Patents

Literature

75results about How to "Guaranteed to run synchronously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

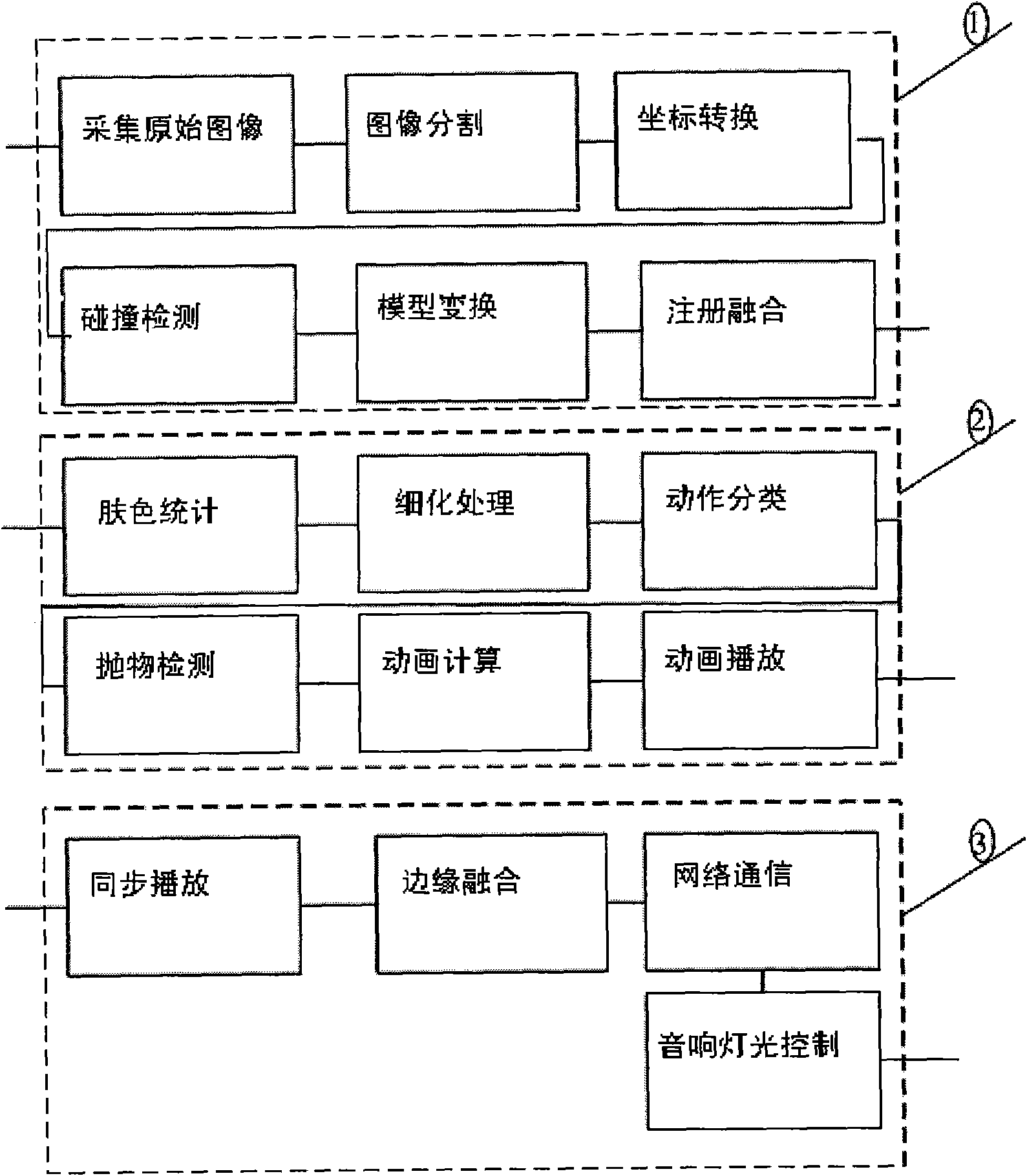

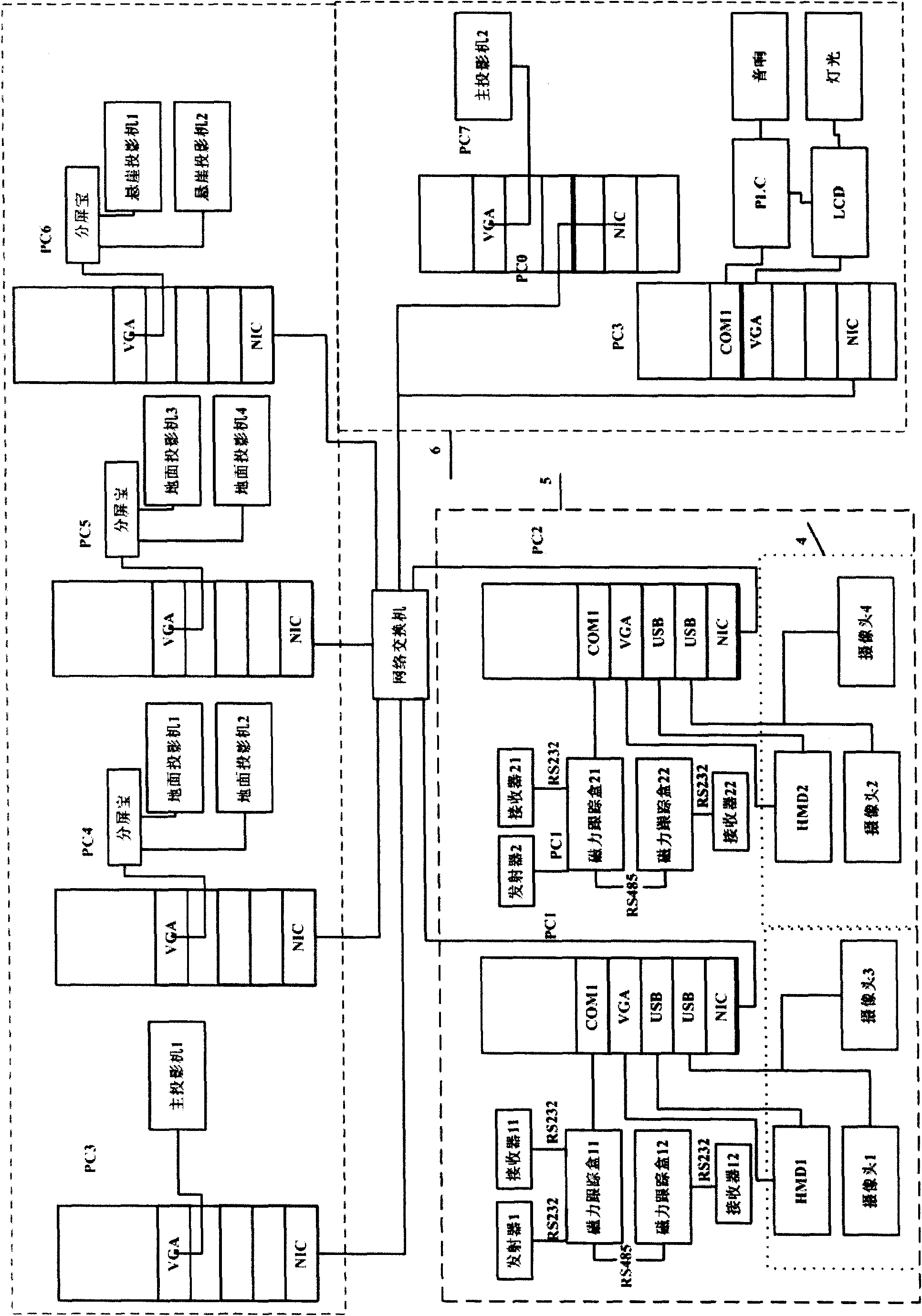

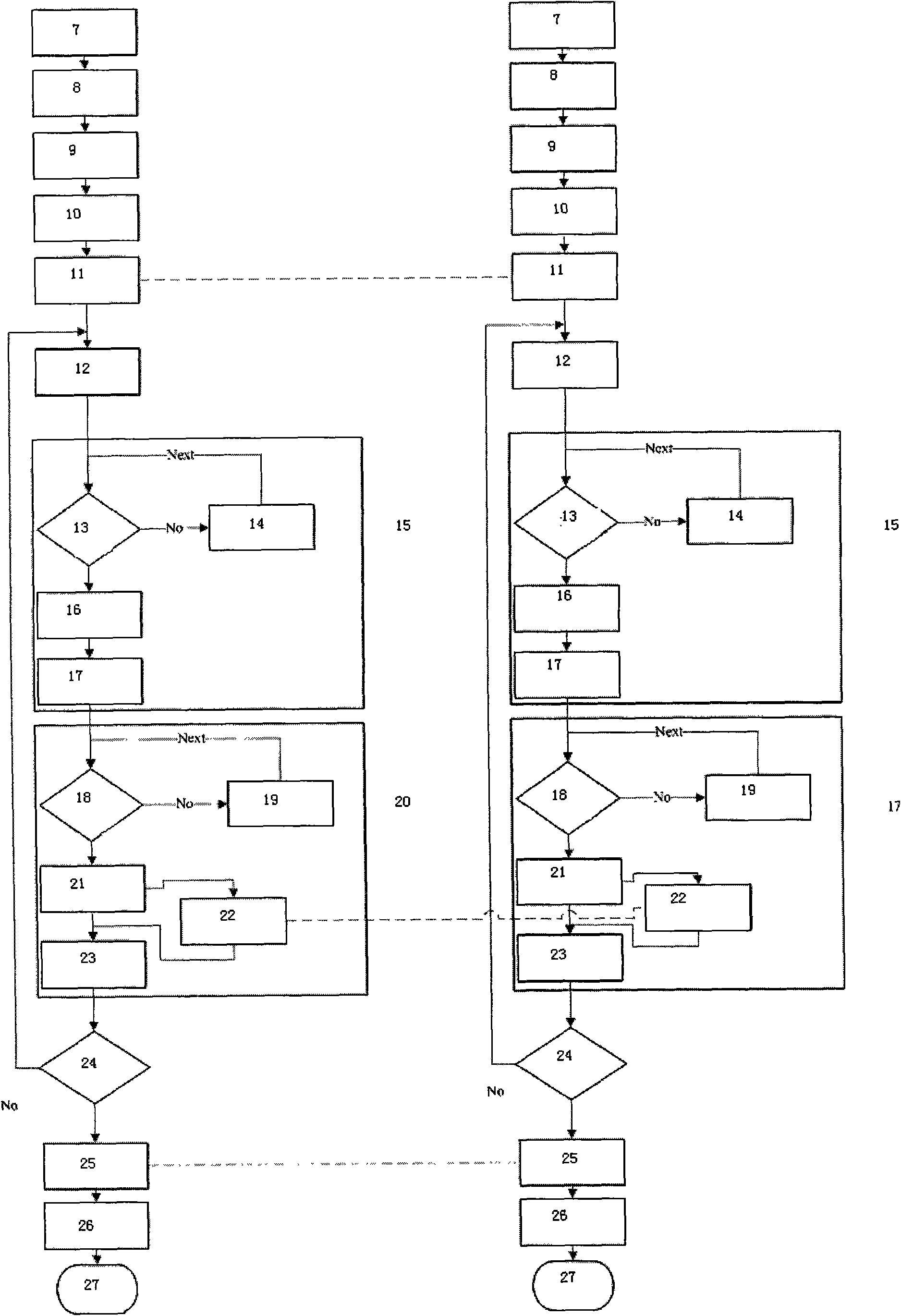

Real time human-machine interaction method and system based on augmented virtual reality and anomalous screen

InactiveCN101539804AStrong real-timeGuaranteed to run synchronouslyInput/output for user-computer interactionAnimationInteractive contentAnimation

The invention provides a real time human-machine interaction method and a system based on augmented virtual reality and anomalous screen. The method comprises the following operation steps: 1) modeling is carried out on virtual objects to be interacted and statistical average hand model ; 2) video acquisition is carried out on hand by N cameras to obtain original image; 3) processing is carried out in a computer. The system comprises a system for realizing real time transparent strengthened display, algorithm and system of real time false or true grasping and parabolic motion detection and real time parabolic animation generating , and real time multi-anomalous screens interactive system. A whole set of large special effect is constructed by various false or true conversion in large anomalous screen scene, three-dimensional animation or three-dimensional image of interactive content expressed in solid spectacles, additionally, video / audio devices, light control devices and the like.

