Non-vulcanized glue film of hydrogenated butyronitrile-polyvinyl chloride blended emulsion and preparation and application thereof

A technology for hydrogenating nitrile butadiene and polyvinyl chloride is applied in the field of chemical products and their preparation, and achieves the effects of good adhesion, easy elimination of bubbles and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

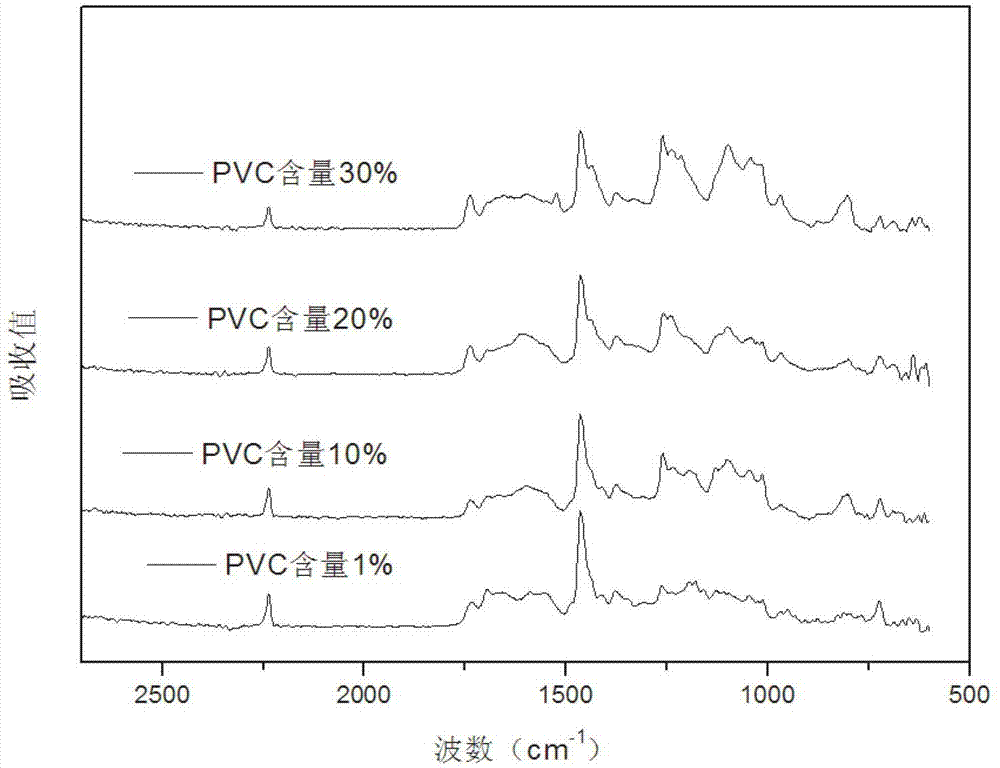

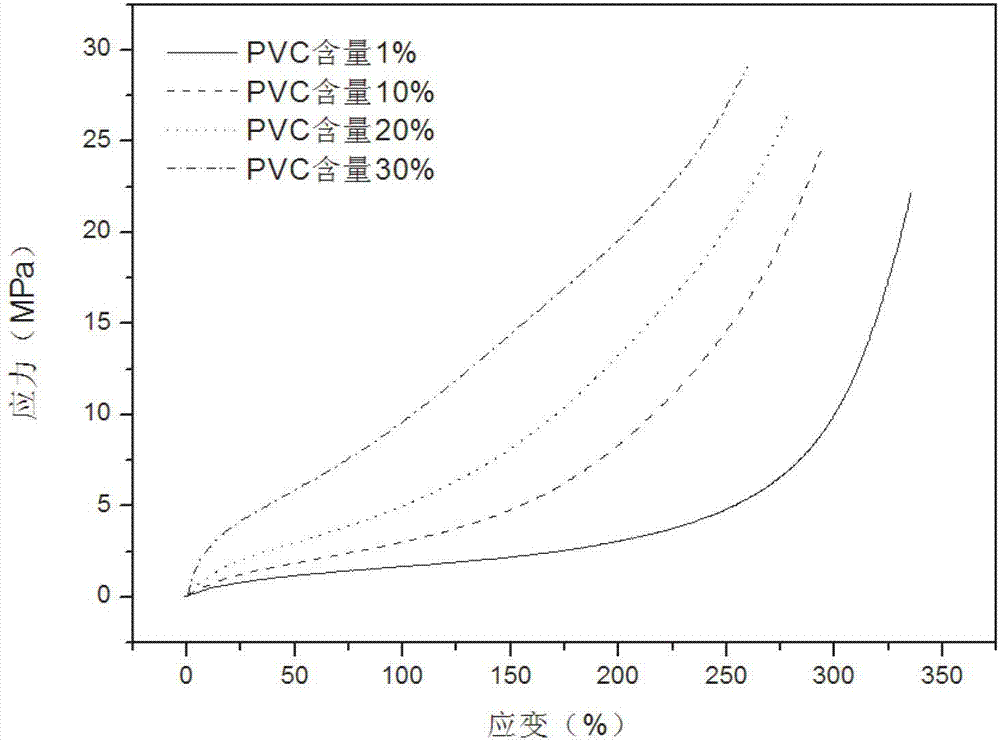

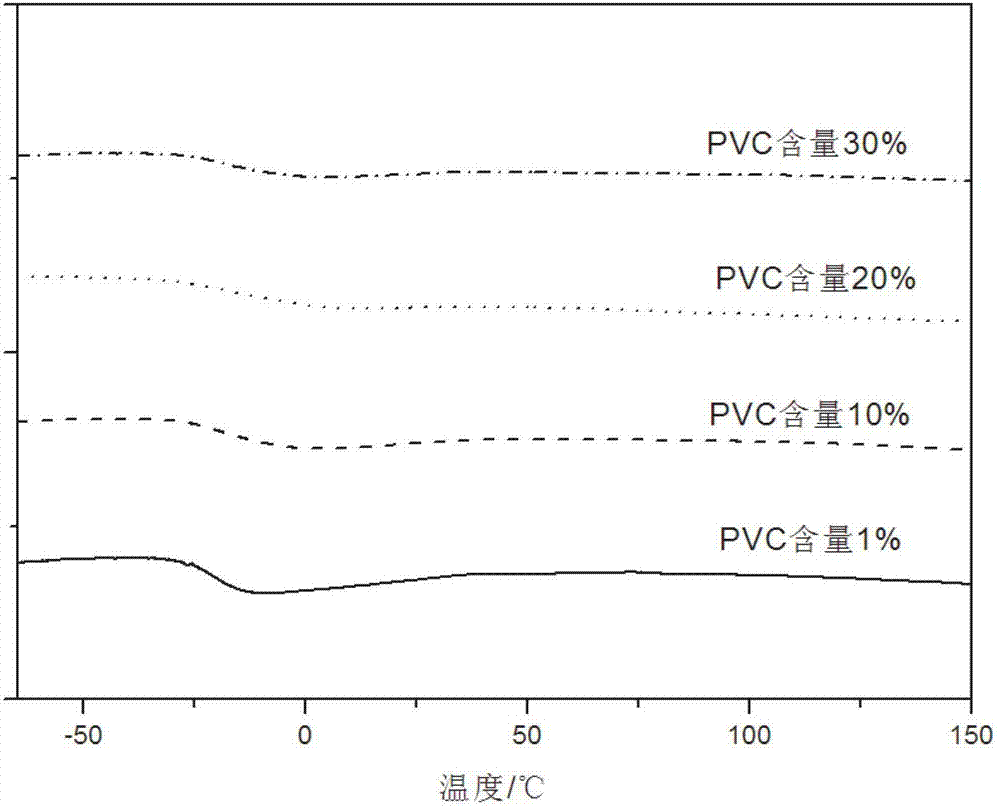

[0026]Put the mixture of 100ml of NBR latex and 45ml of hydrazine hydrate into a 500ml three-neck flask, heat it to a constant temperature of 20°C, and add boric acid hydrogen peroxide solution to the mixture. 15:1, reacted for 12 hours, and obtained HNBR latex with a hydrogenation degree of 90%. Mix HNBR latex and PVC emulsion in a round bottom flask, heat it to a constant temperature of 80°C, the mixing ratio of HNBR and PVC is 99:1 according to the solid content weight ratio, and the PVC content of the blended latex is 1% and PVC is in the blended rubber It has a stable dispersed state. Dip the mold into the prepared mixed emulsion. After dipping for 10 minutes, the emulsion forms a crack-free wet gel film on the surface of the mold. The fluidity of the emulsion is good, there are no bubbles and no skinning on the surface of the emulsion surface during dipping. Soak the wet gel film in warm water at 20°C for 24 hours. Take out the wet gel film and put it in an oven at 60...

Embodiment 2

