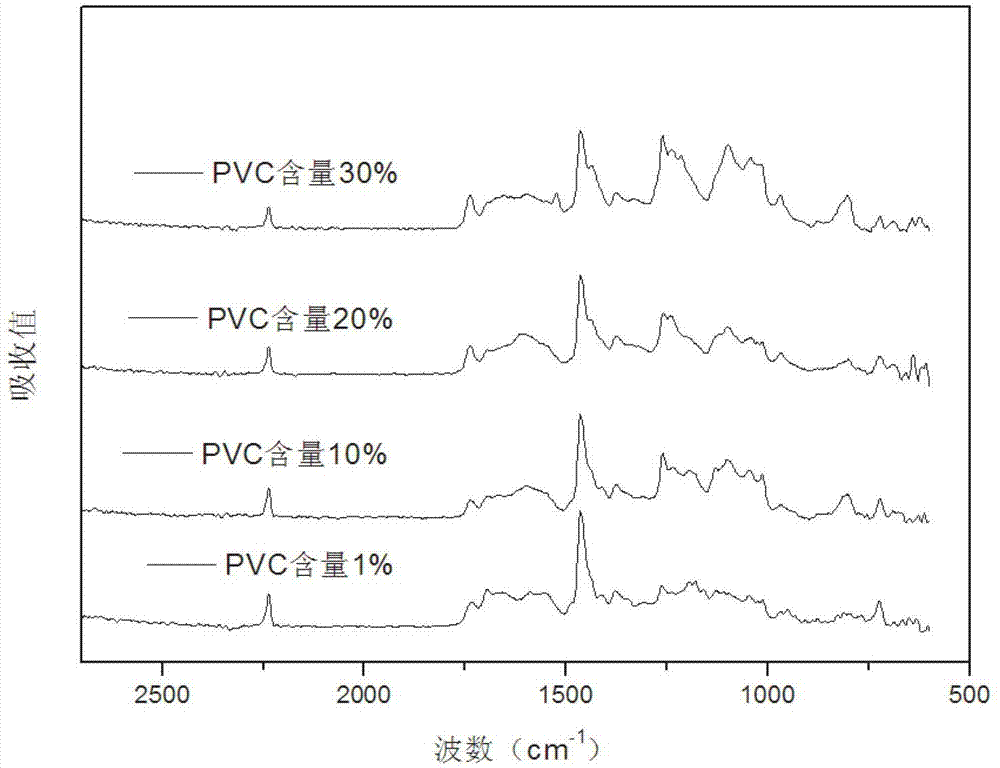

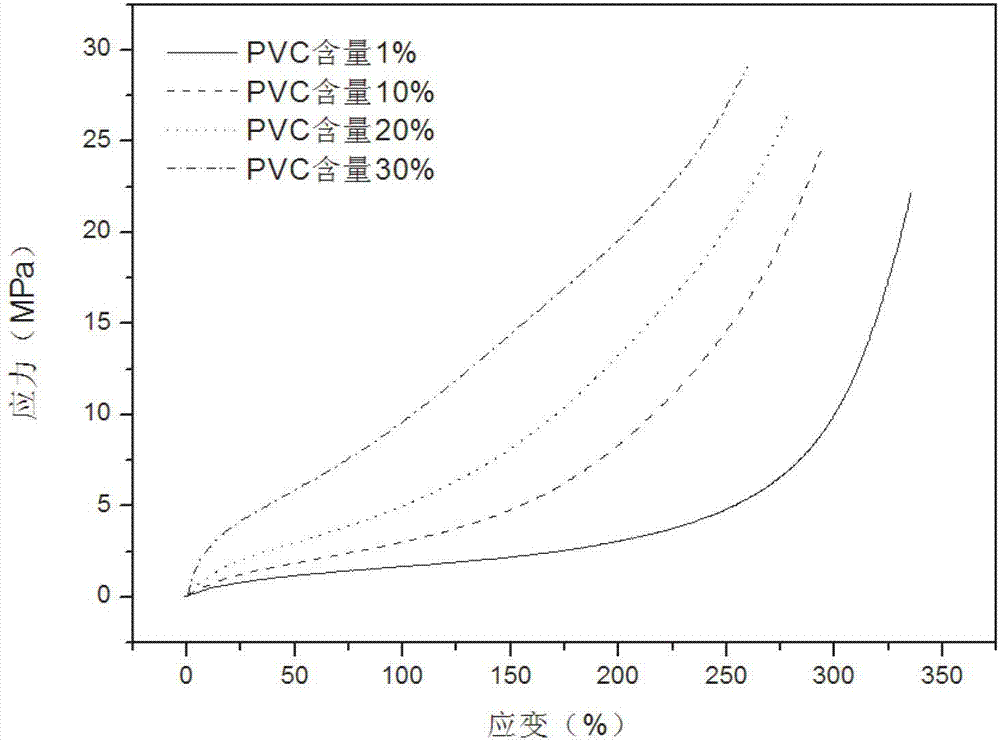

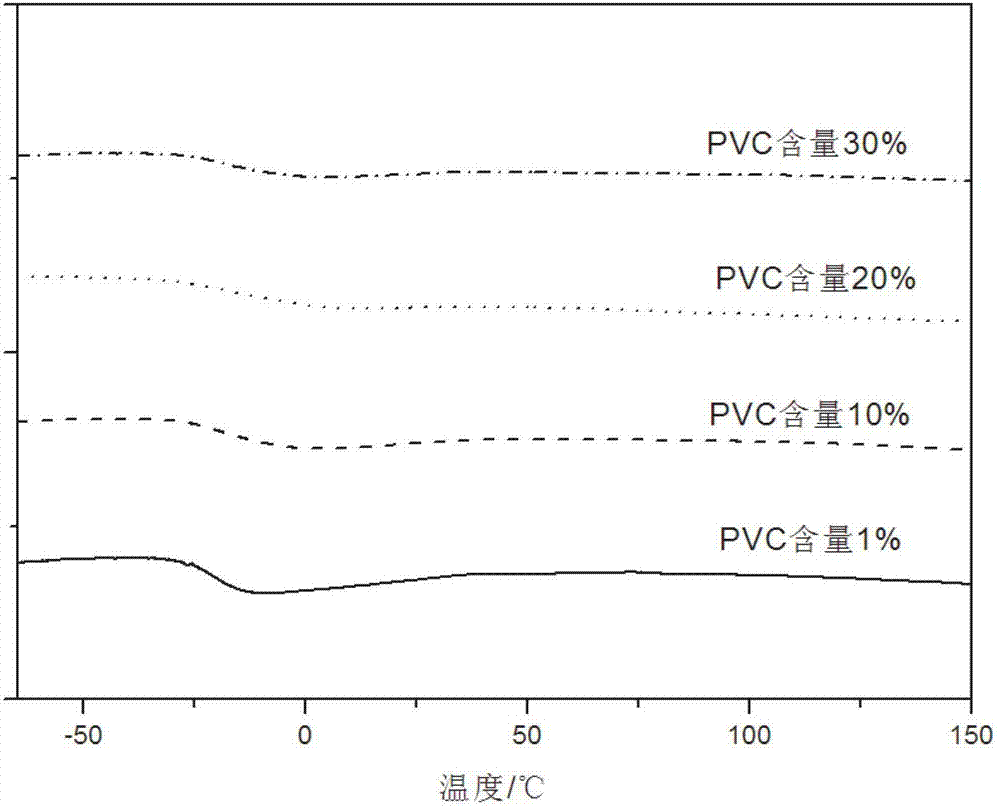

Non-vulcanized glue film of hydrogenated butyronitrile-polyvinyl chloride blended emulsion and preparation and application thereof

The invention discloses a non-vulcanized glue film of a hydrogenated butyronitrile-polyvinyl chloride blended emulsion and a preparation method and an application thereof, which belong to a chemical product and a preparation method thereof. The method is characterized in that: a non-vulcanized self-crosslinking HNBR (Hydrogenated Nitrile Butadiene Rubber) / PVC (Polyvinyl Chloride) latex film is prepared from HNBR or a HXNBR (Hydrogenated Carboxyl Nitrile Butadiene Rubber)-PVC blend emulsion by means of the self-crosslinking capability in the absence of a vulcanizing agent by using the self-crosslinking capability of HNBR or HXNBR latex with a latex steeping method. The method comprises the following steps of: uniformly mixing HNBR or HXNBR latex with a PVC emulsion to prepare a mixed latex emulsion; and steeping, leaching and drying the mixed emulsion to obtain a glue film product. A process of the non-vulcanized glue film has the advantages of simple and practicable process, low energy consumption, capability of self-crosslinking without adding any crosslinking agent and high performance.

