A cable constant sag coil material feeding system

A feeding system and cable technology, which is applied in the field of cable constant sag coil material feeding system, can solve the problem of keeping the cable roller vertical and achieve the effect of sufficient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

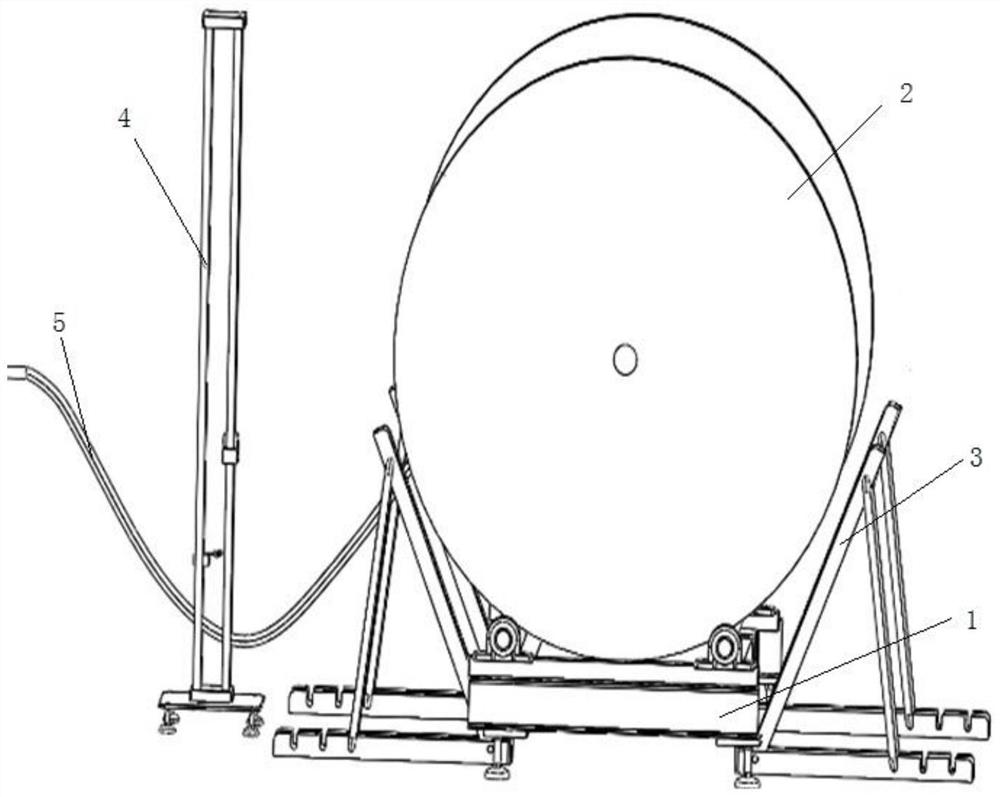

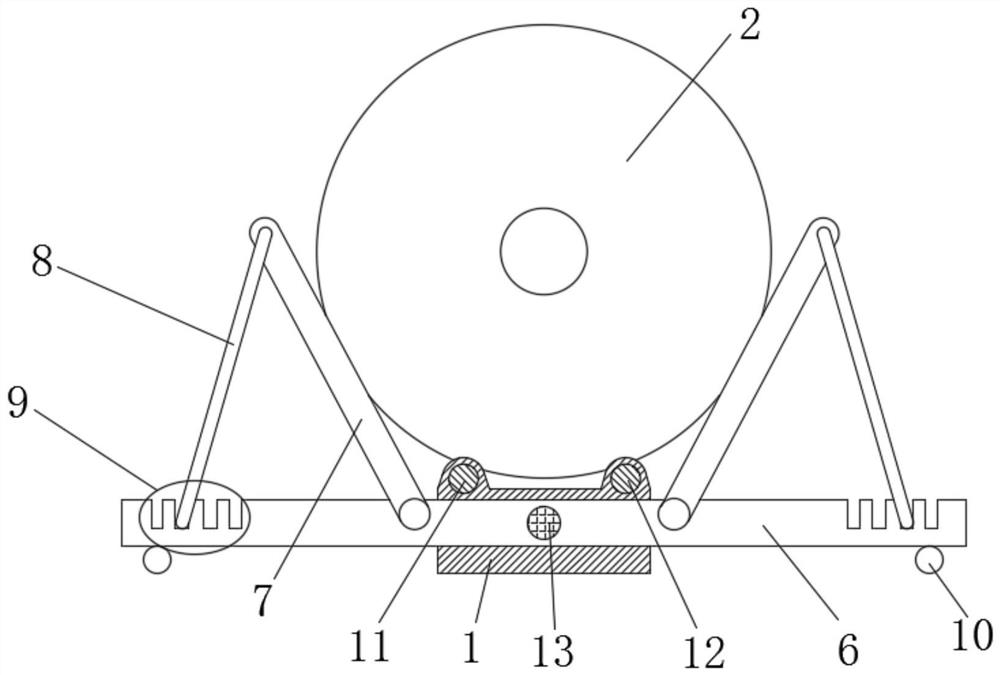

[0025] This embodiment proposes a cable constant sag coil material feeding system, refer to figure 1 , including a drive frame 1, a cable roller 2, a V-shaped cage 3 and a cable floating idler frame 4, the cable roller 2 is clamped on the V-shaped cage 3, and the V-shaped cage 3 is slidably connected to the driving machine On the frame 