Double hard panel polyurethane composite insulation board production line

A composite thermal insulation and production line technology, which is applied in the field of double-hard panel polyurethane composite thermal insulation board production line, can solve problems such as not easy alignment, unstable quality, and time-consuming, so as to reduce labor intensity, improve production quality, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

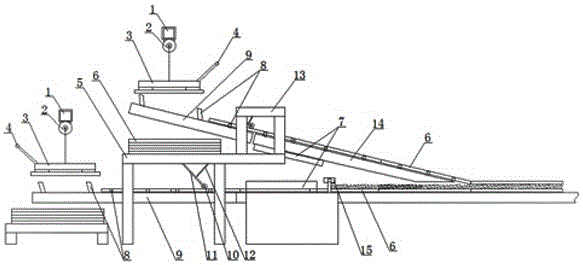

[0021] Such as figure 2 Shown: the production line of polyurethane composite thermal insulation board with double-hard panels of the present invention comprises a sheet material feeding mechanism, a sheet material conveying mechanism and a coating mechanism 15, and the coating mechanism 15 is a moving nozzle that reciprocates laterally along the conveying direction of the material conveying mechanism, so The feeding mechanism includes an upper plate feeding mechanism and a lower plate feeding mechanism. The upper plate feeding mechanism and the lower plate feeding mechanism both include a transverse guide rail 1, and the guide rail 1 is located above the rear end of the plate conveying mechanism. The direction is intersected or perpendicular to the conveying direction of the plate conveying mechanism in space. The guide rail 1 is provided with a traveling mechanism that reciprocates along the guide rail 1. The traveling mechanism can be driven by a motor or a slider drawn by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com