Owner:BEIJING UNIV OF CHEM TECH

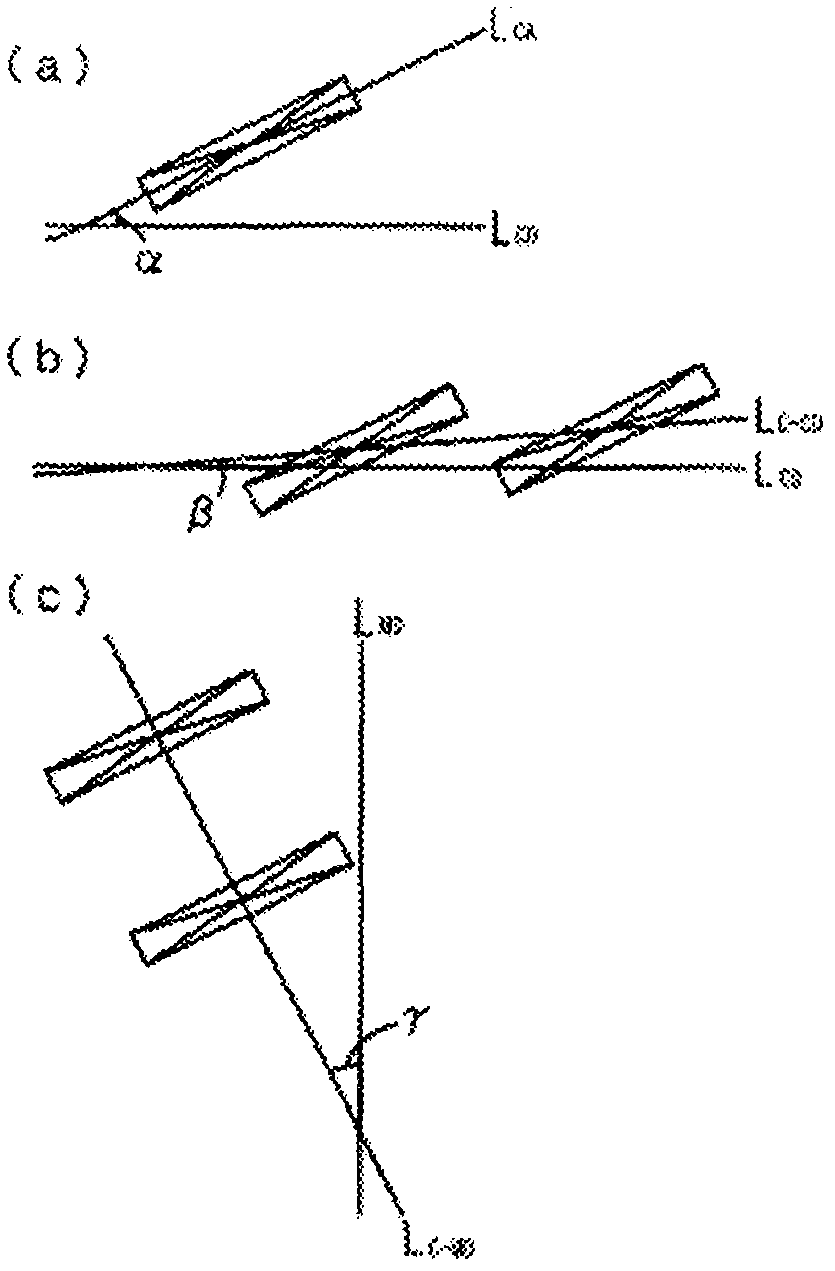

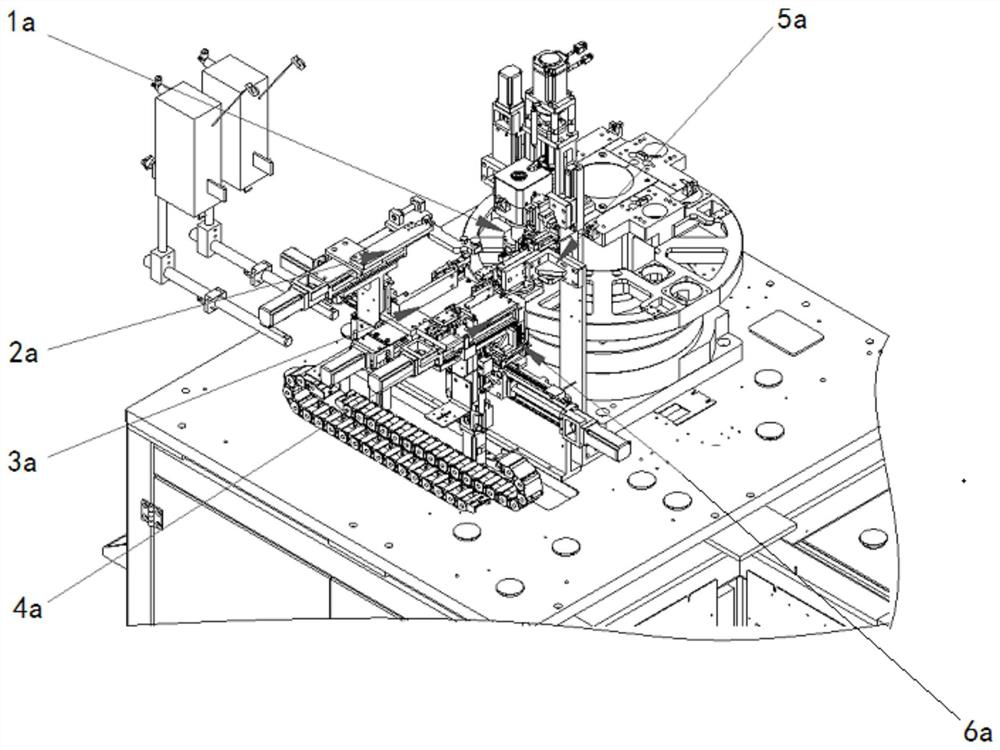

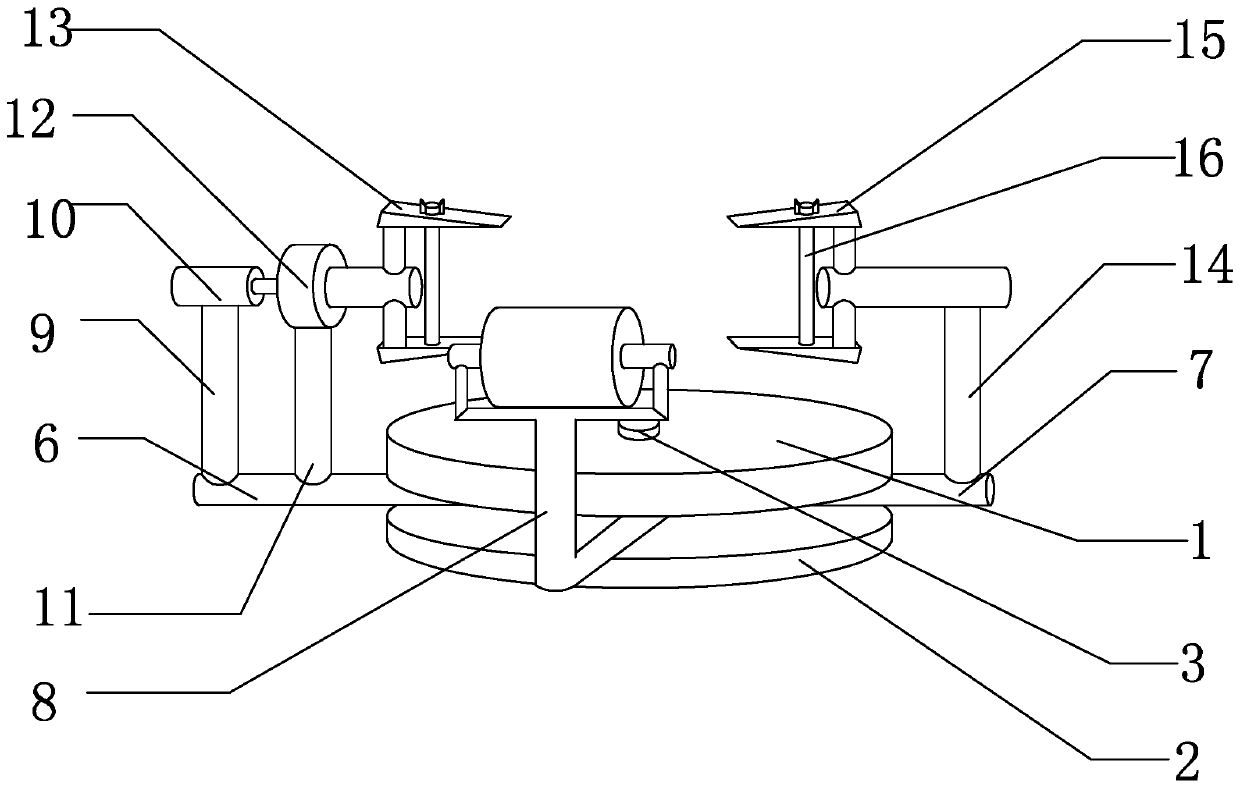

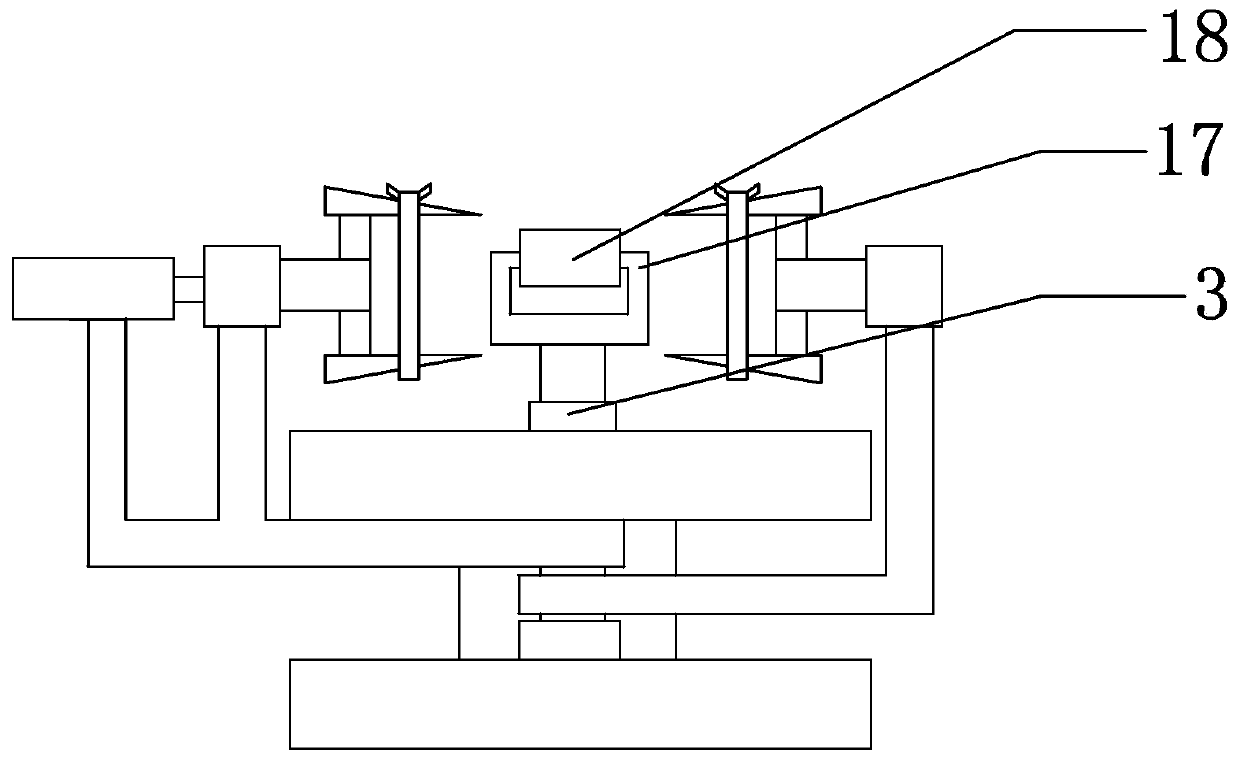

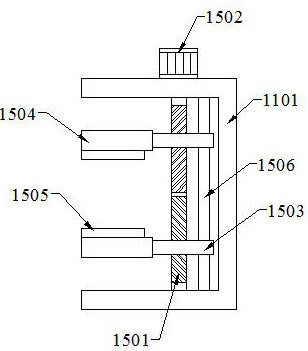

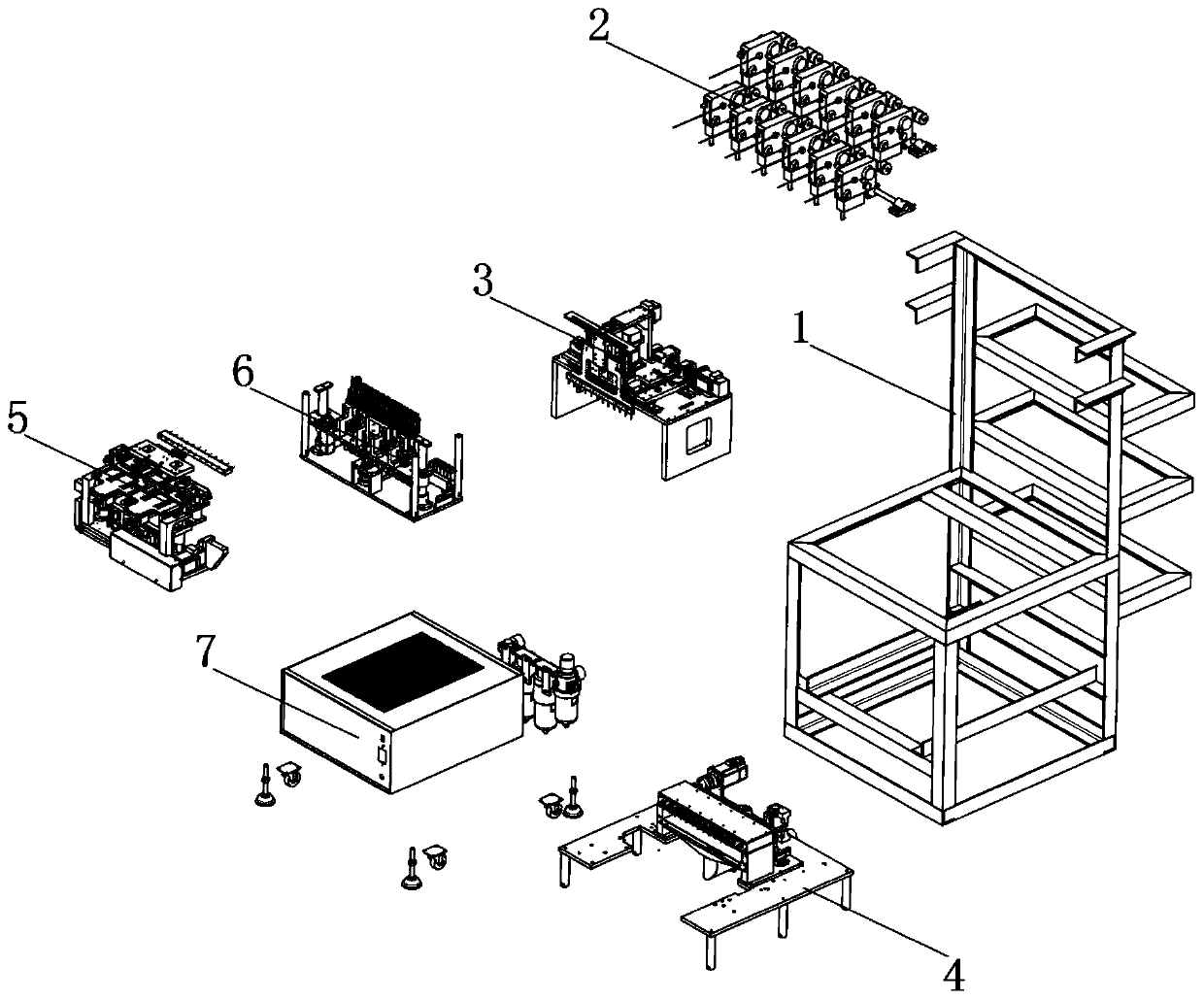

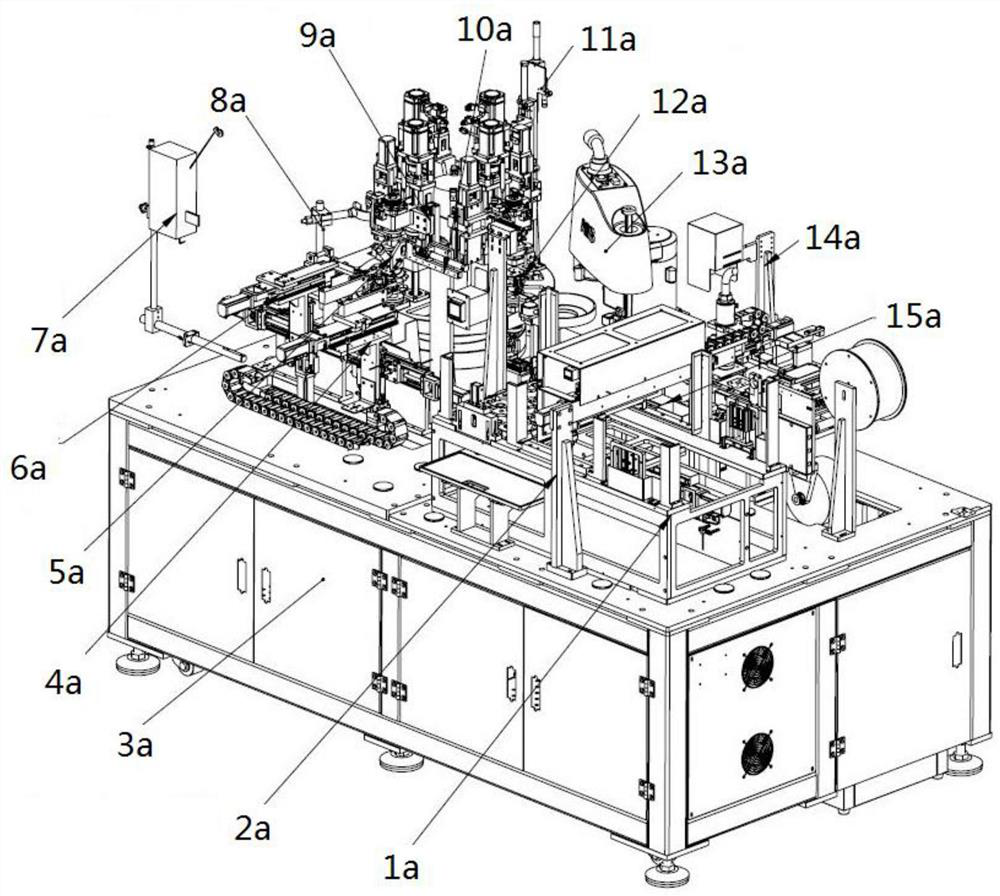

Winding forming equipment and process based on mixed alpha winding technology

ActiveCN112951588AHigh precisionMeet bending requirementsCoils manufactureWire wrapInductive charging

The invention is applicable to the technical field of wireless charging coil manufacturing, and particularly relates to winding forming equipment based on a hybrid alpha winding technology, which comprises an operation table, an upper and lower die group is mounted on the operation table; bending pins, wire clamps and die cores are arranged on the upper and lower die group, and the bending pins, the wire clamps and the die cores are matched to wind one or more enameled wires into a specified shape, including cable bending; a wire passing mechanism and a lead clamping mechanism are mounted on the operation table on the side edge of the upper and lower die group; a straightening wire inlet module, an upper wire clamp opening mechanism, a lower die wire clamp opening mechanism and a bending pin top block mechanism are installed on the side edge of the upper and lower die group. According to the invention, automatic linkage is achieved, large-batch and high-quality coil production is completed, cables can be wound more comprehensively and completely, layering is avoided, the yield of wound wireless charging coil products is high, and the requirement for a large-batch and stable-quality production mode can be met.