1, the drive frame 1 is provided with a main drive shaft 11 and a driven shaft 12, the bottom of the cable roller 2 is in frictional contact with the main drive shaft 11 and the driven shaft 12 at the same time, and the cable floating idler frame 4 is arranged on the cable The coil material feeding port of 5 exits, and the cable roller 2 is used for the storage of the cable 5.

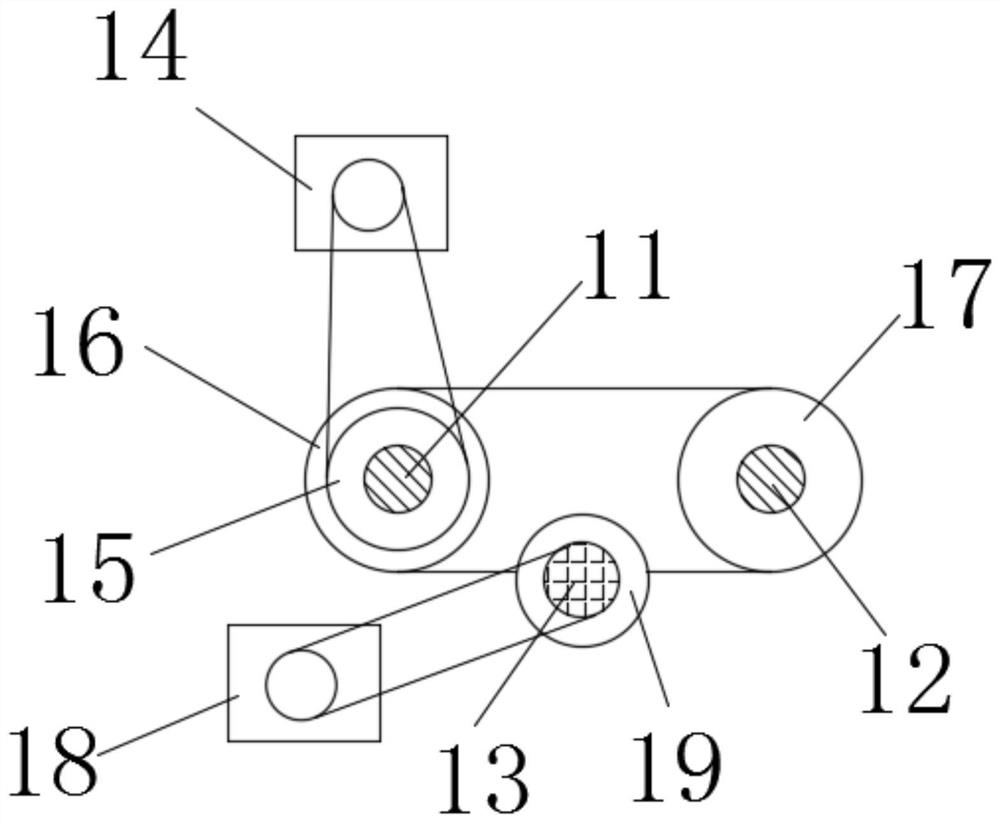

[0026] refer to figure 2 , the V-shaped cage 3 includes a support frame 6, and the two sides of the support frame 6 are symmetrically provided with a roller groove bar 7, a connecting rod 8 and 4 adjustment grooves 9; one end of the roller groove bar 7 is hinged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com