Owner:SHANGHAI UNIV

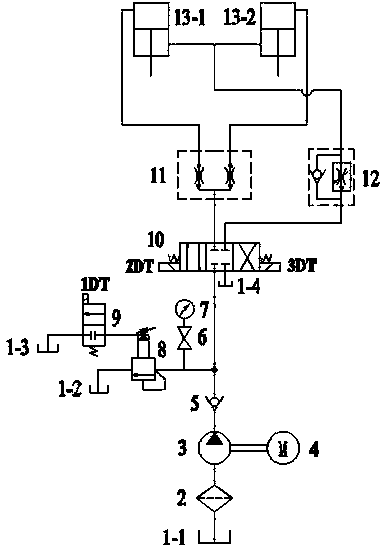

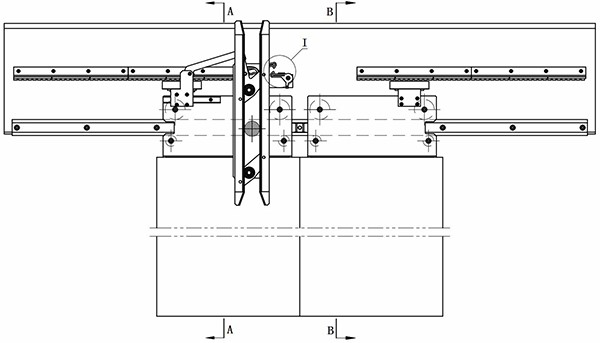

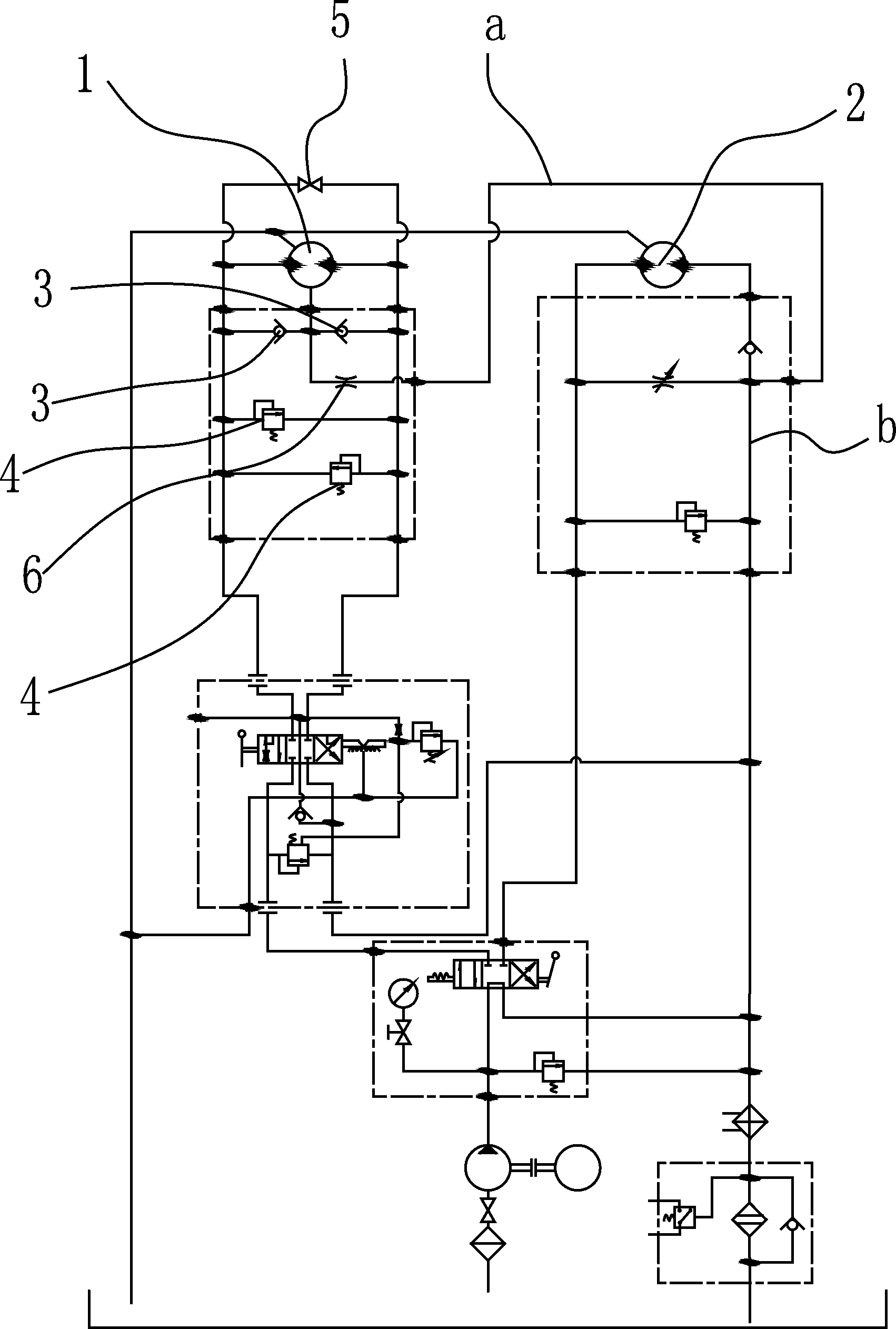

Bending machine hydraulic synchronous system controlled by flow distributing and collecting valve

InactiveCN104006018AGuaranteed to run synchronouslyImprove sync stabilityServomotorsHydraulic cylinderHydraulic pump

The invention provides a bending machine hydraulic synchronous system controlled by a flow distributing and collecting valve. The bending machine hydraulic synchronous system comprises an oil tank, a filter, a hydraulic pump, a motor, a one-way valve, a pilot-operated overflow valve, a two-position two-way solenoid directional valve, a three-position four-way solenoid directional valve, the flow distributing and collecting valve, a one-way speed regulating valve and hydraulic cylinders. When the hydraulic cylinders of the bending machine are in a pressing fast-feeding state or a pressing work-feeding state, after 2DT power-on pull-in, the left position of the three-position four-way solenoid directional valve is connected, under the action of the hydraulic pump, hydraulic oil enters the flow distributing and collecting valve through the one-way valve and the three-position four-way solenoid directional valve and enters rodless cavities of the hydraulic cylinders with flow equally divided. When the hydraulic cylinders are in a fast return stroke state, after 3DT power-on pull-in, the right position of the three-position four-way solenoid directional valve is connected, and the hydraulic oil in the rodless cavities enters the flow distributing and collecting valve and flows back to the oil tank through a flow collecting valve in an equal flow mode. Flow distributing and collecting functions are respectively achieved in the two directions of an oil path of the hydraulic system of the bending machine, so that synchronous operation of the two hydraulic cylinders in the work-feeding state or the return stroke state is effectively ensured, and synchronization precision is high.