Owner:深圳市星特科技有限公司

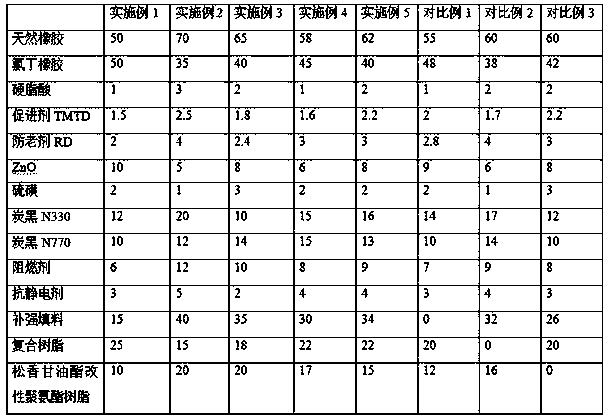

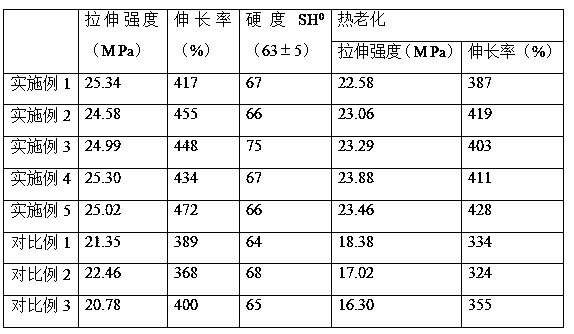

High-strength heat-resistant conveying belt covering rubber material and preparation method thereof

The invention provides a high-strength heat-resistant conveying belt covering rubber material. The preparation method comprises: weighing the following components by weight: 50-70 parts of natural rubber, 35-50 parts of chloroprene rubber, 1-3 parts of stearic acid, 1.5-2.5 parts of an accelerator TMTD, 2-4 parts of an anti-aging agent RD, 5-10 parts of ZnO, 1-3 parts of sulfur, 10-20 parts of carbon black N330, 10-15 parts of carbon black N770, 5-12 parts of a flame retardant, 2-5 parts of an antistatic agent, 15-40 parts of a reinforcing filler, 15-25 parts of a composite resin, and 10-20 parts of rosin glycerin ester modified polyurethane resin. The prepared high-strength heat-resistant conveying belt covering rubber material of the present invention has advantages of high strength andgood heat resistance.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Manufacturing method of fluorinated cladding plastic optical fiber

InactiveCN112327403AFully woundFacilitates subsequent coating operationsCladded optical fibreFilament handlingFiberCore (optical fiber)

The invention discloses a manufacturing method of a fluorinated cladding plastic optical fiber. The manufacturing method comprises the following steps: S1, preparing an optical fiber preform; S2, preparing a fiber core; to be specific, step 1, carrying out melting and wire drawing treatment on an optical fiber preform, and enabling cooling wires to be subjected to wire drawing; step 2, coating theoptical fiber preform subjected to melting and wire drawing treatment at 45-60 DEG C through a coating device, so that a coating is attached to the surface of the optical fiber preform; step 3, putting the optical fiber preform coated with the coating into an ultraviolet curing oven for curing treatment to obtain a fiber core; and S3, putting the fiber core into a fluorination furnace containinga fluorinating agent, carrying out fluorination reaction at 5-30 DEG C for 20-50 hours, and forming a fluorination cladding with the thickness of 5-12 microns on the surface of the fiber core to prepare the fluorination cladding plastic optical fiber.

Owner:广州凯杰环保新材料科技有限公司

Process for producing nitrile-butadiene rubber (NBR) and polrvinyl chloride (PVC) mixed rubber by latex coprecipitation method

The invention discloses a process for producing NBR and PVC mixed rubber by using a latex coprecipitation method, which comprises: uniformly mixing NBR and PVC at 50 to 70 DEG C according to a ratio of 3:1 to prepare NBR / PVC mixed latex; and adding a deflocculant into the NBR / PVC mixed latex for curing, adding a flocculating agent at last to perform coprecipitation and flocculation in the NBR / PVC mixed latex, and drying the flocculate to obtain the finished product. The production process is simple, easy and low in energy consumption, and the produced NBR / PVC blended rubber has high performance.

Owner:天津市铭仁化工科技有限公司

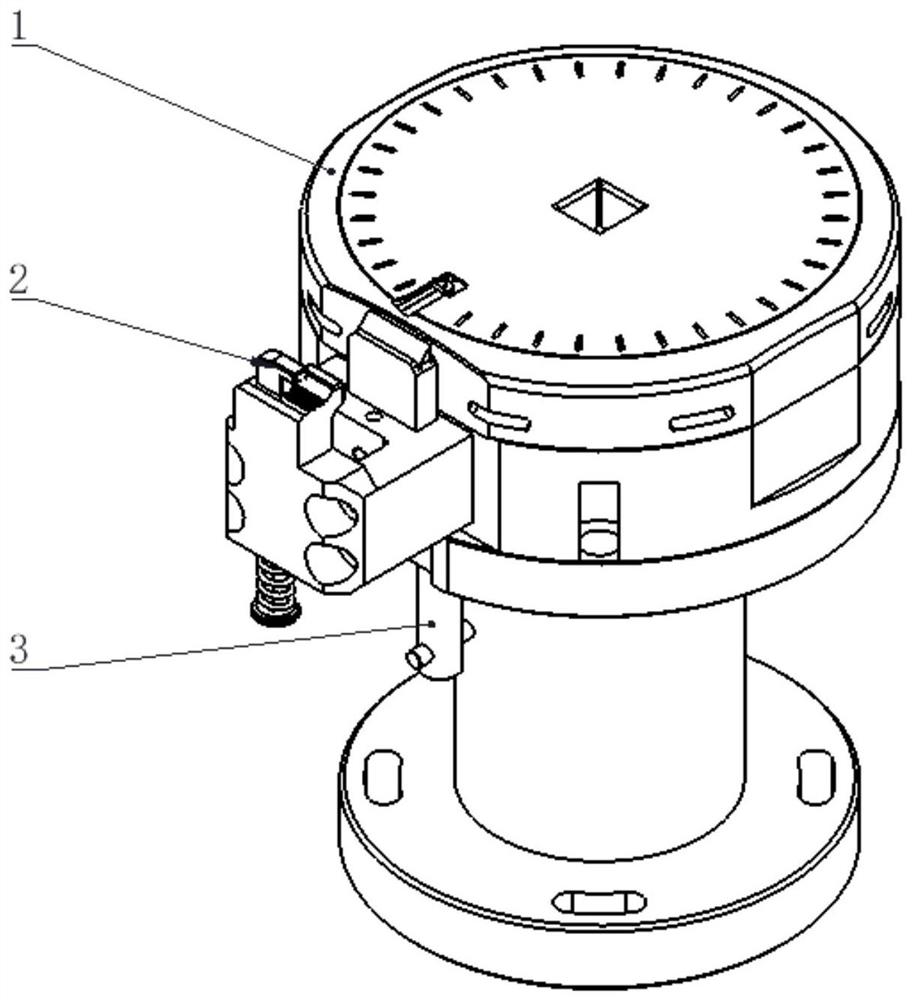

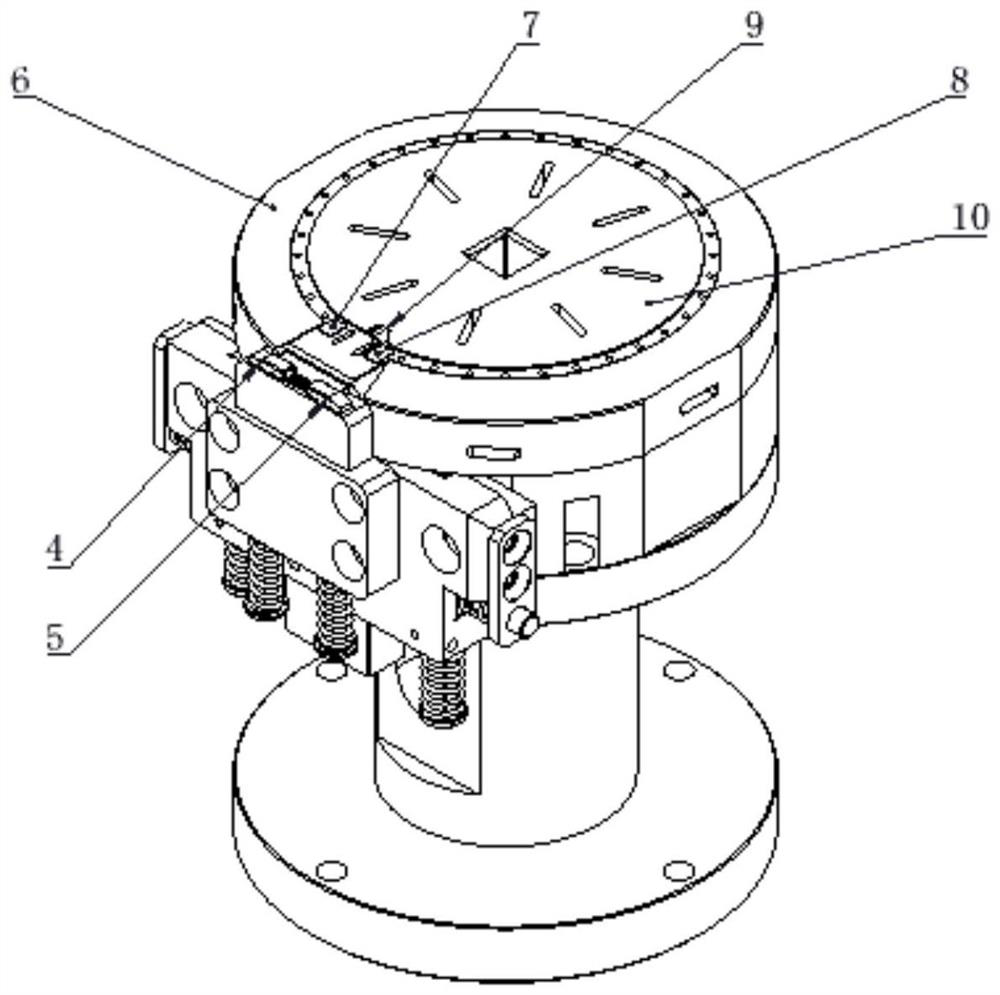

Multi-angle adhesive tape winding positioning device

PendingCN110979780AFully woundWrapping material feeding apparatusWrapping with article rotationAdhesive beltStructural engineering

The invention belongs to the field of winding positioning devices, and particularly relates to a multi-angle adhesive tape winding positioning device. The multi-angle adhesive tape winding positioningdevice comprises an upper closing cover, wherein a lower closing cover is arranged on the lower side of the upper closing cover; the upper end of the upper closing cover is connected with a fixed knob; the lower end of the fixed knob is connected with a rotating screw; a screw protecting housing is arranged on the outer surface of the rotating screw in a surrounding manner; a first connecting rodis connected to a position, which is close to the upper closing cover, of the outer surface of the rotating screw; a second connecting rod is connected to a position, which is close to the lower endof the first connecting rod, of the outer surface of the rotating screw; one end of a rotating shaft which is connected with a third supporting rod is connected with a second fixing rack; fixing screws are arranged on the inner sides of a first fixing rack and the second fixing rack; the upper end of the third connecting rod is connected with a fourth supporting rod; and an adhesive tape is arranged on the inner side of the fourth supporting rod. The problem that a package cannot be positioned in traditional package winding operation is solved, and meanwhile, a technical scheme capable of winding automatically is provided.

