Patents

Literature

32results about How to "Realize continuous production operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of chewing pet food and its production process

InactiveCN102258143AMeeting nutritional needsSatisfy chewing instinctFood processingAnimal feeding stuffSpherical shapedBone shape

The invention discloses a chewing pet food, which is characterized in that it contains the following raw materials and is prepared according to the following weight ratio: edible meat: 50-80 parts, moisturizing agent: 5-20 parts, edible gum: 2-16 parts servings, plant protein: 4-15 servings, the pet chews produced not only have the advantages of good toughness and chewiness of traditional chewing products, but also greatly improve the disadvantages of poor palatability of traditional chewing products, which can reach The double function of making pets play and eat reduces the waste of resources and the pollution of the environment. The present invention takes edible meat as the main raw material, adds certain auxiliary materials for cutting and mixing, and is made into bone shape, bone shape, rod shape, heart shape through processes such as extrusion and baking, and is woven into spherical shape, ponytail shape, and twist shape. Chewing pet products in various shapes, the process mostly uses mechanical equipment, which reduces the use of labor, reduces costs, improves processing efficiency, and expands the product line.

Owner:YANTAI CHINA PET FOODS GRP

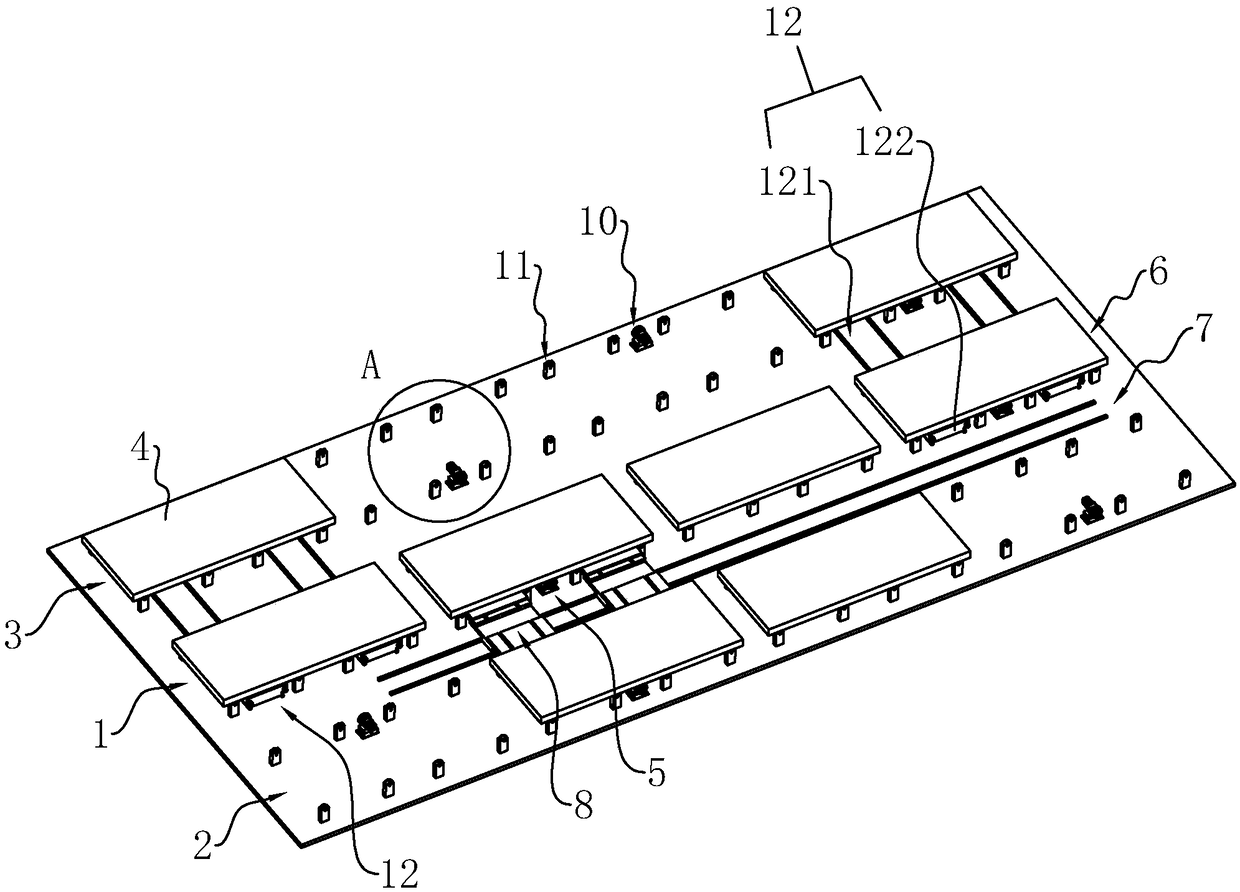

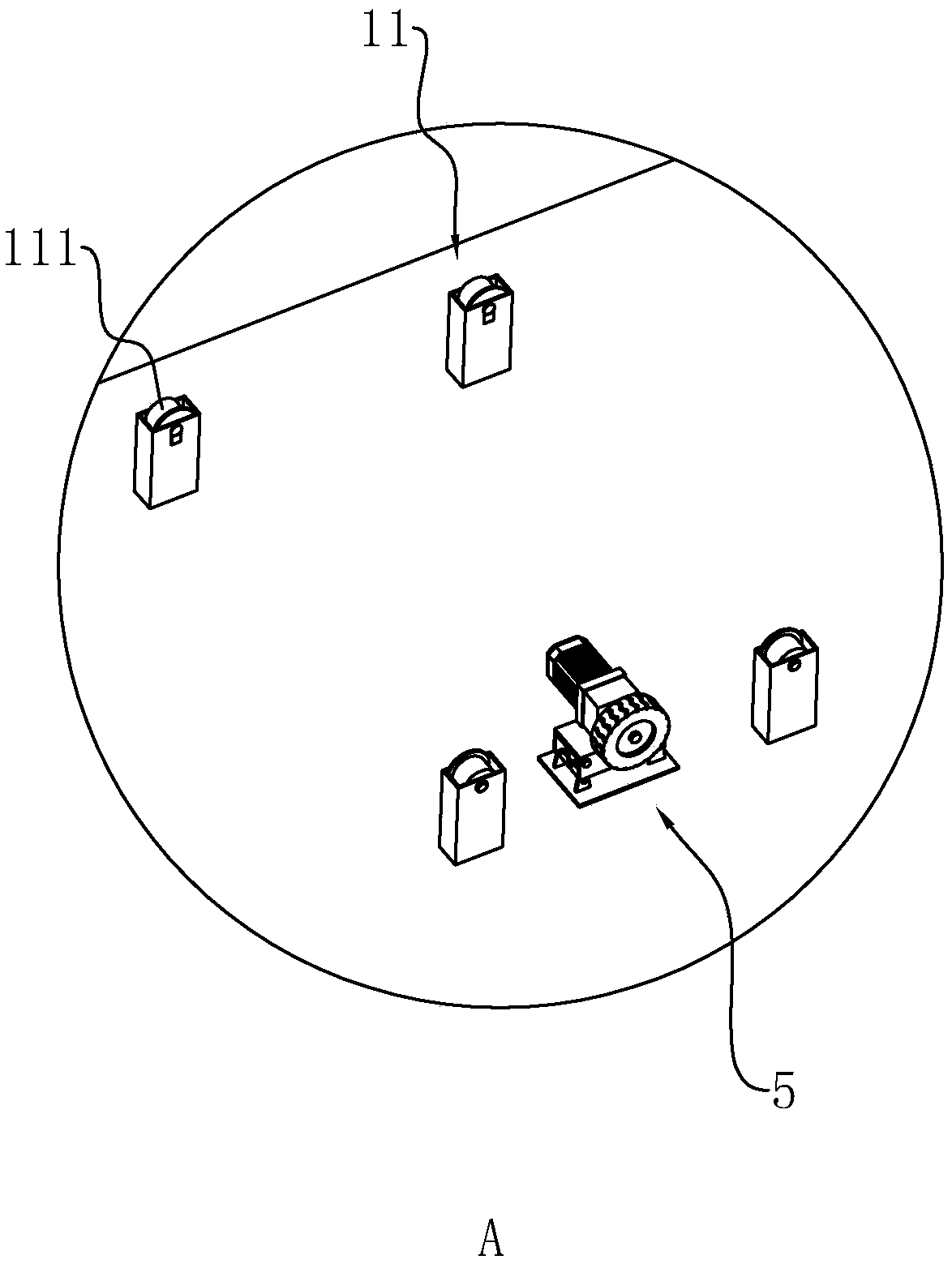

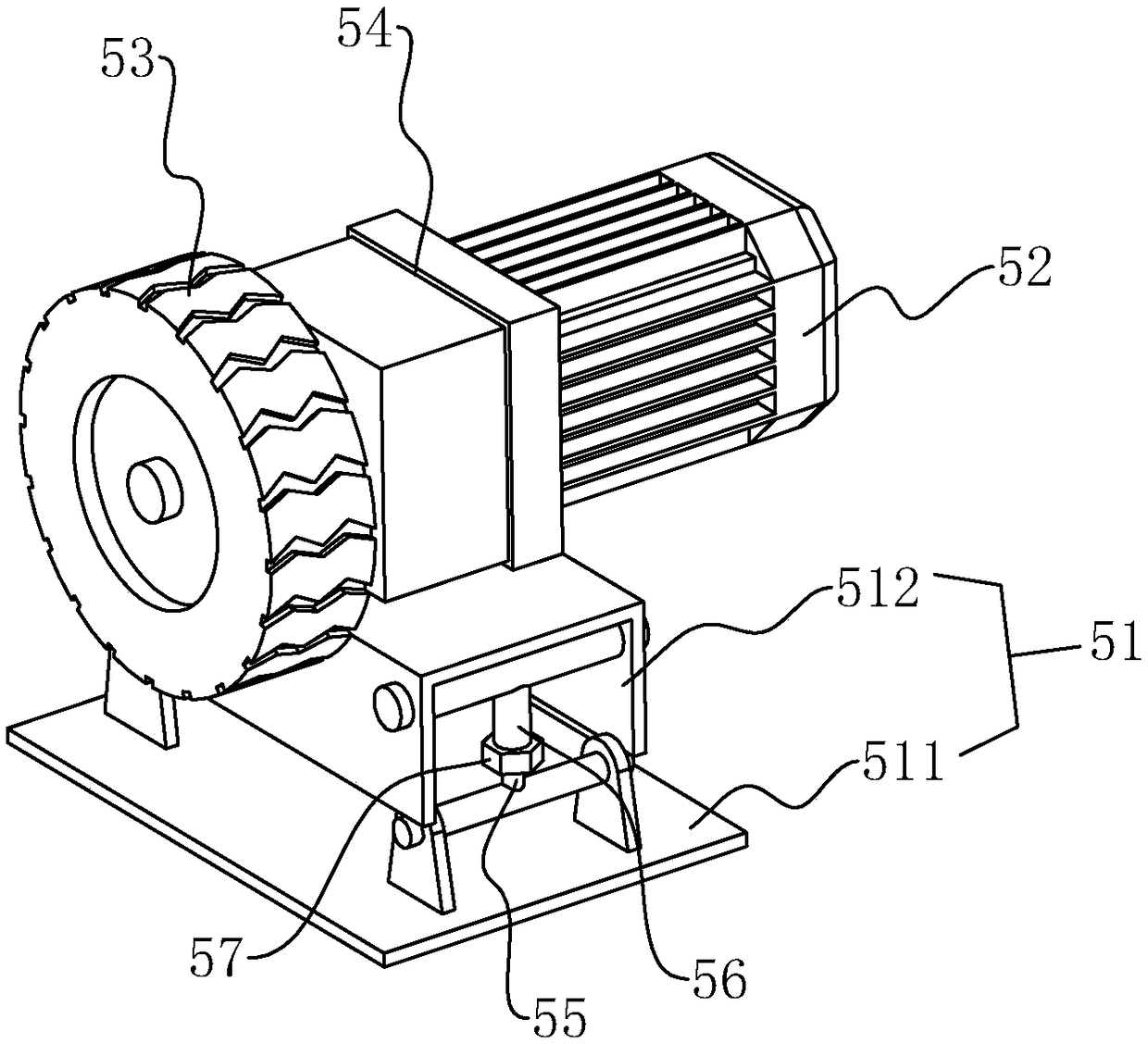

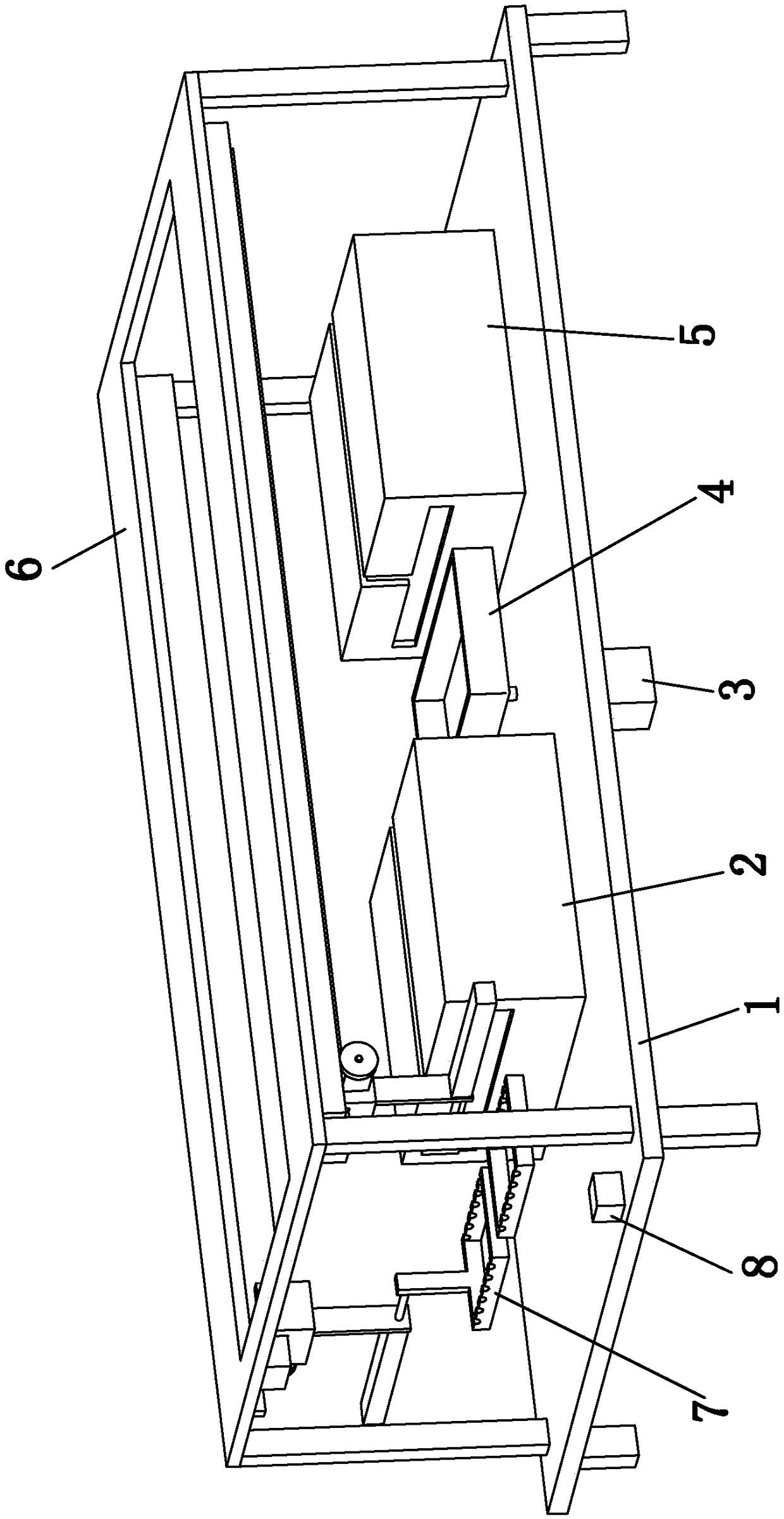

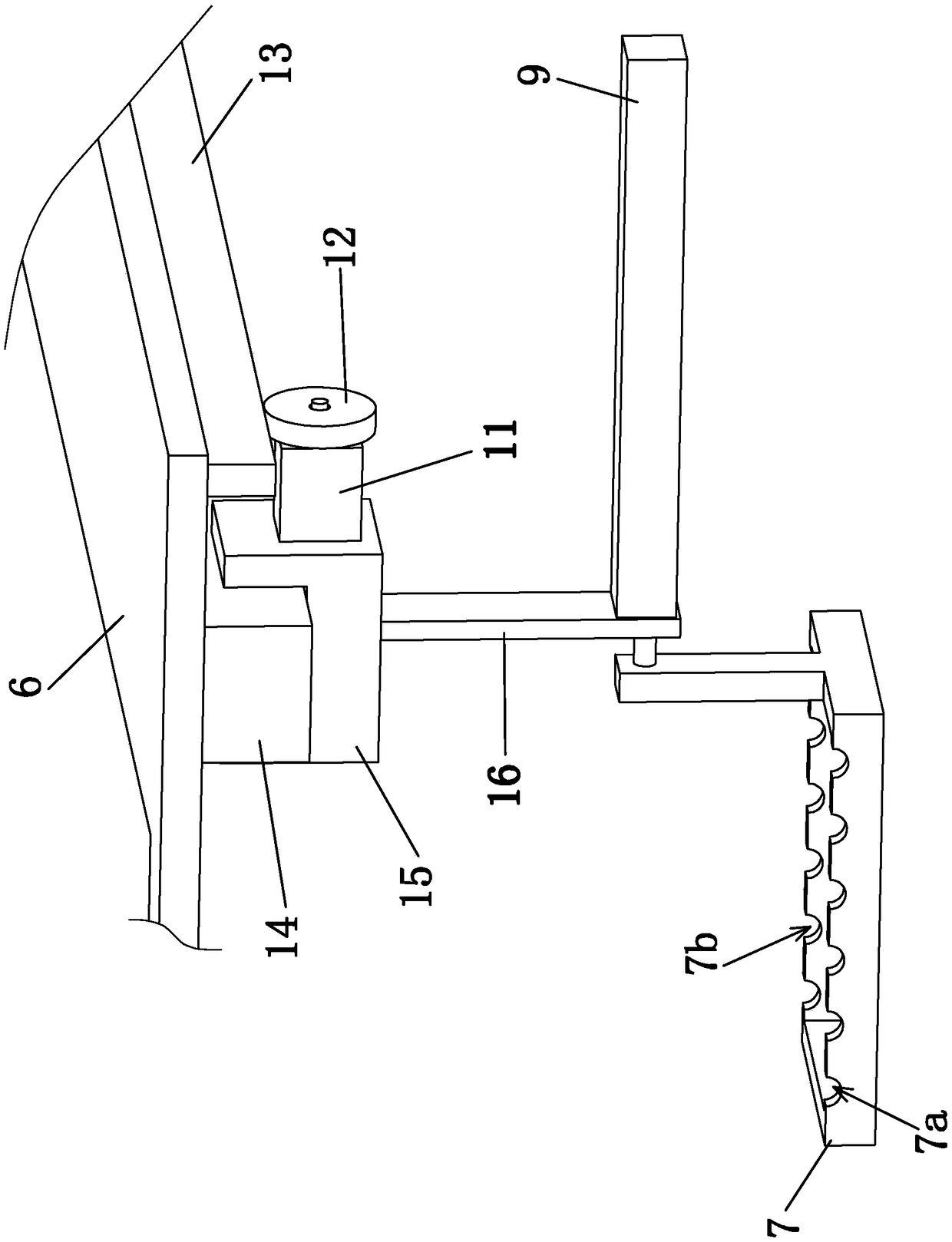

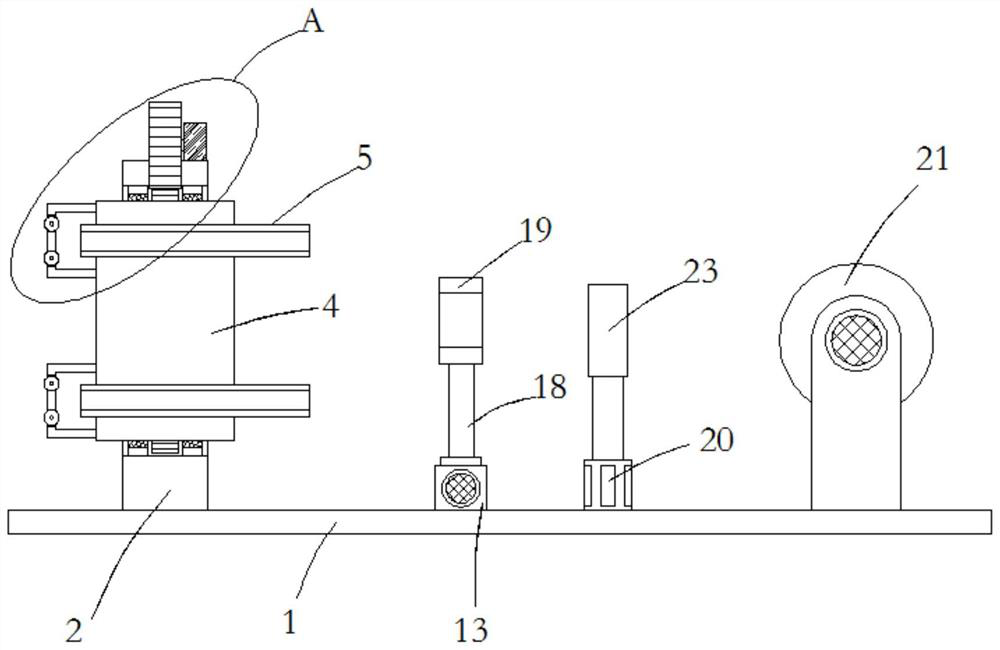

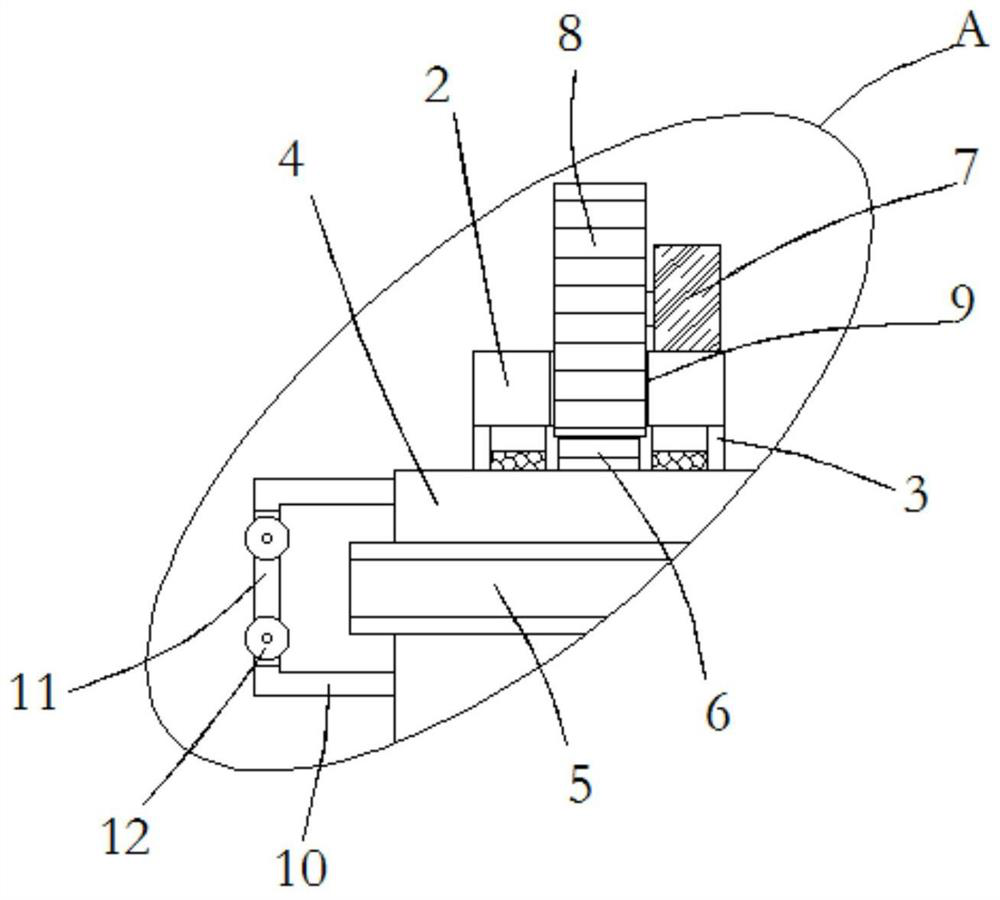

Prefabricated component production system

ActiveCN109049315AImprove continuityImprove fluencyCeramic shaping plantsProduction lineManufacturing engineering

The invention discloses a prefabricated component production system, and relates to the technical field of prefabricated component production. The system comprises a main production line, a pluralityof steel molding stations and a main feeding device. A plurality of backup stations are arranged near the main production line, and a first molding station lifting and traversing device is arranged between the main production line and the backup stations. The first molding station lifting and traversing device comprises a first ferrying track, a first molding station ferrying vehicle is movably arranged on the first ferrying track. An adjusting track is arranged on a ground near the main production line, a movable platform is movably arranged on the adjusting track, and the first molding station lifting and traversing device is integrally arranged on the movable platform. A maintenance production line and an auxiliary feeding device are arranged in parallel on one side of the main production line, and a second molding station lifting and traversing device is arranged between the main production line and the maintenance production line. According to the prefabricated component production system, the production cost can be reduced, and the production efficiency of the prefabricated component can be greatly improved.