Owner:JIANGSU UNIV +1

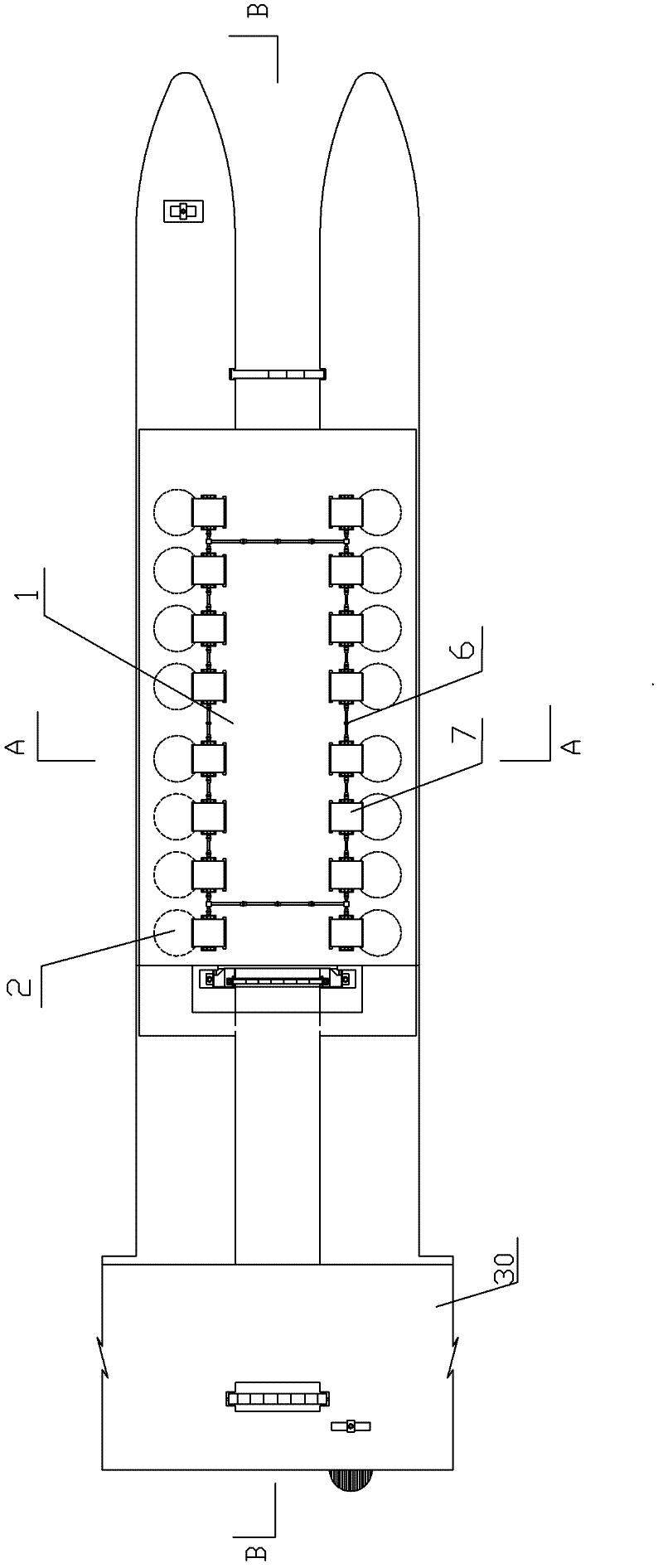

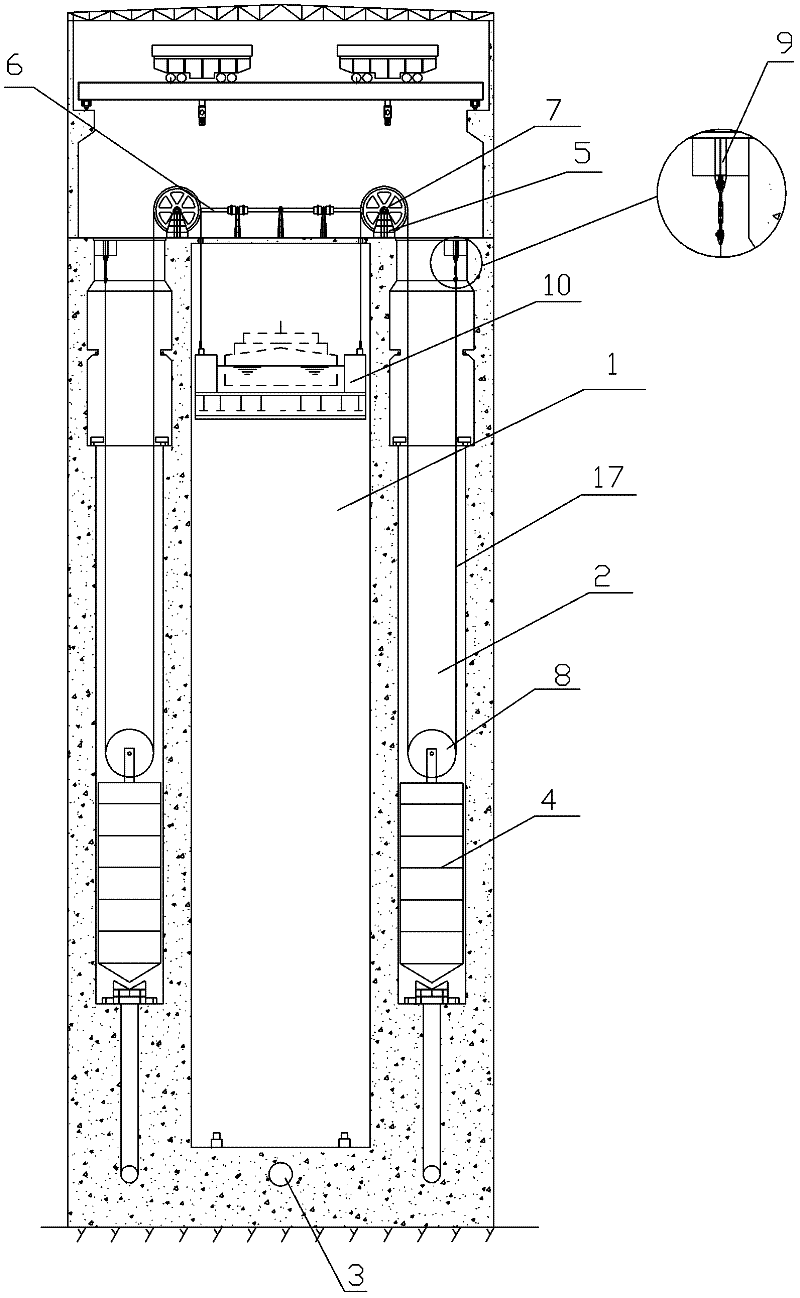

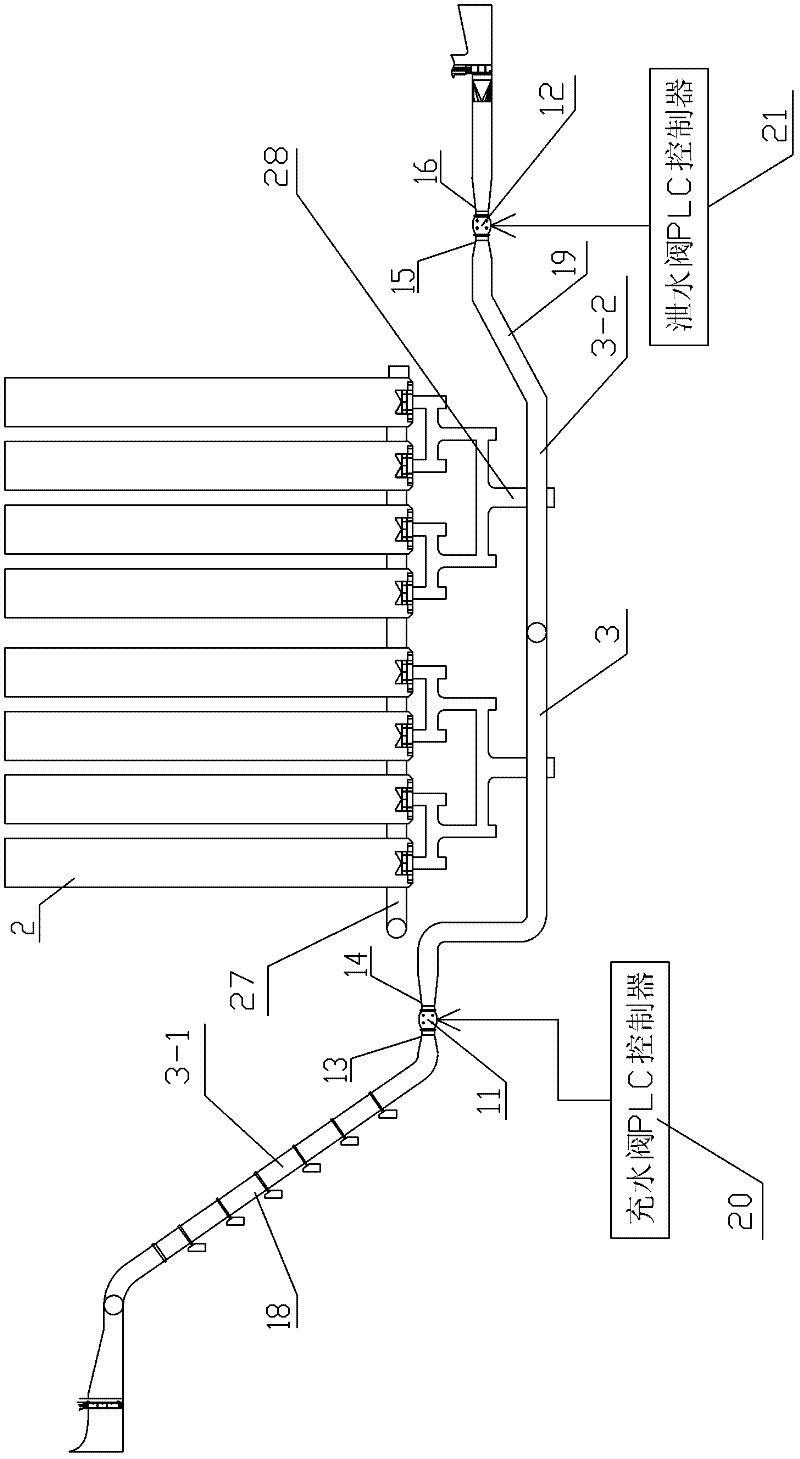

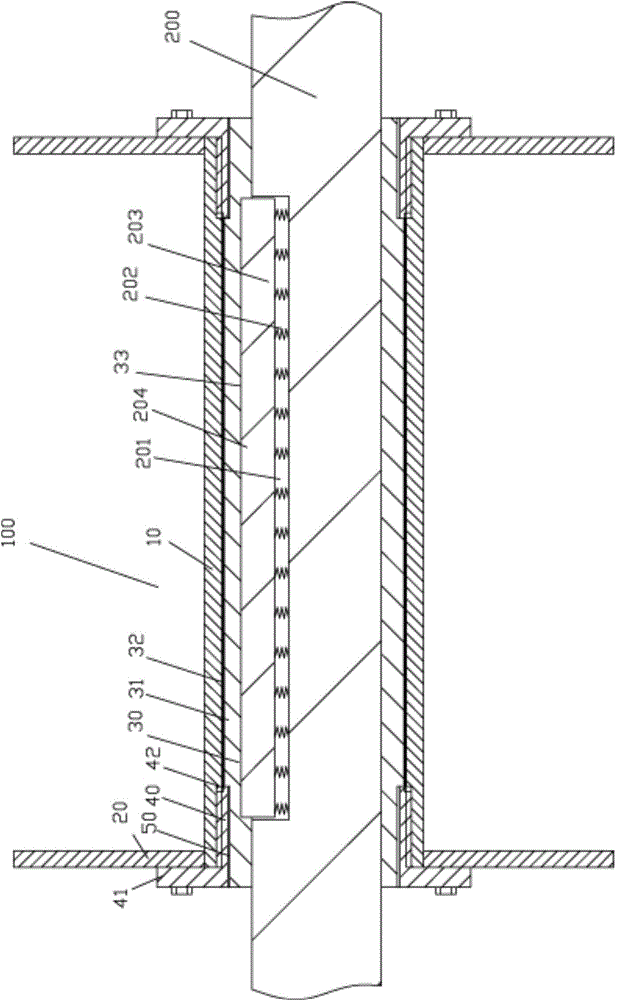

Hydraulic driving system of hydraulic-driven ship lift

ActiveCN102505676AGuaranteed to run synchronouslyUniform tensionVertical ship-liftingMarine engineeringProgrammable logic controller

