Glass fiber battery separator winding and cutting device

A technology of cutting device and glass fiber battery, which is applied in the directions of coiling strips, transportation and packaging, thin material processing, etc., can solve the problems of affecting work efficiency, low reliability of use, cumbersome work, etc., to improve work efficiency and use The effect of reliability and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

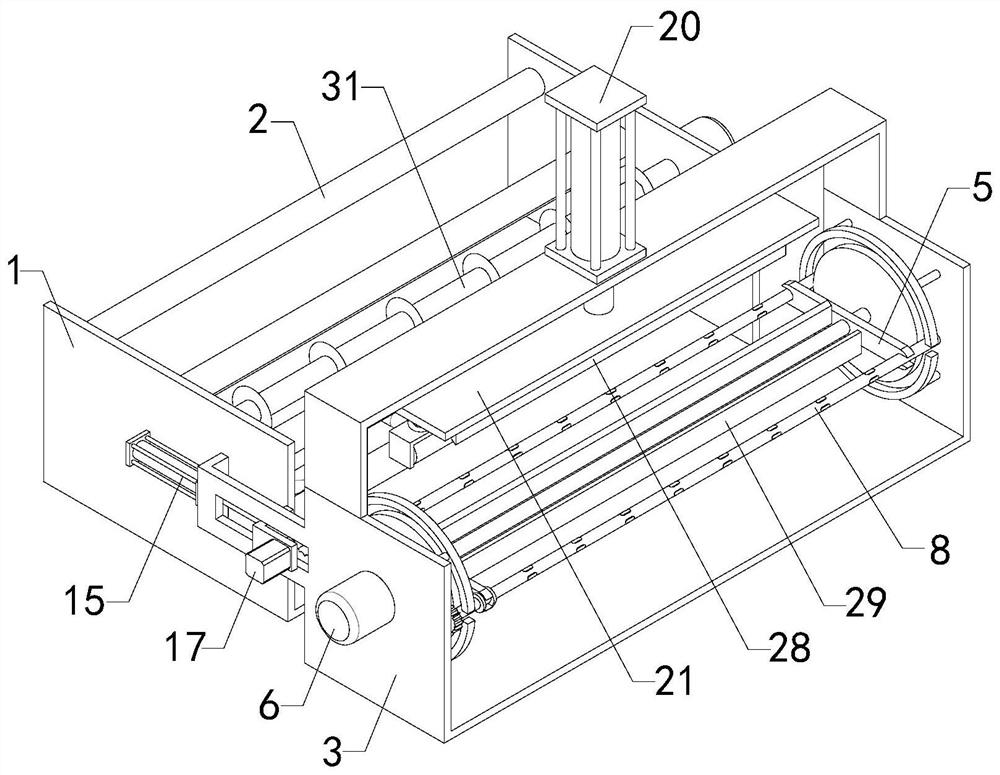

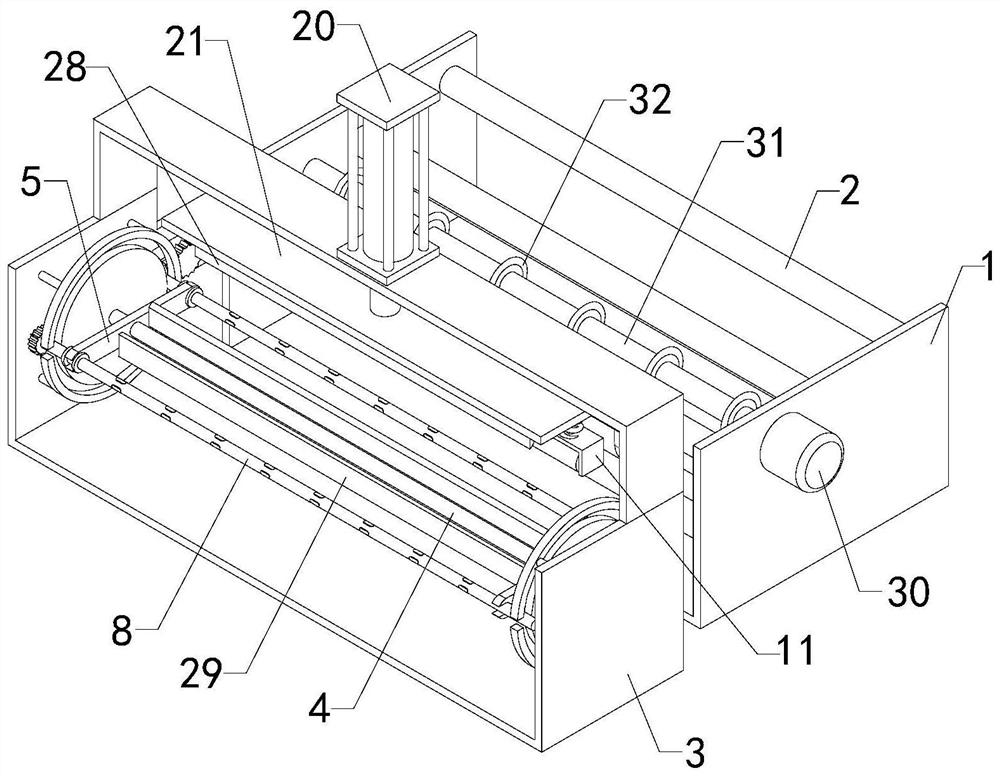

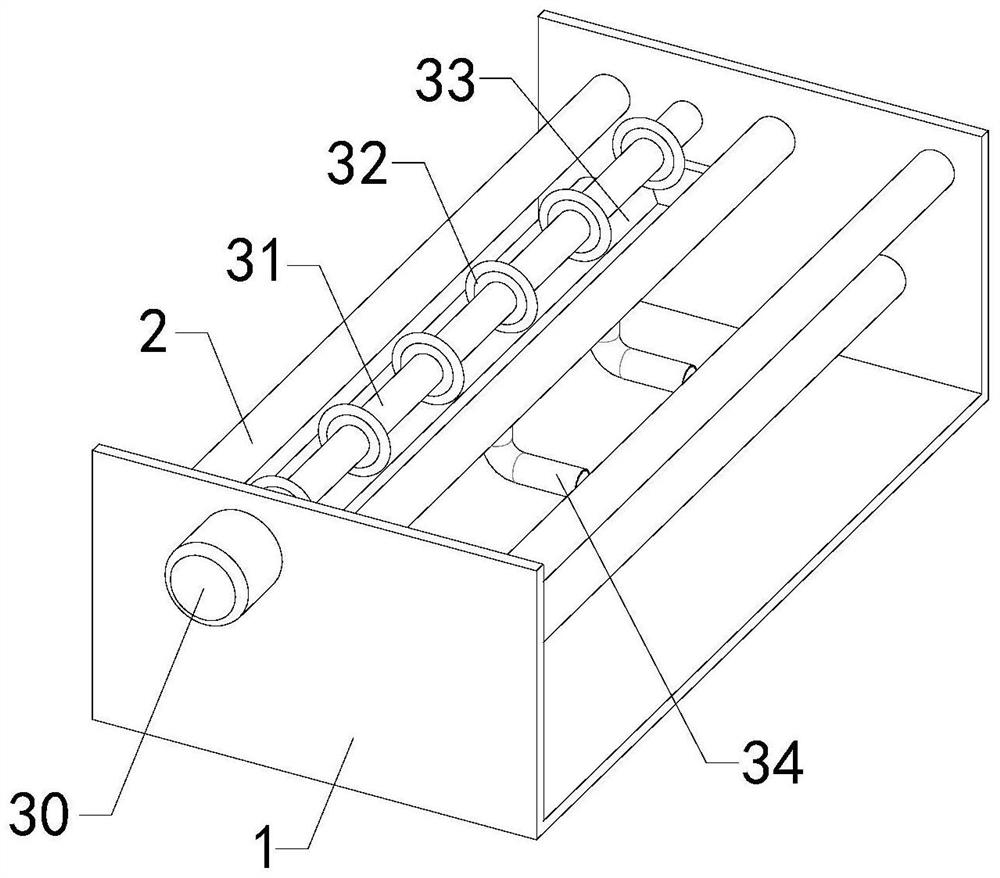

[0032] see Figure 1-8 , a glass fiber battery separator rewinding and cutting device of the present invention includes a frame 1 and a rewinding mechanism, and the frame 1 is provided with several guide shafts 2 and a cutting mechanism; the rewinding mechanism includes a fixed frame 3 , the inner side of the fixed frame 3 is rotatably provided with a rotating shaft 4, and a rotating material rack 5 is arranged on the outside of the rotating shaft 4, the front end of the fixed frame 3 is provided with a servo motor 6 that drives the rotating shaft 4 to rotate, and the left end of the rotating material rack 5 and the right end are all provided with arc-shaped draw-in groove 7, and described arc-shaped draw-in groove 7 places are movably provided with rewinding inflatable shaft 8, and the front end and the rear end of fixed mount 3 inner side are all provided with guide plate, and described guide plate is provided with There is an annular guide hole 9, the distance between the a...

Embodiment 2

[0042] See attached Figure 9 , the top and bottom of the rotating material rack 5 can also be provided with arc-shaped slots 7, a total of four sets of arc-shaped slots 7, so that the servo motor 6 can rotate 90° each time, and it can also replace the winding gas without stopping the machine. Axis 8 purpose.

[0043] When in use, the separator coil is guided by multiple sets of guide shafts 2, and the separator coil is cut by the slitting mechanism. After the separator coil is cut, it is rewound on the left 8 for rewinding. During the rewinding process, the driving mechanism drives the rewinding air-expanding shaft 8 on the left side to rotate to complete the rewinding, and the spare rewinding inflating shaft 8 is placed on the rotating material rack 5 through the pick-and-place port 10 There are 7 arc-shaped card slots at the right end. After the winding is completed, the traversing mechanism drives the driving mechanism to separate from the winding air-inflating shaft 8 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com