Owner:上海汉石昀升住宅工业发展有限公司

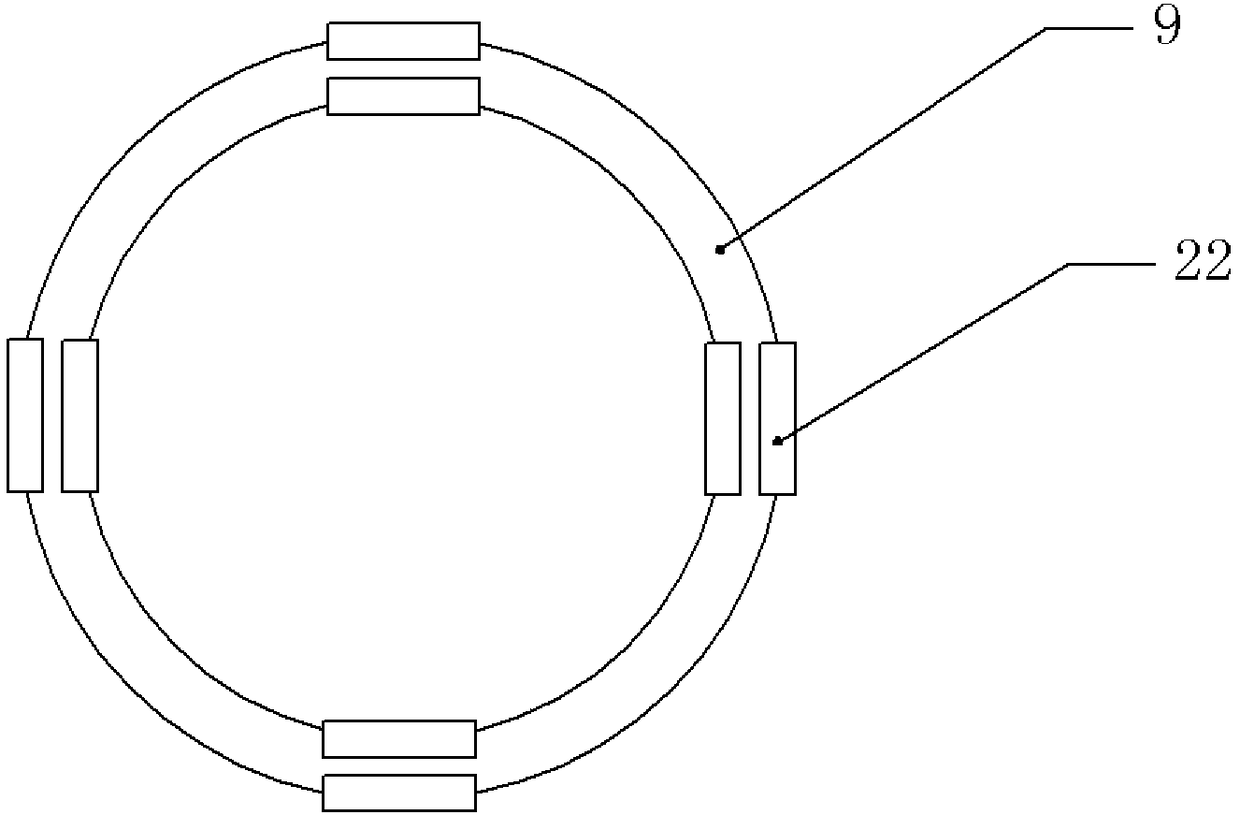

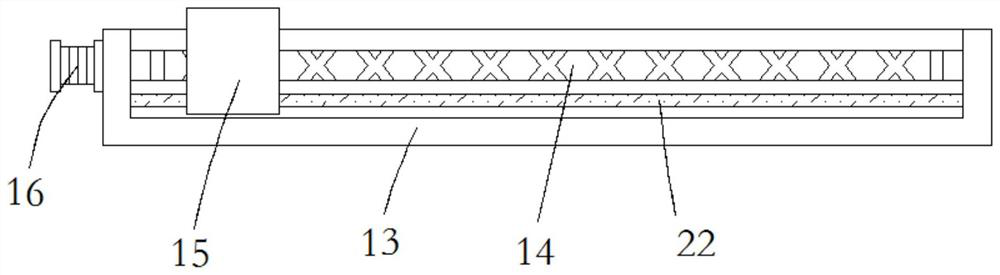

Glass fiber battery separator winding and cutting device

PendingCN113697552AEasy to disassembleImprove work efficiency and use reliabilityWebs handlingContinuous productionStructural engineering

The invention relates to the technical field of glass fiber battery separator processing accessory devices, in particular to a glass fiber battery separator winding and cutting device. The glass fiber battery separator winding and cutting device comprises a machine frame and a winding mechanism, and further comprises a transverse moving mechanism, a driving mechanism, a lifting mechanism, pressing mechanisms and a cutting mechanism, a plurality of guiding and conveying shafts and a slitting mechanism are arranged on the machine frame, the winding mechanism comprises a fixing frame and a servo motor, a rotating shaft is arranged on the inner side of the fixing frame in a rotating mode, a rotating material frame is arranged on the outer side of the rotating shaft, arc-shaped clamping grooves are formed in the left end and the right end of the rotating material frame correspondingly, winding air swelling shafts are movably arranged at the arc-shaped clamping grooves, guide plates are arranged at the front end and the rear end of the fixing frame correspondingly, annular guide holes are formed in the guide plates, and pick-and-place openings communicating with the annular guide holes are formed in the right ends of the guide plates. According to the glass fiber battery separator winding and cutting device, winding sleeves can be fed and discharged conveniently, in the feeding and discharging process, shutdown is not needed, continuous production operation is achieved, and the working efficiency and the use reliability are improved.

Owner:天长市永昌玻纤制品有限公司

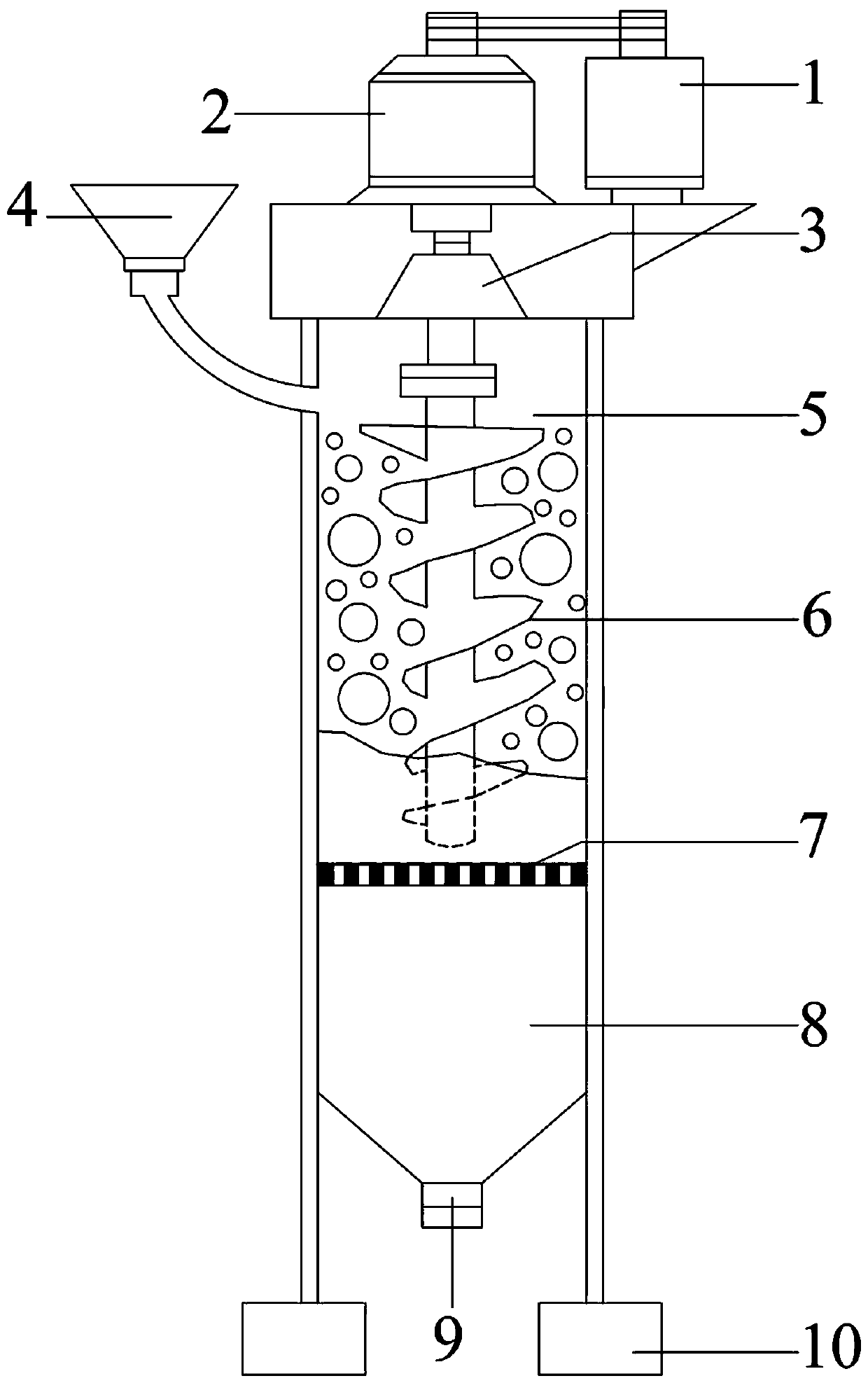

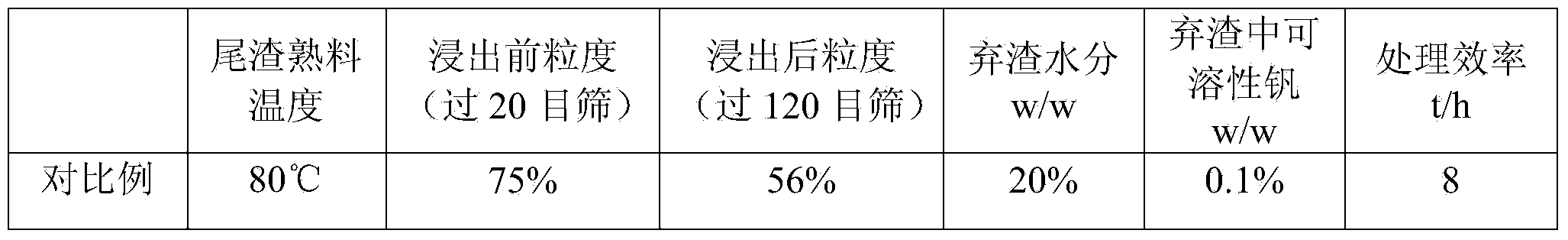

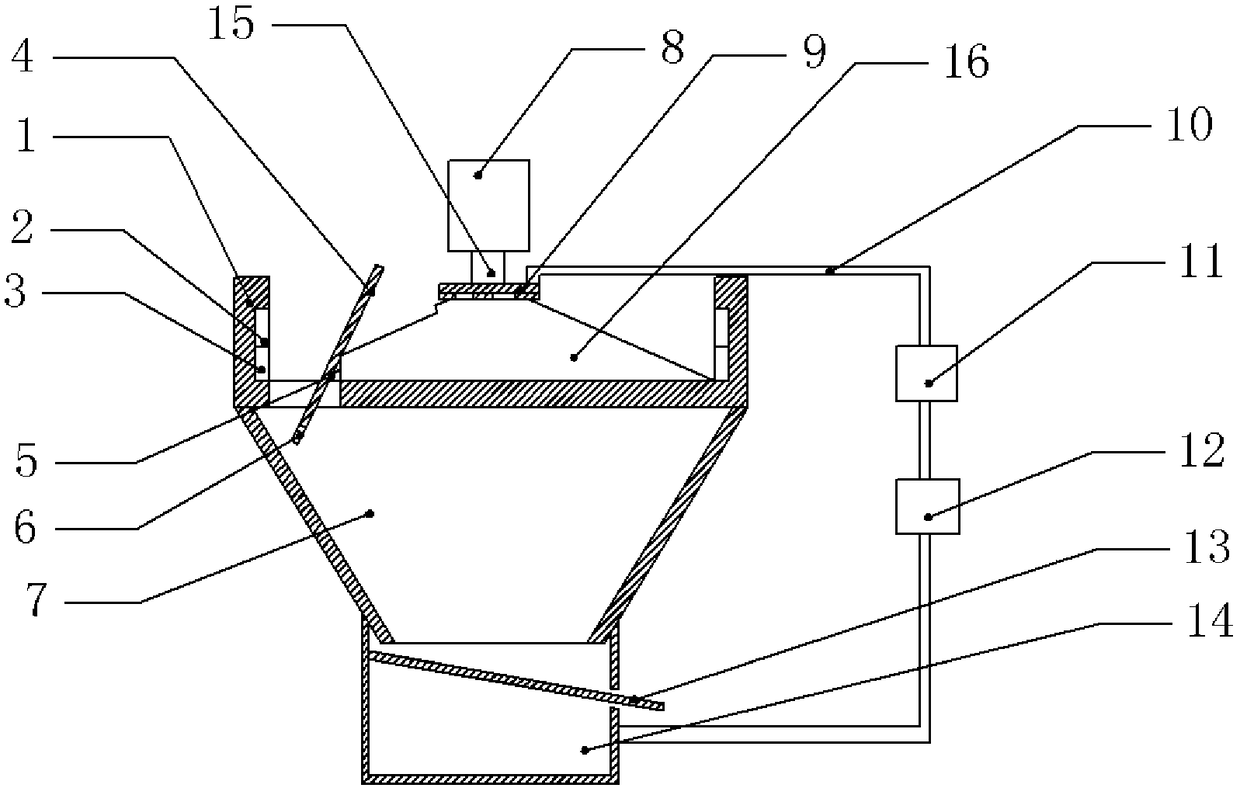

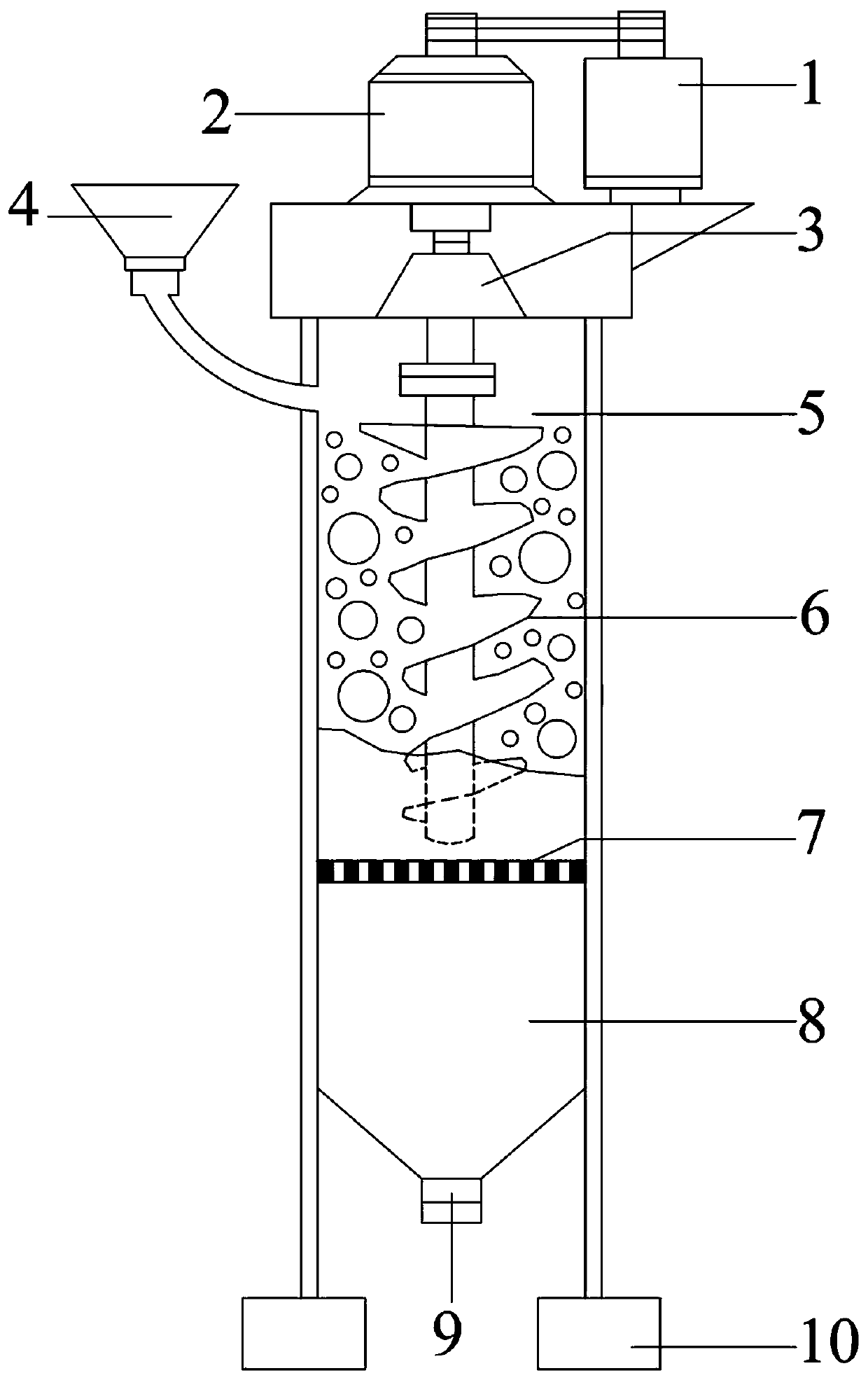

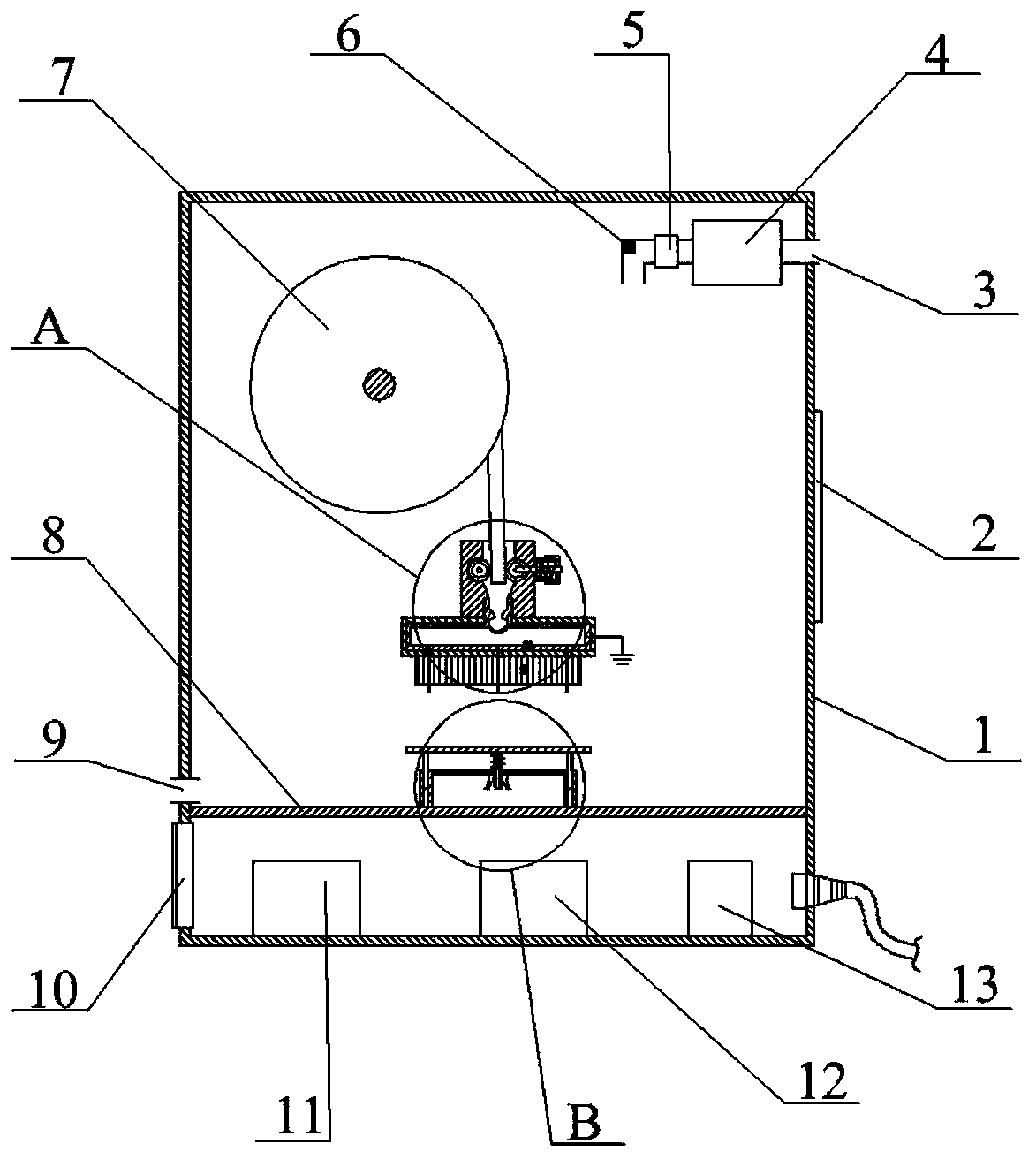

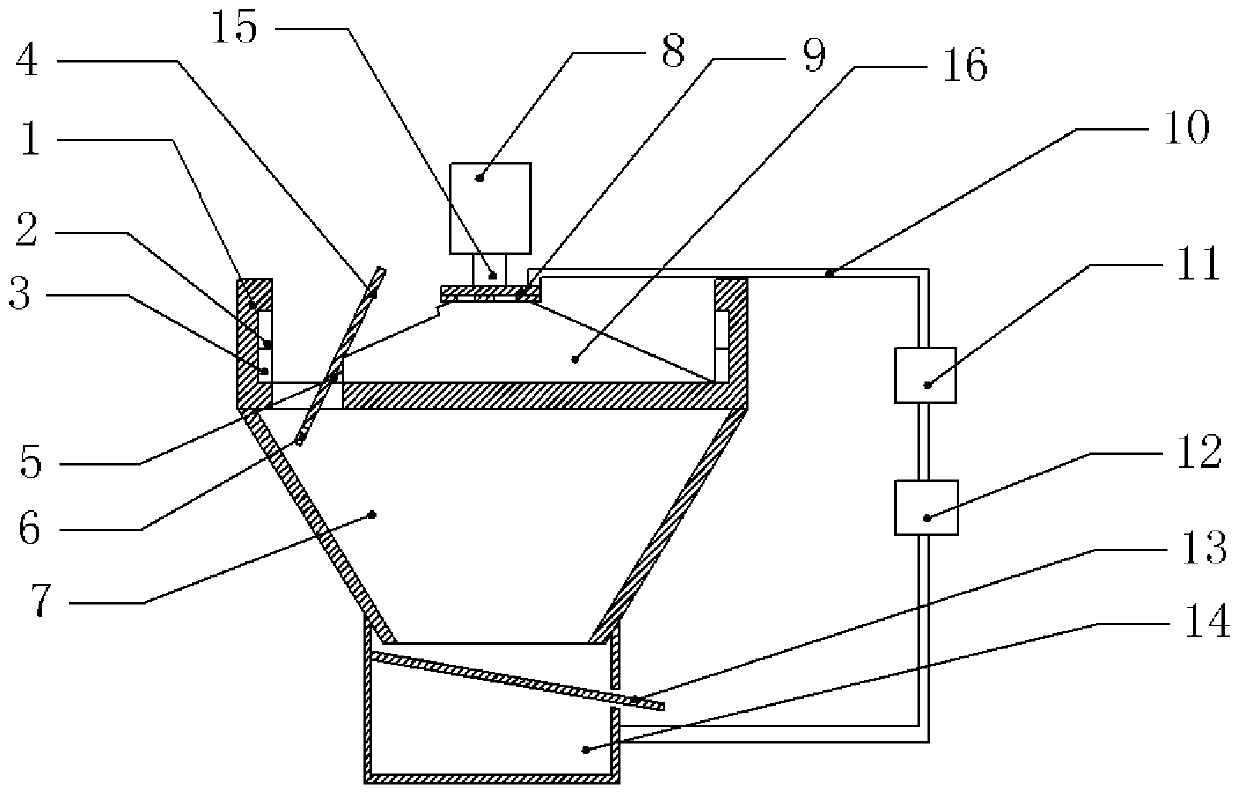

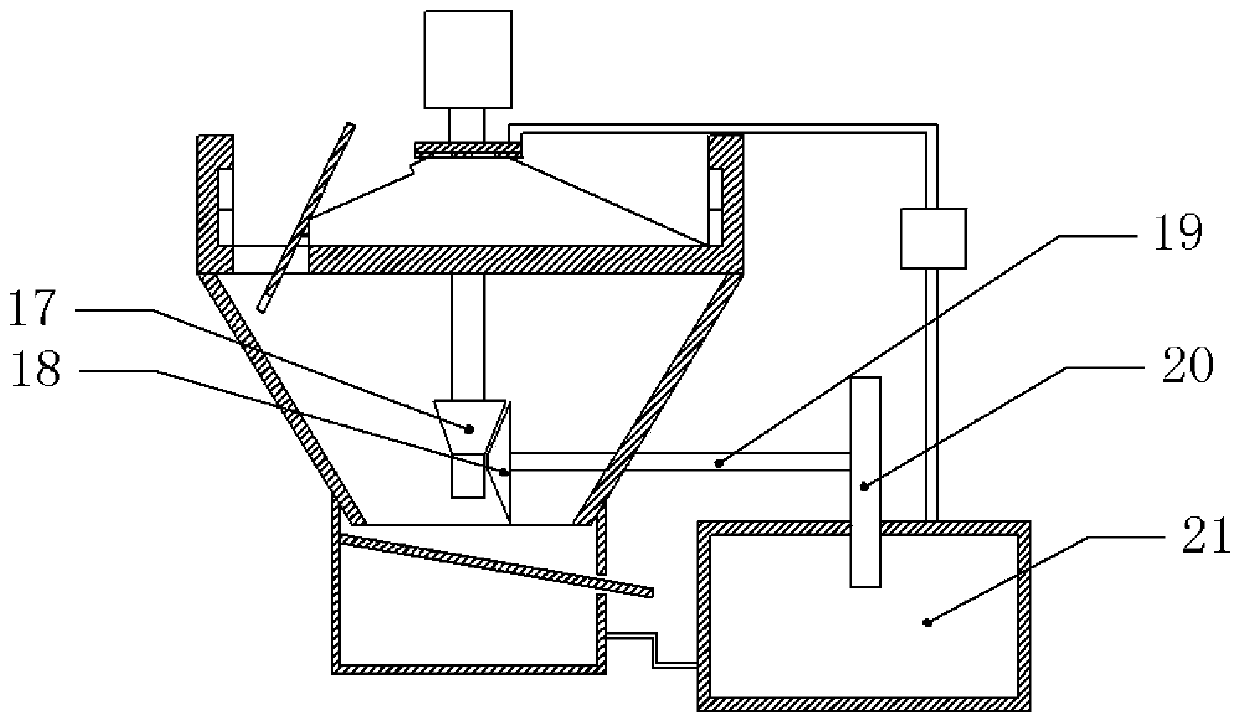

Dispersion mill for preparing nanometer material modified cement

ActiveCN108514928ADisperse fully and evenlyGet over reunion seriousGrain treatmentsMachining processMixing ratio

The invention discloses a dispersion mill for preparing nanometer material modified cement. A cabin body is separated into a mixing and grinding cabin and a material collecting cabin by a grid plate;the lateral upper part of the mixing and grinding cabin is provided with two feeding openings; a stirrer is arranged in the mixing and grinding cabin; a plurality of metal blocks are arranged in the mixing and grinding cabin; the lower half part of the material collecting cabin is a funnel; the bottom of the funnel is provided with a discharging opening. The mixing and grinding cabin can effectively realize the simultaneous mixing and grinding of nanometer materials and cement; the nanometer ore powder agglomeration is broken; the sufficient and uniform mixing of nanometer particles and otherpowder can be realized. In the use process, a discharging opening at the lower part of the material collecting cabin is connected with a concrete stirring machine; a certain mass of composite materials are regularly discharged according to the concrete mixing ratio and the stirring machine process parameters; meanwhile, through the feeding opening of the mixing and grinding cabin, nanometer materials and cement are respectively and regularly added according to the production requirement proportion, so that the continuous production operation with the concrete stirring machine can be realized.