The invention relates to a hydraulic driving system of a hydraulic-driven ship lift. The hydraulic driving system is provided with a ship lift chamber vertical lifting operation passage. Two axisymmetric rows of floating camel shafts are arranged on the two sides of the passage. The lower end of each floating camel shaft is communicated with a main pipe through an equal-inertia conveyance system. A filling valve and a drain valve are respectively arranged at the upstream and the downstream of the main pipe. A counter weight floating camel is arranged in each floating camel shaft. A rectangular synchronous driving shaft is arranged at the top of the ship lift chamber operation passage. A steel wire rope hoisting mechanism is arranged among each counter weight floating camel, the rectangular synchronous driving shaft and the ship lift chamber. The filing valve and the drain valve are intelligent control valves which are the most advanced at preset. The filled flow and the drained flow of the filling valve and the drain valve are respectively controlled by a filling valve programmable logic controller (PLC) and a drain valve PLC. A closed-loop control system for detecting and controlling the filled flow and the drained flow is formed. At the same time, each of the filling valve and the drain valve adopts a one-main two-auxiliary structure to enable the control of the filled flow and the drained flow and the stopping position of the ship lift to be more precise.

Owner:XIAN AEROSPACE AUTOMATION

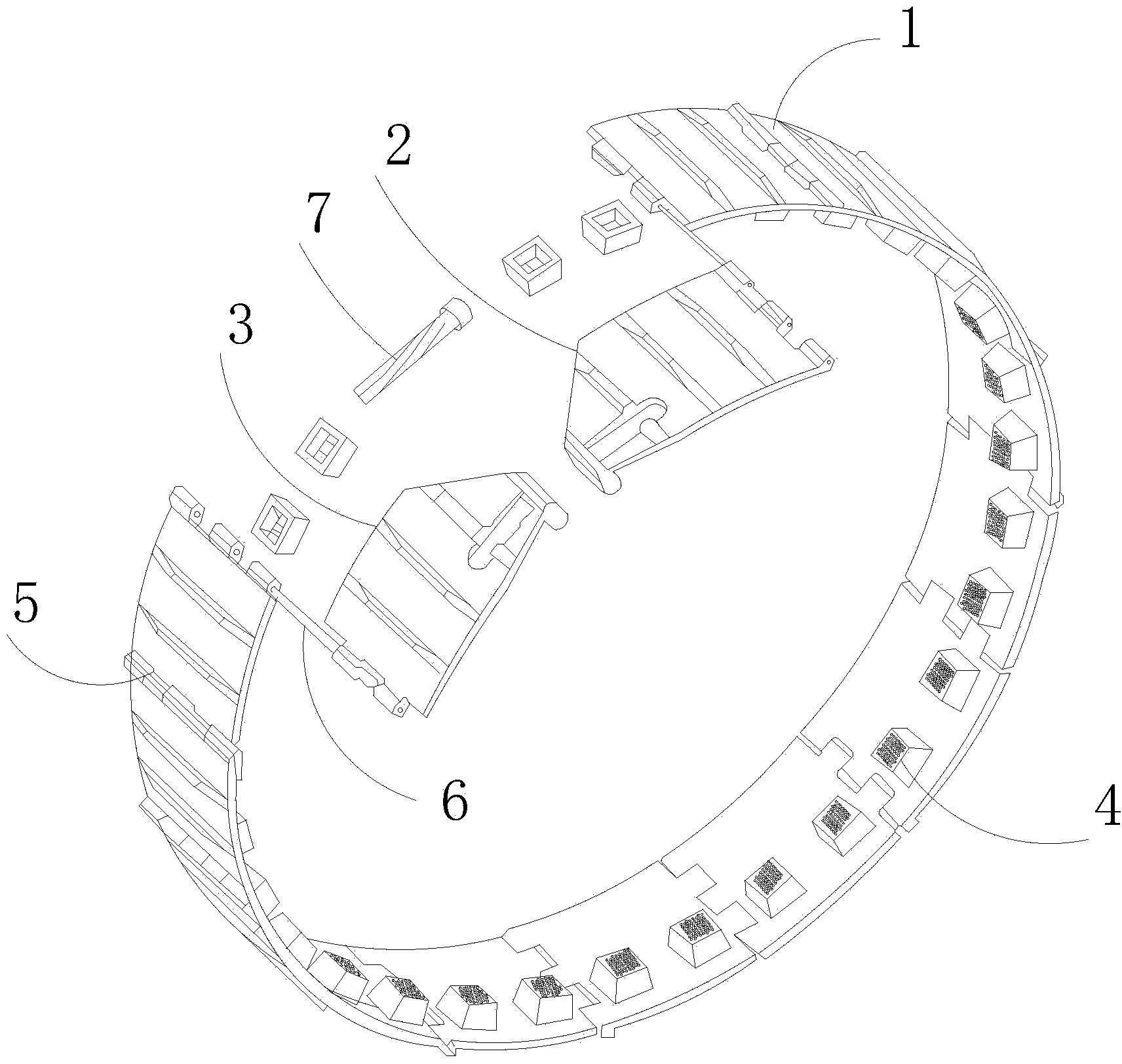

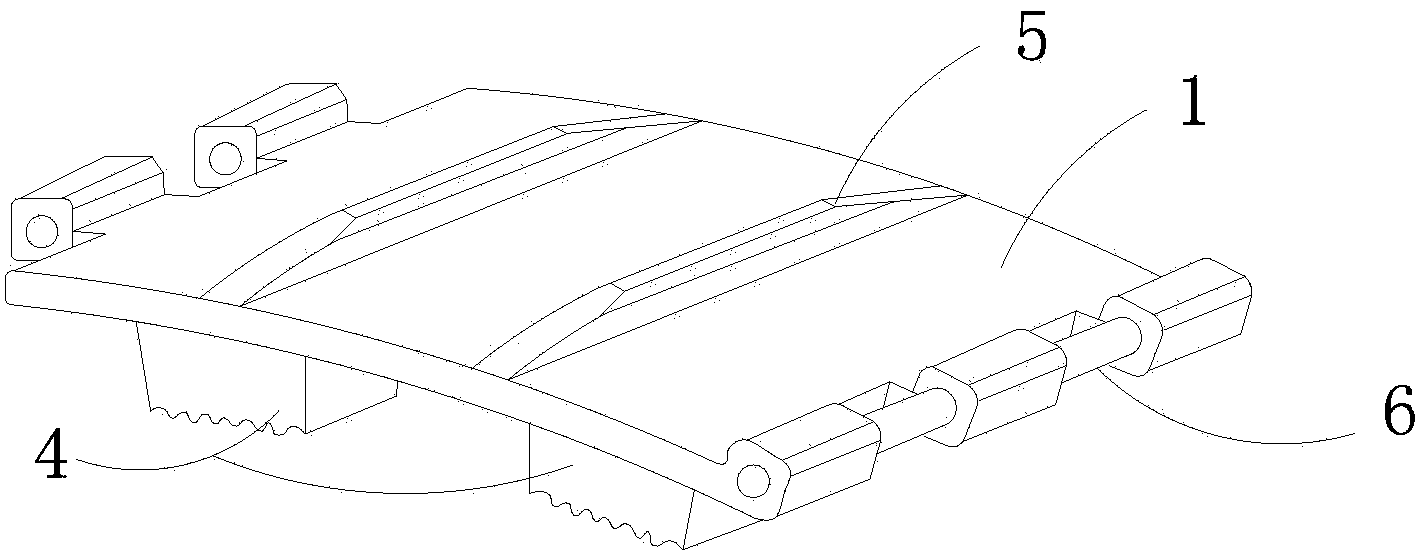

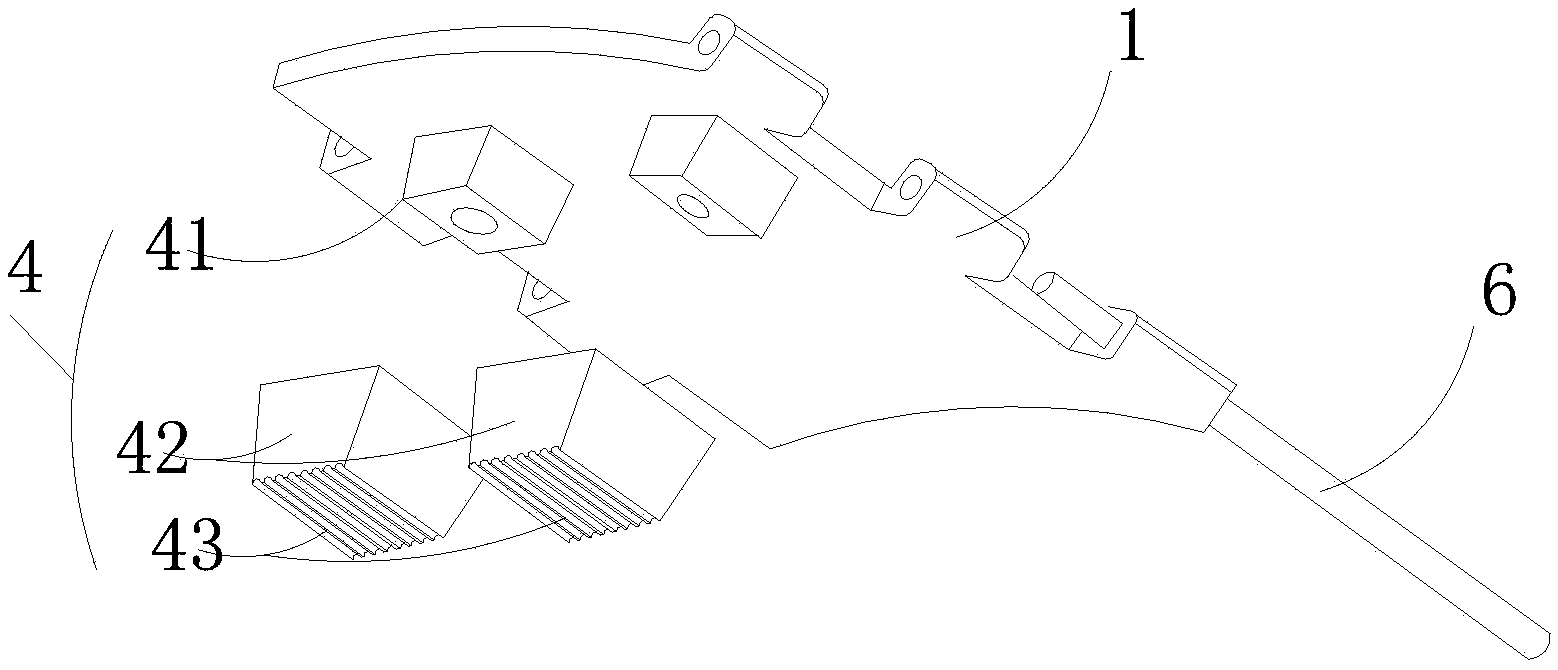

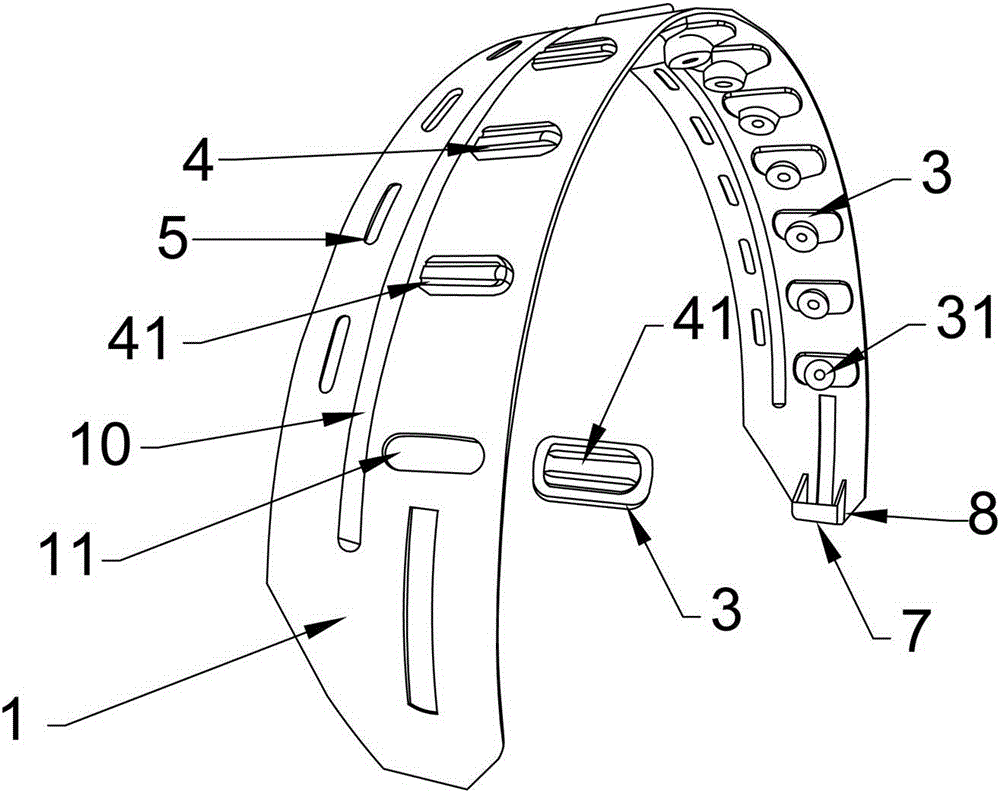

Hinge type flat tire emergency support device

ActiveCN103722989ASolve the problem that the tire cannot be effectively supportedReasonable structureTyre partsEngineeringFlat tire

The invention provides a hinge type flat tire emergency support device, and can be used for solving the problem that the structure of the support device is unreasonable, the tire is not effectively supported after flat tire. The hinge type flat tire emergency support device comprises a plurality of belt bodies, a first connecting head, a second connecting head and a plurality of support devices, wherein the adjacent two belt bodies are movably connected; one end of the first connecting head is movably connected with the belt bodies, one end of the second connecting head is connected with the belt bodies, and the other end of the second connecting head is connected with the first connecting head; the plurality of support devices are respectively arranged on radial inner surfaces of the plurality of belt bodies and are used for supporting the plurality of belt bodies after flat tire so as to support the tire; a chain belt device for connecting with the first connecting head, a second connecting head and the plurality of belt bodies is sleeved with a felly. The hinge type flat tire emergency support device provided by the invention has the advantages that the structure is reasonable, the installation and disassembly are convenient, the hinge type flat tire emergency support device after installing is contacted with the groove bottom of the rim in an inosculation manner, the control of the rim is guaranteed, and the safety factor after the flat tire is improved.

