Prefabricated component production system

A technology for production systems and prefabricated components, which is applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve problems such as insufficient production efficiency, and achieve the effects of improving production efficiency, reducing production costs, and improving continuity and fluency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

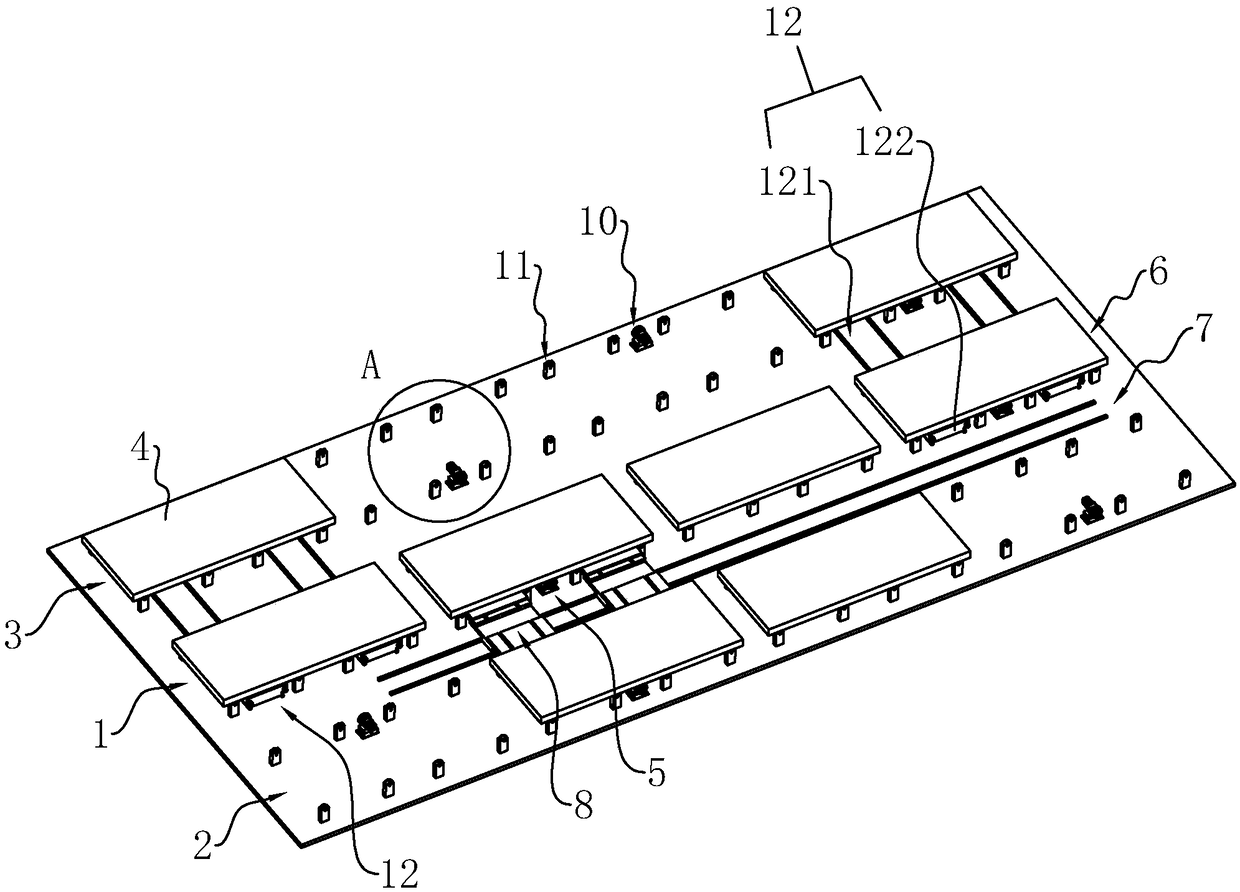

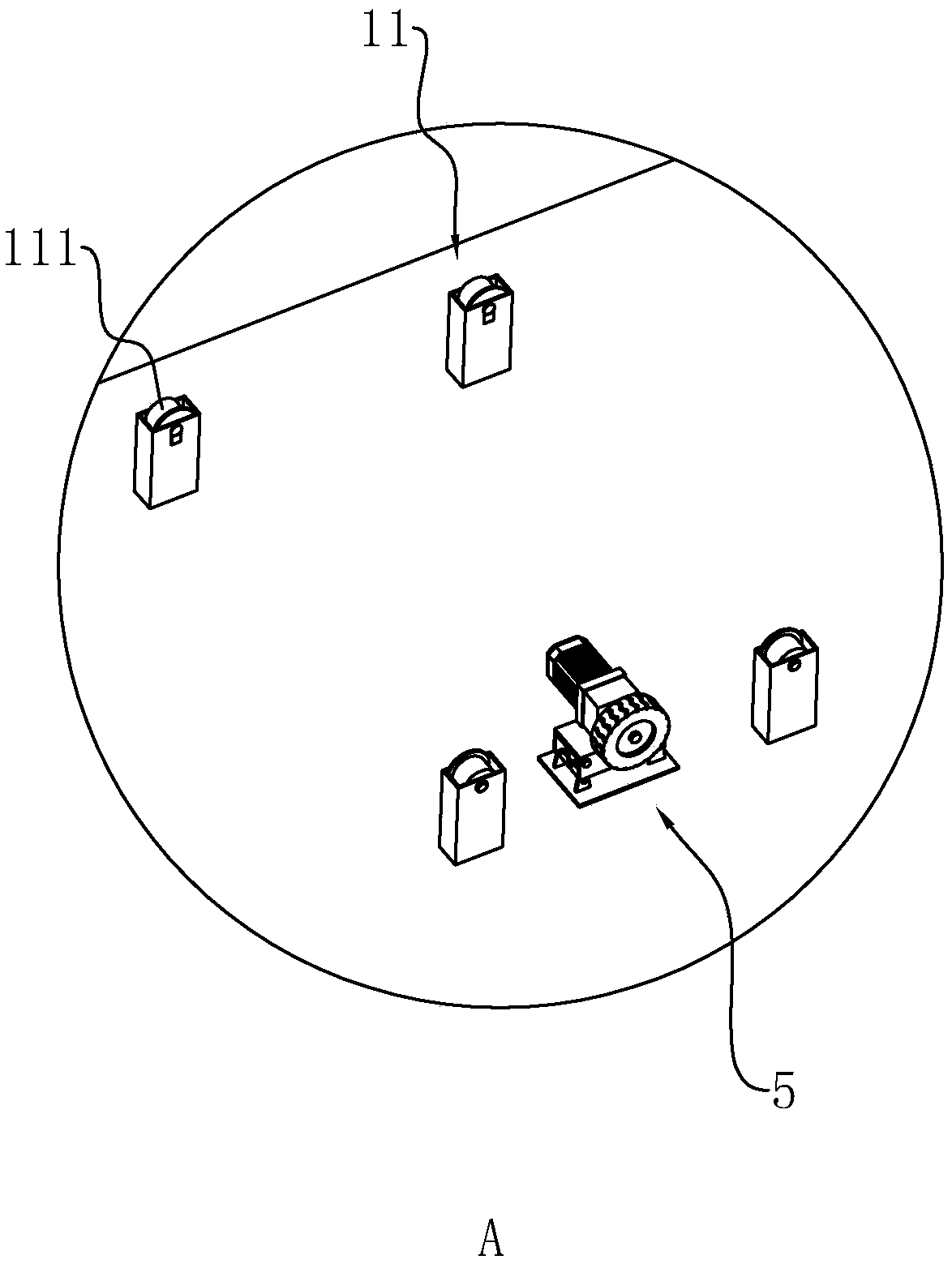