Owner:CHINA UNIV OF MINING & TECH

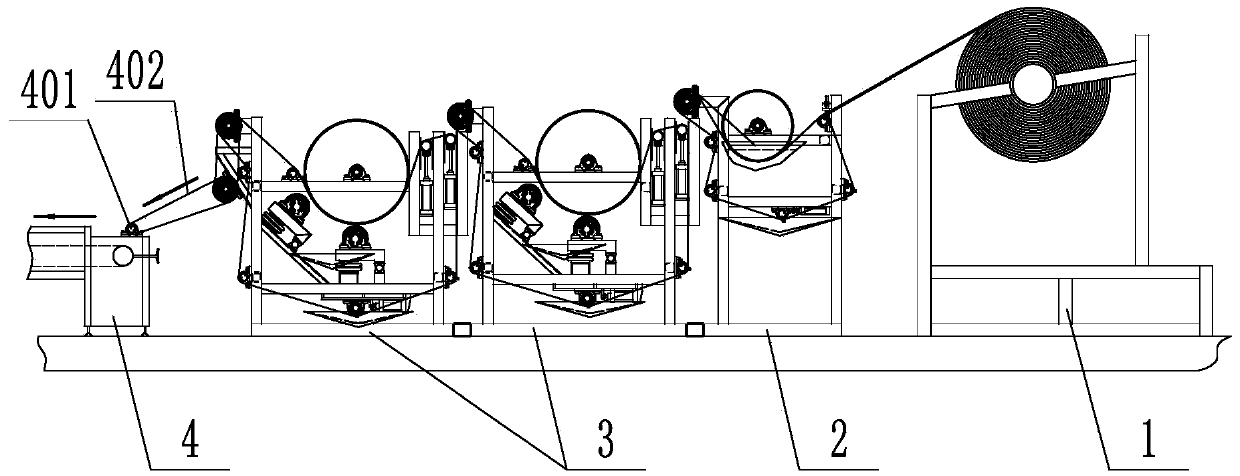

Assembly line for producing bolts

ActiveCN108890292ARealize continuous production operationIncrease productivityOther manufacturing equipments/toolsEngineeringAssembly line

The invention provides an assembly line for producing bolts. The technical problems that existing machining and producing equipment is too simple in structure, manual spray finishing is needed and themachining speed is low are solved. The assembly line for producing the bolts comprises a base plate, and a feeding device, a chamfering device, a thread rolling device, a thermal treatment device, acleaning device and a spray finishing device are arranged on the base plate in sequence. The assembly line has the advantage of being high in production efficiency.

Owner:浙江摩根兄弟科技有限公司

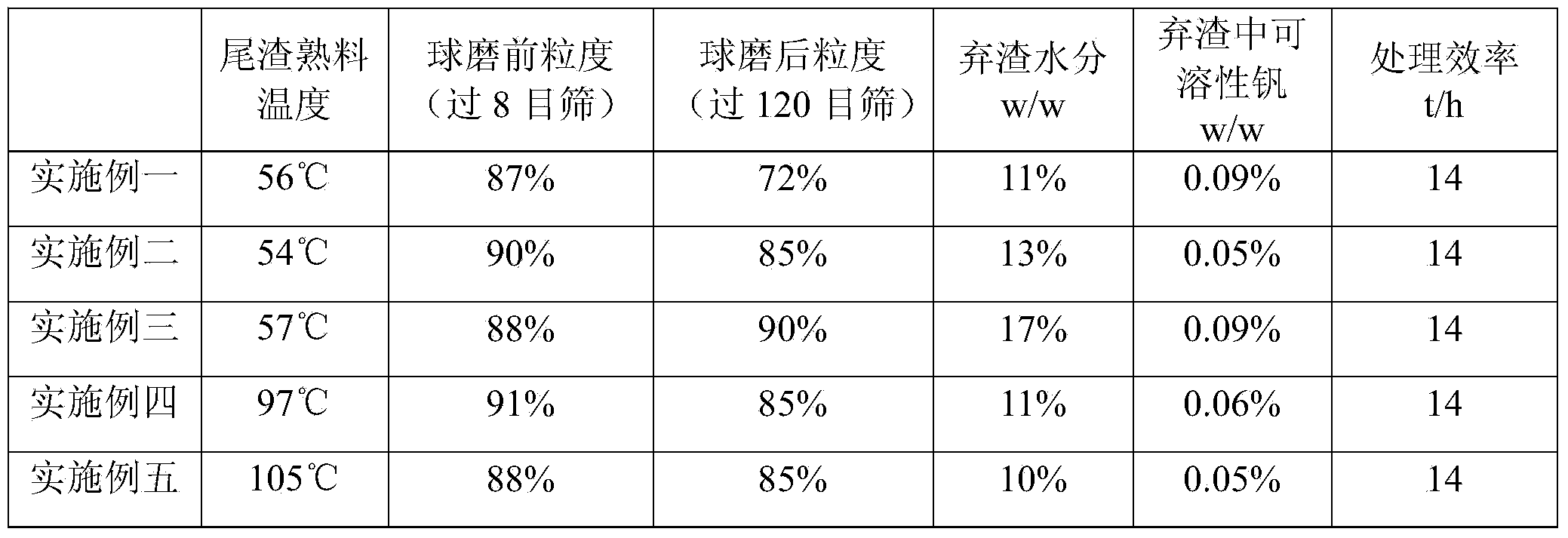

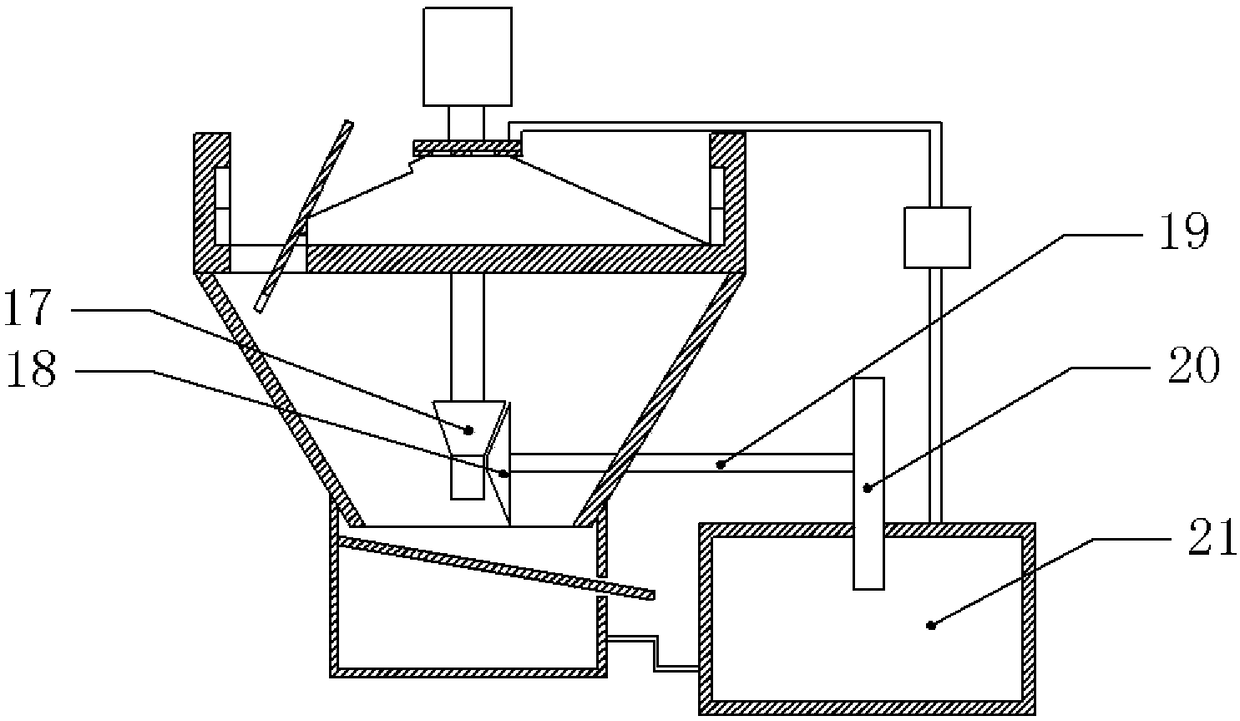

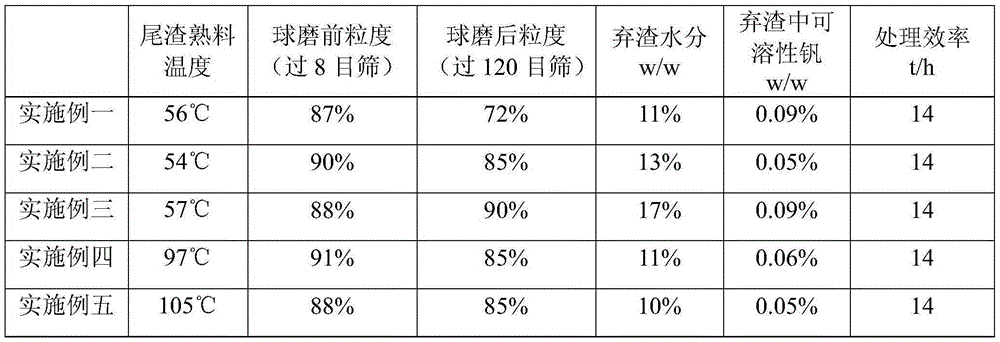

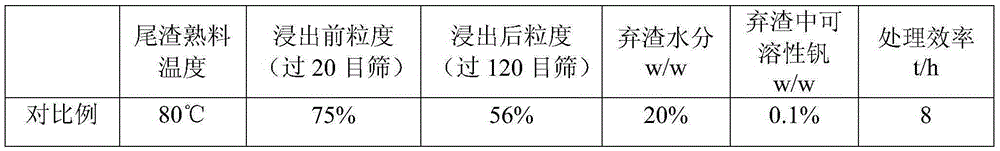

Leaching technology for tailings clinker containing vanadium

ActiveCN103667680AShorten the leaching timeLow particle size requirementProcess efficiency improvementSlagSodium salt

The invention discloses a leaching technology for tailings clinker containing vanadium and belongs to the technical field of extraction of vanadium from vanadium slag. The invention aims to provide a vanadium-extraction leaching technology for tailings clinker containing vanadium, which can achieve continuous production and has high leaching efficiency. The invention adopts the technical scheme as follows: a, ball milling is performed, that is, after being subjected to sodium salt roasting, the tailings clinker containing vanadium is subjected to wet ball milling to obtain a mixture of the tailings clinker containing vanadium and water, wherein the wet ball milling controls the particle size to achieve the effect that 70%-90% of the tailings clinker containing vanadium can pass through a 120-mesh sieve; b, the mixture is filtered in vacuum to obtain a solution and waste slag. The leaching technology provided by the invention can replace a tank car leaching technology in the original extraction technology of vanadium from tailings, achieve continuous production operation, shorten the leaching time of the tailings clinker and reduce the production cost.

Owner:PANZHIHUA ZHUYU VANADIUM TITANIUM

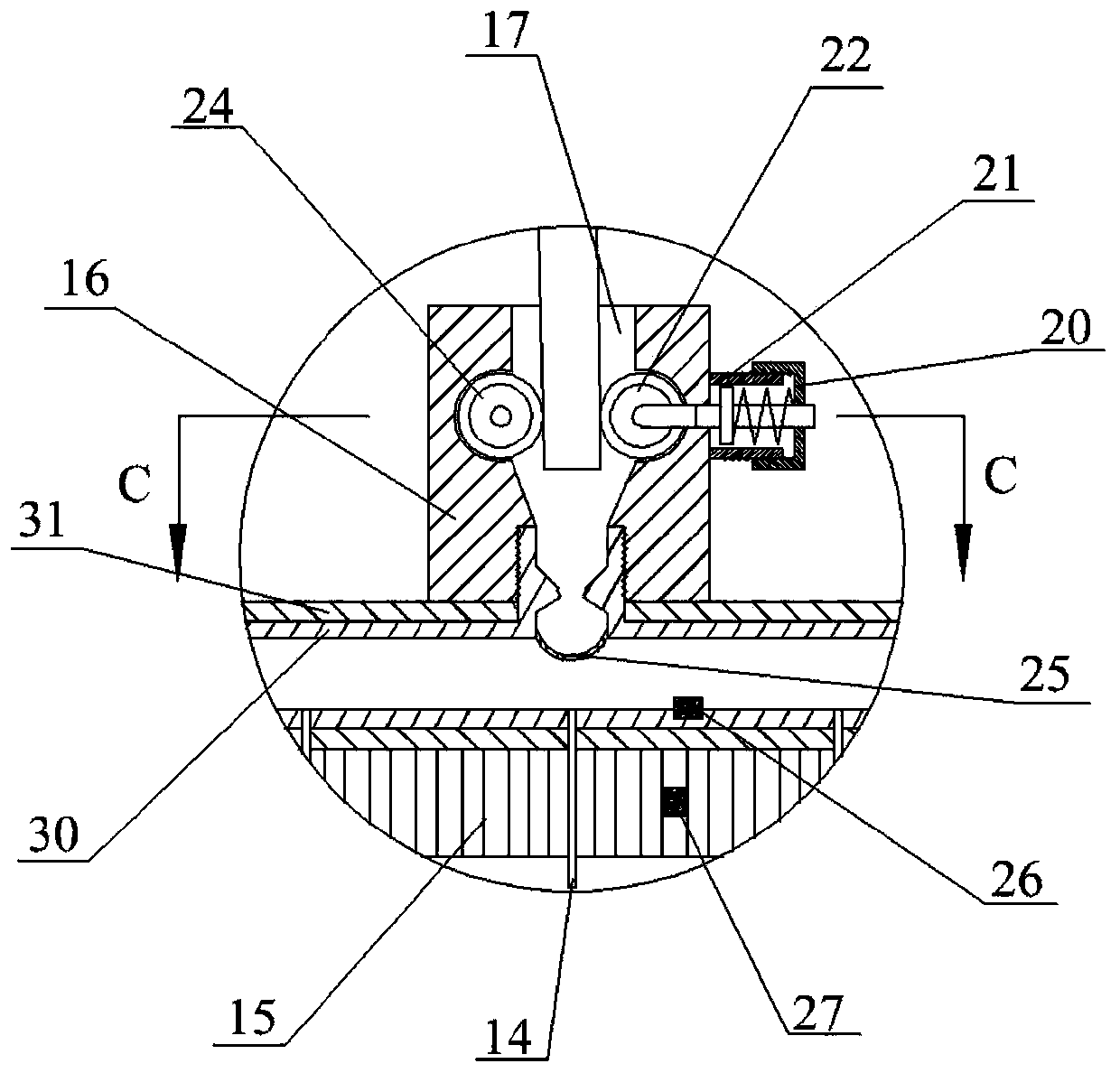

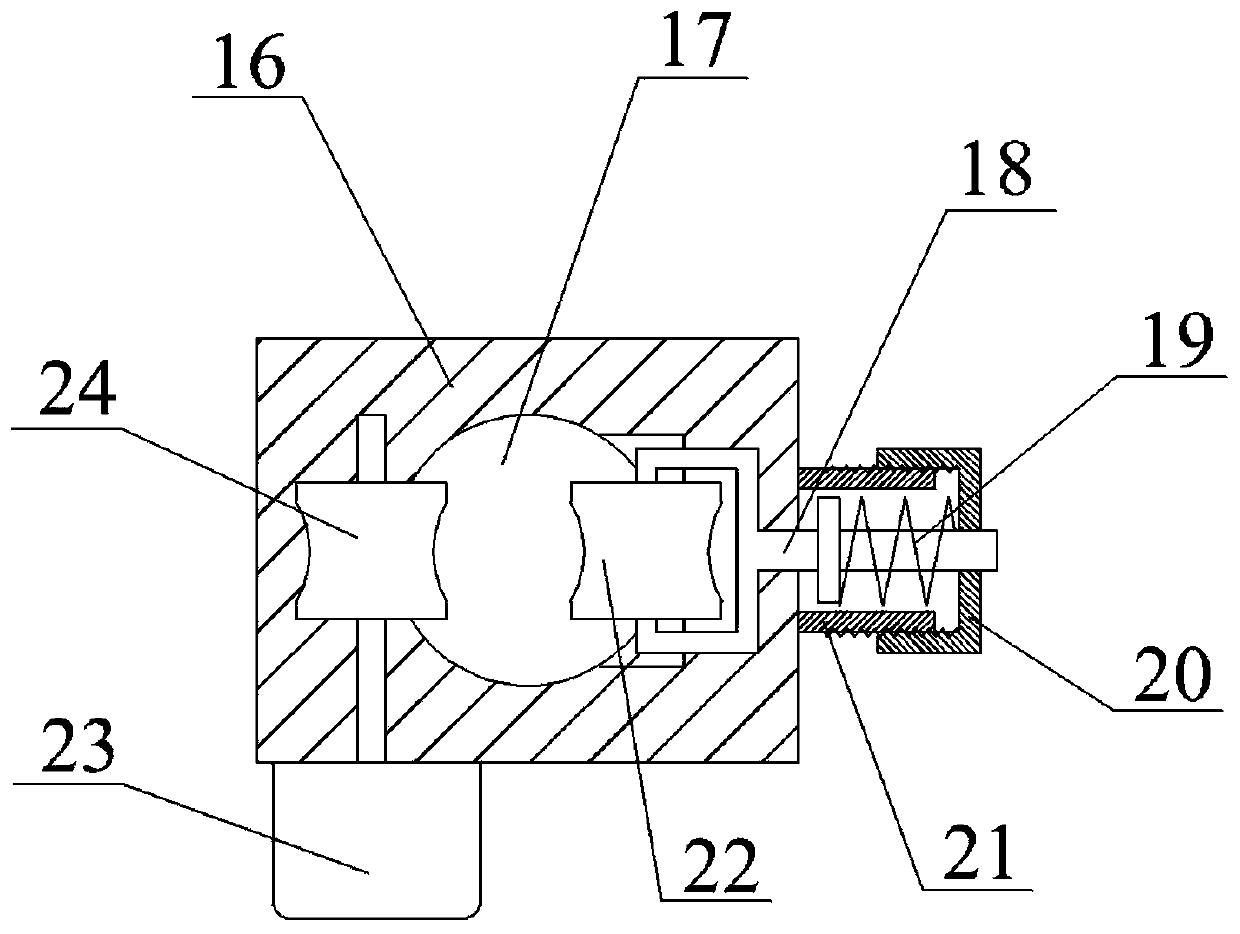

Steel shot quenching device

ActiveCN108504843AShortening the difference between quenching cooling ratesLittle difference in metallographic structureFurnace typesProcess efficiency improvementTemperature controlQuenching

The invention relates to the technical field of steel shot production and discloses a steel shot quenching device which comprises a quenching pool; a centrifugal machine is rotationally connected to the middle part of the quenching pool; a truncated cone is arranged on the bottom surface of the quenching pool; multiple cover plates, each of which comprises a water retaining section and a dischargesection, are hinged to the edge of the truncated cone; a discharge hole is formed in one side, close to each discharge section, of the truncated cone; each discharge section is connected with the truncated cone through a spring; a temperature control circuit and a magnet are arranged on the inner wall of the quenching pool; the temperature control circuit is electrically connected with the magnetand the centrifugal machine; an iron sheet is arranged at the free end of each discharge section; a funnel cavity and a cooling mechanism are arranged at the bottom of the quenching pool; a flume isconnected to the bottom of the funnel cavity; a discharge hole is formed in the side wall of the flume and is provided with a screen plate which is slantingly arranged and is abutted to the side wallof the flume; the flume is connected with the truncated cone through a recovery pipe; and the recovery pipe is provided with a water pump. Through the steel shot quenching device provided by the invention, the existing problem of large difference in properties of steel shots in one batch can be solved, and the properties of the steel shots are improved.

Owner:CHONGQING QINGLAN MACHINERY MFG

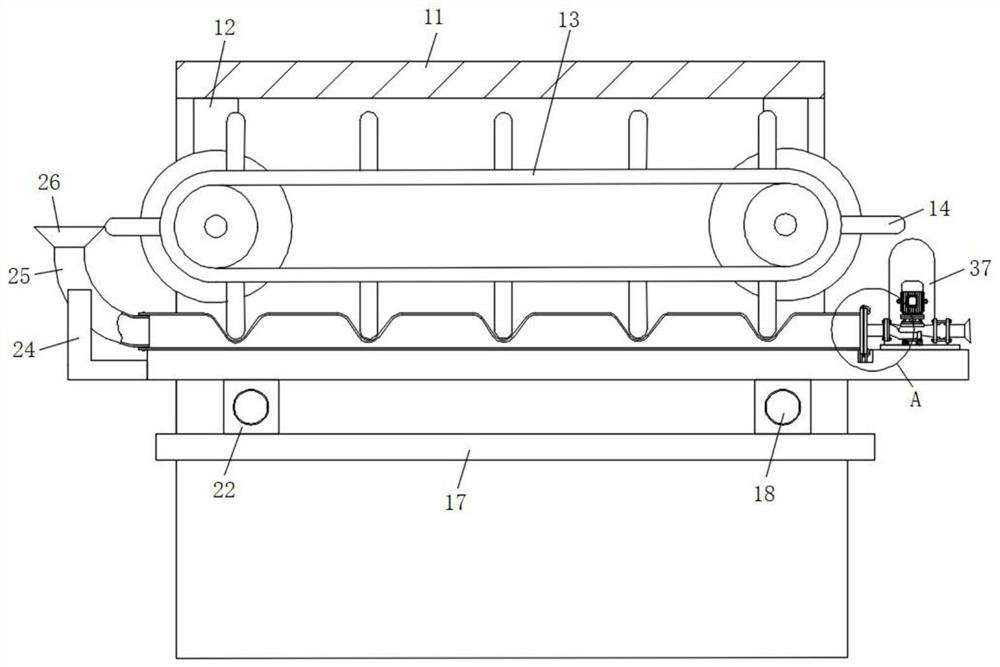

Integrated oil-water separator

PendingCN109847409AImprove separation efficiencyEasy to handleNon-miscible liquid separationTherapeutic effectSmall footprint

The invention provides an integrated oil-water separator. The integrated oil-water separator comprises a horizontal cylindrical shell provided with a left seal head at the left end and a right seal head at the right end, the left seal head is provided with a water inlet tube, the right seal head is provided with a water outlet tube, and the horizontal cylindrical shell is divided into a water inlet chamber and a water collecting chamber by a partition plate; a sedimentation chamber is arranged in the water inlet chamber, and the sedimentation chamber is composed of an upper sedimentation chamber grid plate, a lower sedimentation chamber grid plate and a sedimentation chamber side baffle plate; and the top of the sedimentation chamber side baffle plate is perpendicularly connected with thetop of the horizontal cylindrical shell. The sedimentation chamber and separation chambers are arranged to carry out two-stage separation on oily sewage, and separated oil and water are separately recovered, so the integrated oil-water separator has a high oil-water separation efficiency and a good treatment effect. The integrated oil-water separator has the advantages of reasonable design of theinternal structure of the cylindrical shell, small occupied area, wide adaption range, low running cost, and realization of continuous production operation, can be designed as needed to form oil-waterseparators with different treatment capacities and forms to adapt to complex application occasions, and has a broad application prospect.