Owner:山东泰斯福德科技发展有限公司

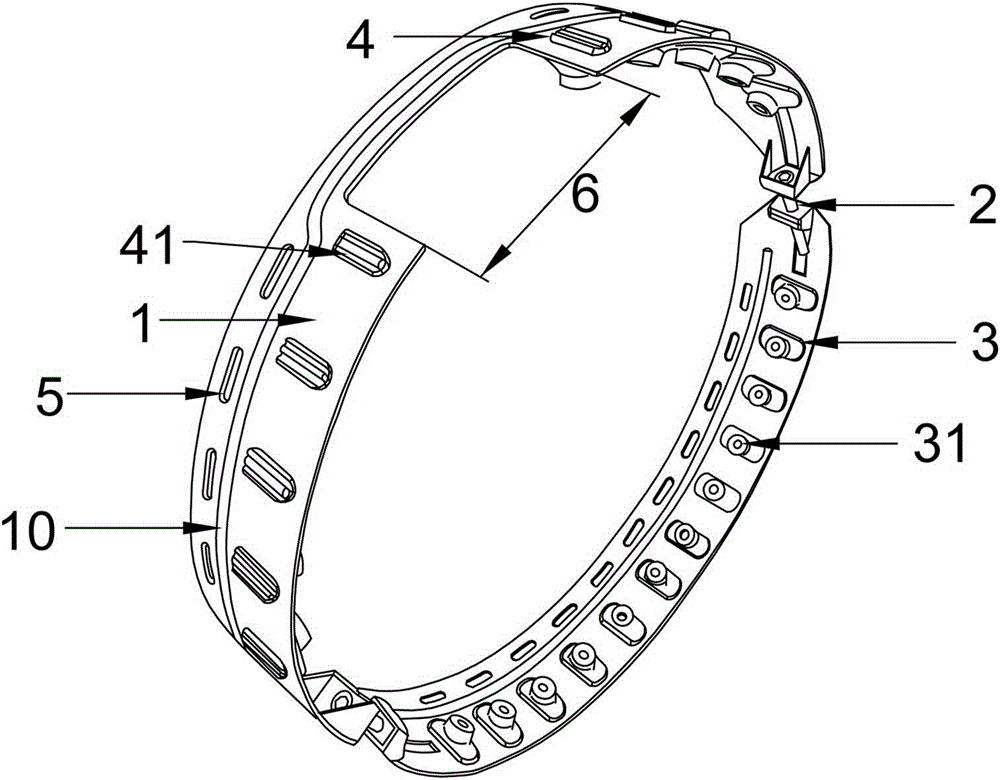

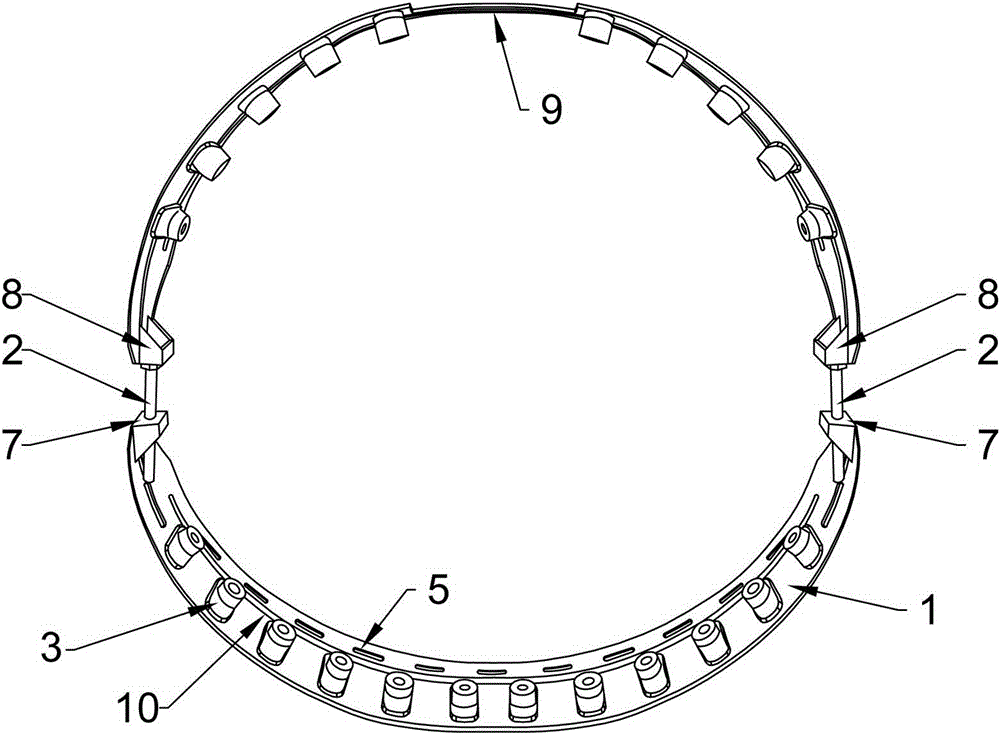

Emergency safety device for car tire explosion

InactiveCN105329048AGuaranteed to run synchronouslyEasy to replaceTyre partsTraffic accidentEngineering

The invention discloses an emergency safety device for car tire explosion. The safety device comprises a circular ring composed of at least two annular support bands, the adjacent ends of every two adjacent annular support bands are connected through an adjustable fastening part, and the annular support bands are installed in wheel grooves of wheel rims to be used; the radial inner surface of each support band is provided with a plurality of support cushion blocks which are evenly distributed, the inner end surface of each support cushion block is in a regular shape, and horizontal surfaces or oblique surfaces with the 10-degree oblique angles serve as the inner end surfaces; the radial outer surface of each support band is provided with a plurality of tooth-shaped engaging strips, the outer surfaces of the tooth-shaped engaging strips are provided with engaging teeth, and when the emergency safety device is used, the tooth-shaped engaging strips are closely engaged with the inner wall of a tire. According to the emergency safety device for car tire explosion, the structure is reasonable, assembling and disassembling are convenient, the tire and the wheel rims can keep synchronous running in the states of tire explosion or tire gas deficiency, the controllability of a steering and braking system is guaranteed, traffic accidents are reduced, and the traffic safety is improved.