Owner:嘉兴市联富电子科技有限公司

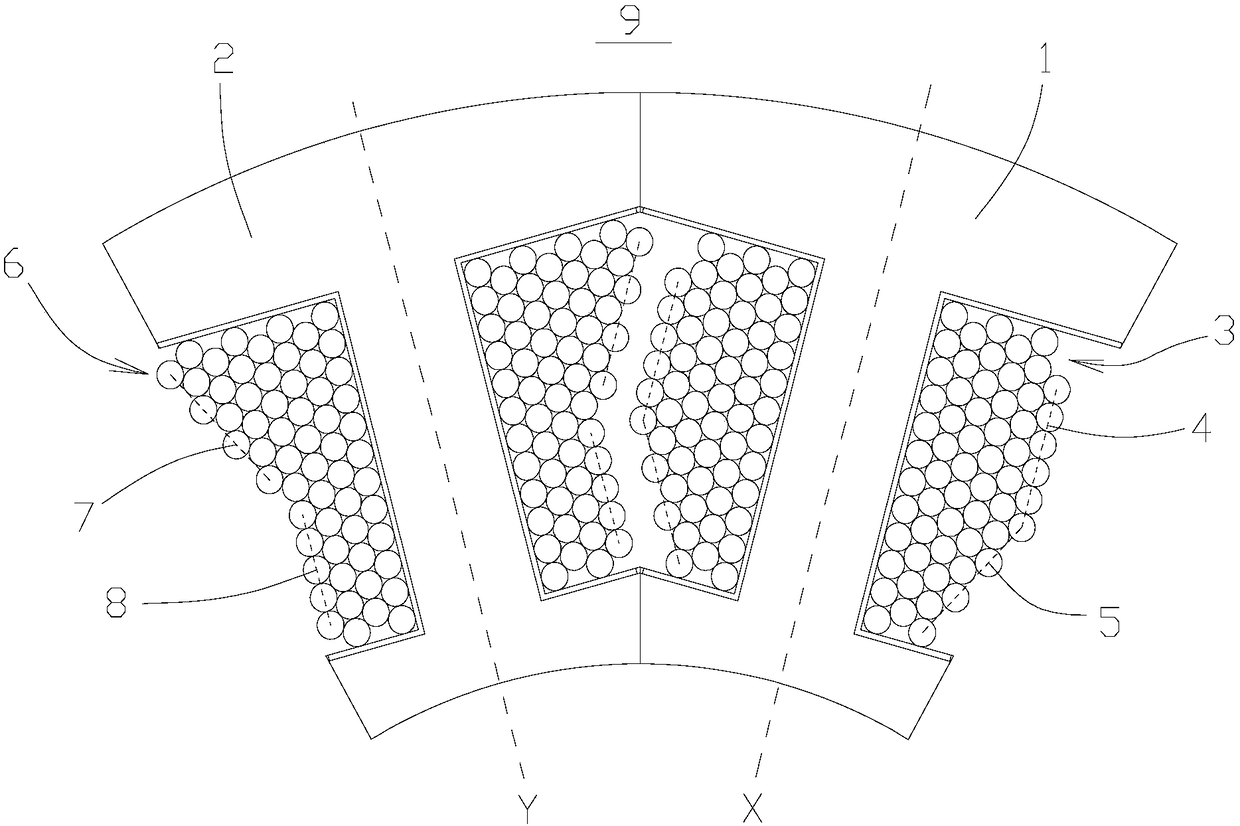

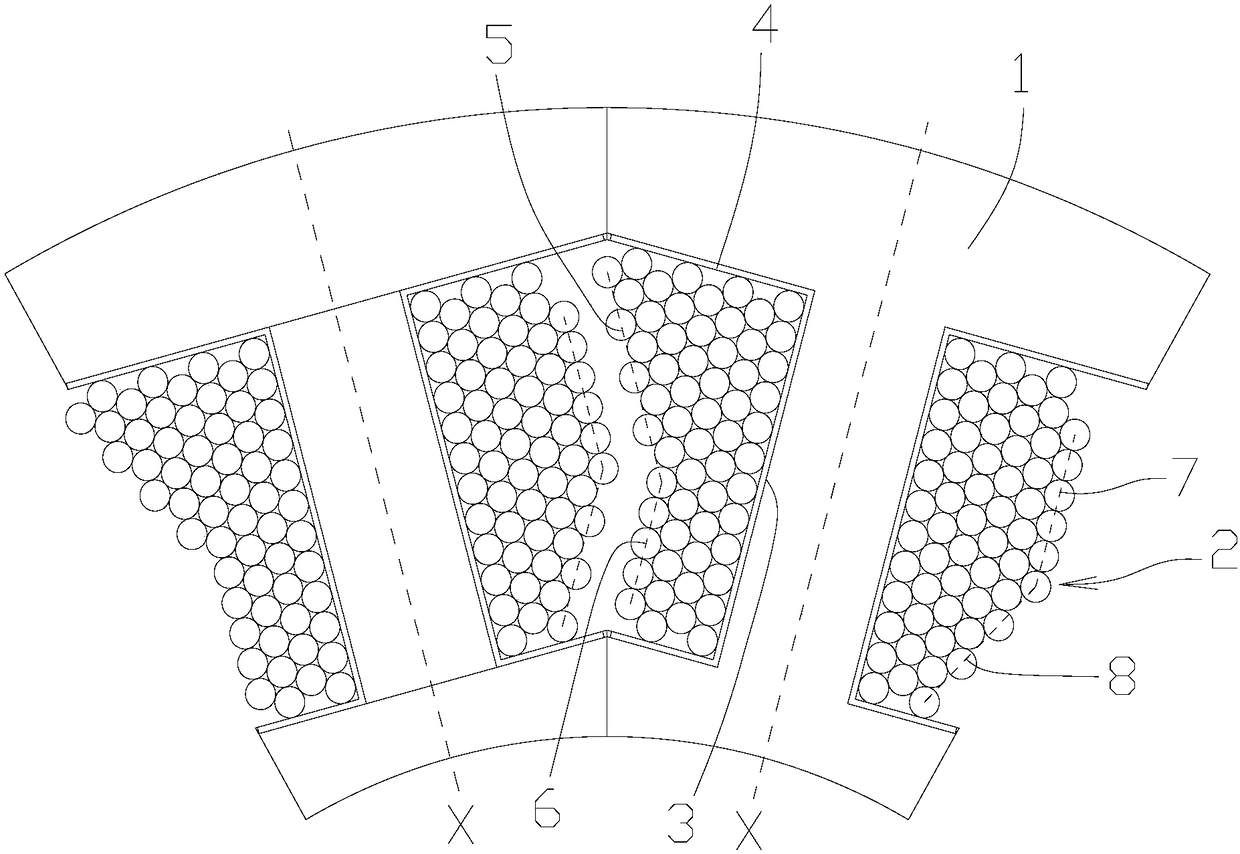

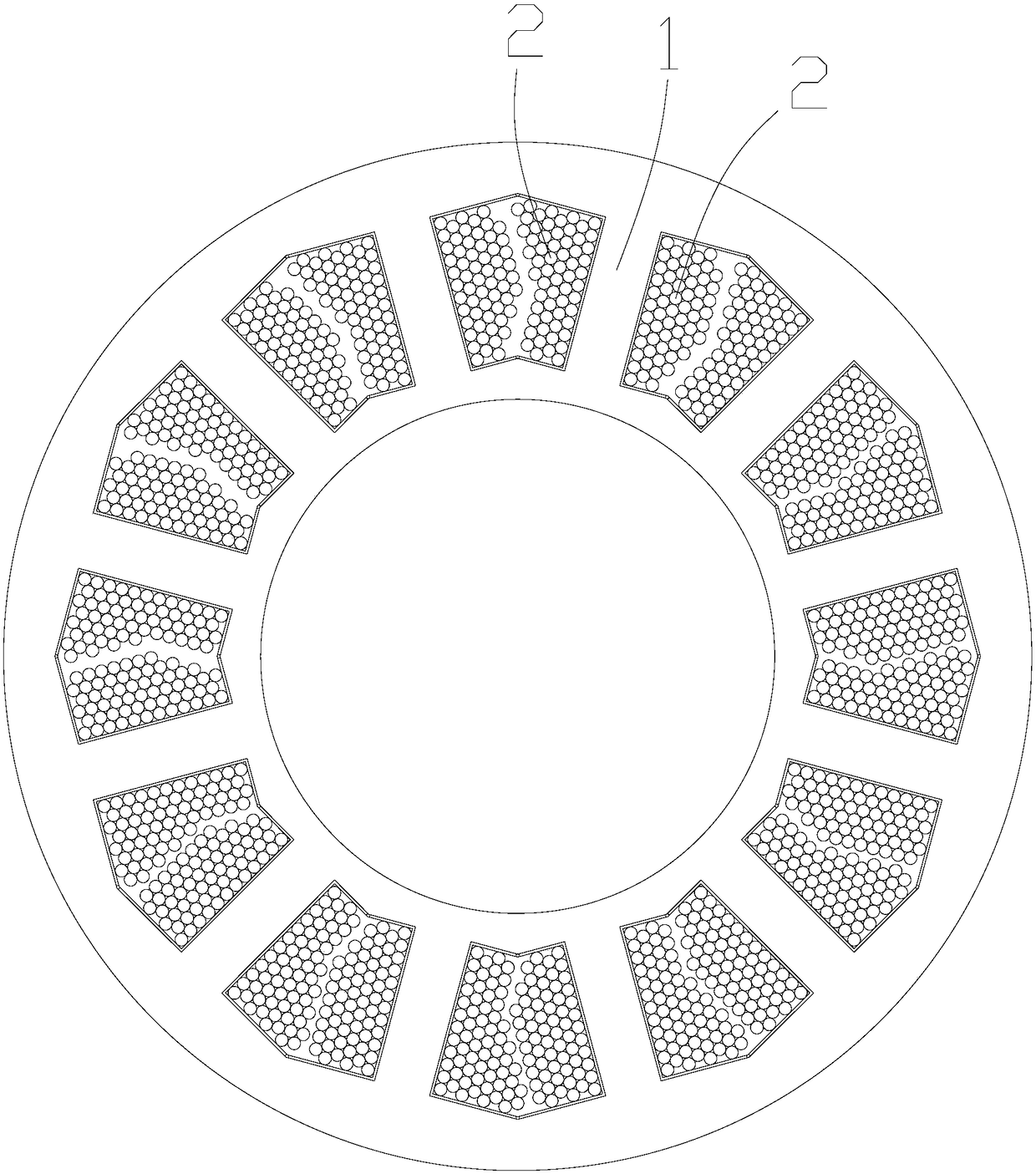

Stator block unit, stator and motor

InactiveCN108599410AIncrease slot fill rateImprove power densityMagnetic circuit stationary partsWindings conductor shape/form/constructionConductor CoilPower density

The invention relates to the technical field of motors, and discloses a stator block unit, a stator and a motor. The stator block unit comprises a first stator block and a second stator block, whereina first coil winding comprises a first straight edge and a first inclined edge; a second coil winding comprises a second inclined edge and a second straight edge; the first straight edge and the second inclined edge are spaced apart in parallel and the first inclined edge and the second straight edge are space apart in parallel. Between the first stator block and the second stator block, the shapes of the first coil winding and the second coil winding shape are complementary so that the spacing between the two is small, the spacing between the first inclined edge and the adjacent second inclined edge and the spacing between the first inclined edge and the adjacent second straight edge can be small, meaning that the coil winding can be fully wound in the respective winding slot, the surplus space of the winding groove between the first stator block and the second stator block is avoided, so that the groove full rate of the stator is obviously improved, the power density of the motor isimproved, and the volume and the cost of the motor are reduced.

Owner:GUANDONG MEDIA INTELLIGENT TECH CO LTD

Wear-resistant oil-proof insulating paint

InactiveCN105860834ARich microporous structureGood oil resistanceConjugated diene hydrocarbon coatingsPolyester coatingsPolyesterWear resistant

The invention discloses a wear-resistant oil-proof insulating paint. The wear-resistant oil-proof insulating paint is prepared from, by weight, 40-44 parts of silicone rubber powder, 26-29 parts of acrylic resin, 18-21 parts of nitrile-butadiene rubber, 10-15 parts of oxalic acid polyester, 22-25 parts of modified graphite, 6-10 parts of zinc oxide, 1.6-2 parts of a defoaming agent, 1.5-1.8 parts of a leveling agent, 1.1-1.4 parts of a dispersing agent, 1.6-1.8 parts of a film-forming aid, 1-1.3 parts of an antioxidant 4020, 3-6 parts of a drier, 1.2-1.5 parts of a mildew preventive, 1.5-1.8 parts of a precipitation preventive and 0.6-1 part of a rust preventive. The wear-resistant oil-proof insulating paint has high wear-resistant performance and good oil-proof performance.

Owner:湖南辛女环保新材料有限公司

Bandage winding device for orthopedics department

PendingCN112674945AEasy to replacePrevent disengagementBandagesHydraulic cylinderOrthopedic department

The invention discloses a bandage winding device for the orthopedics department. The bandage winding device comprises a base, two hydraulic cylinders are arranged at the upper end of the base, a supporting plate is fixedly connected to the telescopic ends of the hydraulic cylinders, a moving assembly is arranged on the right side of a moving plate, a rotating assembly is arranged at the right end of a rotating shaft, a shearing assembly is arranged on a support, and a mounting assembly is arranged at the lower end of a top plate. The hydraulic cylinders are started to adjust the height of the supporting plate and the height of the components on the supporting plate, then a bandage is installed and limited through the mounting assembly, a bandage cylinder is prevented from being disengaged when the bandage is wound, and meanwhile, the bandage can be conveniently replaced; and the bandage is driven by the rotating assembly to rotate and wind around the wounded limb of a patient, the patient can be conveniently wound and bound, meanwhile, winding uniformity and stability are guaranteed, the bandage is driven by the moving assembly to move left and right, left and right different positions of the wounded limb of the patient can be comprehensively wound, winding is more comprehensive and thorough, and the bandage in the middle is sheared through the shearing assembly, an additional cutter is not needed for shearing, so that time and labor are saved.