Owner:青岛亿宁环保科技有限公司

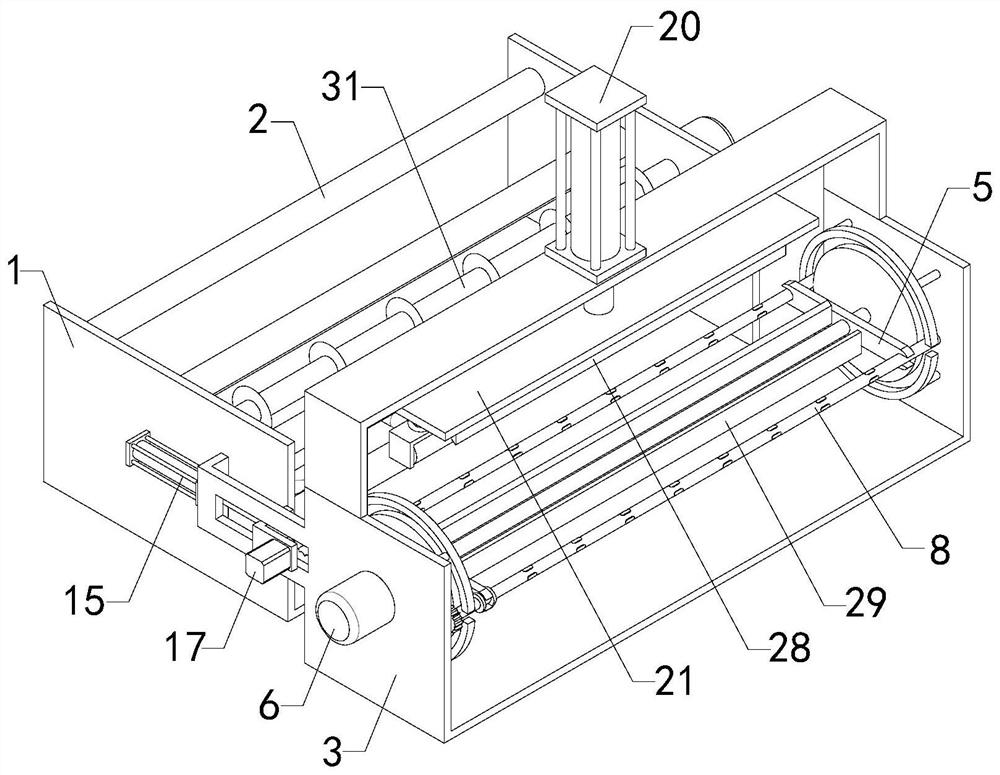

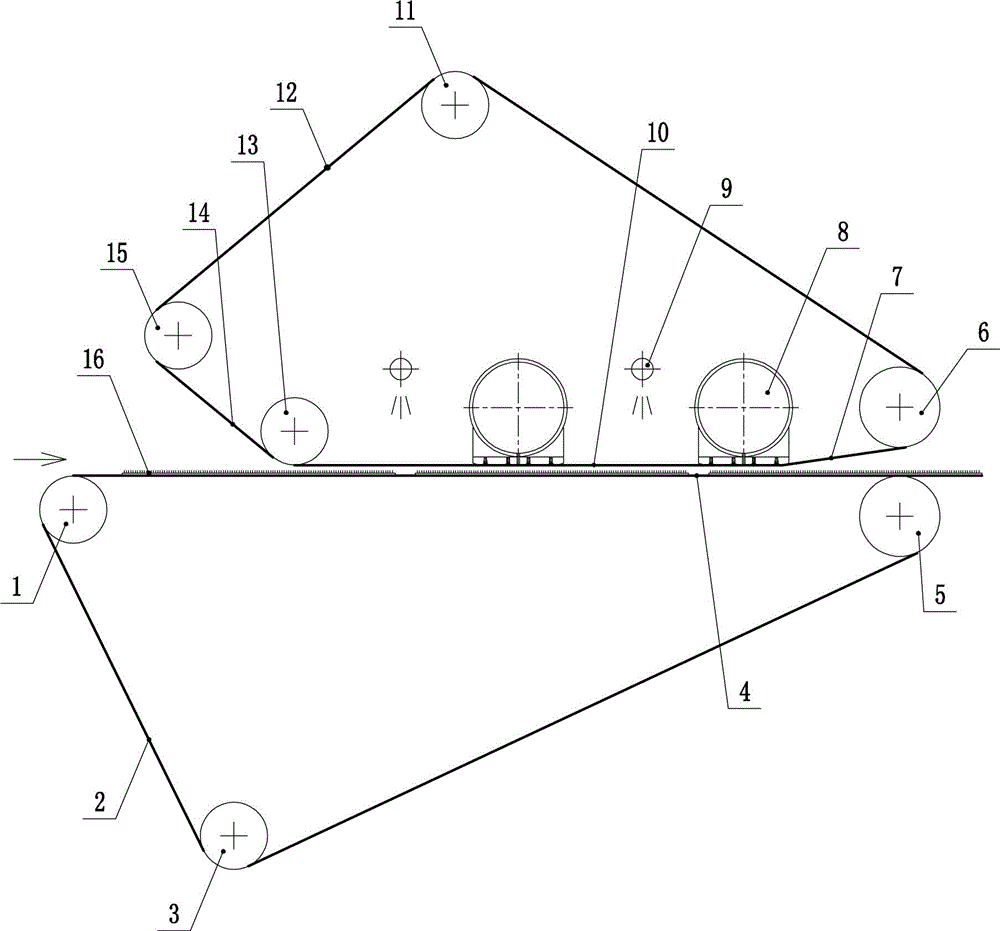

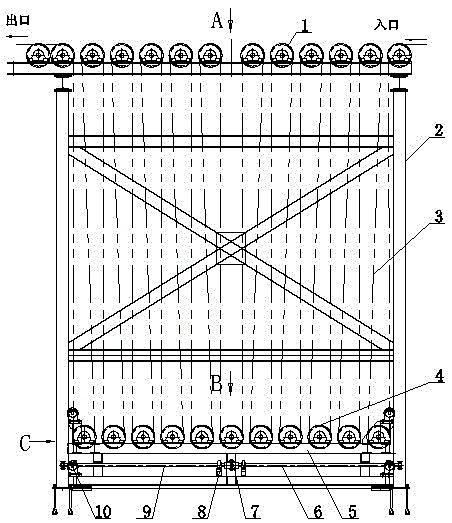

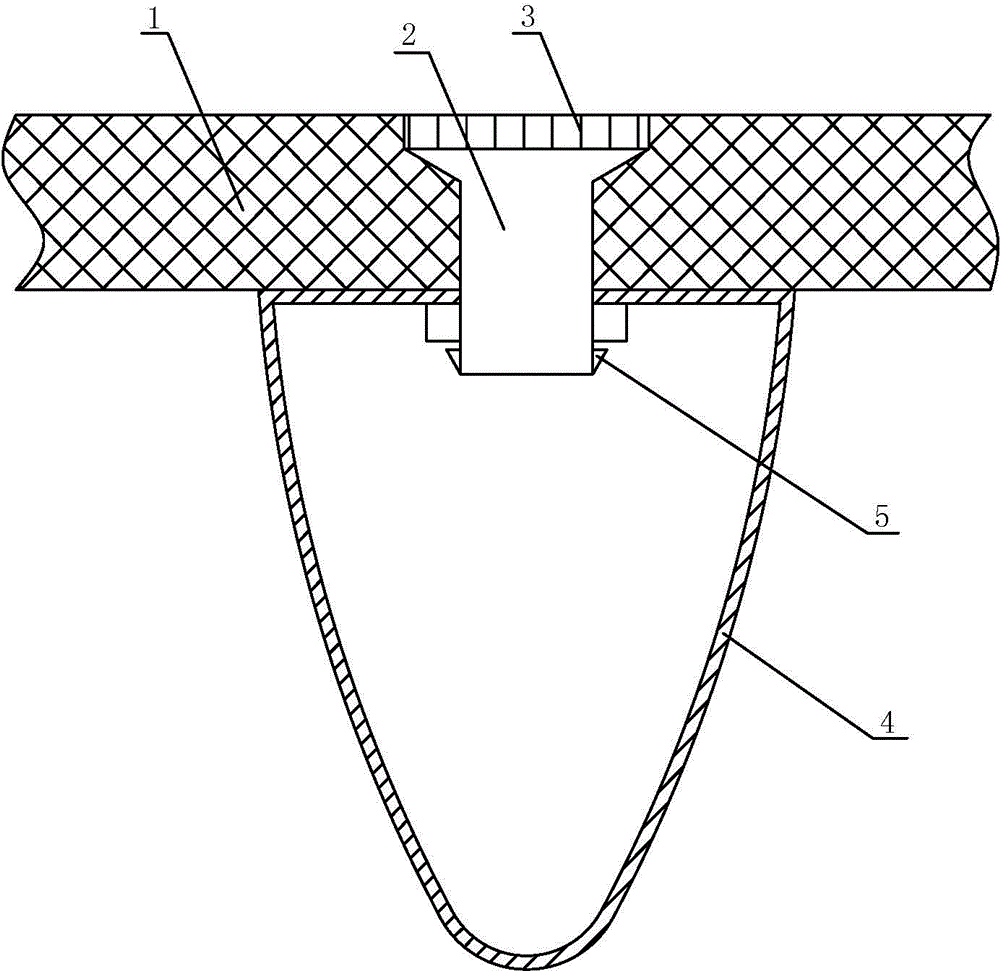

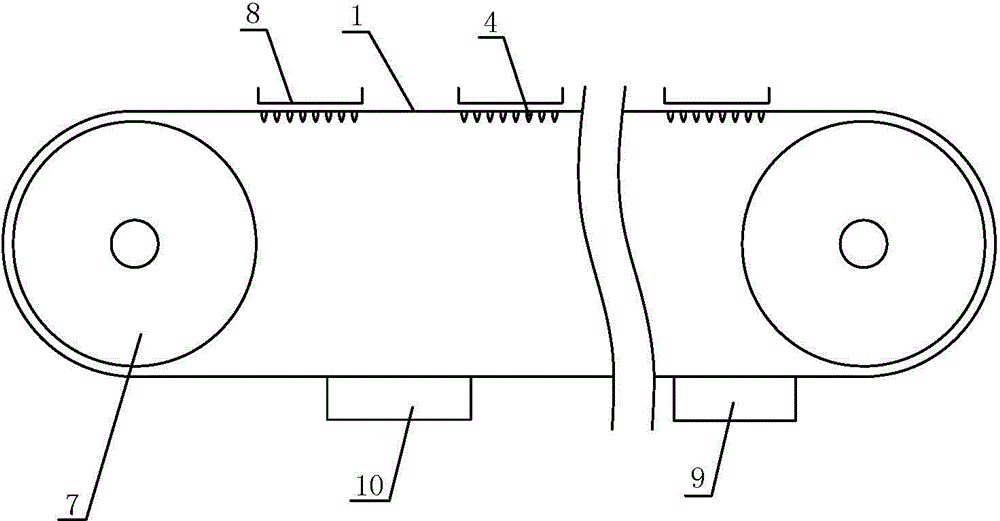

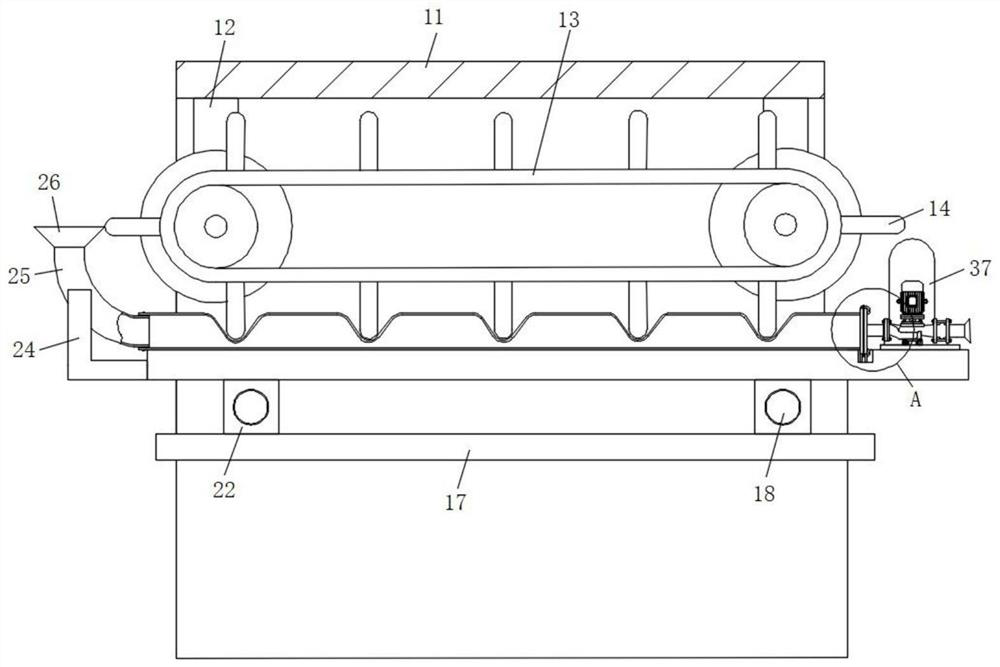

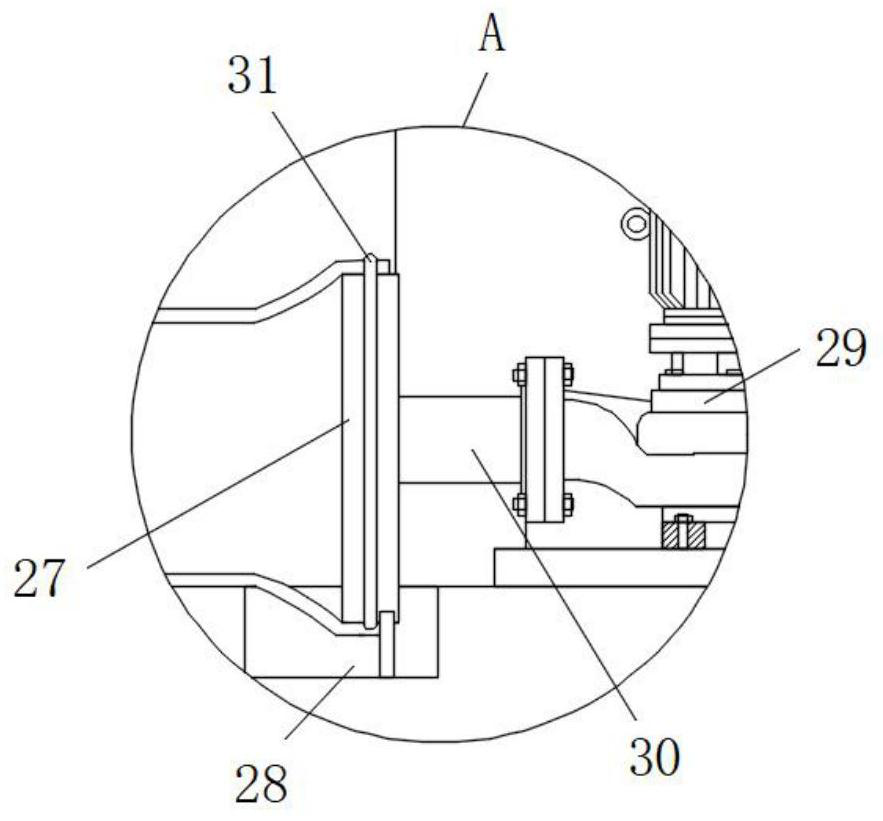

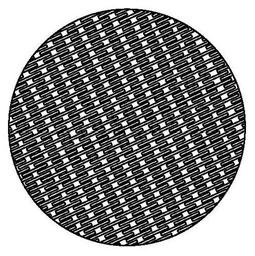

Tufted carpet fabric dual-net-belt clamped washing structure

InactiveCN104924751ARealize continuous production operationGuaranteed to run synchronouslyPrinting press partsEngineeringWater spray

A tufted carpet fabric dual-net-belt clamped washing structure comprises an upper drive operating system and a lower drive operating system which are independent, wherein the lower drive operating system comprises a lower first drive roller and a lower second drive roller which are horizontally arranged, the lower first drive roller and the lower second drive roller perform joint drive and are provided with a lower drive net belt, and the lower drive net belt located on the upper sides of the lower first drive roller and the lower second drive roller is a lower clamping section. An upper drive operating system comprises an upper first drive roller and an upper second drive roller which are horizontally arranged, the upper first drive roller and the upper second drive roller perform joint drive and are provided with an upper drive net belt, and the upper drive net belt located on the upper sides of the upper first drive roller and the upper second drive roller is an upper clamping section. An upper clamping discharge section and a lower clamping discharge section are vertically and correspondingly arranged, the upper drive net belt operates with respect to the lower drive net belt in the reverse direction, and a clear water spraying pipe and a vacuum water suction pipe are arranged above the upper clamping discharge section in a front-rear mode. A gap is reserved between the upper clamping discharge section and the lower clamping discharge section.

Owner:山东源丰印染机械有限公司

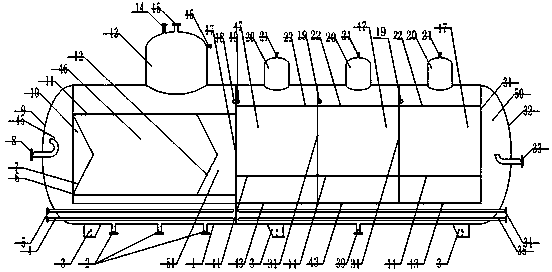

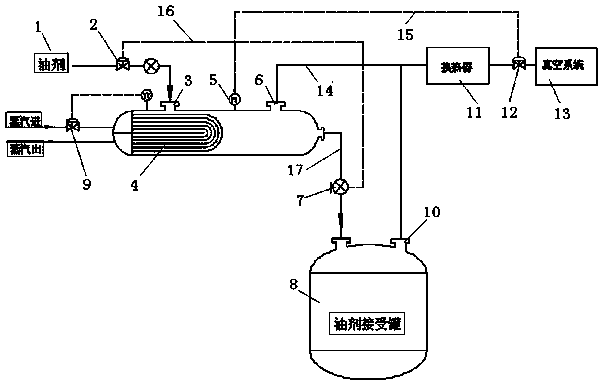

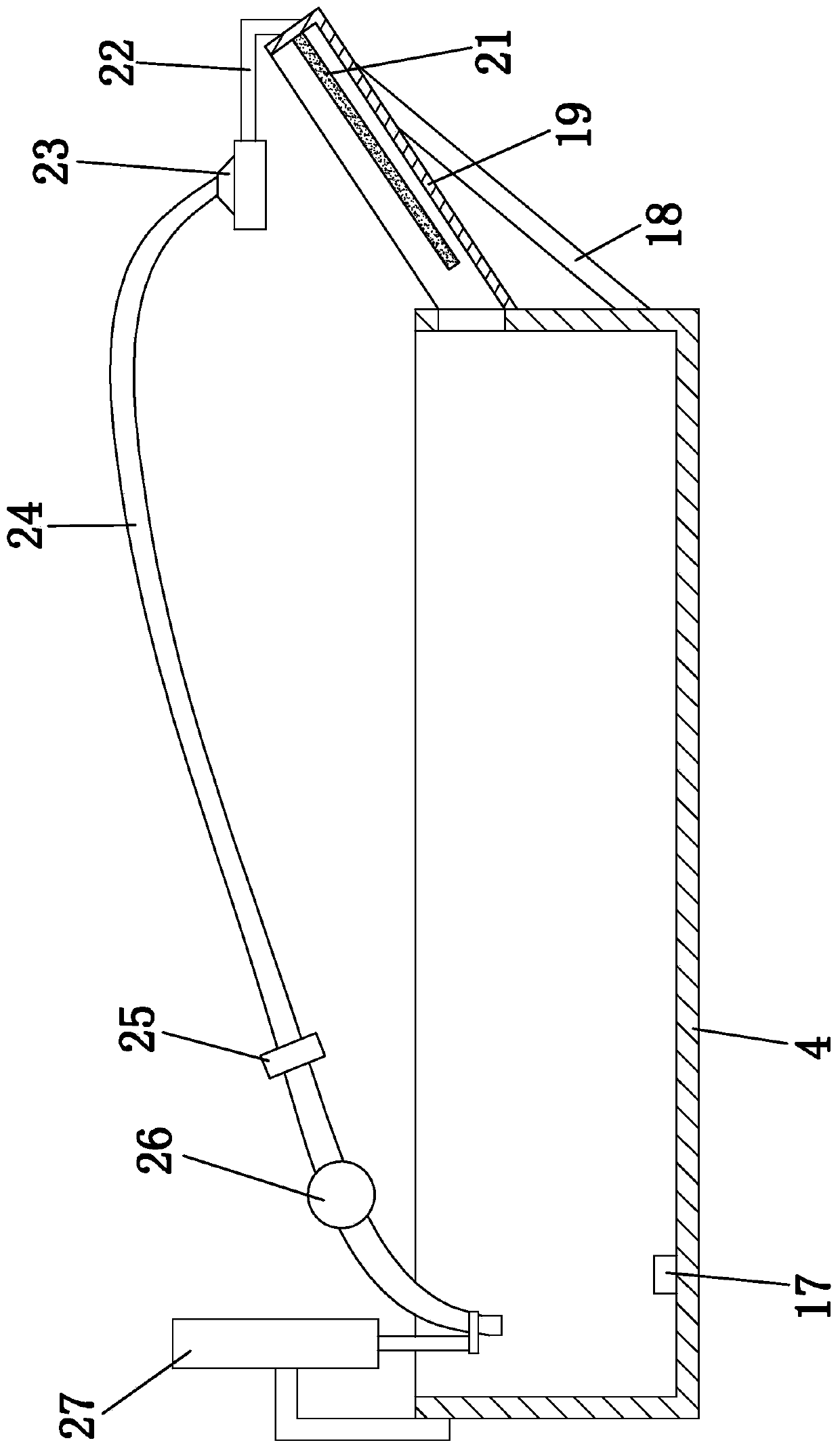

Amide oil agent continuous water removal device and its water removal process

ActiveCN106731011BReduce workloadImprove field automationNon-miscible liquid separationPulp and paper industrySmall footprint

The invention introduces a continuous water removal device for amides oil and a water removal process thereof. An oil regulating valve, a U-tube heat exchanger, an on-line moisture detector and an oil reception trough are arranged in sequence in the oil supply and flow path. The U-type tube heat exchanger is connected with heat transfer steam inlet and outlet pipelines, and the U-type heat exchanger pipe shell is also respectively connected with an oil inlet, a vacuum suction port, a vacuum detector, and an oil discharge pipeline. The vacuum pipeline is connected with a vacuum regulator valve and a vacuum system. In the water removal process adopted in the invention, the vacuum of the vacuum system is less than 97.3KPa, and the temperature of the oil in the pipe shell is 70 to 75 DEG C. The invention realizes continuous production, effectively controls the moisture in the oil, and the heat exchanger has the advantages of small input and small occupied area.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

An assembly line for producing bolts

ActiveCN108890292BRealize continuous production operationIncrease productivityOther manufacturing equipments/toolsEngineeringAssembly line

Owner:浙江摩根兄弟科技有限公司

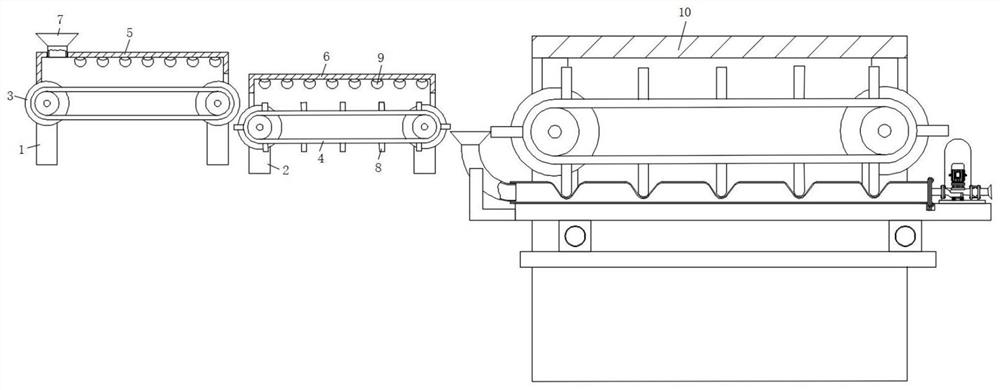

Automatic and quantitive dipping sizing equipment

The invention discloses automatic and quantitive dipping sizing equipment, belonging to the field of material processing equipment. The automatic and quantitive dipping sizing equipment comprises a cotton withdrawing device, a soaking device, an extrusion degumming device / extrusion degumming devices and a conveying device. The automatic and quantitive dipping sizing equipment has the beneficial effects that the structure is scientific and reasonable, the efficiency is high, the energy is saved, the degree of automation is high, continuous production operation can be realized, fiber texture is not damaged, the glue content of the fiber texture is conveniently controlled, the mechanical structure is simplified, the singles-stage land occupation and volume can be reduced, and the equipment is convenient to maintain.

Owner:王春光

Leaching process of vanadium-containing tailings clinker

ActiveCN103667680BShorten the leaching timeLow particle size requirementProcess efficiency improvementSlagSodium salt

The invention discloses a leaching technology for tailings clinker containing vanadium and belongs to the technical field of extraction of vanadium from vanadium slag. The invention aims to provide a vanadium-extraction leaching technology for tailings clinker containing vanadium, which can achieve continuous production and has high leaching efficiency. The invention adopts the technical scheme as follows: a, ball milling is performed, that is, after being subjected to sodium salt roasting, the tailings clinker containing vanadium is subjected to wet ball milling to obtain a mixture of the tailings clinker containing vanadium and water, wherein the wet ball milling controls the particle size to achieve the effect that 70%-90% of the tailings clinker containing vanadium can pass through a 120-mesh sieve; b, the mixture is filtered in vacuum to obtain a solution and waste slag. The leaching technology provided by the invention can replace a tank car leaching technology in the original extraction technology of vanadium from tailings, achieve continuous production operation, shorten the leaching time of the tailings clinker and reduce the production cost.