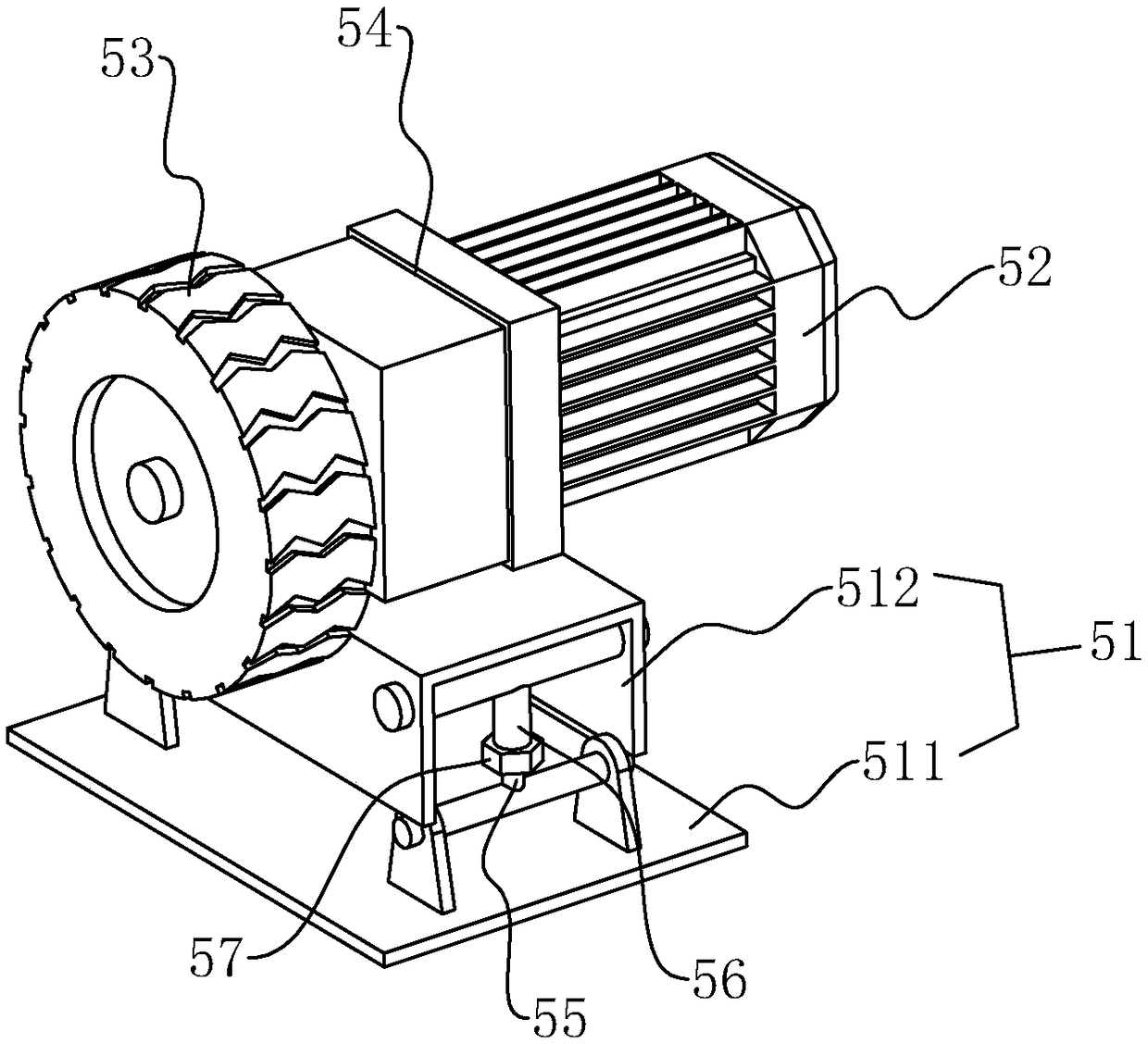

[0033] See attached figure 1, a prefabricated component production system, including a main production line 1, on which multiple groups of steel formwork tables 4 can be set at intervals; in actual production, the same or different molds can be set on different steel formwork sets 4, each steel The mold platform 4 can be equipped with different staff members, and each group of staff can complete the preparatory work before pouring such as cleaning, line drawing, formwork support and binding steel bars on the steel mold platform 4 successively. At the same time, the main production line 1 is also provided with a main feeding device 5 for driving the linear feed of each steel mold table 4; when the preparation work before pouring on each steel mold table is completed, the main feeding device 5 can drive each steel The mass formwork platform 4 moves to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com