[0028] Put the mixture of 100ml of NBR latex and 45ml of hydrazine hydrate into a 500ml three-necked flask, heat it to a constant temperature of 20°C, and add boric acid hydrogen peroxide solution to the mixture. 15:1, reacted for 12 hours, and obtained HNBR latex with a hydrogenation degree of 90%. Mix HNBR latex and PVC emulsion in a round bottom flask, heat it to a constant temperature of 80°C, the mixing ratio of HNBR and PVC is 9:1 according to the solid content weight ratio, and the PVC content of the blended latex is 10% and PVC is in the blended rubber It has a stable dispersed state. Dip the mold into the prepared mixed emulsion. After dipping for 10 minutes, the emulsion forms a crack-free wet gel film on the surface of the mold. The fluidity of the emulsion is good, there are no bubbles and no skinning on the surface of the emulsion surface during dipping. Soak the wet gel film in warm water at 20°C for 24 hours. Take out the wet gel film and put it in an oven at...

Embodiment 3

[0030] Put the mixture of 100ml of NBR latex and 120ml of hydrazine hydrate into a 500ml three-neck flask, heat it to a constant temperature of 80°C, add boric acid hydrogen peroxide solution to the mixture, the total amount of hydrogen peroxide is 3.0 of the moles of carbon-carbon double bonds, and the molar ratio of boric acid to hydrogen peroxide is 40:1, reacted for 12 hours, and obtained HNBR latex with a hydrogenation degree of 90%. Mix HNBR latex and PVC emulsion in a round-bottomed flask, heat to 20°C constant temperature, the mixing ratio of HNBR and PVC is 8:2 according to the solid content weight ratio, and the PVC content of the blended latex is 20% and PVC is in the blended rubber It has a stable dispersed state. Dip the mold into the prepared mixed emulsion. After dipping for 1 min, the emulsion forms a crack-free wet gel film on the surface of the mold. The fluidity of the emulsion is good, there are no bubbles and no skinning on the surface of the emulsion sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com