Owner:PANZHIHUA ZHUYU VANADIUM TITANIUM

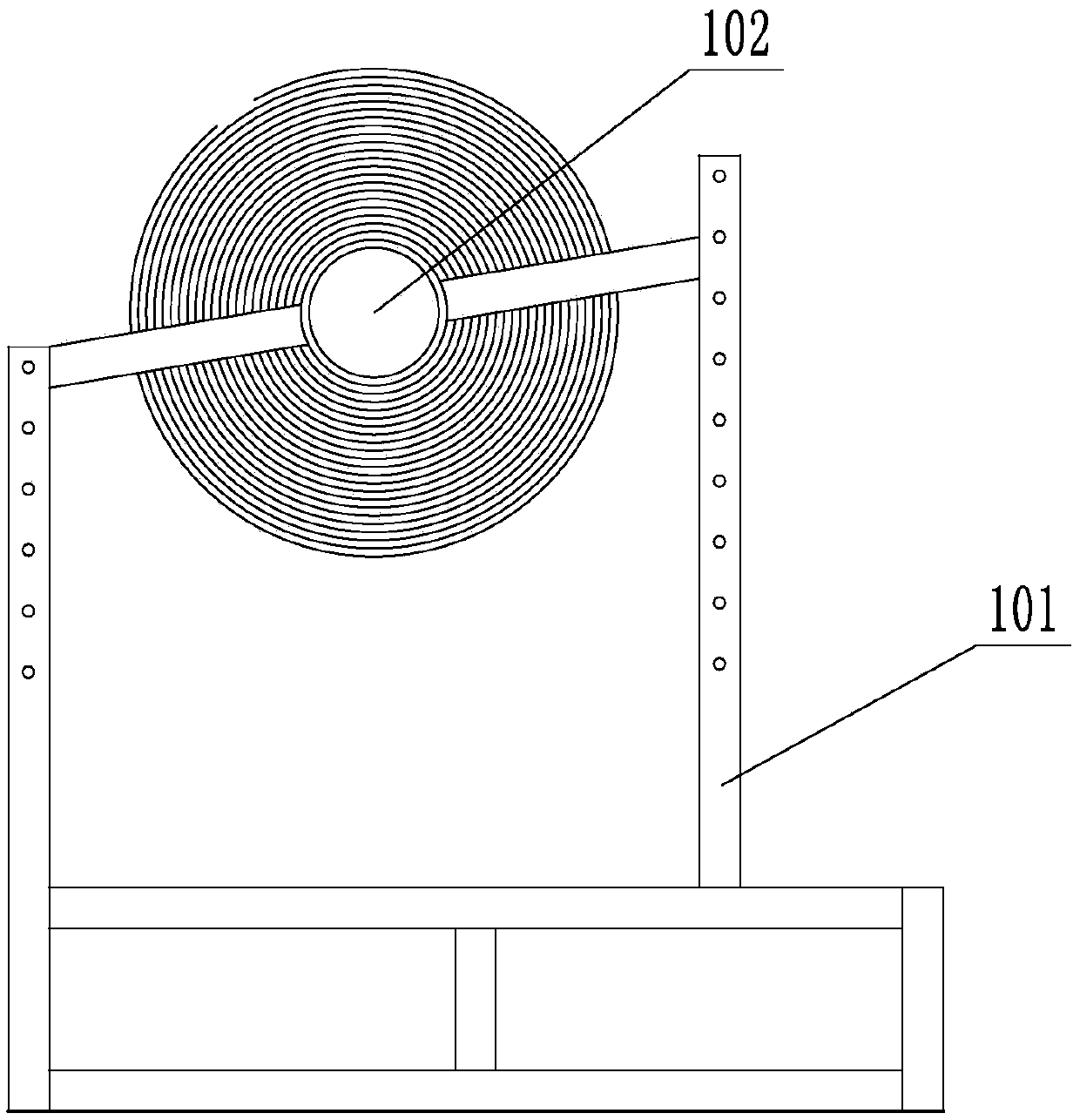

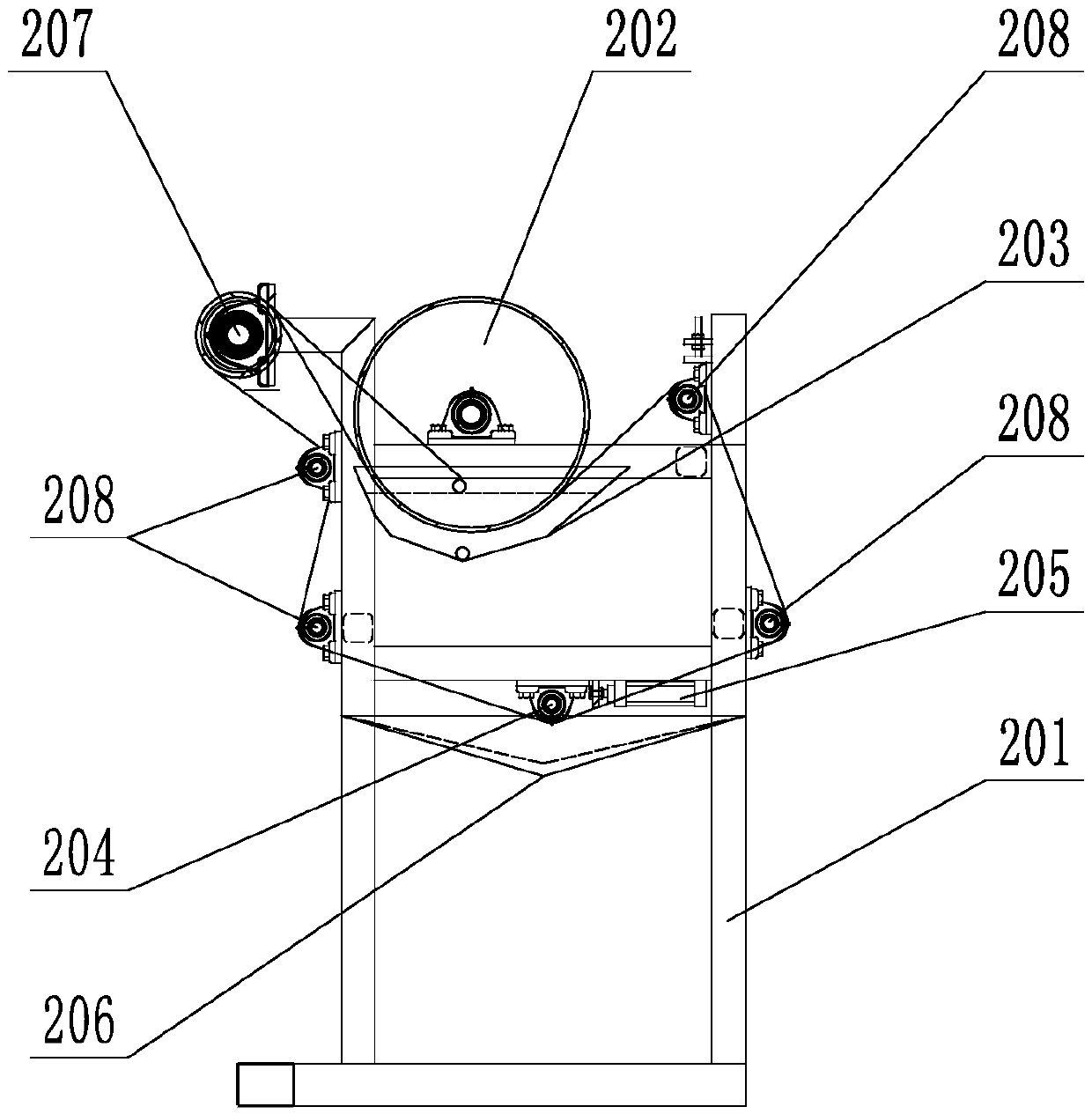

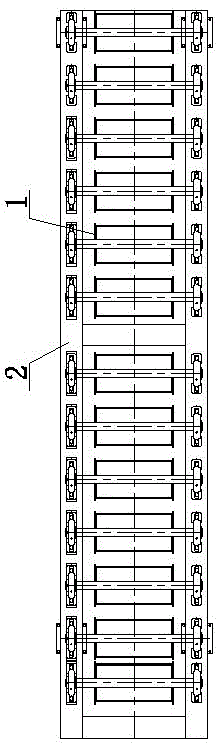

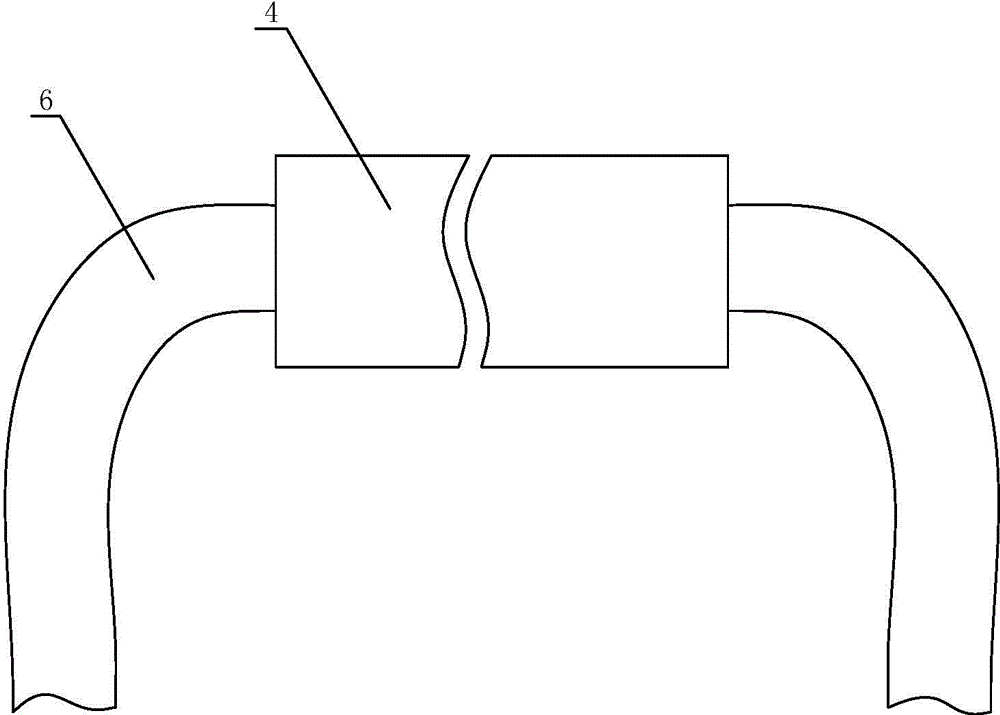

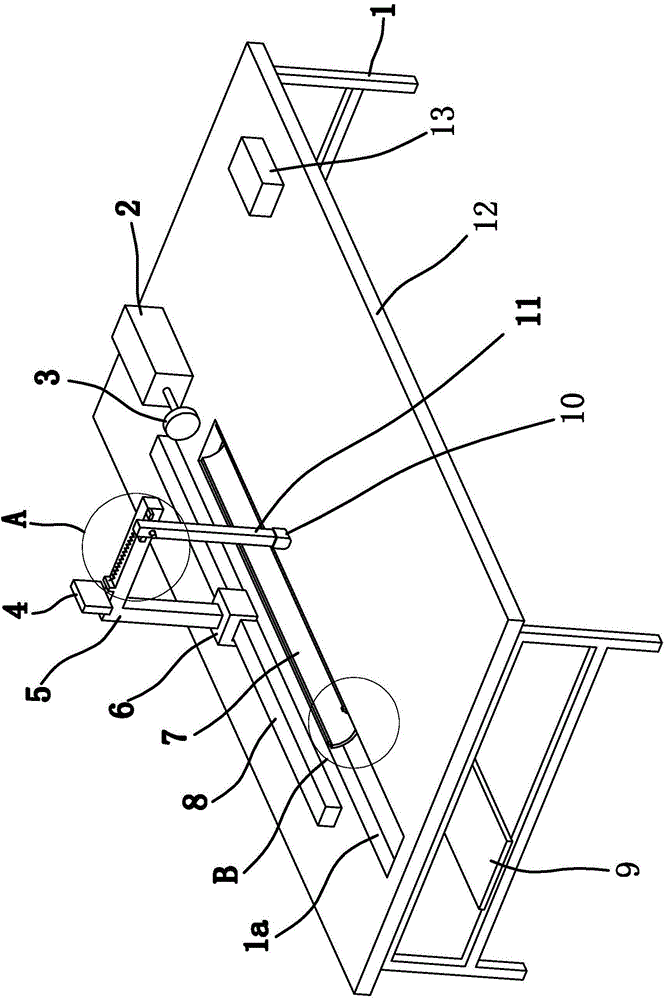

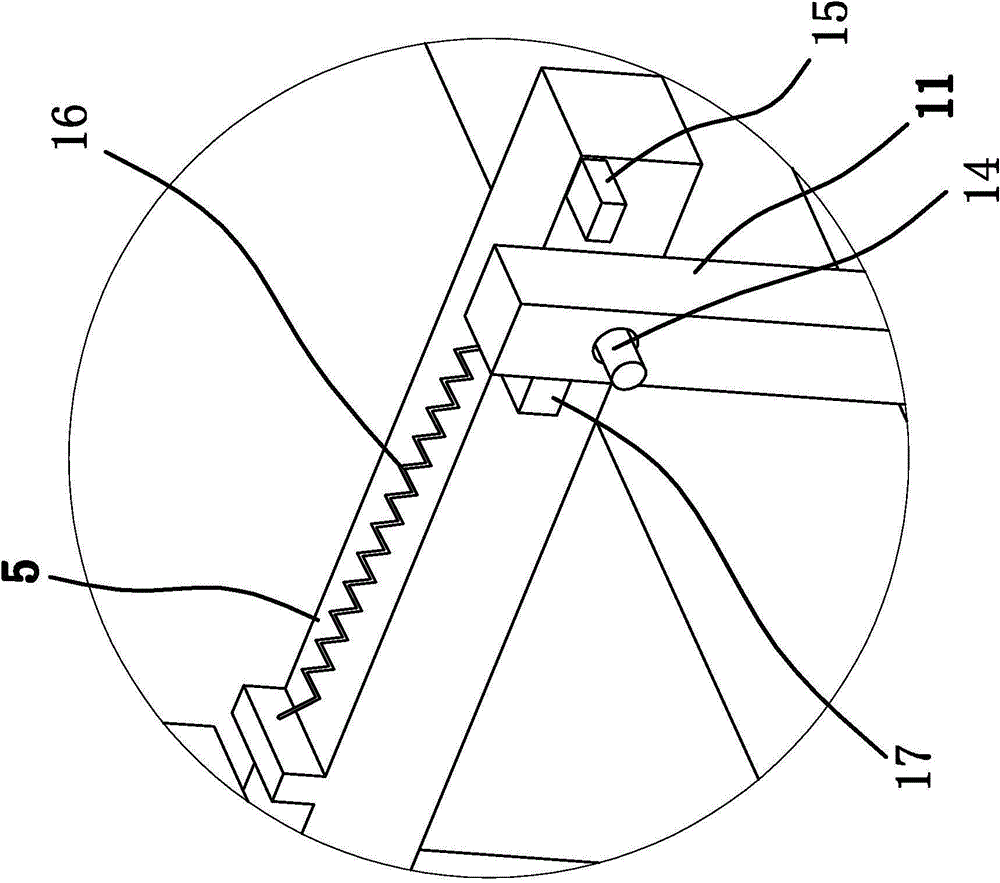

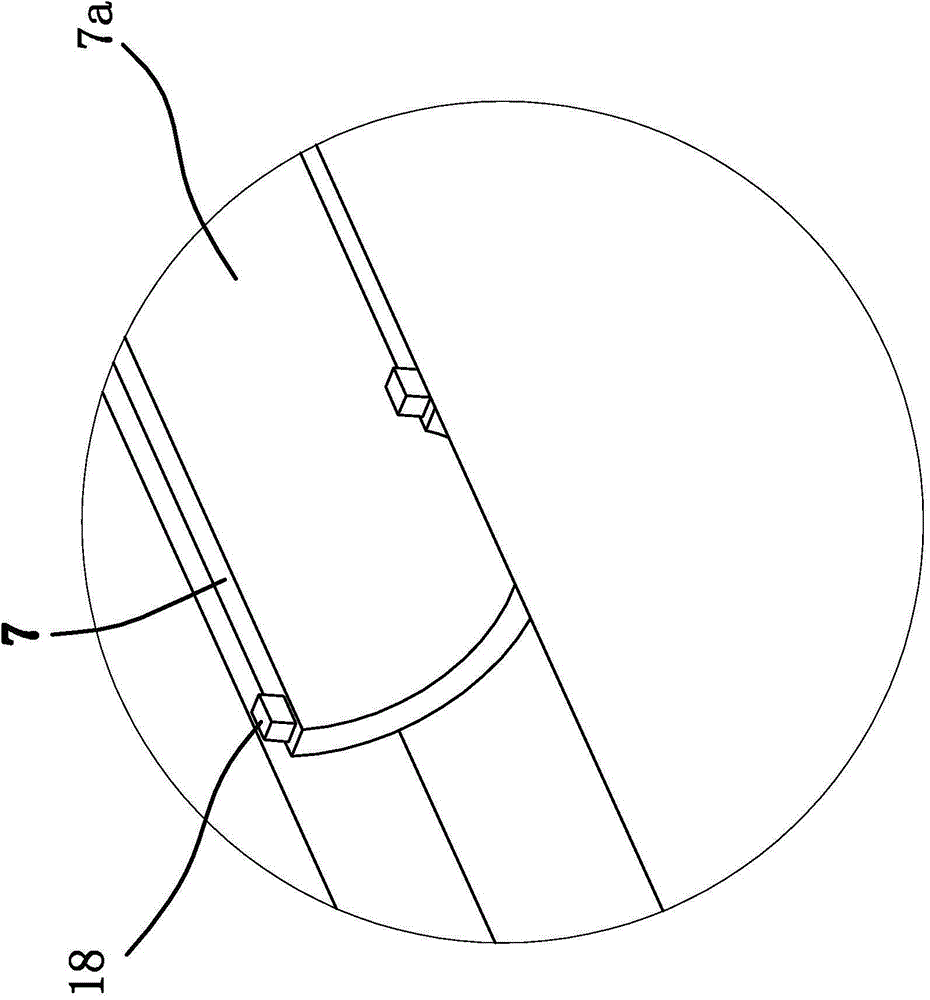

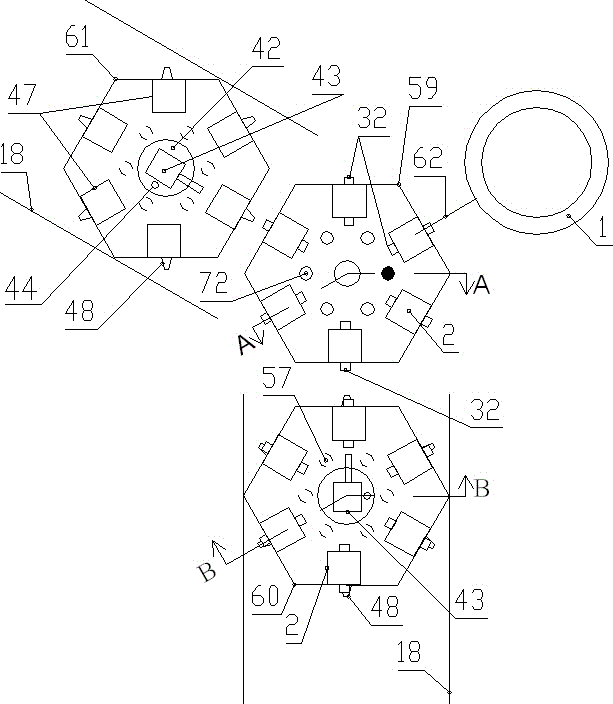

Vertical unpowered strip stocker

ActiveCN104016169BRealize continuous production operationRealize non-power storageWebs handlingProduction lineStrip steel

The invention relates to a vertical type powerless strip steel storage machine. The vertical type powerless strip steel storage machine comprises a frame, a movable loop roller set, a fixed loop roller set and a loop vehicle body. The vertical type powerless strip steel storage machine is characterized in that the fixed loop roller set is fixed to the top of the frame, the movable loop roller set is fixed to the top of the loop vehicle body, the loop vehicle body is connected into the frame in a sliding mode, straightening mechanisms are symmetrically arranged at the two ends of the loop vehicle body, the guide mechanisms are composed of gear straightening wheels and racks, wherein the gear straightening wheels are fixed to the loop vehicle body, and the racks are fixed to the frame and meshed with the gear straightening wheels, a balance shaft is connected between rotating shafts of the two gear straightening wheels, and slide way straightening wheels are arranged on vertical beams, corresponding to the four corners of the frame, of the loop vehicle body respectively. The vertical type powerless strip steel storage machine has the advantages that the structure is simple, mounting and demounting are convenient, production cost is low, the problems that an existing storage device is complex in structure, large in design difficulty, high in requirement for manufacturing accuracy, inconvenient to mount and demount, large in investment amount and high in production cost, continuous automatic production of a production line can be achieved, and production efficiency and the quality of products are remarkably improved.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