Owner:莒县中医医院

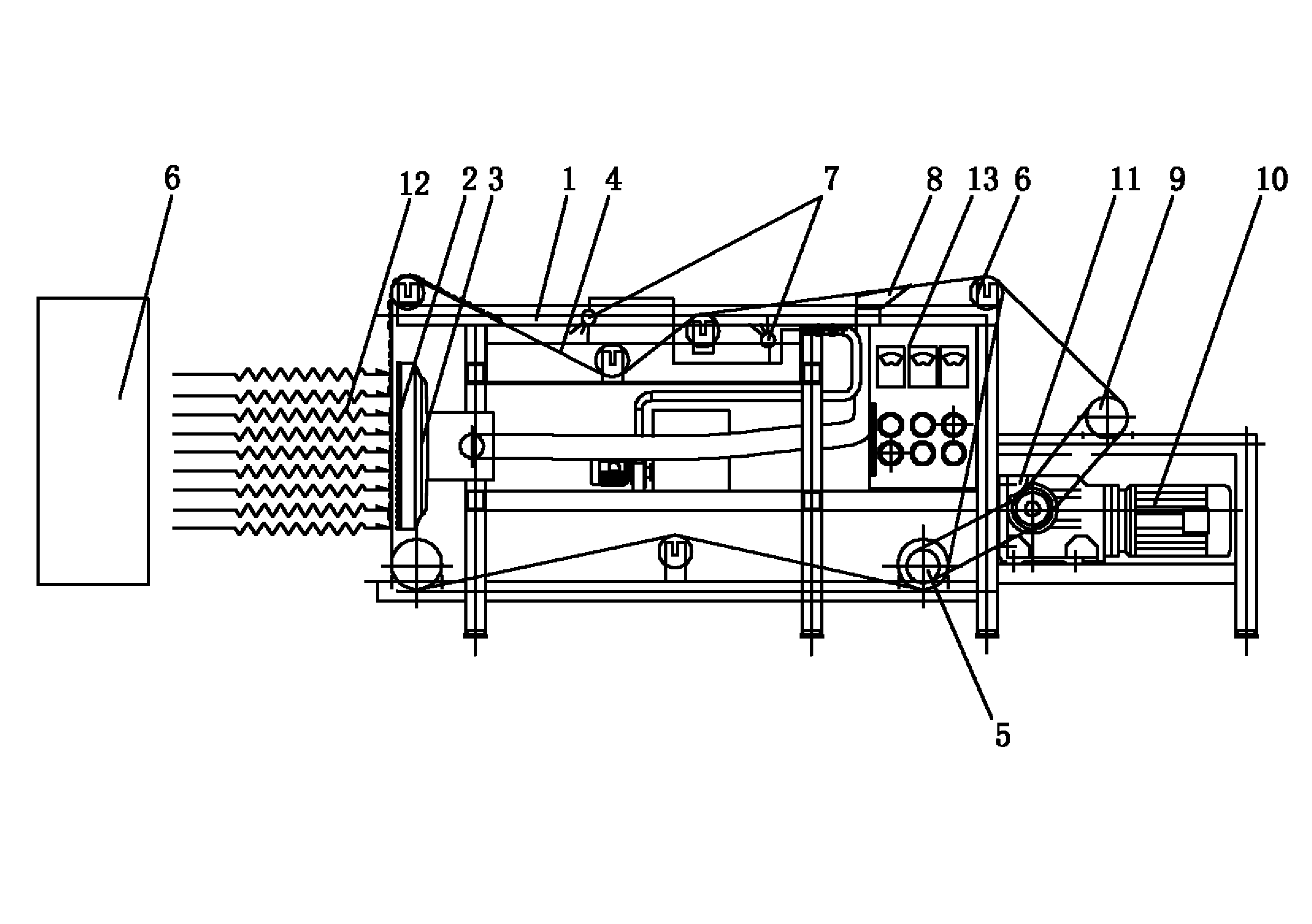

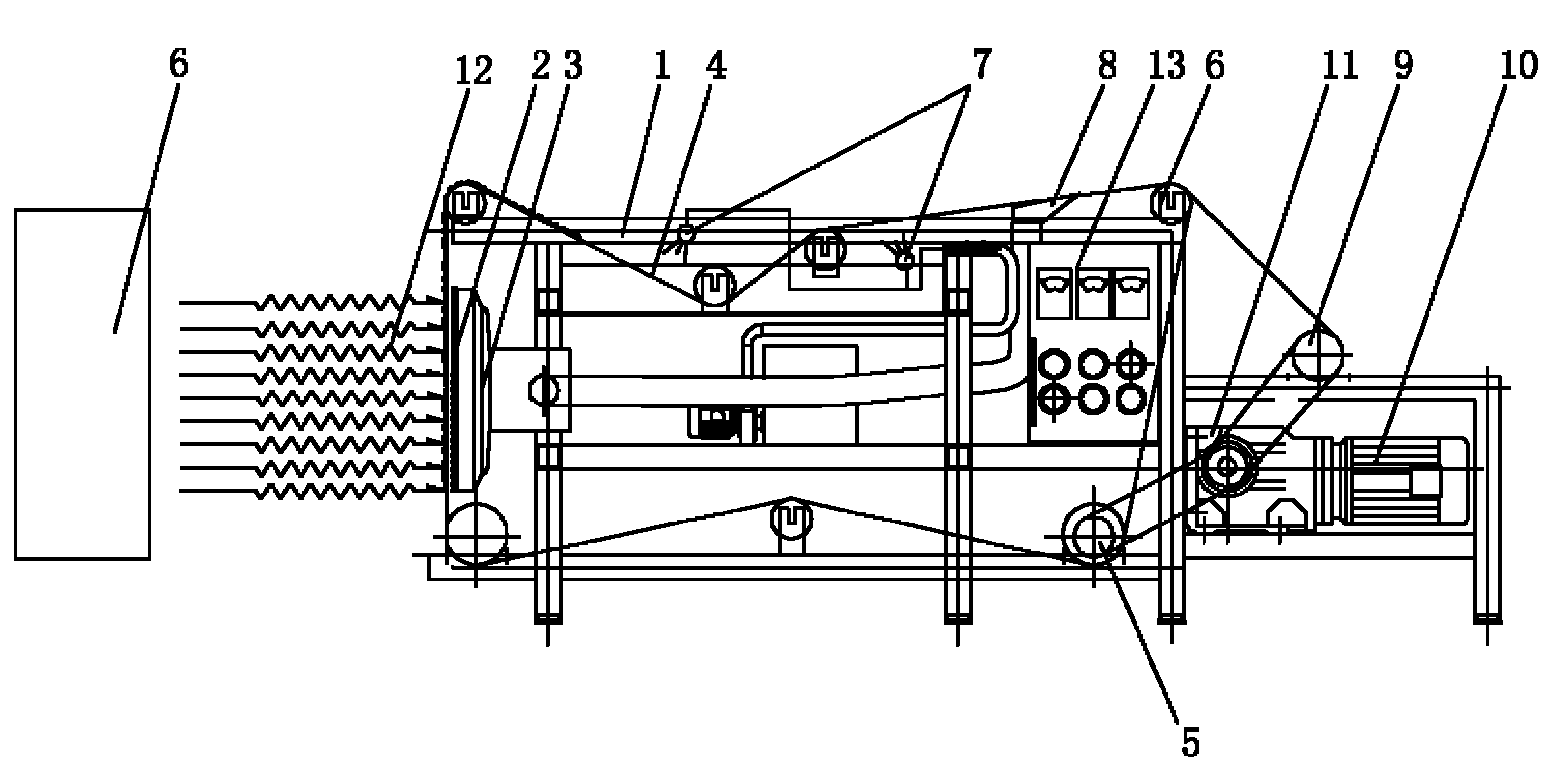

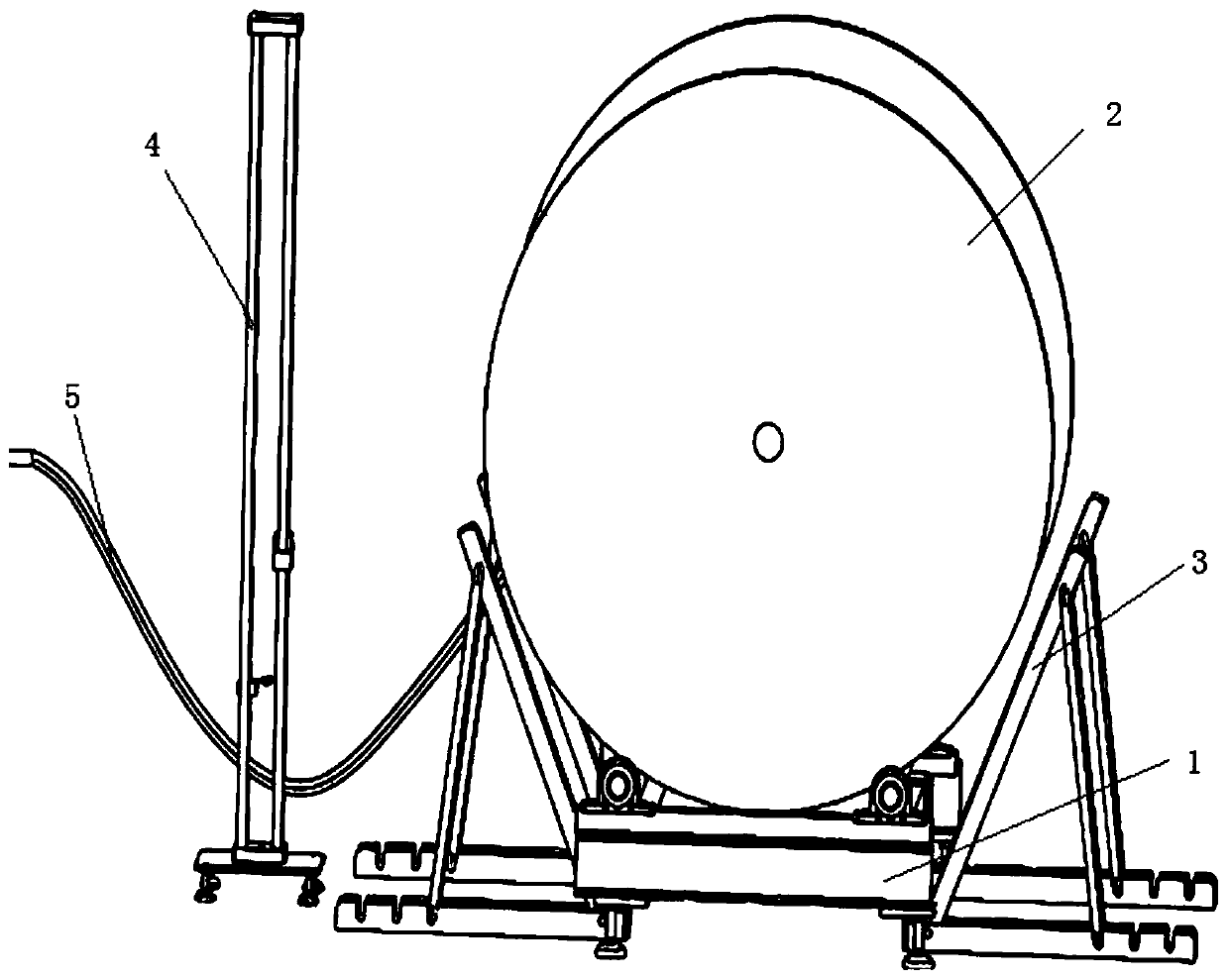

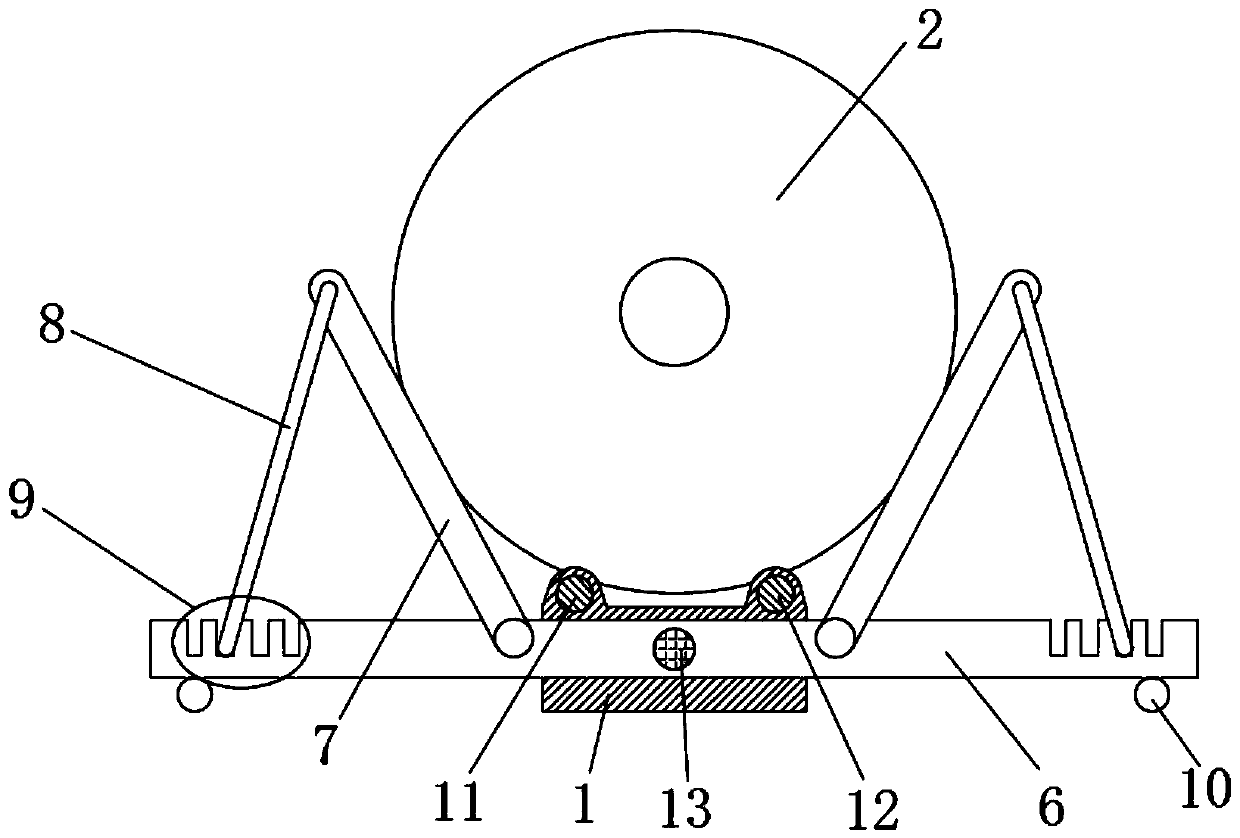

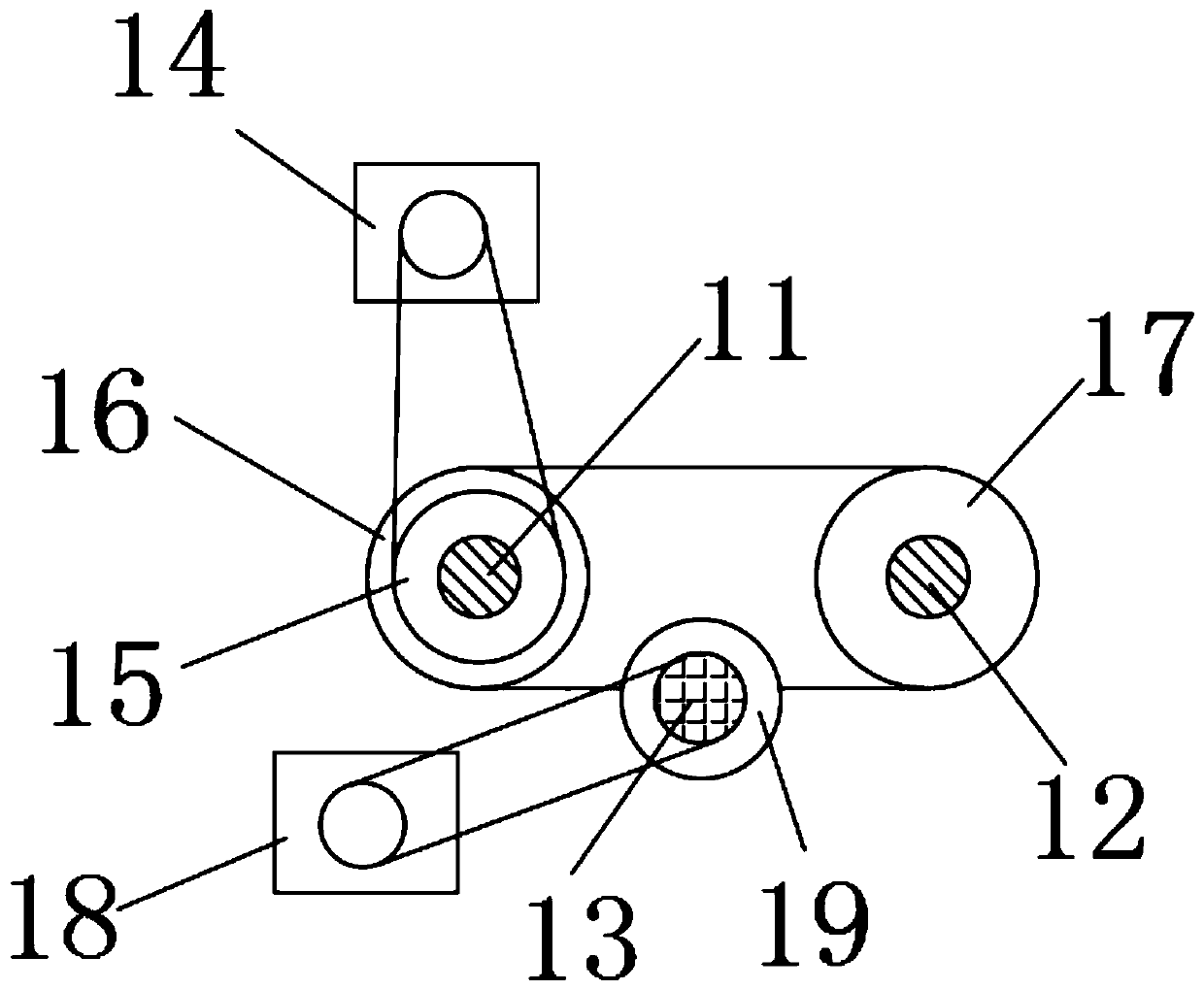

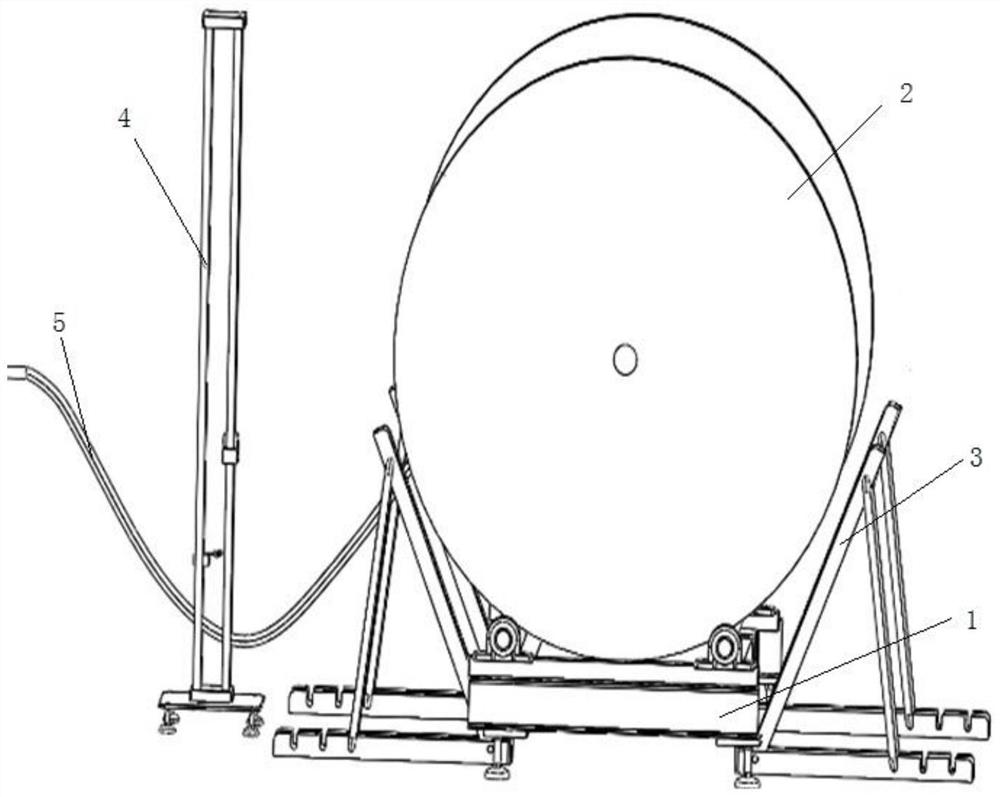

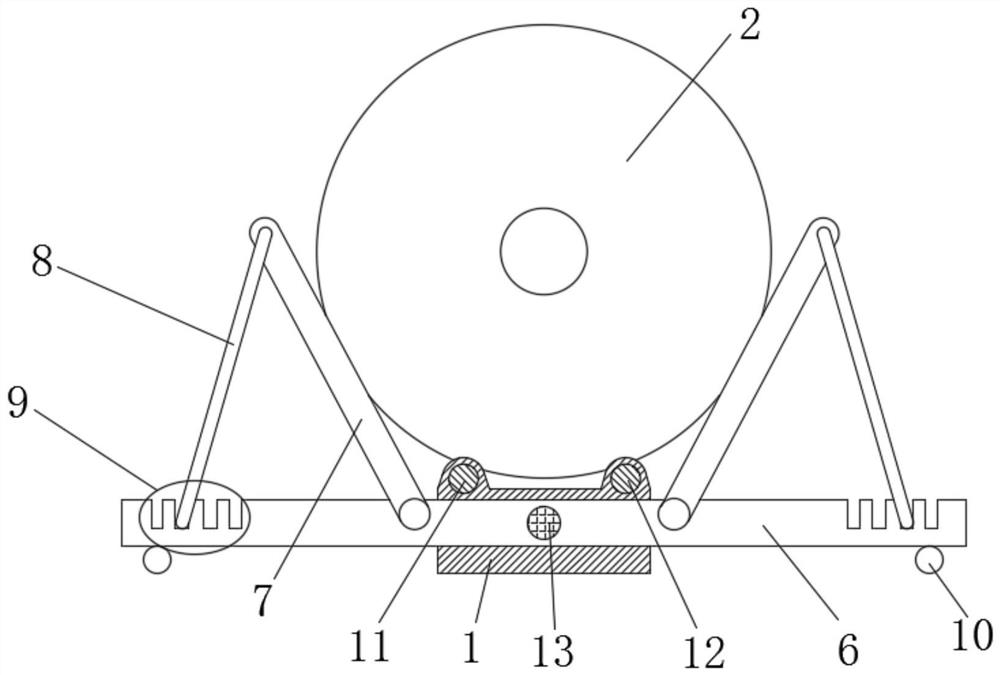

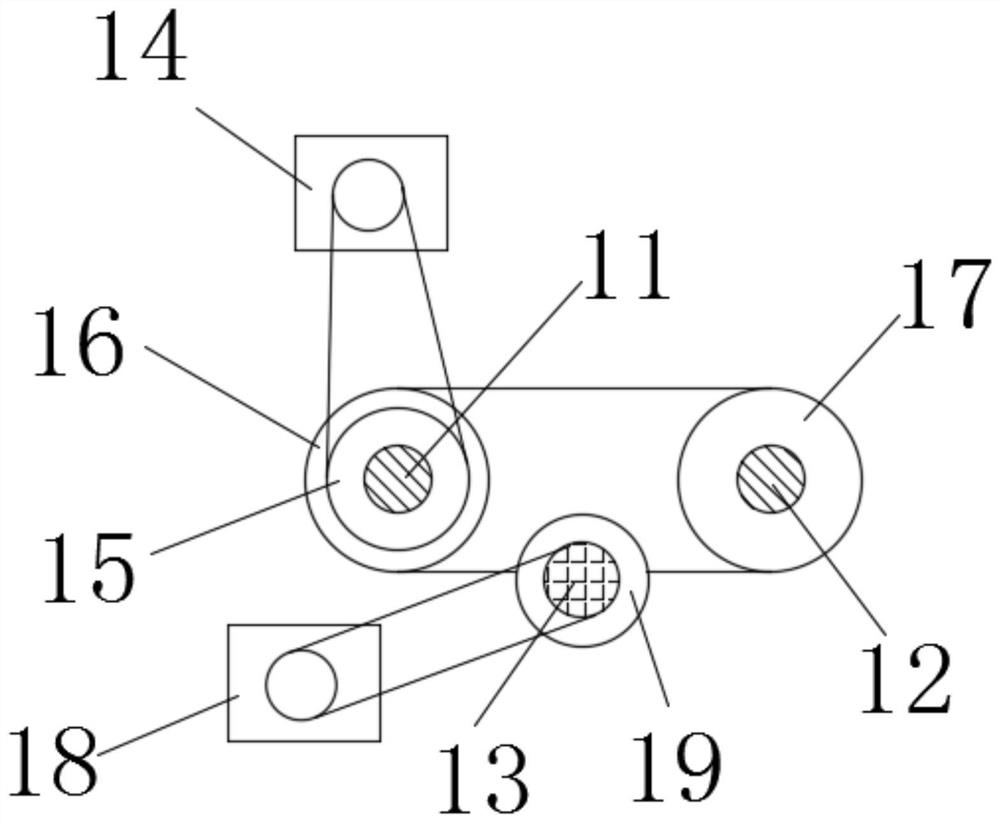

Cable winding and feeding system capable of maintaining constant perpendicularity

ActiveCN111532877ARealize constant sag winding operationAvoid position shiftFilament handlingDrive shaftControl theory

The invention provides a cable winding and feeding system capable of maintaining constant perpendicularity. The feeding system comprises a driving rack, a cable roller, a V-shaped retainer and a cablefloating roller support frame, wherein the cable roller is clamped on the V-shaped retainer, the V-shaped retainer is slidably connected to the driving rack, the driving rack is provided with a maindriving shaft and a driven shaft, the bottom of the cable roller is in frictional contact with the main driving shaft and the driven shaft simultaneously, the cable floating roller support frame is arranged at a winding and feeding port of the cable, and the cable roller is used for storing the cable. According to the cable winding and feeding system, the cable roller can transversely move while conducting winding, thus it is guaranteed that the cable is kept perpendicular to the cable roller in the winding or feeding process of the cable, so that the cable is wound sufficiently, and the deformation of the cable is reduced.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD

