A dispersion mill for preparing nanomaterial modified cement

A nanomaterial and dispersing mill technology is applied in the equipment for preparing nano-modified cement and the field of dispersing mill for preparing nano-material modified cement, which can solve the problems such as the inability to realize the co-grinding of nano-materials, and achieve the effect of overcoming serious agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment.

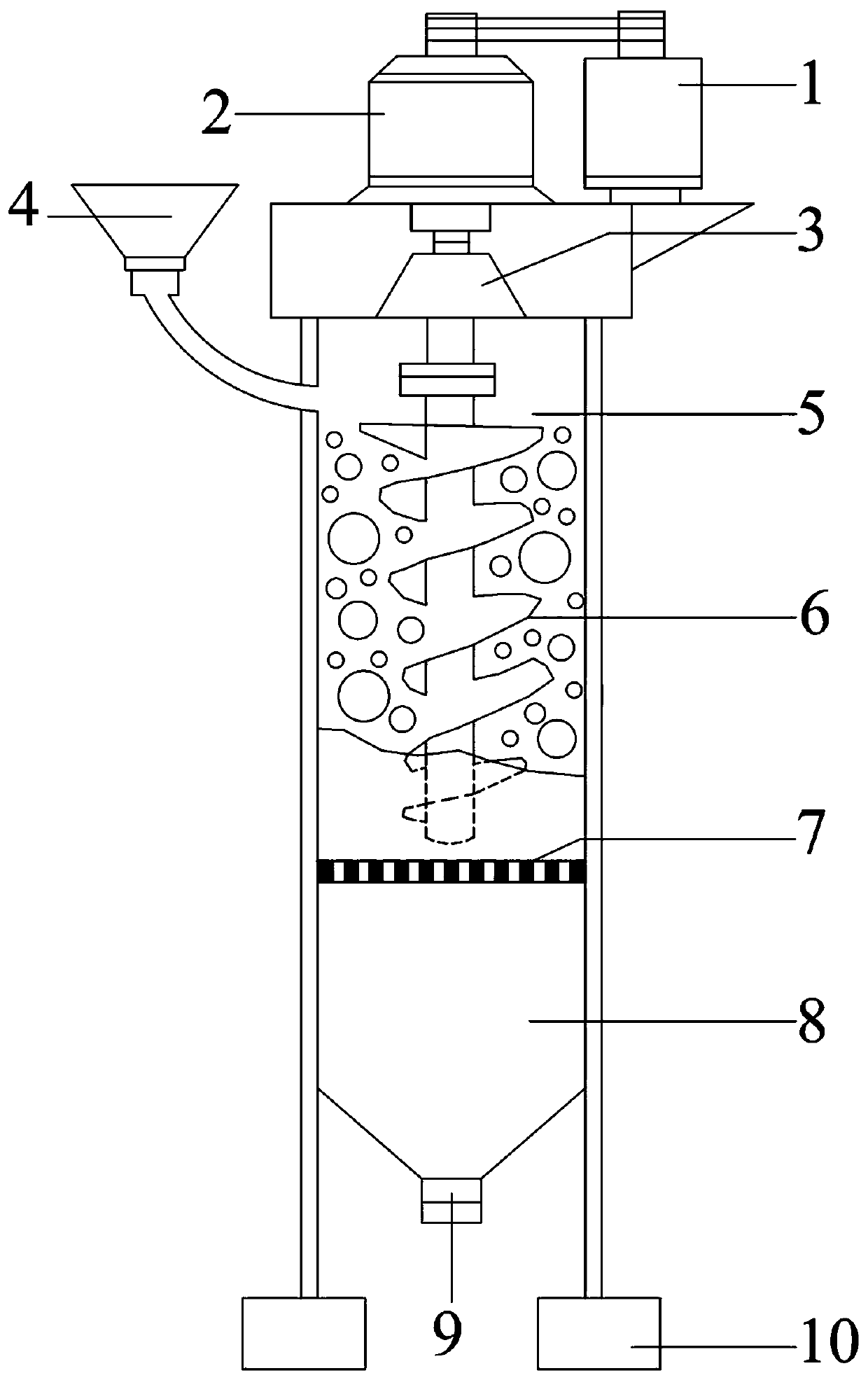

[0032] Such as figure 1 As shown, the dispersion mill for preparing nanomaterial-modified cement in the present invention includes a bin body, an agitator 6 , a motor 1 and a transmission 2 .

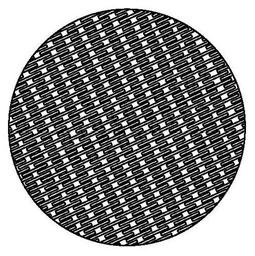

[0033] The bin body is divided into a mixed grinding bin 5 and a collection bin 8 by a grate plate 7, the upper part is a mixed grinding bin, and the lower part is a collection bin.

[0034] Two feeding ports 4 are arranged on the side upper part of the mixing chamber 5 , a bearing seat 3 is arranged at the center of the top cover of the mixing chamber, and the transmission 2 is arranged above the bearing seat 3 . The agitating shaft of the agitator 6 is installed on the bearing seat through bearings, the agitating shaft is connected with the power output shaft of the transmission 2, the driving pulley is set on the motor shaft, the driven pulley is set on the power input shaft of the transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com