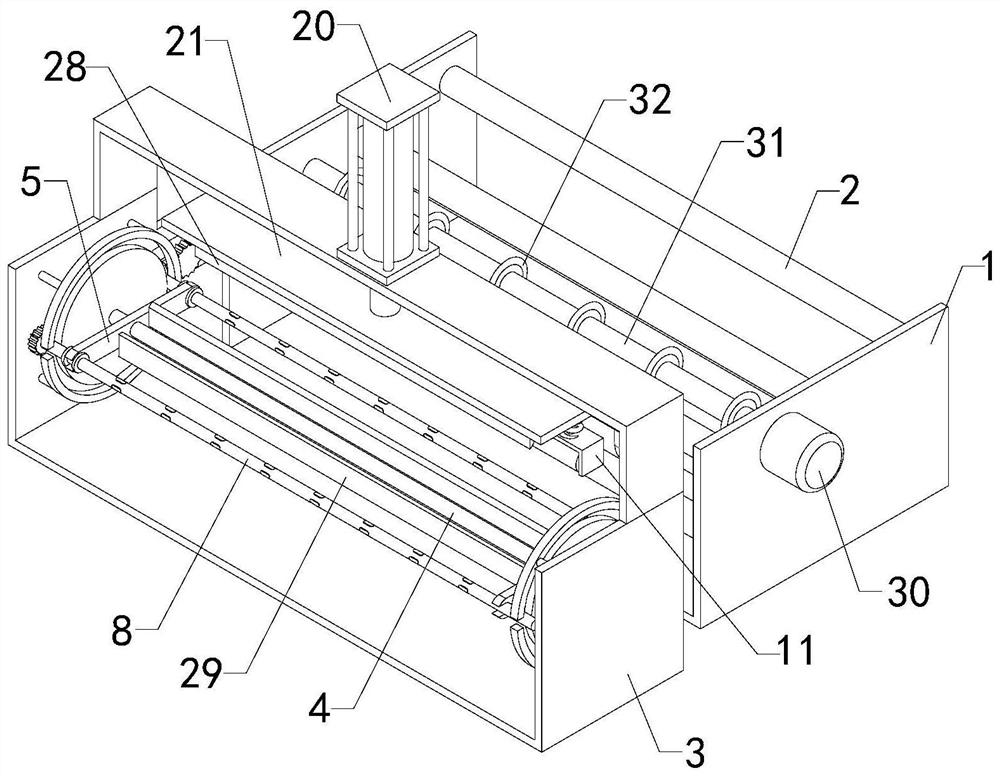

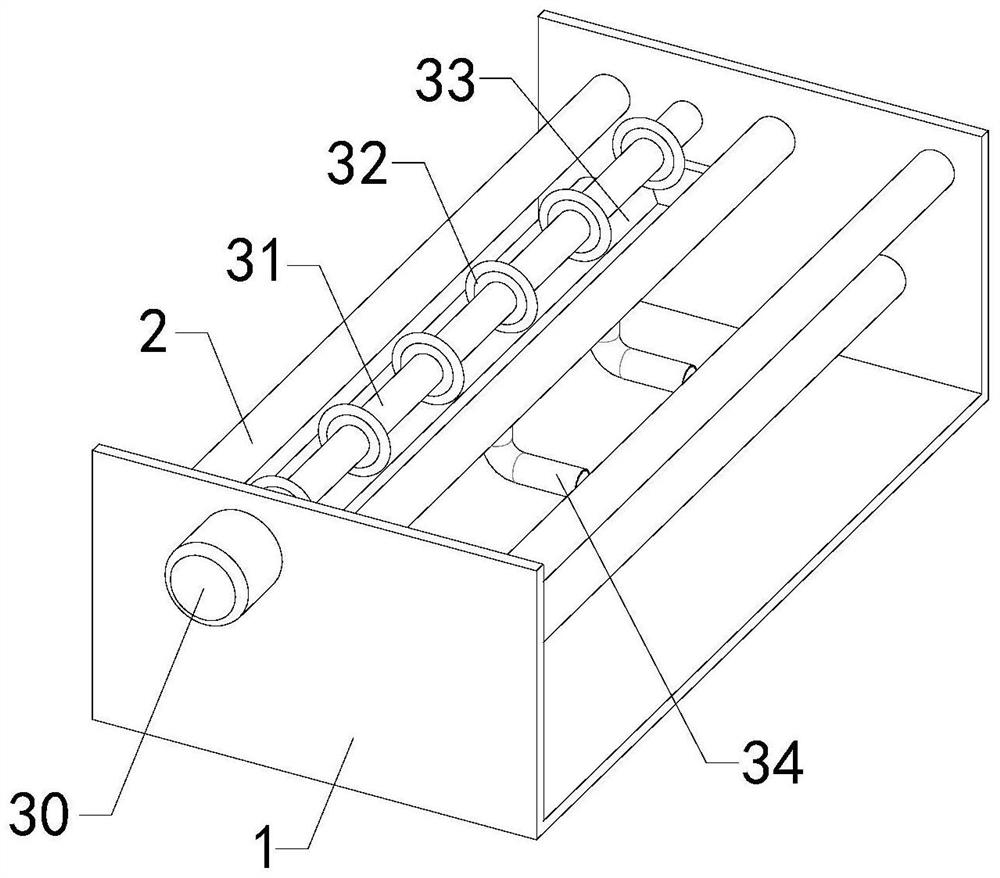

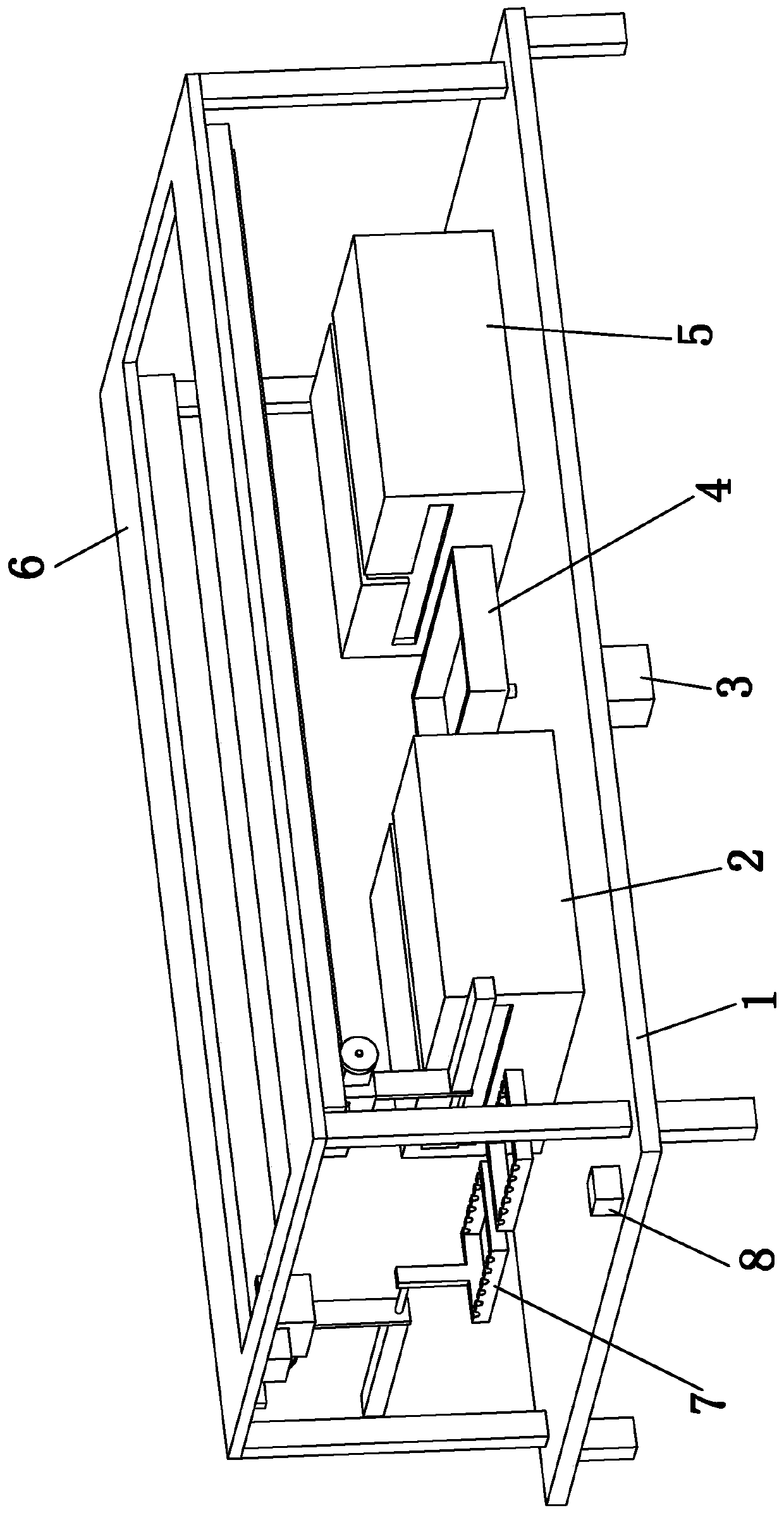

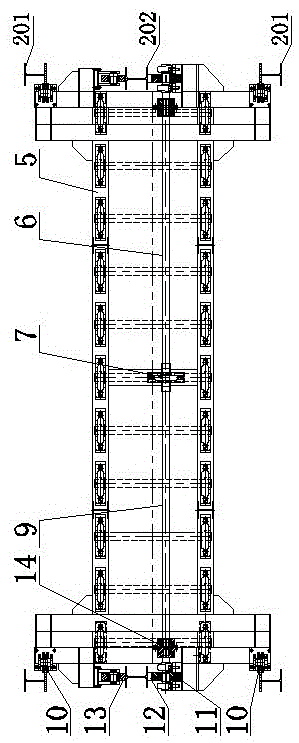

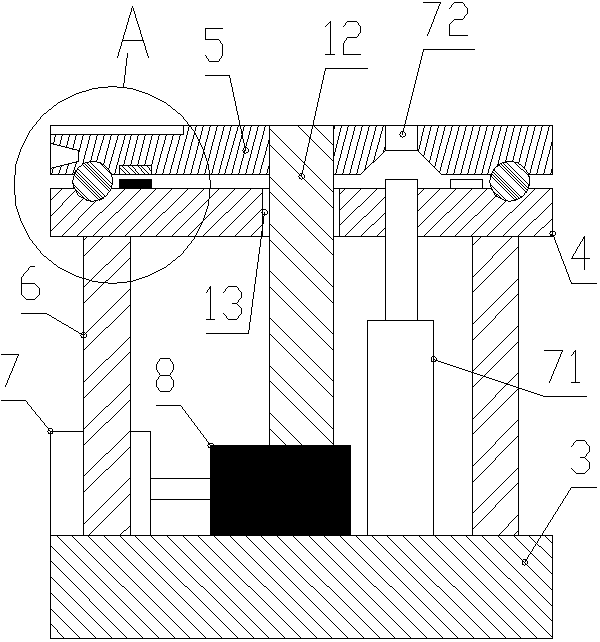

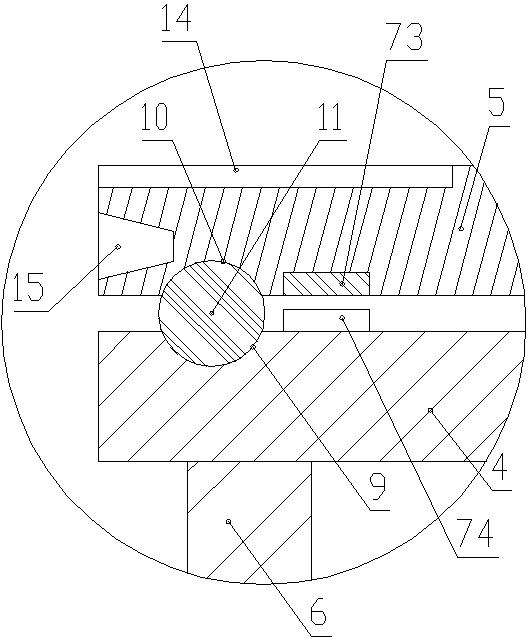

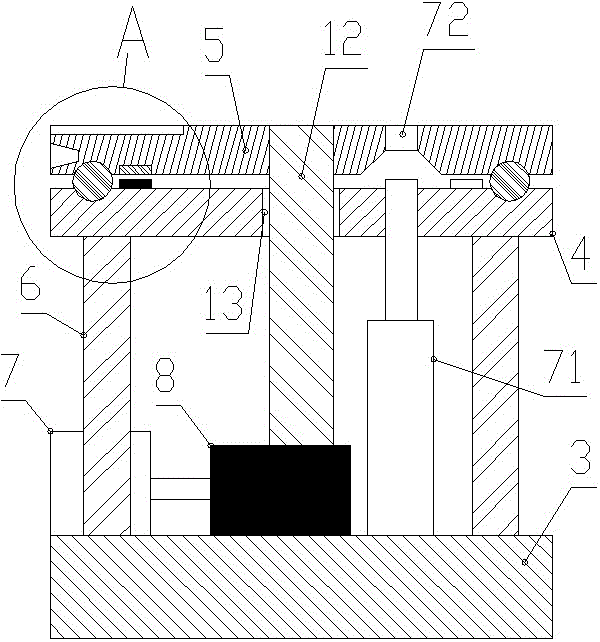

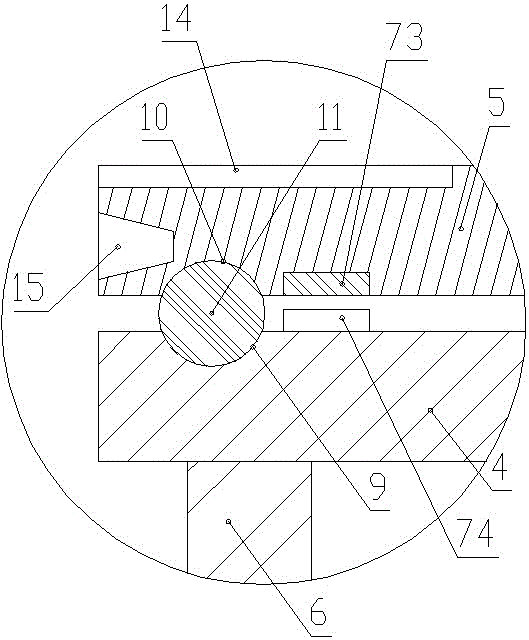

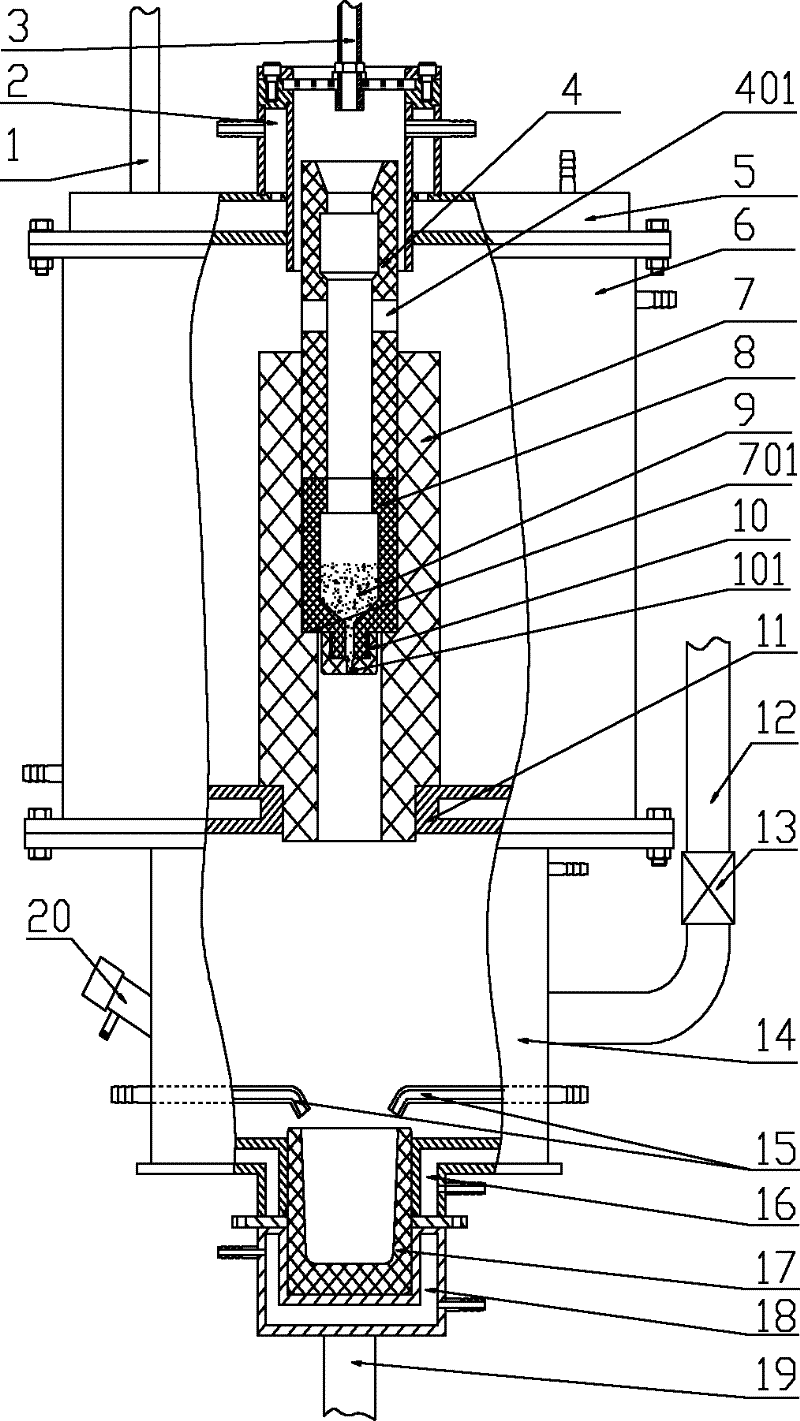

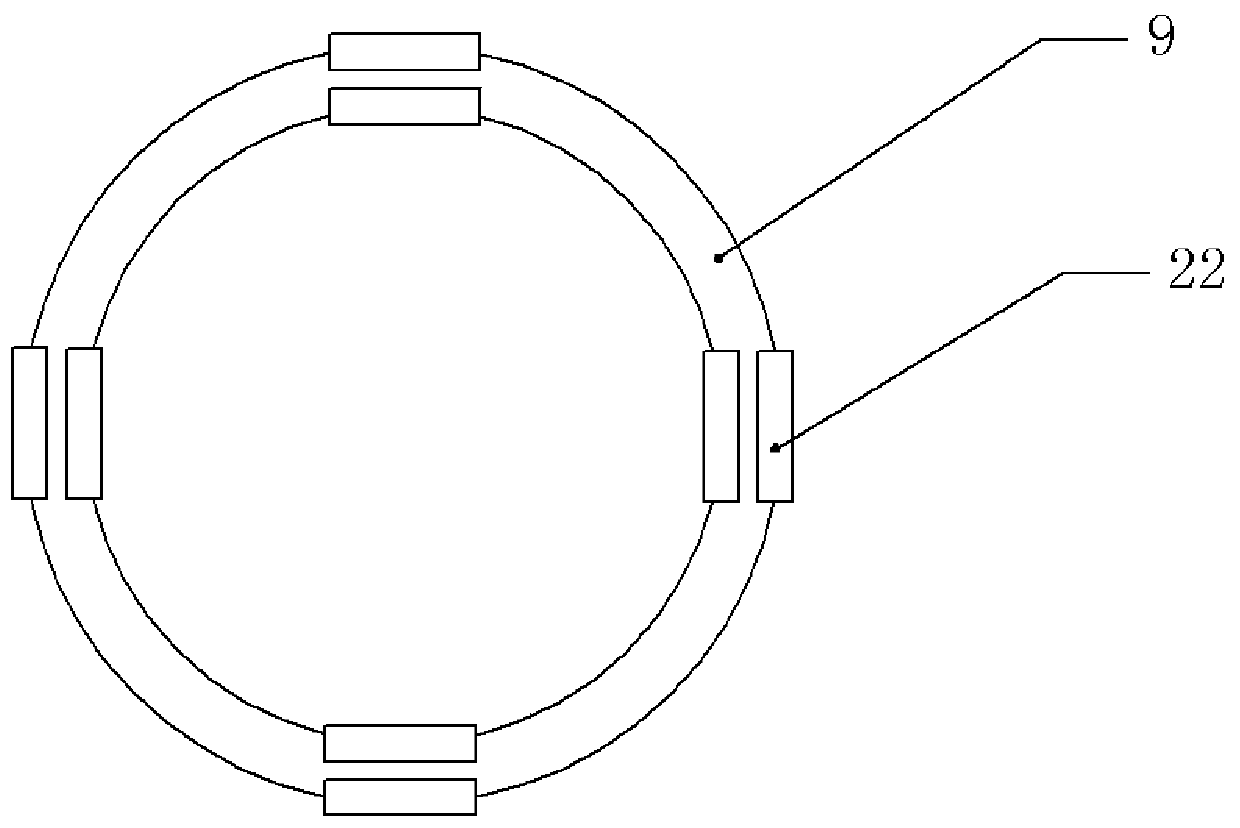

Continuous production system for molten injection refractories

ActiveCN106113225BShorten heating timeRealize continuous production operationAuxillary shaping apparatusHydraulic cylinderElectric arc furnace

The invention discloses a continuous production system for a cast refractory material. The continuous production system comprises an electric arc furnace, casting boxes, a rotating casting device, a rotating box feeding mechanism and a rotating box discharging mechanism. Each casting box comprises a box body with an opened top end, wherein the two opposite side walls of the box body are fixedly connected with box moving stress blocks correspondingly. The rotating casting device comprises a casting base, a casting supporting plate and a casting rotating bearing plate. The rotating box feeding mechanism and the rotating box discharging mechanism are of the same structure, and each of the rotating box feeding mechanism and the rotating box discharging mechanism comprises an outer frame, an upper positioning hydraulic cylinder arranged on the top of the outer frame downwards, a rotating box moving device arranged in the outer frame and located below the upper positioning hydraulic cylinder, and two guide rails arranged on the ground. According to the continuous production system, due to the cooperative work of the rotating casting device, the rotating box feeding mechanism and the rotating box discharging mechanism and the continuous and synchronous cooperative operation of the continuous box feeding substep, the rotating casting substep and the continuous box discharging substep, people do not need to wait for a crane or a forklift truck in the production process, continuous production work is achieved, and the production efficiency is greatly improved.