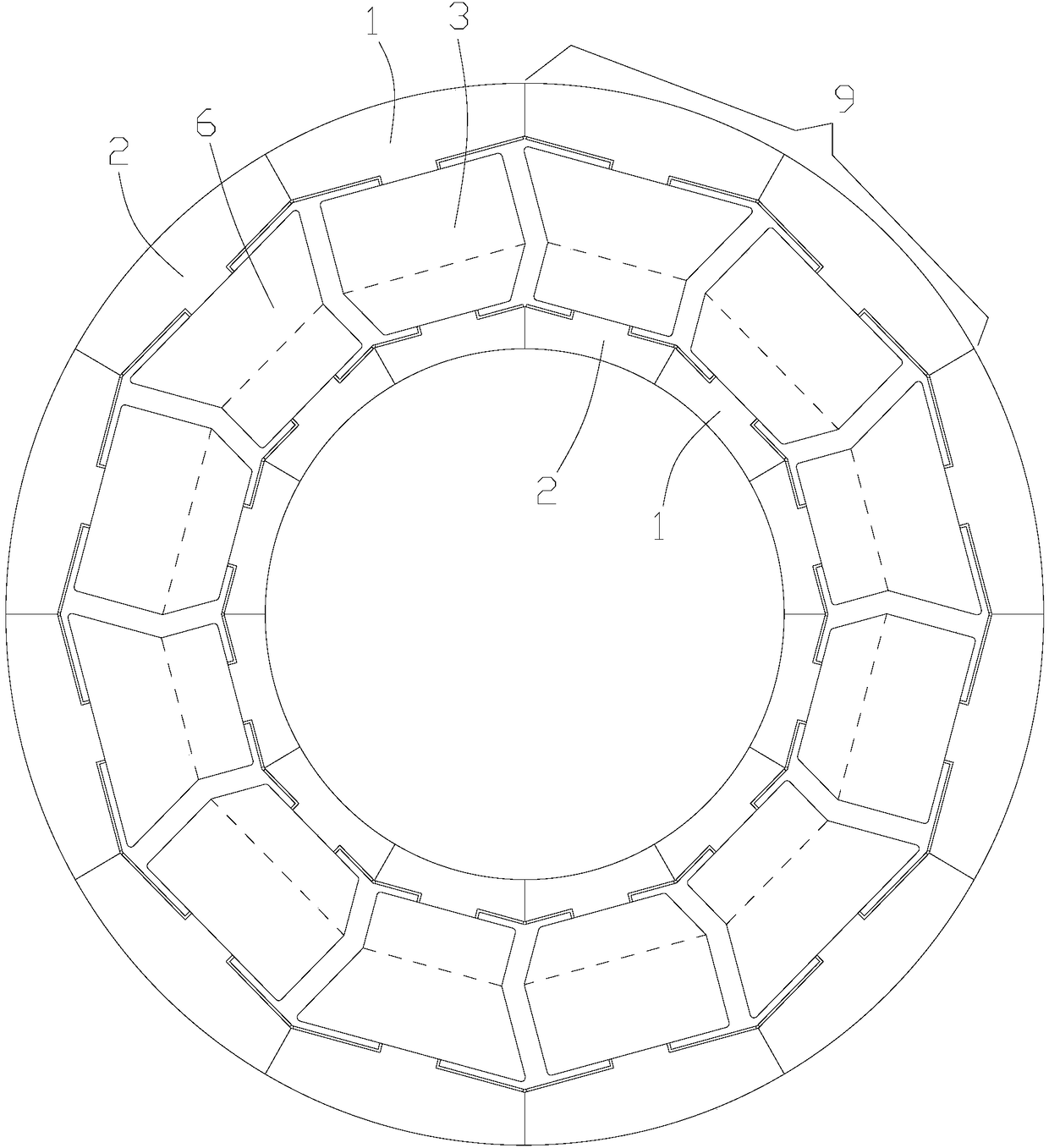

Stator block, stator and motor

InactiveCN108599425AIncrease slot fill rateImprove power densityWindings insulation shape/form/constructionWindings conductor shape/form/constructionStraightedgeConductor Coil

The invention relates to the technical field of motors, and discloses a stator block, a stator and a motor. The stator block comprises a splicing block core and a coil, wherein the coil forms a coil winding; the first side winding structure of the coil winding and the second side winding structure of the coil winding are asymmetrically arranged relative to the radial center line X of the splicingblock core; and in the first side winding structure, a first side inclined edge is formed on the connecting line of the radially innermost one turn coil of the other multilayer coil outside the firstpreset layer coil, and the part of the first preset layer coil is not shielded to form a first side straight edge; in the second side winding structure, the outermost coil forms a second side straightedge, the connecting line of the second preset layer coil and the radially innermost one turn coil of the outer other multilayer coil forms a second side inclined edge, the shape is complementary after the two stator blocks forming the stator, avoiding excessive residual space in the tolerance line space between the stator blocks, obviously improving the groove fullness rate of the stator, and further improving the power density of the motor and reducing the volume and the cost of the motor.

