Cover window for flexible display device and flexible display device

A flexible display device and durability technology, which is applied in the field of cover windows, can solve the problems that it is not easy and glass is not suitable for flexible displays, and achieve the effect of high scratch resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-1

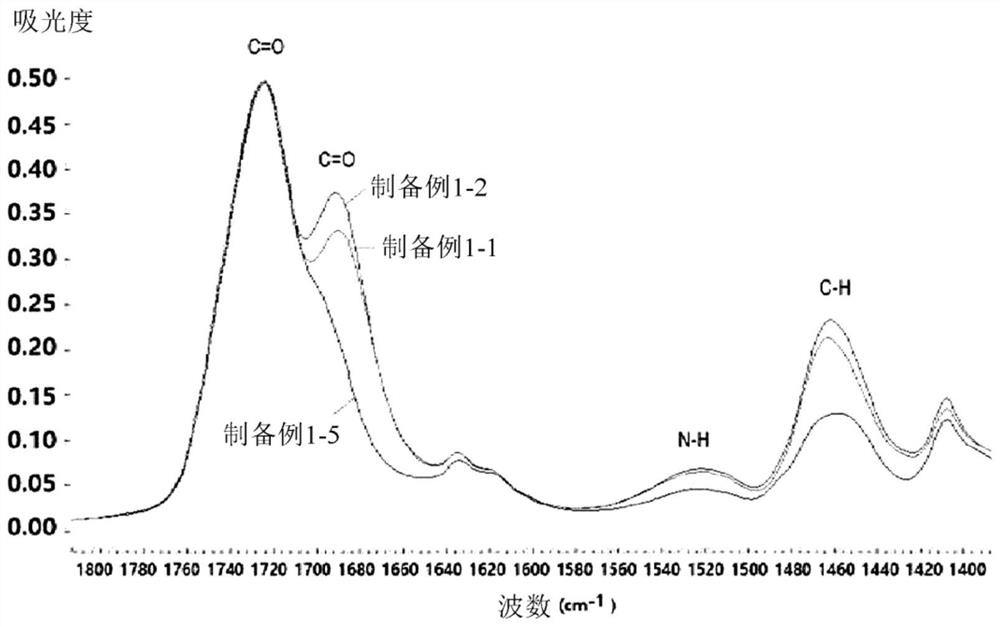

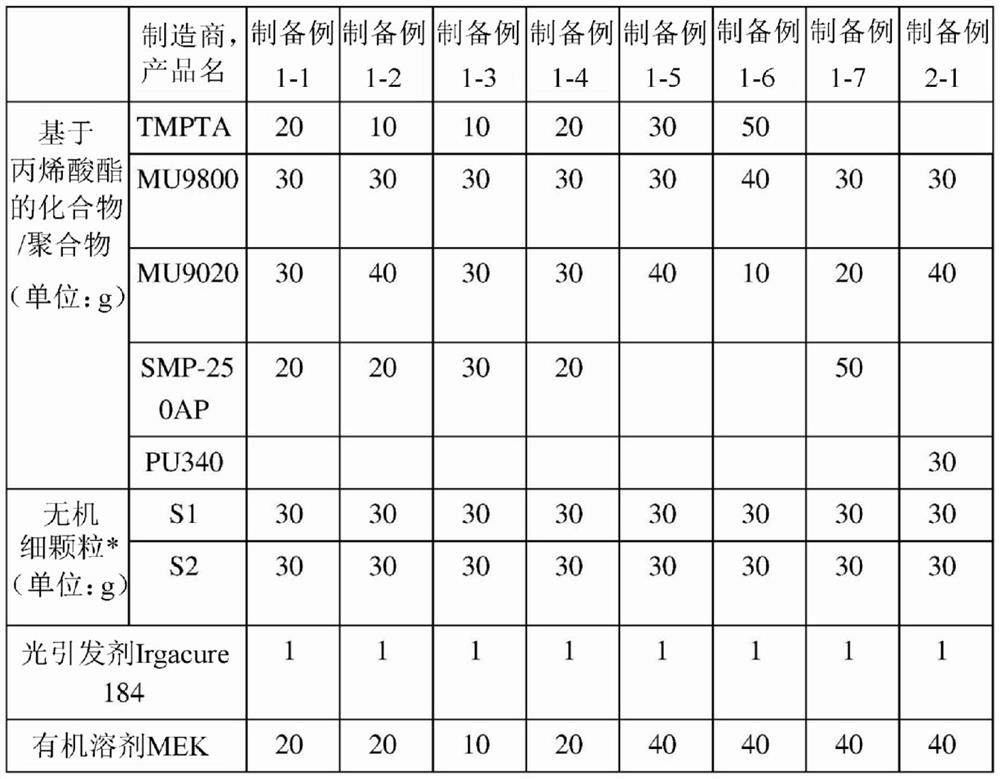

[0102] 20 g of trimethylolpropane triacrylate (TMPTA) (manufactured by Cytec, Mw = 296 g / mol, acrylate group equivalent weight = 99 g / mol) as a trifunctional acrylate-based compound, 30 g as a 9-functional MU9800 (manufactured by Miwon, Mw = 3500 g / mol, acrylate group equivalent weight = 389 g / mol), 30 g of a 10-functional urethane acrylate-based compound MU9020 (manufactured by Miwon, Mw = 4500 g / mol, acrylate group equivalent weight = 450 g / mol), 40 g of them, SMP-250AP (acrylic polymer, manufactured by Kyoeisha Chemical, acrylic acid) as an acrylate-based polymer compound Ester group equivalent weight = 240 g / mol to 260 g / mol, weight average molecular weight (Mw): 37,000) binder solution dissolved in propylene glycol monomethyl ether in an amount of 50% by weight, 1 g of Irgacure 184 as a photoinitiator (manufactured by Ciba) and 20 g of methyl ethyl ketone (MEK) were mixed to prepare an acrylate solution.

[0103] 60 g of a solution in which silica particles S1 (average p...

preparation example 1-2 to 1-7

[0105] A coating solution for forming a hard coat layer was prepared in the same manner as in Preparation Example 1-1, except that the contents of the components used were adjusted as shown in Table 1 below.

preparation example 2-1

[0107]30 g of MU9800 (manufactured by Miwon, Mw = 3500 g / mol, acrylate group equivalent weight = 389 g / mol) as a 9-functional urethane acrylate-based compound, 40 g of 10-functional urethane acrylate-based compound MU9020 (manufactured by Miwon, Mw=4500g / mol, acrylate group equivalent weight=450g / mol), 30g of PU340 (manufactured by Miwon, Mw=2400g) as a trifunctional urethane acrylate-based compound / mol, acrylate group equivalent weight=800 g / mol), 1 g of Irgacure 184 (manufactured by Ciba) as a photoinitiator, and 40 g of methyl ethyl ketone (MEK) were mixed to prepare an acrylate solution.

[0108] 60 g of a solution in which silica particles S1 (average particle diameter of 20 nm, surface-modified by a methacrylate silane coupling agent) was dispersed in n-butyl acetate in an amount of 50% by weight and 100 g of the silica particles A solution of S2 (average particle size of 40 nm, surface modified by acrylate silane coupling agent) dispersed in methyl ethyl ketone (MEK) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com