Owner:郑州东方安彩耐火材料有限公司

Glue-free continuous printing machine

Owner:强记实业公司

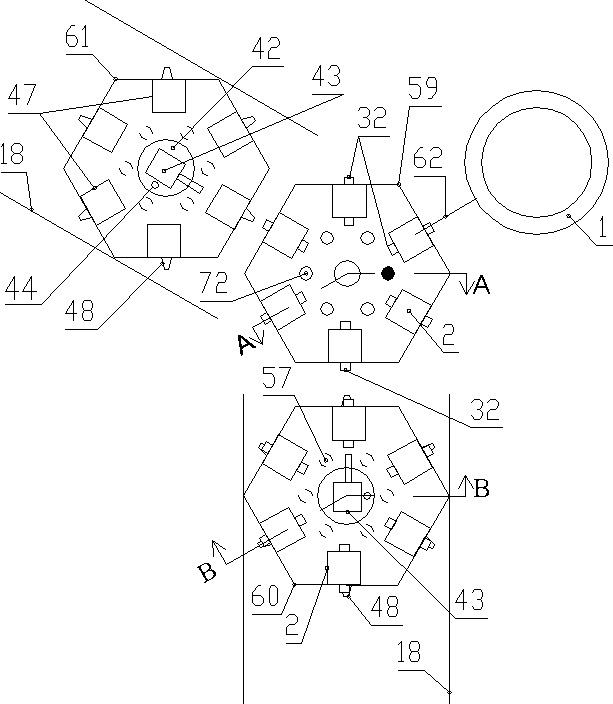

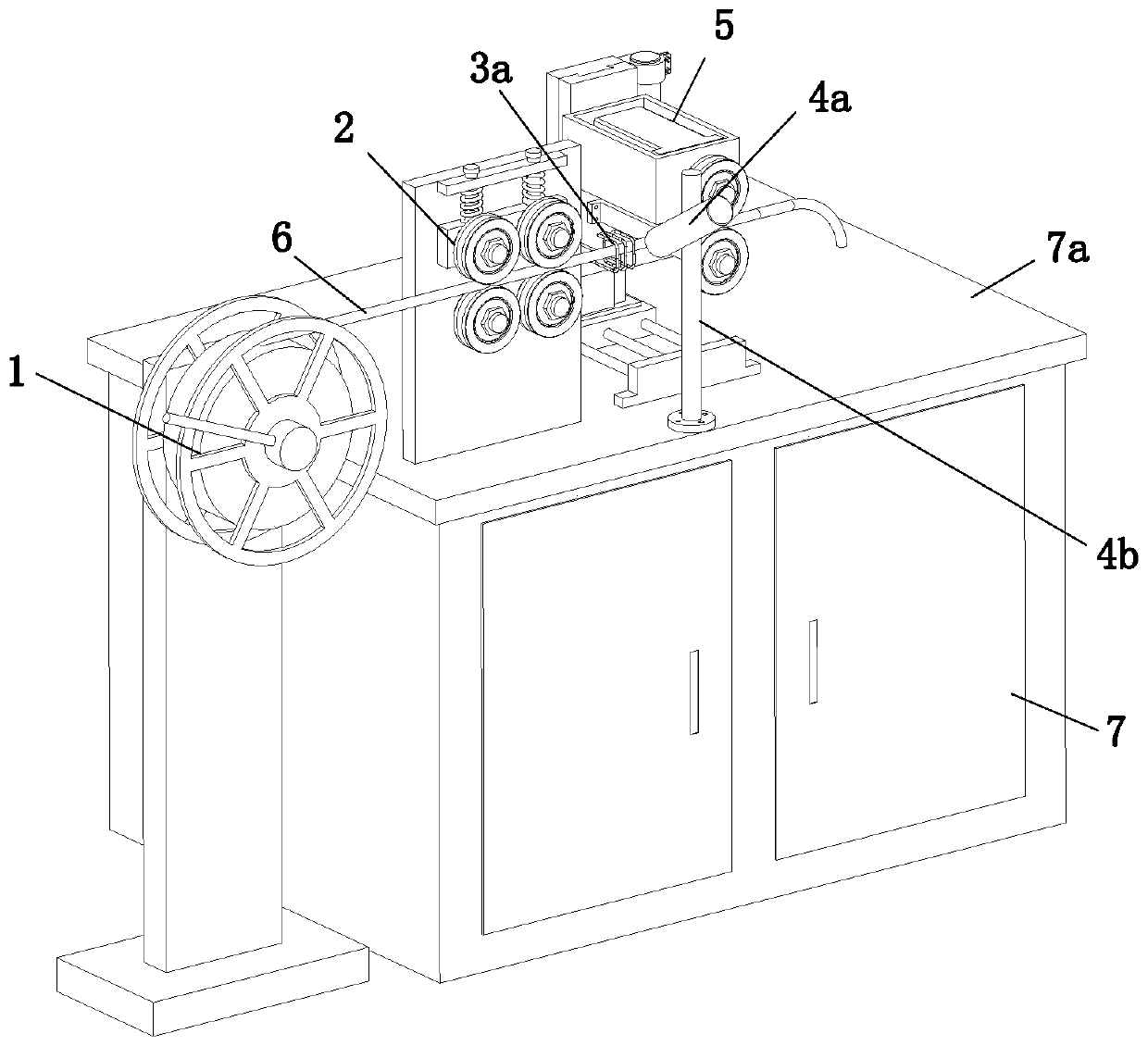

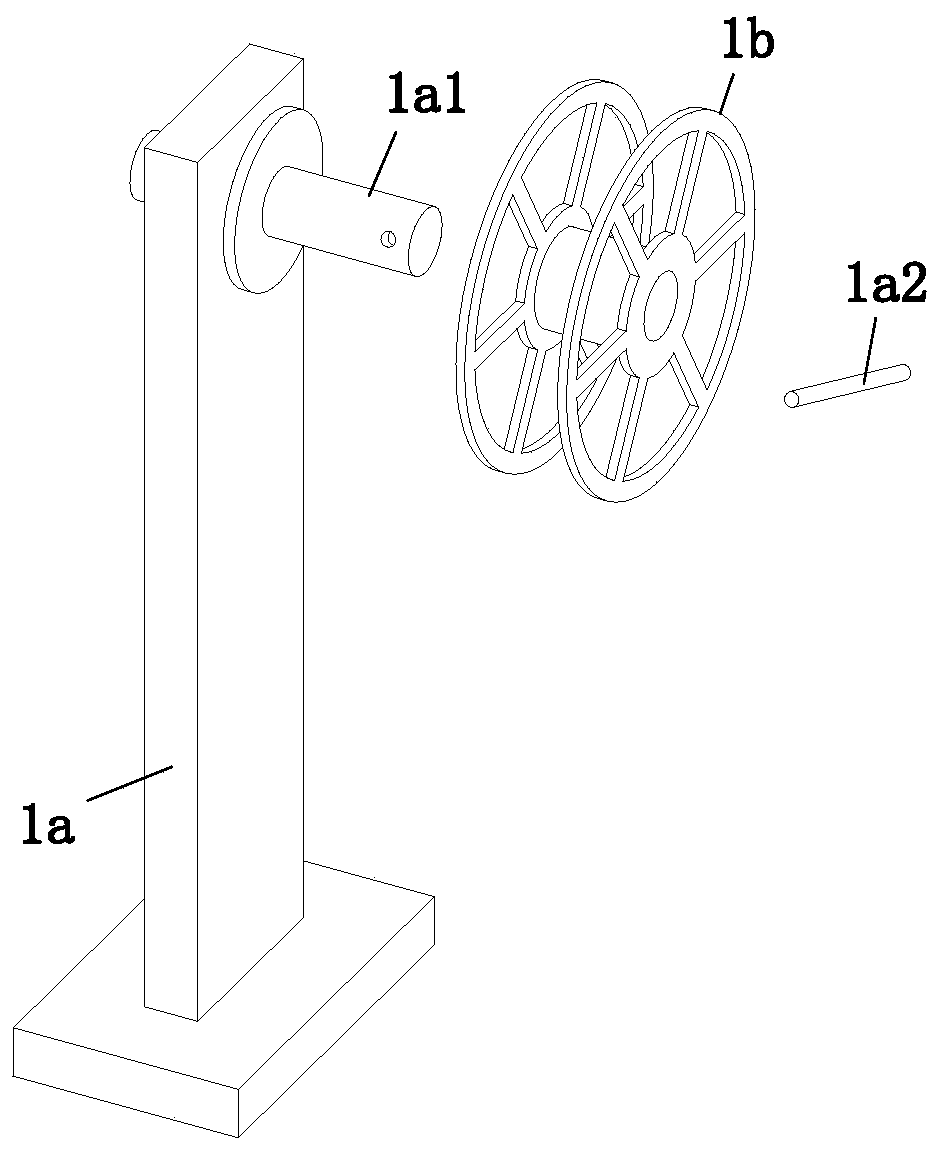

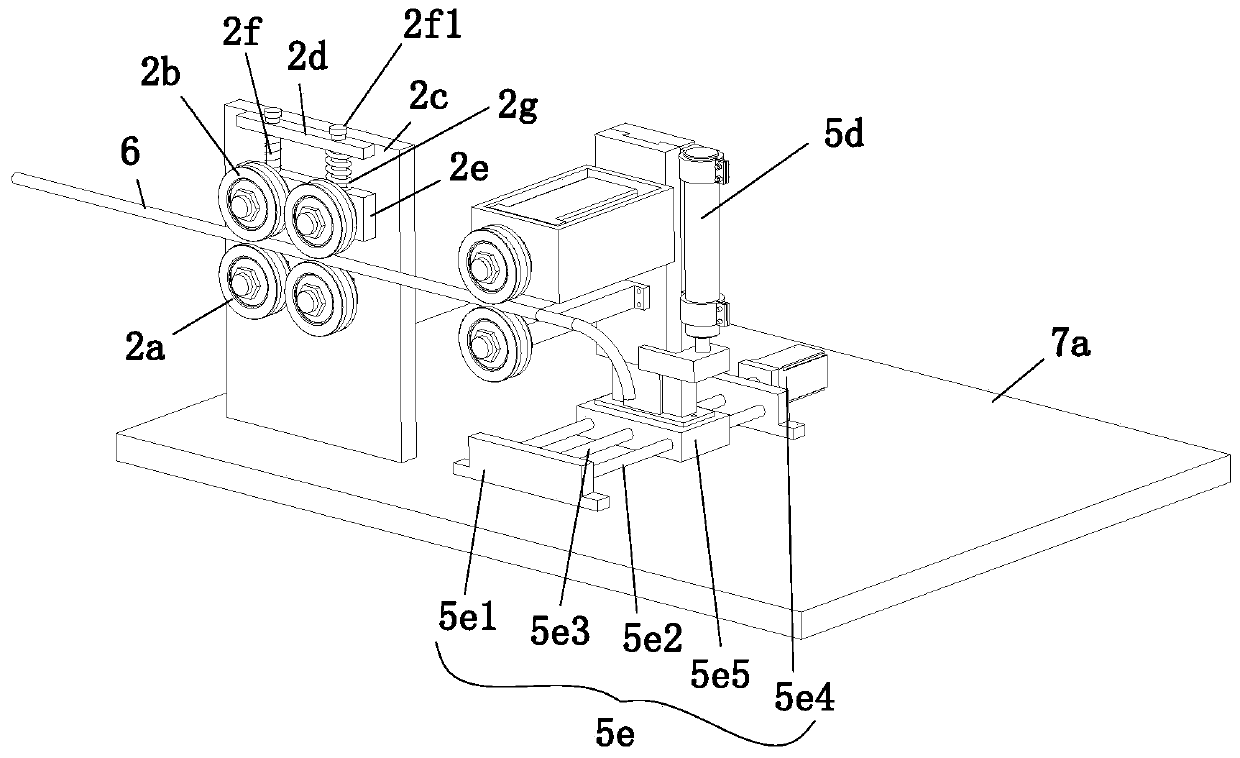

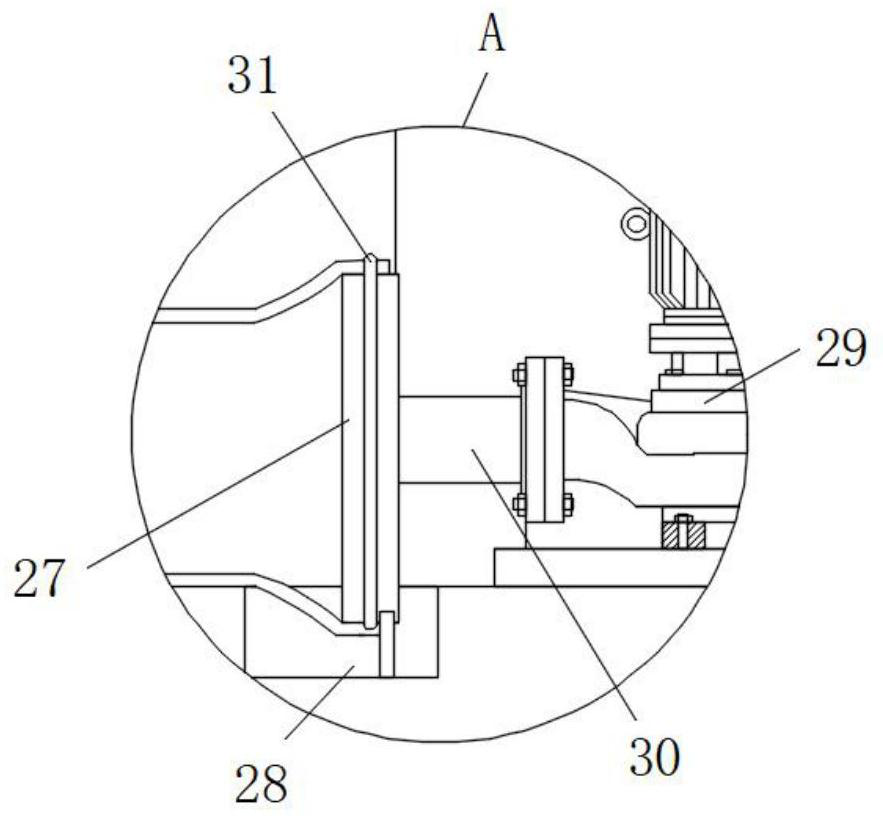

Twisting mechanism of metal wire twisting processing equipment

The invention relates to the field of automatic machining equipment, in particular to a twisting mechanism of metal wire twisting machining equipment. The twisting mechanism comprises a supporting wheel, a driving wheel, a motor, a lifting driving assembly and a transverse movement driving assembly. The supporting wheel and the motor are fixedly arranged on the lifting driving assembly. The motoris in transmission connection with the driving wheel. The lifting driving assembly is fixed to the transverse movement driving assembly. The transverse movement driving assembly and the lifting driving assembly are used for driving the supporting wheel and the driving wheel to do the ascending, descending and transverse movement motions, wires penetrate the part between the supporting wheel and the driving wheel, and the wires are twisted along with ascending, descending and transverse movement of the supporting wheel and the driving wheel. The twisting mechanism has the beneficial effects ofbeing simple in structure and low in cost, and has the function of driving the wires to move, and the functions are not single any more.

Owner:HANGZHOU XINGGUAN MACHINERY

Counting and packaging integration machine for zippers

InactiveCN104828268ARealize continuous production operationIncrease productivityPackaging automatic controlIndividual articlesEngineeringMechanical engineering

The invention provides a counting and packaging integration machine for zippers, belongs to the technical field of machinery, and solves the technical problems that the existing zipper counter is not provided with a packaging device, and a worker needs to pack the zippers after the zippers are counted, so that the production efficiency is low. The counting and packaging integration machine for the zippers comprises a stander, wherein a workbench is fixed on the stander; a counting device and a packing device are arranged on the workbench; the counting device comprises a bracket, a swinging rod and a counter; the bracket is fixedly connected to the workbench through an adjustment mechanism; the swinging rod is hinged to the bracket; a travel switch which can be in contact with the upper end of the swinging rod is fixed on the bracket and is connected with the counter through a line; the packing device comprises a material receiving piece and a push plate; the material receiving piece is arranged on the workbench; a through material chute is formed in the upper part of the material receiving piece; when outer force is applied, the zippers cross the counting device and fall into the material chute; the push plate is arranged on the workbench. The counting and packaging integration machine has the advantages of high production efficiency and high universality.

Owner:ZHEJIANG JKJ ZIPPER TECH CO LTD

Continuous production system for cast refractory material

ActiveCN106113225AContinuous productionIncrease productivityAuxillary shaping apparatusContinuous productionForklift truck

The invention discloses a continuous production system for a cast refractory material. The continuous production system comprises an electric arc furnace, casting boxes, a rotating casting device, a rotating box feeding mechanism and a rotating box discharging mechanism. Each casting box comprises a box body with an opened top end, wherein the two opposite side walls of the box body are fixedly connected with box moving stress blocks correspondingly. The rotating casting device comprises a casting base, a casting supporting plate and a casting rotating bearing plate. The rotating box feeding mechanism and the rotating box discharging mechanism are of the same structure, and each of the rotating box feeding mechanism and the rotating box discharging mechanism comprises an outer frame, an upper positioning hydraulic cylinder arranged on the top of the outer frame downwards, a rotating box moving device arranged in the outer frame and located below the upper positioning hydraulic cylinder, and two guide rails arranged on the ground. According to the continuous production system, due to the cooperative work of the rotating casting device, the rotating box feeding mechanism and the rotating box discharging mechanism and the continuous and synchronous cooperative operation of the continuous box feeding substep, the rotating casting substep and the continuous box discharging substep, people do not need to wait for a crane or a forklift truck in the production process, continuous production work is achieved, and the production efficiency is greatly improved.

Owner:郑州东方安彩耐火材料有限公司

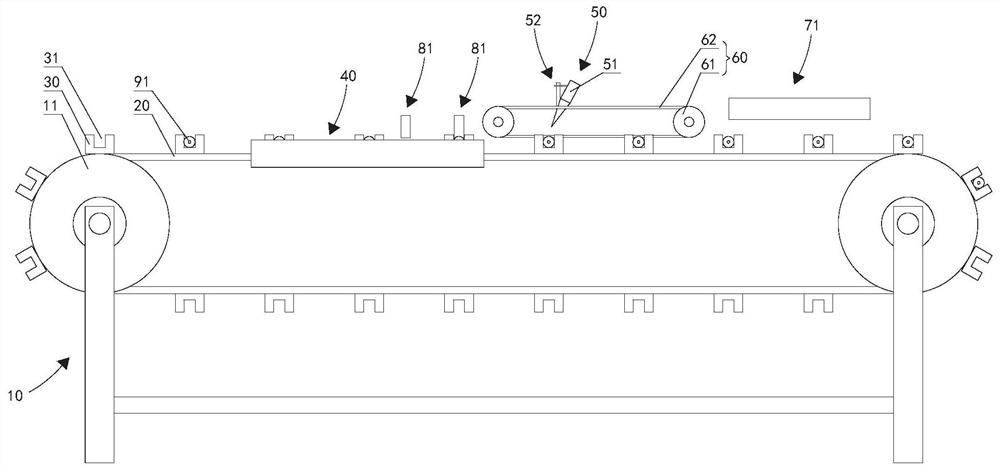

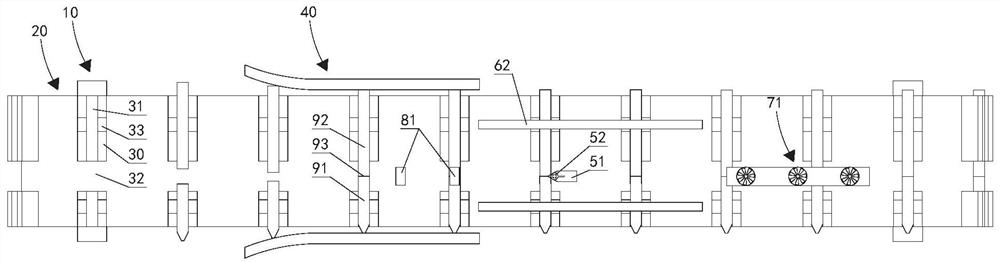

Tattooing needle handle welding machine and tattooing needle manufacturing method

PendingCN112935453AGood welding performanceRealize continuous production operationMedical devicesMetal working apparatusTattoo needleEngineering

The invention provides a tattooing needle handle welding machine. The tattooing needle handle welding machine comprises a rack, and a conveying belt, bearing blocks, a flat guide plate, a welding assembly and a driving assembly which are rotatably disposed on the rack, wherein the bearing blocks are arranged on the conveying belt in parallel in two rows, bearing grooves in the two rows of bearing blocks are aligned one by one and are perpendicular to the rotating plane of the conveying belt, the flat guide plate is used for pushing needle tips and needle handles in the bearing grooves to get close to the middle so that the needle tips and the needle handles can be attached to form attaching parts. A solder tip of the welding assembly is used for melting a solder wire and enabling the solder wire to drop on the attaching parts, the needle tips and the needle handles are driven to move through rotation of the conveying belt, feeding and discharging can be achieved at the two ends of the rack, continuous production operation is achieved, operation is convenient, efficiency is high, and consistency and safety are high. The needle tips and the needle handles are controlled to rotate synchronously through the driving assembly, liquid soldering tin dripping on the attaching parts can be evenly wrapped on the attaching parts, complete covering can be achieved, and the welding effect is good. The tattooing needle manufacturing method is easy to implement and good in welding effect.

Owner:苏州市相城区棱峰医疗用品有限公司

Cable production stranding device capable of automatically inserting cables

ActiveCN113257487AAuto insertWind evenlyCable/conductor manufactureElectronic waste recyclingBall bearingElectric machine

The invention belongs to the technical field of cable production, and discloses a cable production stranding device capable of automatically inserting cables. The cable production stranding device comprises a bottom plate, a fixing seat is fixedly arranged on the left side of the upper end of the bottom plate, round holes are formed in the side wall of the fixing seat, and the fixing seat is rotatably connected with a wire stranding seat through two ball bearings in the corresponding round holes, a plurality of wire pipes which are annularly distributed are fixedly inserted into the side wall of the wire stranding seat in a sleeving mode, a driven gear is fixedly connected to the outer wall of the wire stranding seat in a sleeving mode, a rotating motor is fixedly arranged at the upper end of the fixing seat, and an output shaft of the rotating motor is fixedly connected with a driving gear meshed with the driven gear, the upper end of the fixing seat is provided with a through groove used for the driving gear to stretch in, and the side wall of the wire stranding seat is fixedly connected with U-shaped supporting plates located on the left sides of the wire pipes. The cable production stranding device capable of automatically inserting the cables can realize continuous production operation and improve working efficiency.

Owner:ANHUI CABLE

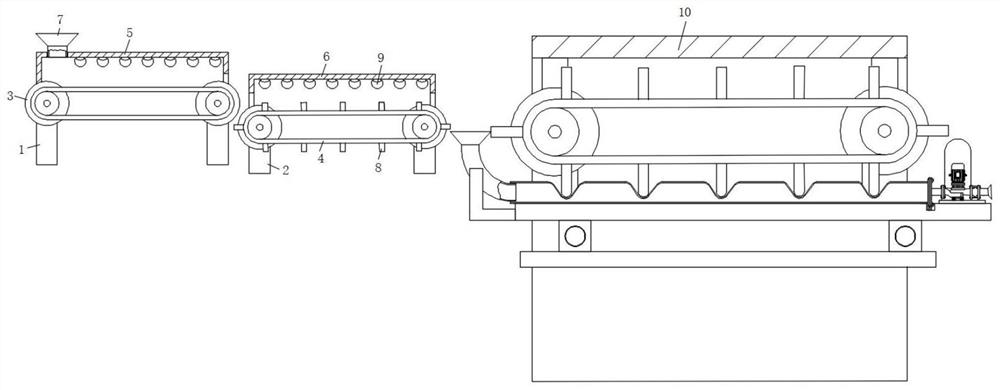

Automatic packaging equipment for small bread processing

ActiveCN112224516AReasonable designThe device runs stablyPackaging by pressurising/gasifyingWrapper twisting/gatheringProcess engineeringBatch production

The invention discloses an automatic packaging equipment for small bread processing. The automatic packaging equipment comprises a feeding mechanism and a dispersing mechanism, the feeding mechanism comprises a first supporting base, the dispersing mechanism comprises a second supporting base, a first conveying belt and a second conveying belt are installed at the upper end of the first supportingbase and the upper end of the second supporting base respectively, a first sealing vessel and a second sealing vessel are arranged at the upper end of the first conveying belt and the upper end of the second conveying belt respectively, a feeding hopper is connected to one side of the top face of the first sealing vessel in a penetrating mode, a partition plate is further fixed to the belt face of the second conveying belt, ultraviolet sterilization lamps are further fixed to the inner top faces of the first sealing vessel and the second sealing vessel, and a packaging mechanism is further arranged on the side, deviating from the feeding mechanism, of the dispersing mechanism. The device is reasonable in design, stable in operation, capable of achieving continuous dispersing and packagingoperation of small bread and high in working efficiency, so that batch production operation of the small bread is conveniently completed, and the requirement for batch efficient production of the small bread is well met.

Owner:济南沃德爱礼食品有限公司

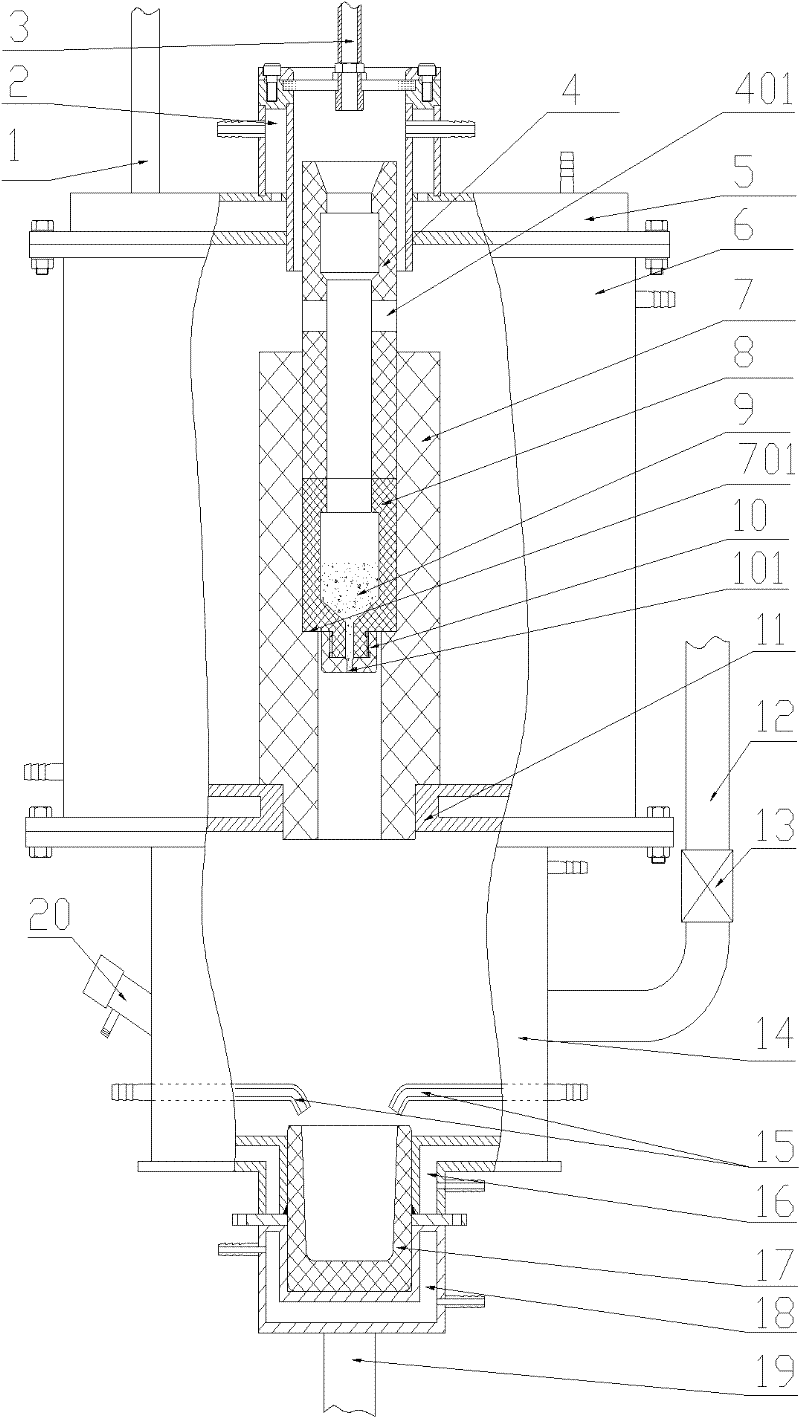

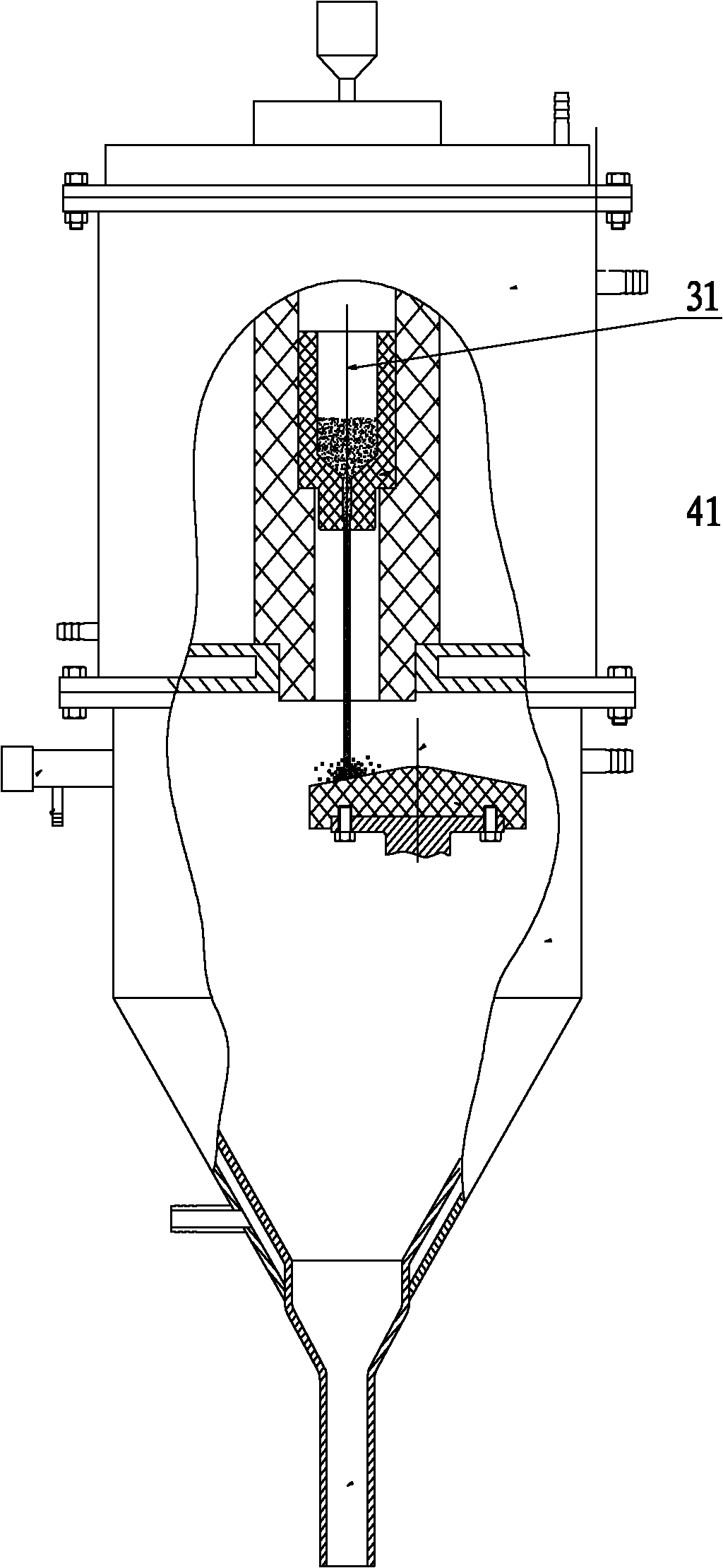

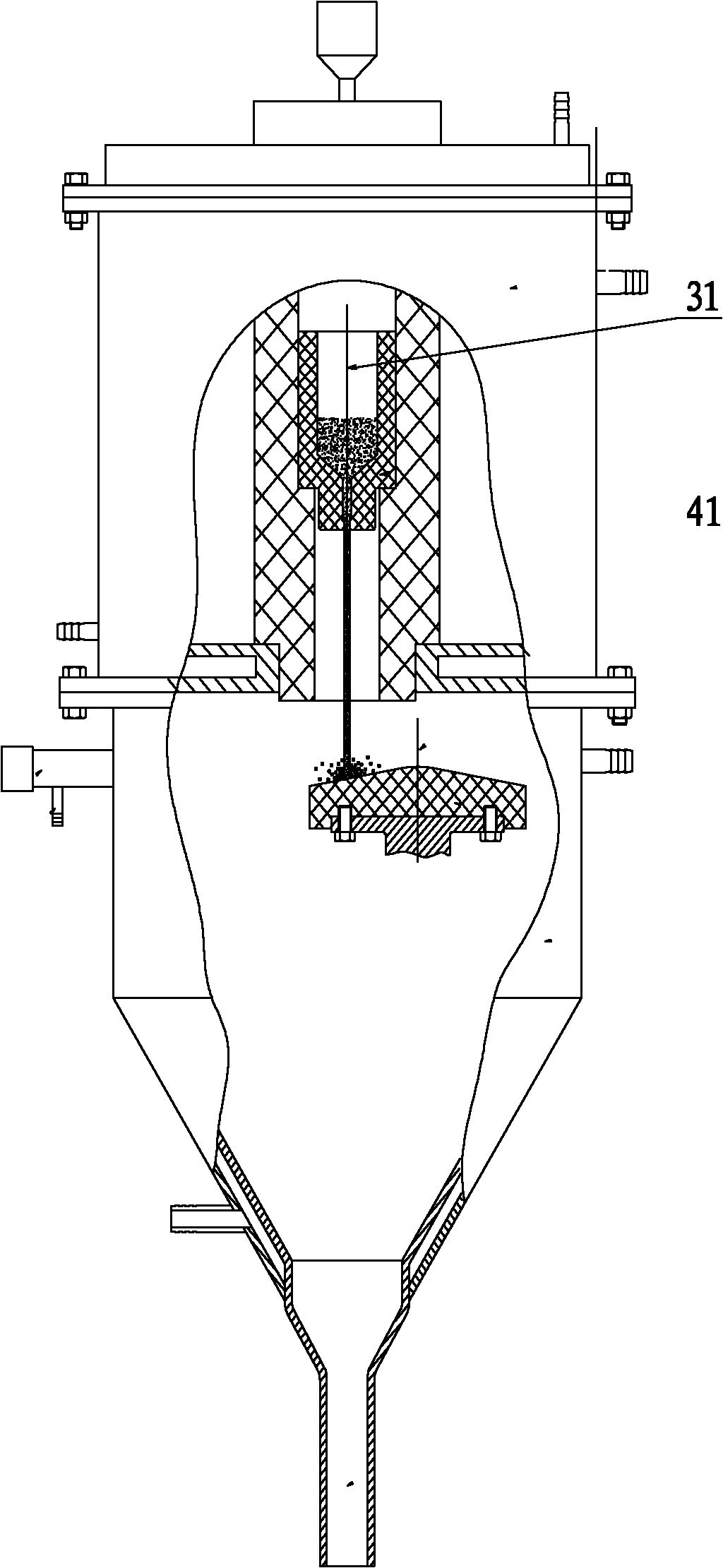

Vertical smelting furnace for continuously casting tungsten carbide

ActiveCN102095309BGuaranteed disassemblyReduce the degree of oxidationTungsten/molybdenum carbideGraphiteTungsten

The invention relates to a vertical smelting furnace for continuously casting tungsten carbide, which is of a vertical structure and consists three parts, namely a feeding part, a heating part and a cooling part, wherein the feeding part is used for providing a mixture of tungsten powders and tungsten carbide powders for the heating part; an inner step is arranged in a heating pipe of the heatingpart; a graphite funnel is arranged on the inner step and is provided with a lining with exhaust holes; the mixture is heated in the funnel to form a cast tungsten carbide solution in a WC+W2C eutectic structure, and the solution continuously drops to the cooling part; the cooling part is of a double-cooling structure consisting of a cooling air pipe and a bucket-type water cooling jacket or is in a direct water cooling structure; and the cooling part is used for quickly cooling the solution dropping from the heating part to a process temperature and conveying the solution outside the furnace. The smelting furnace has the advantages of high cooling speed, low degree of oxidation for materials, low energy consumption, high yield and continuous production and operation. In addition, the graphite funnel is provided with the lining with the exhaust holes, so that the heating pipe is prevented from being adhered with the graphite funnel, and the graphite funnel is convenient to be disassembled from the heating pipe.