Owner:GUANDONG MEDIA INTELLIGENT TECH CO LTD

Non-vulcanized glue film of hydrogenated butyronitrile-polyvinyl chloride blended emulsion and preparation and application thereof

The invention discloses a non-vulcanized glue film of a hydrogenated butyronitrile-polyvinyl chloride blended emulsion and a preparation method and an application thereof, which belong to a chemical product and a preparation method thereof. The method is characterized in that: a non-vulcanized self-crosslinking HNBR (Hydrogenated Nitrile Butadiene Rubber) / PVC (Polyvinyl Chloride) latex film is prepared from HNBR or a HXNBR (Hydrogenated Carboxyl Nitrile Butadiene Rubber)-PVC blend emulsion by means of the self-crosslinking capability in the absence of a vulcanizing agent by using the self-crosslinking capability of HNBR or HXNBR latex with a latex steeping method. The method comprises the following steps of: uniformly mixing HNBR or HXNBR latex with a PVC emulsion to prepare a mixed latex emulsion; and steeping, leaching and drying the mixed emulsion to obtain a glue film product. A process of the non-vulcanized glue film has the advantages of simple and practicable process, low energy consumption, capability of self-crosslinking without adding any crosslinking agent and high performance.

Owner:BEIJING UNIV OF CHEM TECH

An impact-resistant cold-resistant anti-corrosion coating

ActiveCN104327670BImprove interface performanceImprove stabilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyShock resistance

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

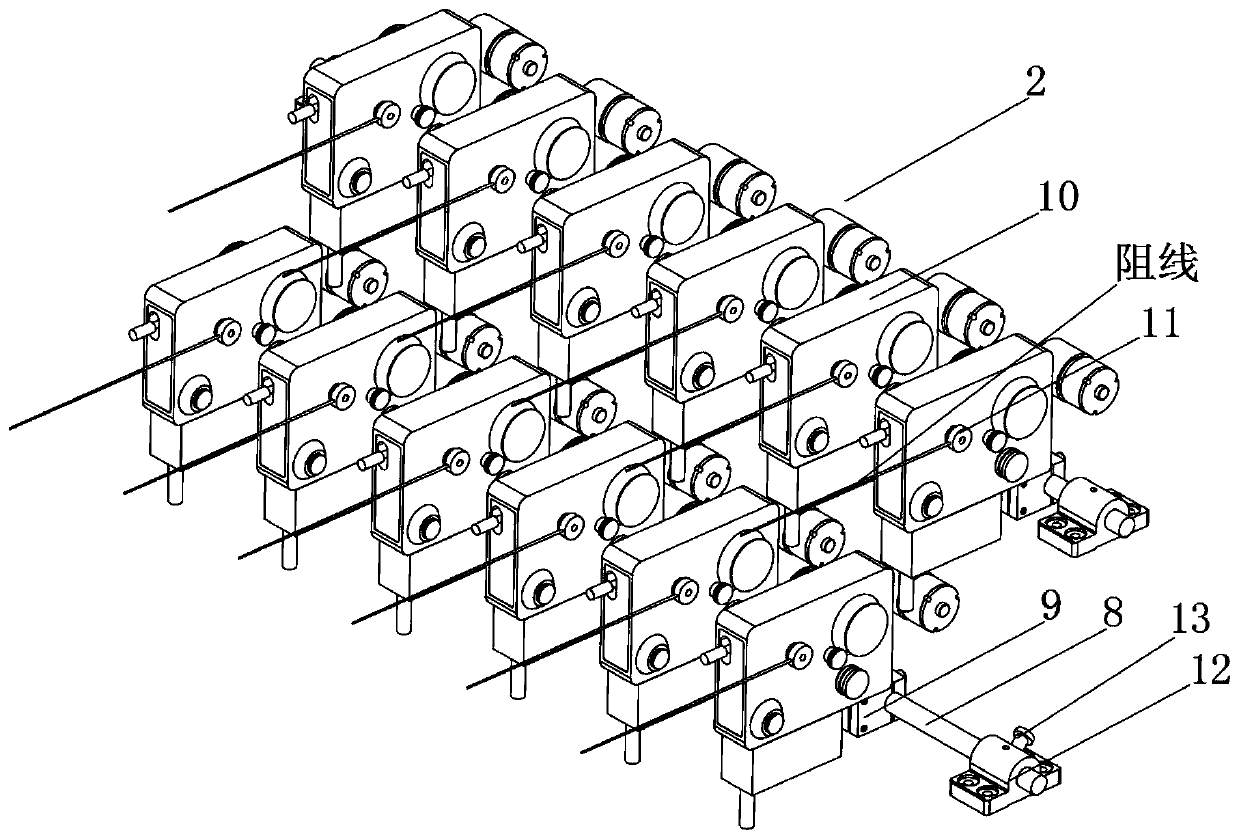

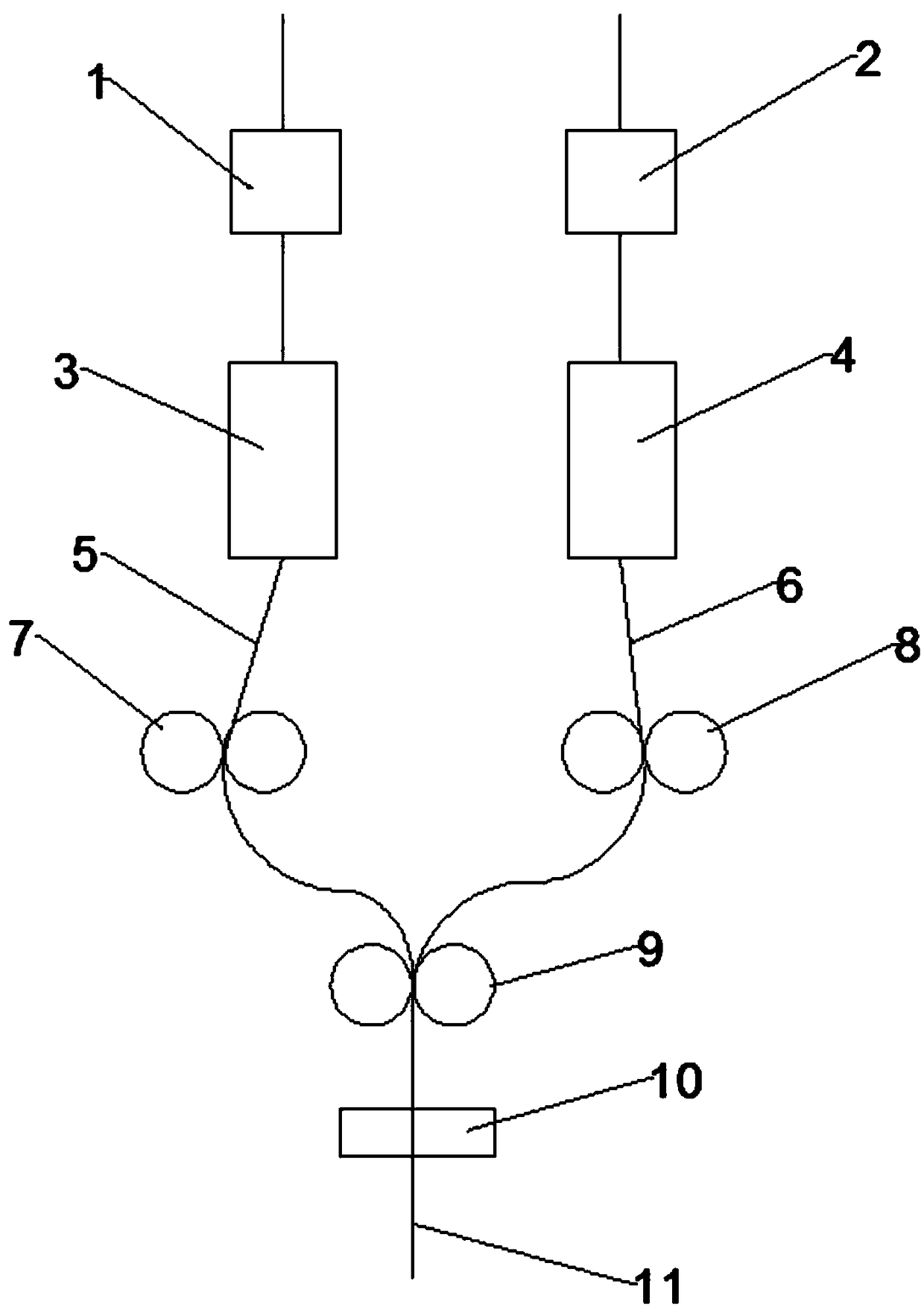

Wire-wound resistor resistance wire winding equipment and winding method thereof

PendingCN110265199AHigh degree of automationSave time and effortResistive element windingsResistance wireEngineering

The invention discloses wire-wound resistor resistance wire winding equipment and a winding method thereof. The wire-wound resistor resistance wire winding equipment comprises a mounting table, wire trays, a lead wire base, a front hanging disc, a back hanging disc, a wire pressing bench and a power distribution base. The top portion of the mounting table is provided with the wire trays; the lead wire base is arranged under the wire trays; and the front hanging disc is arranged under the lead wire base. The beneficial effects are that the equipment is high in working automation degree, and saves time and labor; one-to-one coordinated resistance wire winding work is realized through multiple wire trays, multiple lead cones and multiple insulation skeletons, thereby greatly improving work efficiency of the equipment and reducing land occupation area of the equipment; a hydraulic pump drives stretching bars to move back and forth cooperated with back plug cones so as to drive the insulation skeletons to move back and forth to wind resistance wires, thereby ensuring that the resistance wires are wound on the insulation skeletons more uniformly and comprehensively, and improving resistance wire winding efficiency and winding quality of the equipment.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Production system and process for double-colored spinning yarns

The invention provides a production system and process for double-colored spinning yarns which are not dyed but have a double-colored effect. A first POY spinning machine in the system is used for producing spun yarns A, a second POY spinning machine is used for producing spun yarns B, the spun yarns A are twisted by a first twister, the spun yarns B are twisted by a second twister, and the spun yarns A and the spun yarns B are twisted in a compounded manner by a third twister. The production process is simple, dyeing costs are saved, and environmental problems such as sewage caused by a dyeing process are reduced.

Owner:杭州辰泽新材料有限公司

A cable constant sag coil material feeding system

ActiveCN111532877BRealize constant sag winding operationAvoid position shiftFilament handlingDrive shaftControl theory

The present invention proposes a cable constant sag coil material feeding system, which includes a drive frame, a cable roller, a V-shaped cage and a floating cable idler frame, and the cable roller is clamped on the V-shaped cage , the V-shaped cage is slidably connected to the drive frame, the drive frame is provided with a main drive shaft and a driven shaft, and the bottom of the cable roller is in frictional contact with the main drive shaft and the driven shaft at the same time, and the wire The cable floating idler frame is arranged at the coil material feeding port of the cable, and the cable roller is used for storing the cable. The invention enables the cable roller to move laterally at the same time during the winding operation, thereby ensuring that the cable is always kept perpendicular to the cable roller during the coiling or feeding process, so that the cable is fully wound and the deformation of the cable is reduced.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD

Process for producing nitrile-butadiene rubber (NBR) and polrvinyl chloride (PVC) mixed rubber by latex coprecipitation method

The invention discloses a process for producing NBR and PVC mixed rubber by using a latex coprecipitation method, which comprises: uniformly mixing NBR and PVC at 50 to 70 DEG C according to a ratio of 3:1 to prepare NBR / PVC mixed latex; and adding a deflocculant into the NBR / PVC mixed latex for curing, adding a flocculating agent at last to perform coprecipitation and flocculation in the NBR / PVCmixed latex, and drying the flocculate to obtain the finished product. The production process is simple, easy and low in energy consumption, and the produced NBR / PVC blended rubber has high performance.

