Full-automatic wireless charging multi-circle four-station winding and arranging machine

A wireless charging, four-station technology, applied in the direction of coil manufacturing, etc., can solve problems such as delamination, incapable of cable winding, inability to meet high-volume, stable quality production methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solutions of the present invention will be further described in further detail below in conjunction with specific embodiments. In the description of the invention, the meaning of "multiple" is two or more than one other words unless otherwise stated.

[0069] In the prior art, the winding of the coil does not make the cable completely winding, hierarchical, wound wireless charging coil products, and does not meet the problem of mass, quality and stable production methods, the present invention The purpose is to provide a fully automatic wireless charging multi-circle four-station winding set machine to solve the above proposed problems. In order to achieve the above object, the present invention provides the following technical solutions:

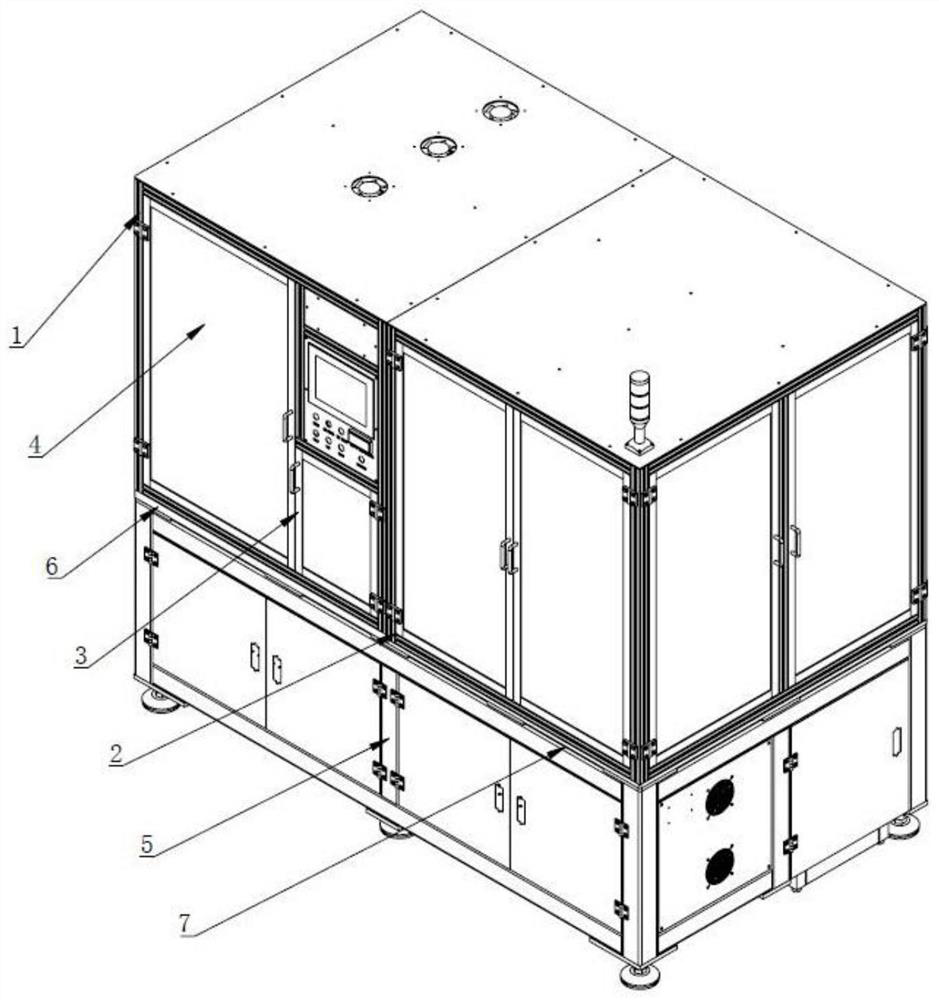

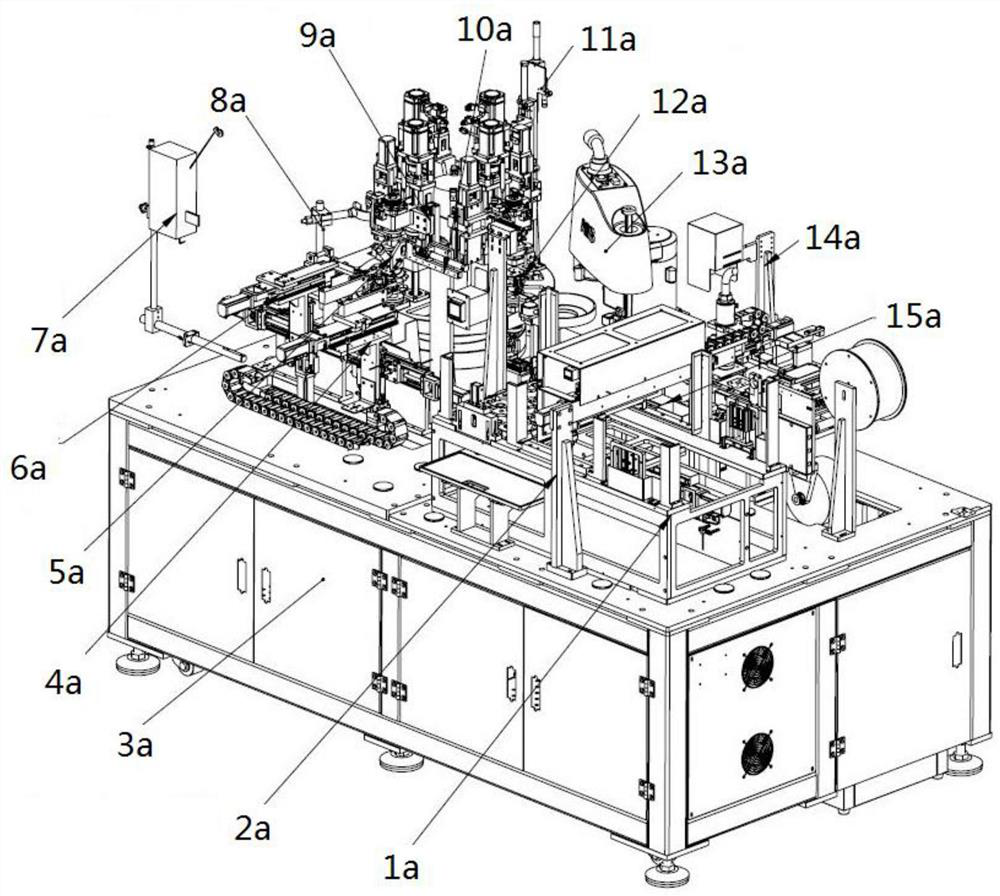

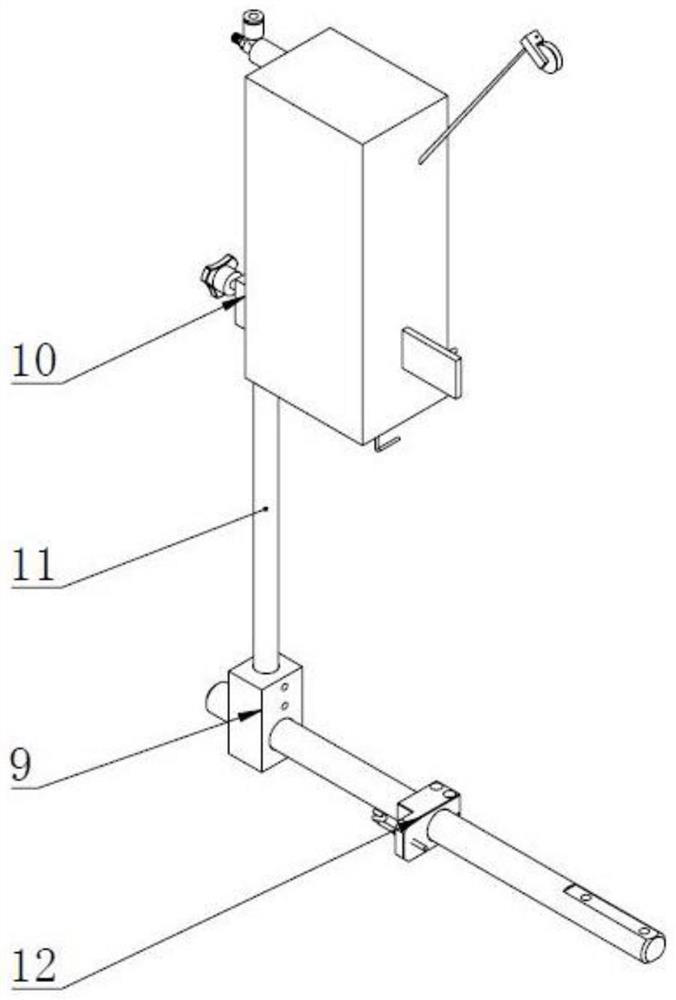

[0070] In the embodiment of the present invention, such as figure 1 with figure 2 As shown, a fully automatic wireless charging multi-circle four-station winding panel machine, including: taking the BBA manipulator device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com