Owner:株洲弗拉德科技有限公司

A dispersion mill for preparing nanomaterial modified cement

ActiveCN108514928BFully dispersedElimination of nano-agglomeratesGrain treatmentsEngineeringMachining process

The invention discloses a dispersion mill for preparing nanometer material modified cement. A cabin body is separated into a mixing and grinding cabin and a material collecting cabin by a grid plate;the lateral upper part of the mixing and grinding cabin is provided with two feeding openings; a stirrer is arranged in the mixing and grinding cabin; a plurality of metal blocks are arranged in the mixing and grinding cabin; the lower half part of the material collecting cabin is a funnel; the bottom of the funnel is provided with a discharging opening. The mixing and grinding cabin can effectively realize the simultaneous mixing and grinding of nanometer materials and cement; the nanometer ore powder agglomeration is broken; the sufficient and uniform mixing of nanometer particles and otherpowder can be realized. In the use process, a discharging opening at the lower part of the material collecting cabin is connected with a concrete stirring machine; a certain mass of composite materials are regularly discharged according to the concrete mixing ratio and the stirring machine process parameters; meanwhile, through the feeding opening of the mixing and grinding cabin, nanometer materials and cement are respectively and regularly added according to the production requirement proportion, so that the continuous production operation with the concrete stirring machine can be realized.

Owner:CHINA UNIV OF MINING & TECH

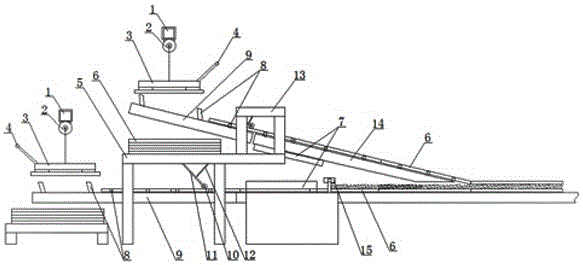

Double hard panel polyurethane composite insulation board production line

The invention discloses a polyurethane composite thermal insulation board production line with double-hard panels, which includes a panel feeding mechanism, a panel conveying mechanism and a coating mechanism. The feeding mechanism includes an upper layer feeding mechanism and a lower layer feeding mechanism. The plate conveying mechanism includes an upper plate conveying mechanism and a lower plate conveying mechanism, the upper plate conveying mechanism and the lower plate conveying mechanism are respectively provided with a heating mechanism, and the upper plate conveying mechanism and the lower plate conveying mechanism are arranged at an angle less than 45° . It effectively solves the problem of difficult feeding of the upper and lower composite boards in the production process of the double-hard surface polyurethane composite insulation board, and realizes the continuous transfer operation of the boards, which greatly improves the production efficiency. At the same time, through the coating of polyurethane foam Preheating the board bridge before the material, effectively guarantees the reliability of the composite bonding of the boards, greatly improves the production quality of the double-hard polyurethane composite insulation board, and its quality is more stable.

Owner:徐振飞

An automatic packaging equipment for small bread processing

ActiveCN112224516BRealize continuous distributed packing operationFacilitate the completion of mass production operationsPackaging by pressurising/gasifyingWrapper twisting/gatheringProcess engineeringConveyor belt

The invention discloses an automatic packaging equipment for small bread processing, which includes a feeding mechanism and a dispersing mechanism, the feeding mechanism includes a support seat 1, the dispersing mechanism includes a support seat 2, the upper ends of the support seat 1 and the support seat 2 are Conveyor belt 1 and conveyor belt 2 are installed, and the upper ends of conveyor belt 1 and conveyor belt 2 are respectively provided with sealing dish 1 and sealing dish 2. The top side of the sealing dish 1 is connected with a feeding funnel, and the belt surface of conveyor belt 2 There is also a partition plate fixed on the upper surface, and an ultraviolet sterilizing lamp is also fixed on the inner top surface of the sealing dish 1 and the sealing dish 2, and the dispersing mechanism is also provided with a packing mechanism on the side away from the feeding mechanism. The invention has reasonable design, stable operation of the device, can realize the continuous dispersed packing operation of the small bread, and has high working efficiency, thereby facilitating the batch production of the small bread, and well satisfying the demand for high-efficiency batch production of the small bread.

Owner:济南沃德爱礼食品有限公司

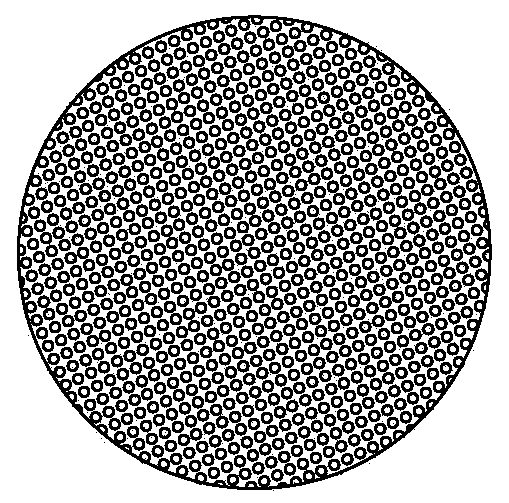

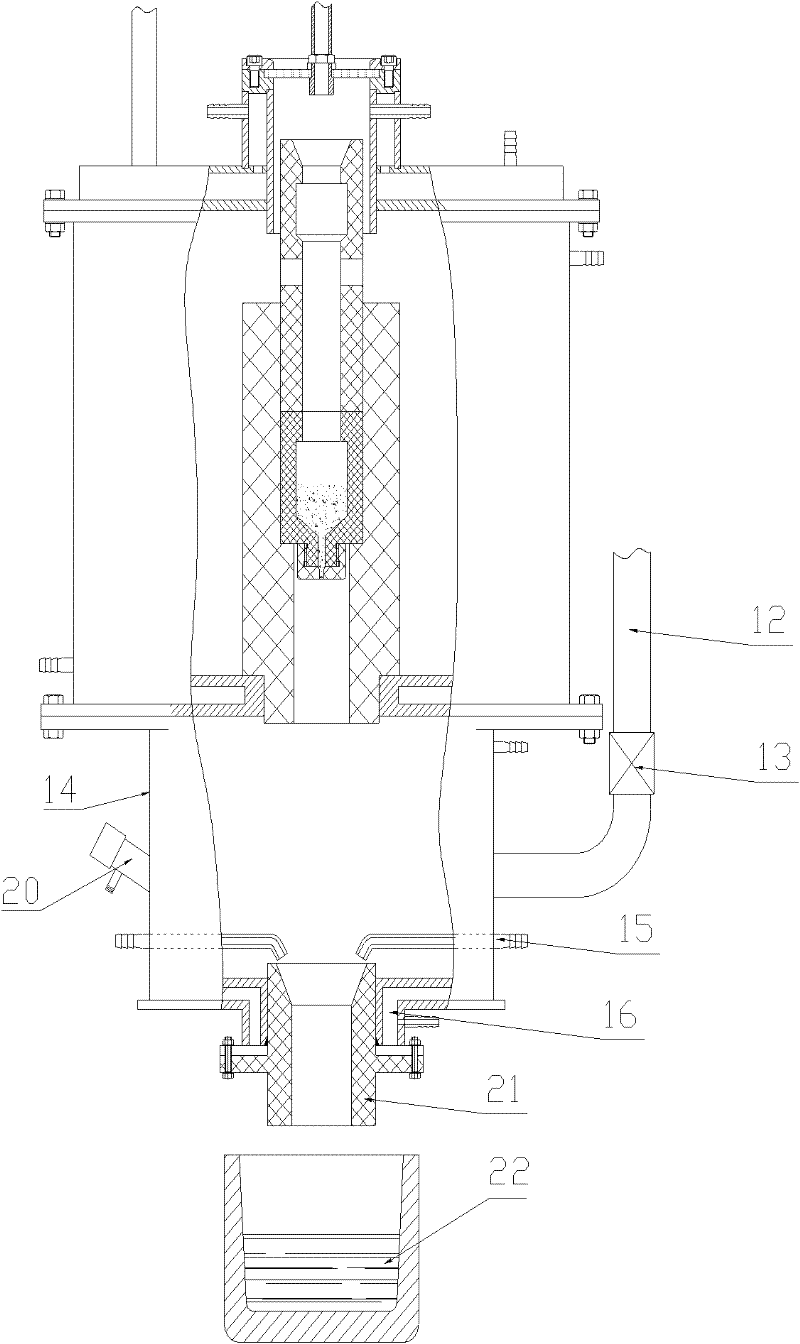

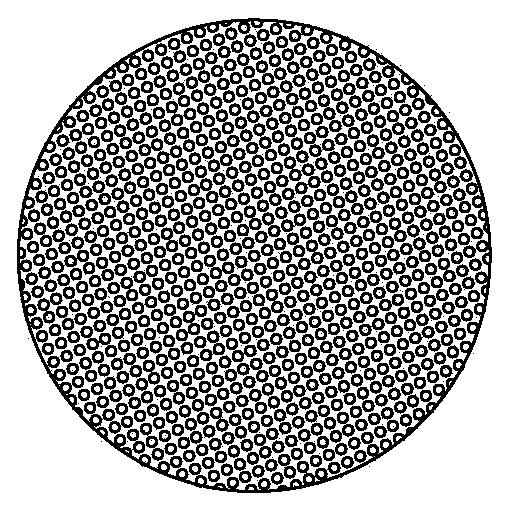

Fine grain casting tungsten carbide continuous production furnace

InactiveCN102092714AFast coolingImprove working conditionsGranulation by liquid drop formationTungsten/molybdenum carbideHigh-temperature corrosionSmall hole

The invention relates to a fine grain casting tungsten carbide continuous production furnace. The production furnace is divided into three parts, namely a feeding device, an upper furnace body and a lower furnace body. the integral structure of the production furnace is a vertical structure. The production furnace contains the feeding device, the upper furnace body, a conical throwing disk, the lower furnace body, a discharging pipe, a gas inlet nozzle and an observation pipe. The production furnace is characterized in that the inside of the upper furnace body is provided with a round graphite crucible with a central small hole at the bottom; and the conical throwing disk is arranged below the graphite crucible, the conical throwing disk is near the graphite crucible and performs high-speed circular motion around the axis, and the axis is parallel to the central vertical line of the graphite crucible to maintain a proper horizontal distance. Under the centrifugal force of the conical throwing disk, the solution is broken to tiny particles and the tiny particles are thrown on the inner wall of a water-cooled sandwich cylinder, thus the high temperature solution can be fast cooled and the fine grain casting tungsten carbide product with fine grains can be obtained; and the production furnace has high cooling speed, low degree of oxidation of material, low energy consumption and high yield, and can be used to realize continuous production operation.

Owner:株洲弗拉德科技有限公司

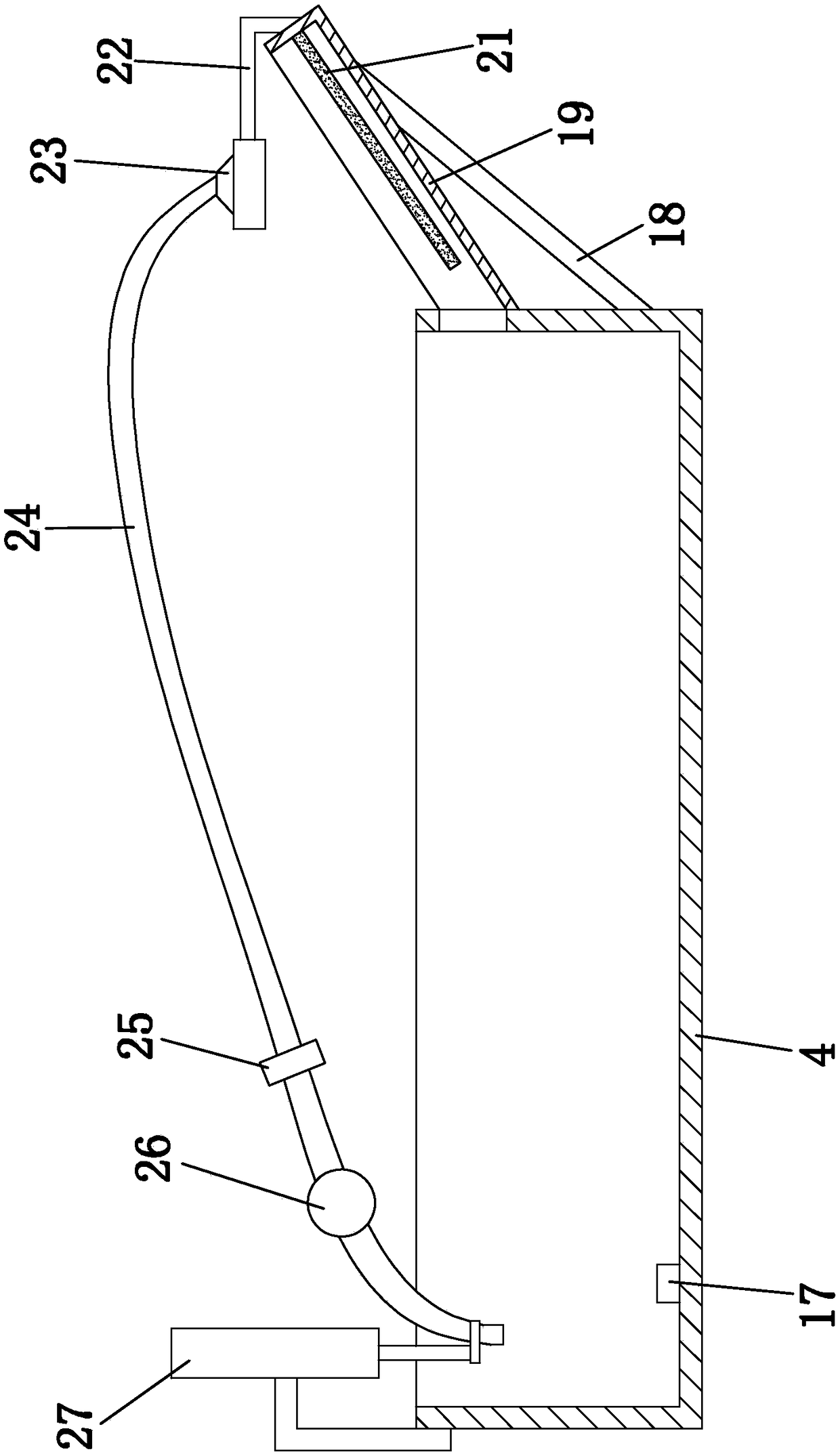

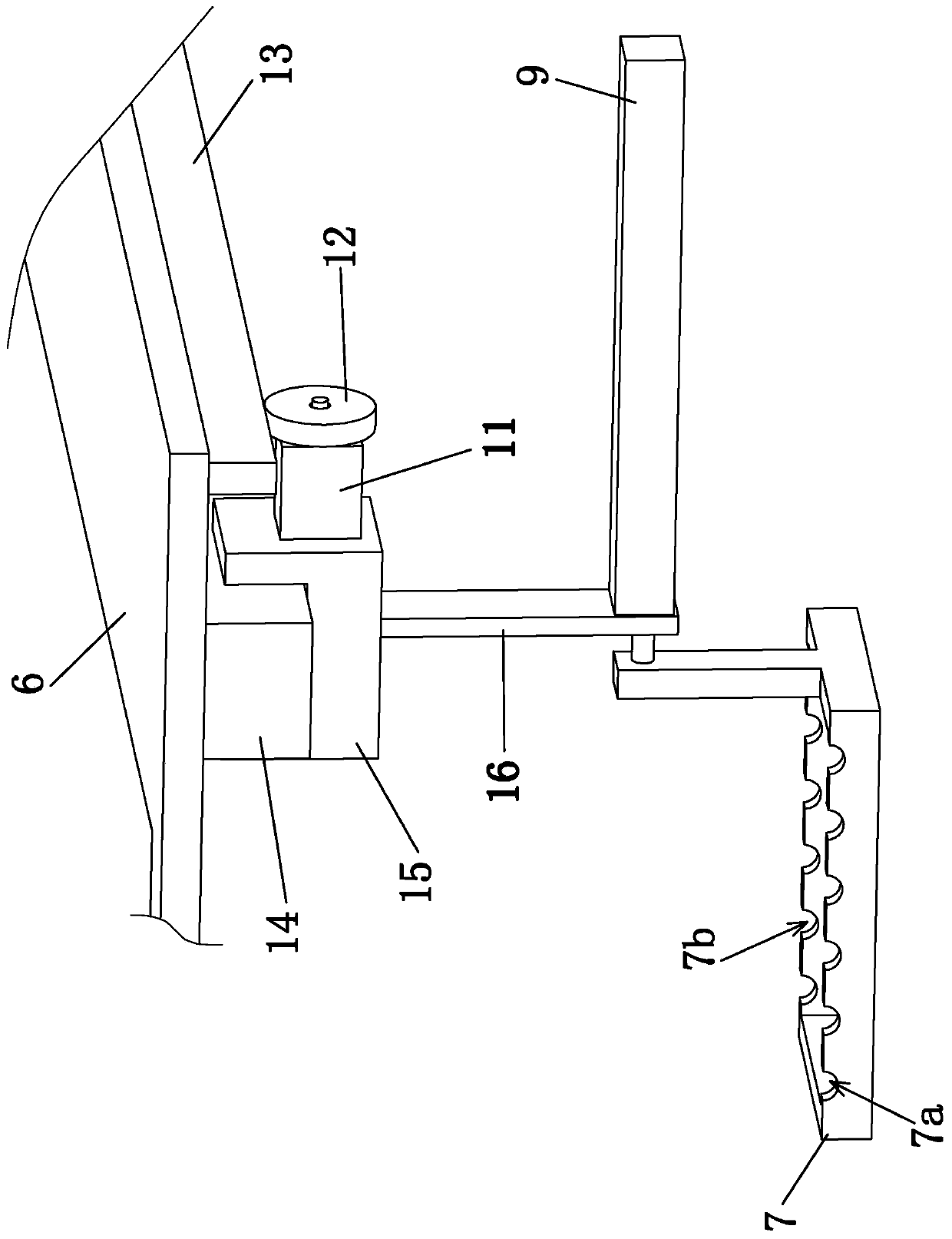

A melt electrospinning device

InactiveCN108823652BReduce volumeReduce weightSpinning head liquid feederArtificial thread manufacturing machinesFiberSpinning

The invention discloses a melt electrostatic spinning device. The device comprises a material supply unit, an electrostatic spinning unit, an atmosphere adjusting unit and a control unit; the materialsupply unit comprises a feeding roll, a feeding stepping motor, a material pressing roll, a spinning material roll and a spinning material heater, the feeding stepping motor is connected with the feeding roll, the material pressing roll is parallel to the feeding roll, and spinning material roll is used for supplying materials to the gap between the feeding roll and the material pressing roll; the electrostatic spinning unit comprises a grounding spraying head, an adjustable high-voltage static generation module and an electrospinning fiber collecting plate, wherein the electrospinning fibercollecting plate is in positive connection with the adjustable high-voltage static generation module; the atmosphere adjusting unit comprises a gas flow sensor, a temperature sensor, a control panel,a transformer and a controller. The melt electrostatic spinning device is high in integration degree, realizes control over the temperature and flow of the spinning materials, adjusts spinning voltageand spinning distance, can realize continuous production operation, and has good application prospects in the field of melt electrostatic spinning.

Owner:安徽东蒙环保科技有限公司

Steel shot quenching device

ActiveCN108504843BShortening the difference between quenching cooling ratesLittle difference in metallographic structureFurnace typesProcess efficiency improvementTemperature controlEngineering

The invention relates to the technical field of steel shot production, and discloses a steel shot quenching device, which includes a quenching pool, a centrifuge is rotatably connected to the middle of the quenching pool, a round table is arranged on the bottom of the quenching pool, and a plurality of cover plates are hinged on the edge of the round table. Including the water retaining section and the discharge section, the side of the round table close to the discharge section is provided with a discharge port, the discharge section and the round table are connected by springs; the inner wall of the quenching pool is equipped with a temperature control circuit and a magnet, the temperature control circuit is connected with the magnet, the centrifugal Electromechanical connection, the free end of the discharge section is provided with an iron sheet; the bottom of the quenching pool is provided with a funnel chamber and a cooling mechanism, the bottom of the funnel chamber is connected to a water tank, and the side wall of the water tank is provided with a discharge port, and the discharge port is equipped with a tilting device. And the net plate which is against the side wall of the water tank, the water tank and the round table are connected through a recovery pipe, and a water pump is installed on the recovery pipe. The present invention can solve the problem of large performance differences of the same batch of steel shot in the prior art, and improve the performance of the steel shot.

Owner:CHONGQING QINGLAN MACHINERY MFG

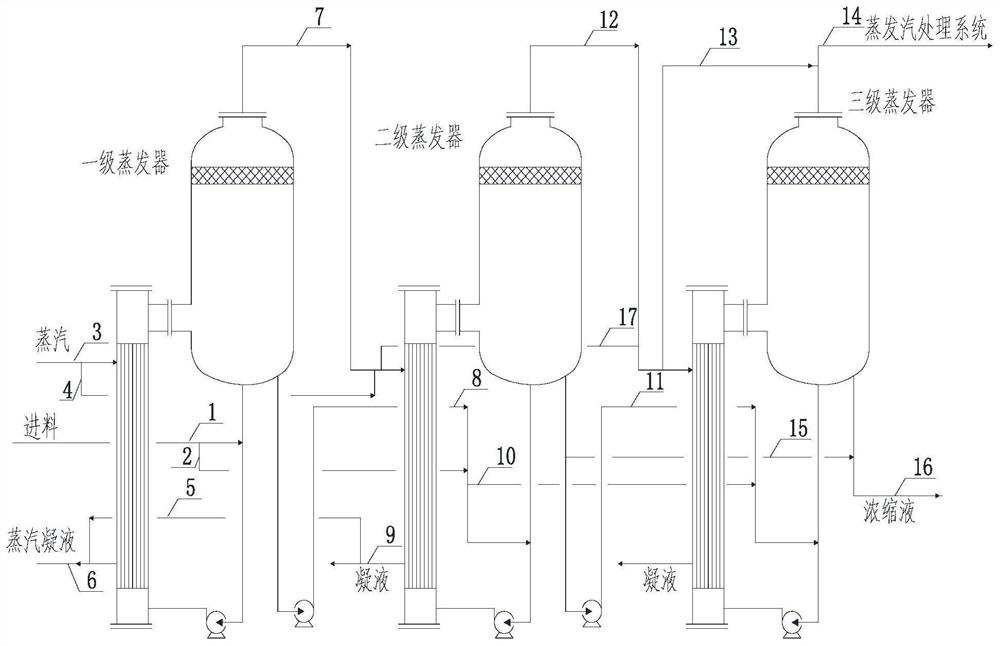

Switchable salt solution multi-effect concentration and evaporation system and effect reduction operation method thereof

PendingCN114100166AEasy to adjustQuick matchEvaporator accessoriesMultiple-effect evaporationControl engineeringEconomic benefits

The invention relates to a switchable salt solution multi-effect concentration and evaporation system and an effect reduction operation method thereof, and provides the switchable salt solution multi-effect concentration and evaporation system and the effect reduction operation method, the effect reduction operation can be carried out once a certain effect is blocked, and meanwhile, a rapid matching method of operation parameters after effect reduction is provided. The temperature and pressure of evaporation operation are rapidly matched, the evaporation capacity of each effect evaporator and the steam heat source supply amount of an evaporation system are rapidly adjusted, and therefore continuous production operation is achieved, the operation flexibility is high, the device runs rapidly to reach the stable state, the product performance is kept stable, the maintenance workload and maintenance cost of the device are reduced, and the production efficiency is improved. And the economic benefit is improved.

Owner:SINOPEC NINGBO ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com