Owner:天津市铭仁化工科技有限公司

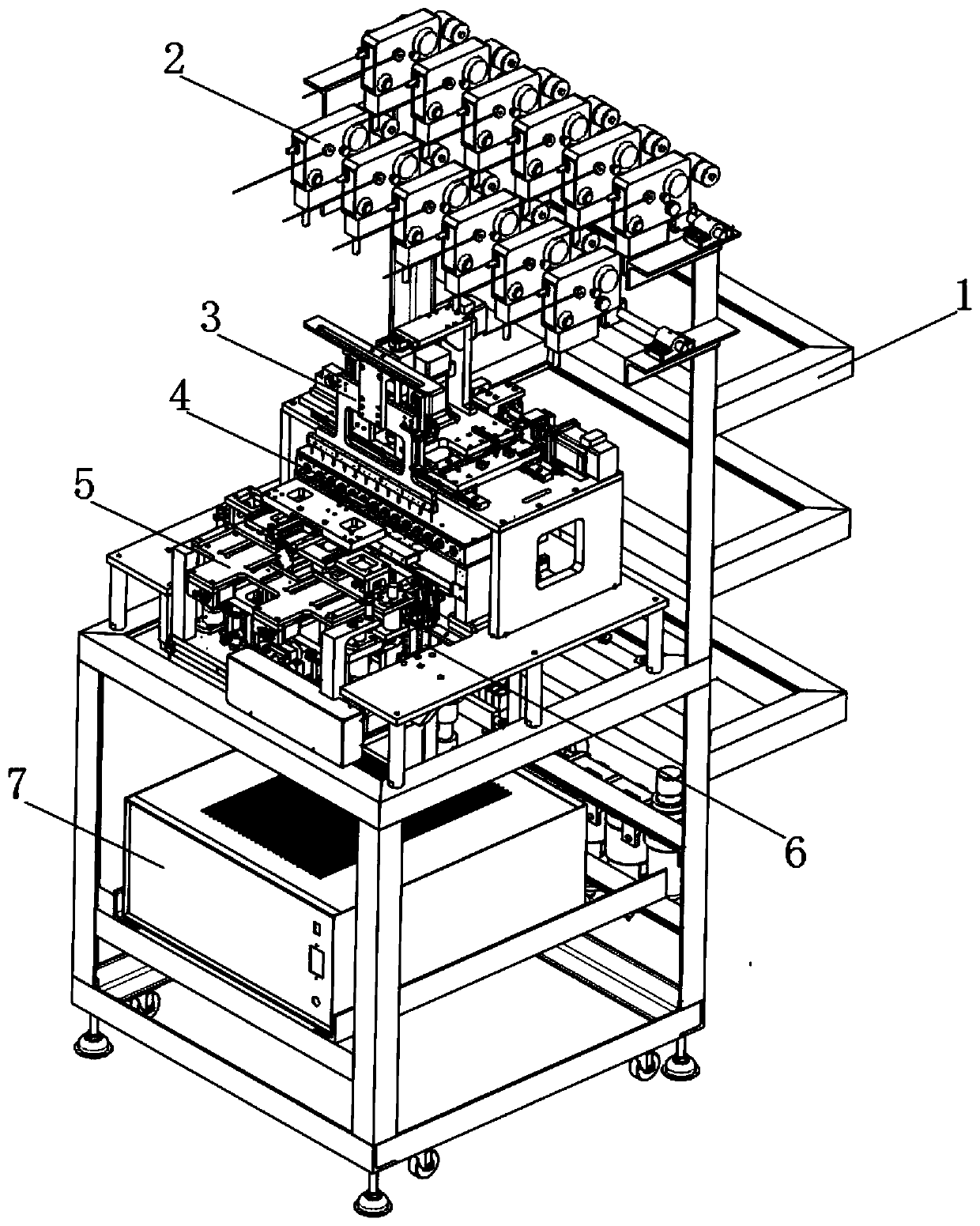

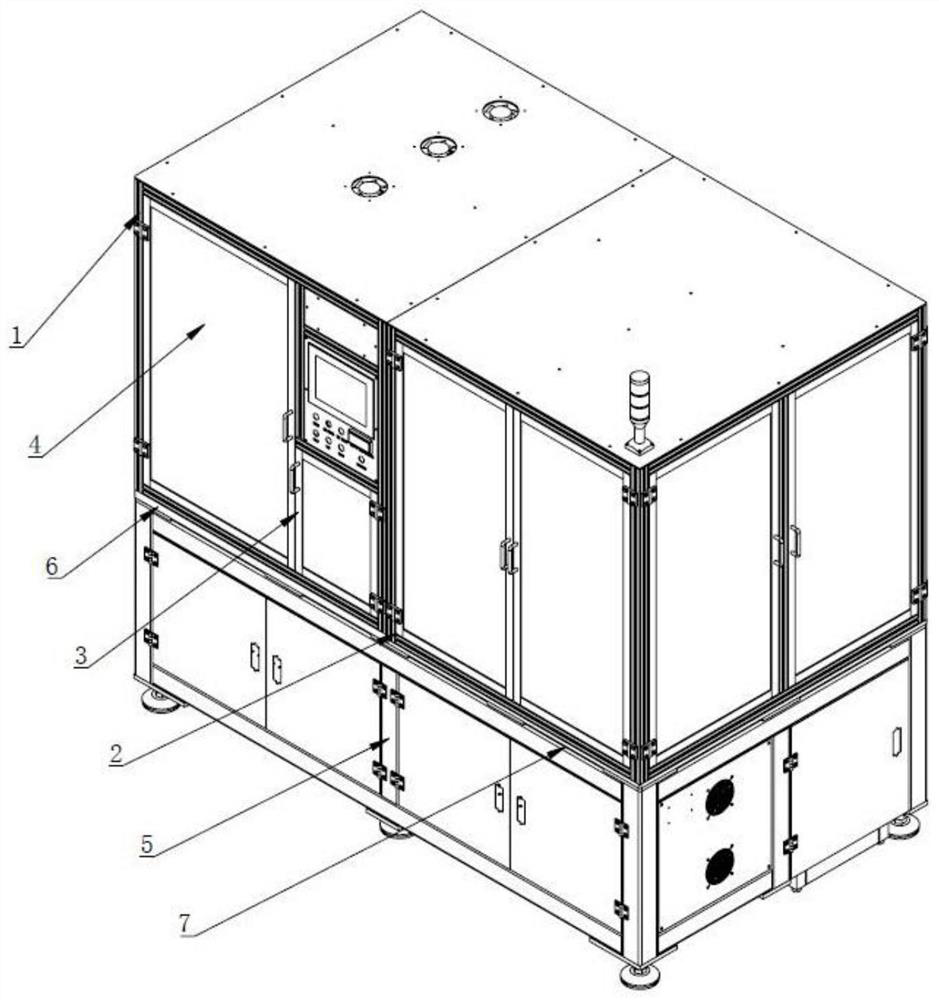

Full-automatic wireless charging multi-circle four-station winding and arranging machine

The invention is applicable to the technical field of wireless charging, and particularly relates to a full-automatic wireless charging multi-circle four-station winding and arranging machine which comprises a material taking BBA mechanical arm device, the material taking BBA mechanical arm device is mounted at the top of the case, and is used for taking and placing coils, is matched with CCD photographing detection, and is used for putting qualified products into a transfer station device mounted at the top of the case, and the material taking mechanical arm device is used for taking and placing materials in a tray placing bin device mounted at the top of the case. A pay-off and lead device, a stay wire displacement device, a winding and shaping station device, a disc four-station device,a wire clamping and shearing device, a heating station device, a preheating device and a cooling station device are mounted at the top of the case. According to the machine, the cable can be wound more comprehensively and completely, layering is avoided, the yield of wound wireless charging coil products is high, and the large-batch and stable-quality production mode can be met.

Owner:深圳市星特科技有限公司

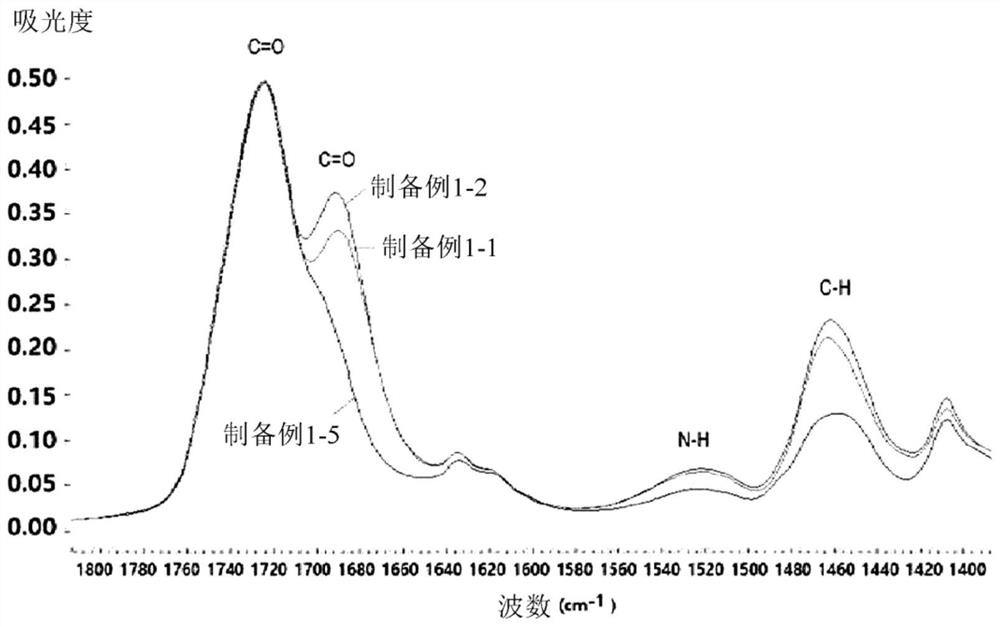

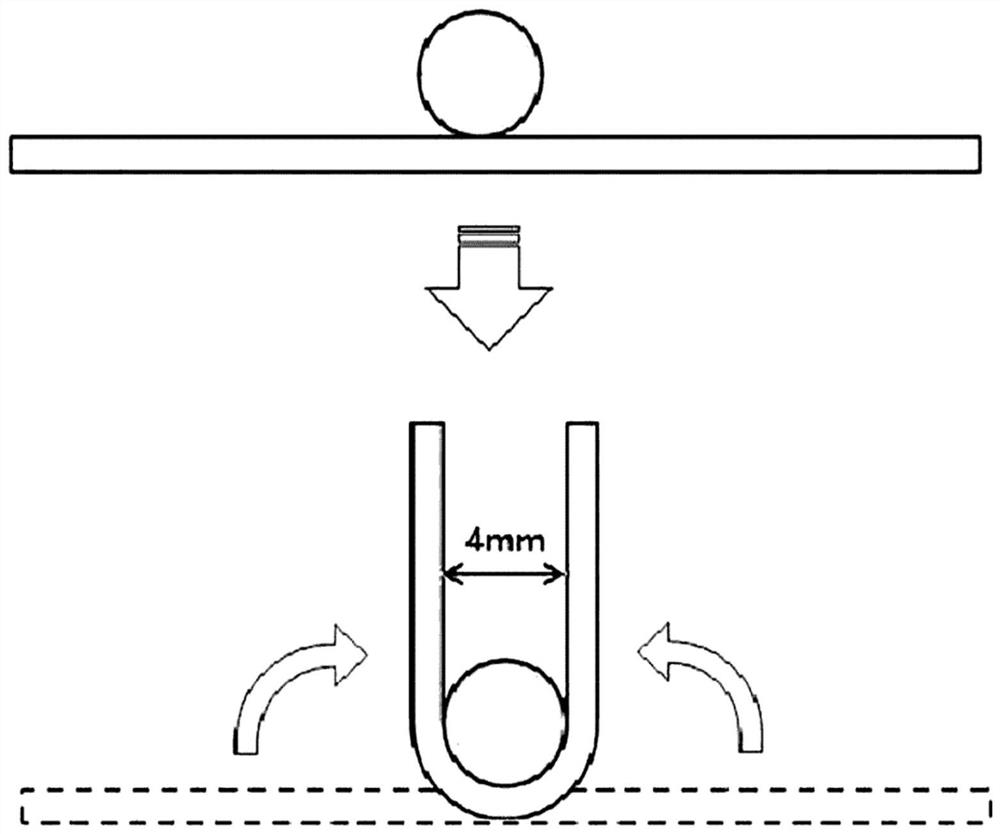

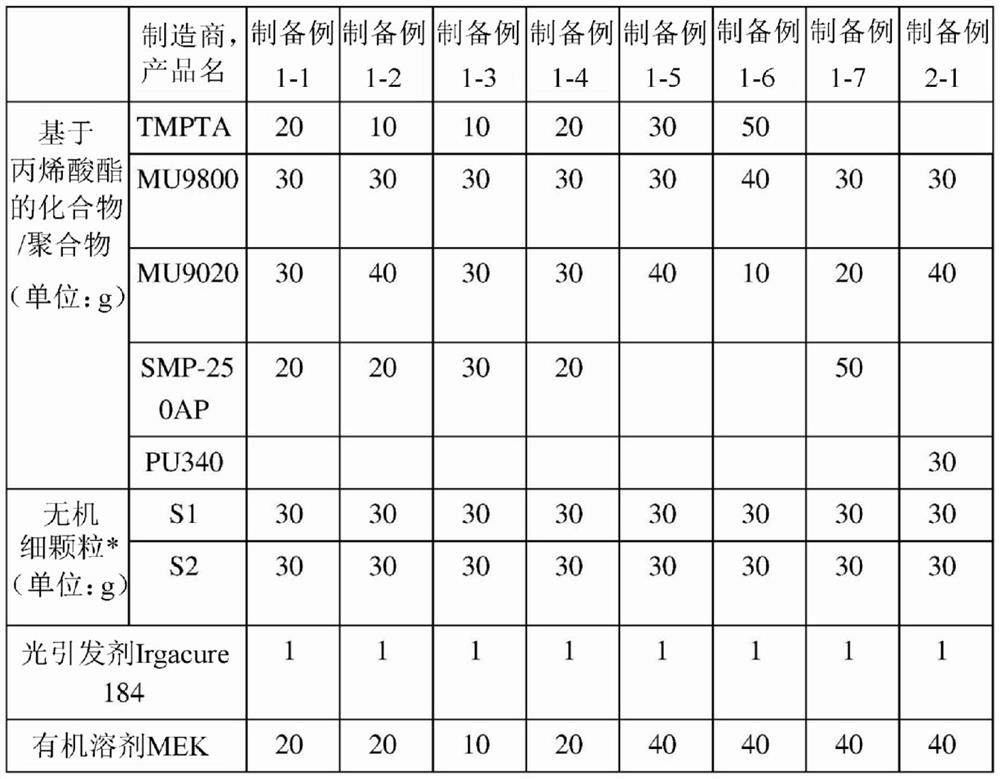

Cover window for flexible display device and flexible display device

ActiveCN113490975AHigh hardnessImprove scratch resistanceProtective equipmentSynthetic resin layered productsFlexible displayElectrical and Electronics engineering

The present invention relates to a cover window for a flexible display device and a flexible display device comprising the cover window, the cover window comprising: a light-transmitting substrate; and a first hard coating layer and a second hard coating layer which are disposed on opposite surfaces of the light-transmitting substrate, respectively, wherein the first hard coating layer and the second hard coating layer have IR spectrums in which the ratio of the amide C=O peak to the ester C=O peak is within a predetermined range.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com