Owner:林春

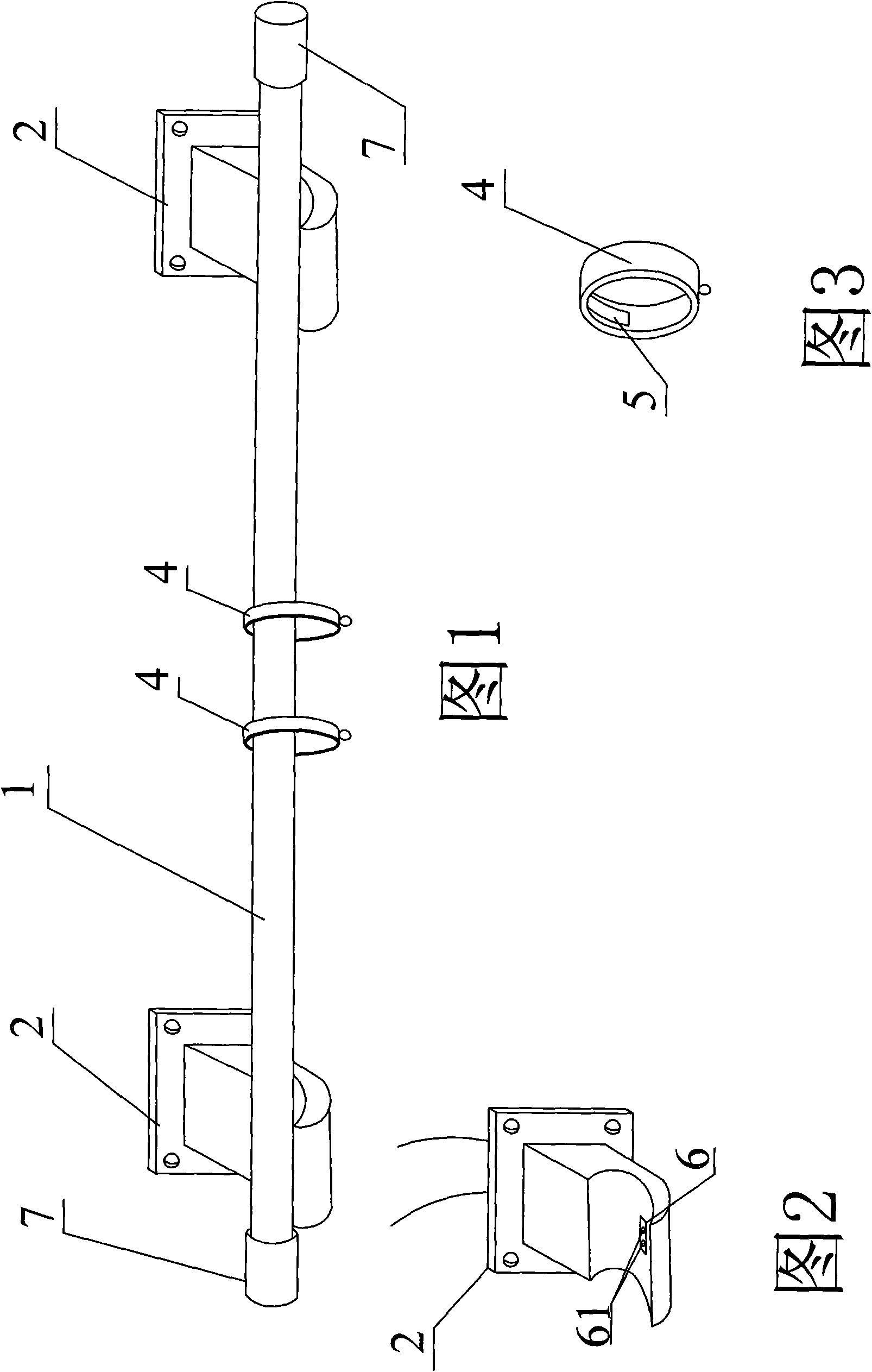

Electric curtain

InactiveCN101983605AReduce weightReduce noiseCurtain suspension devicesCurtain rodsEngineeringGuide tube

The invention discloses an electric curtain which comprises a bracket, a fixed seat, a driving device and a pull ring, wherein the fixed seat is arranged at two ends of the bracket; the bracket is a seamless tube body; the pull ring is sleeved outside the tube body; the driving device is arranged in an inner cavity of the bracket tube body; the driving device comprises two guide rails, two guiders, two speed reducing motors and a constant voltage / constant current power supply, wherein the guide rails are driven by the speed reducing motor to rotate and drive the guiders to travel left and right along the guide rails; a magnet is inlaid on the top surface of each guider; the magnet corresponds to a permanent magnet on the inner surface of the pull ring outside the tube body; the guiders which move left and right attract the pull ring to synchronously move on the tube body; a wiring guide tube is arranged through fixing blocks in the middle and at two ends and the two guiders; and the connection of all circuits is arranged in the wiring guide tube. The invention has the advantages of lower operation noise and compact and esthetic overall appearance, the curtain and a transmission mechanism are synchronously operated, the speed reducing motor uses a DC12V power supply, so that the use safety is ensured, and when the power is cut off, the curtain can be opened and closed by hand.

Owner:王宇

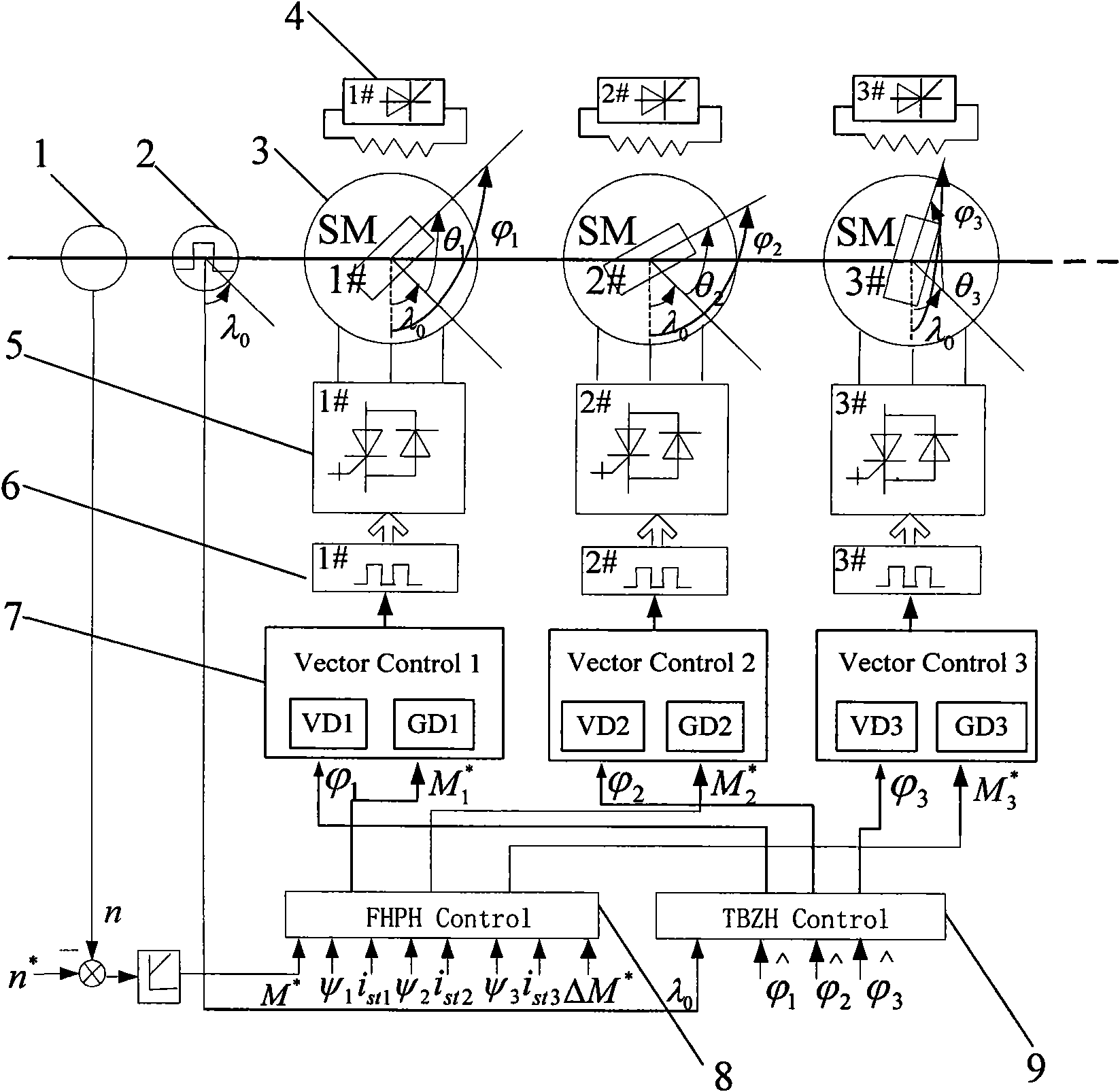

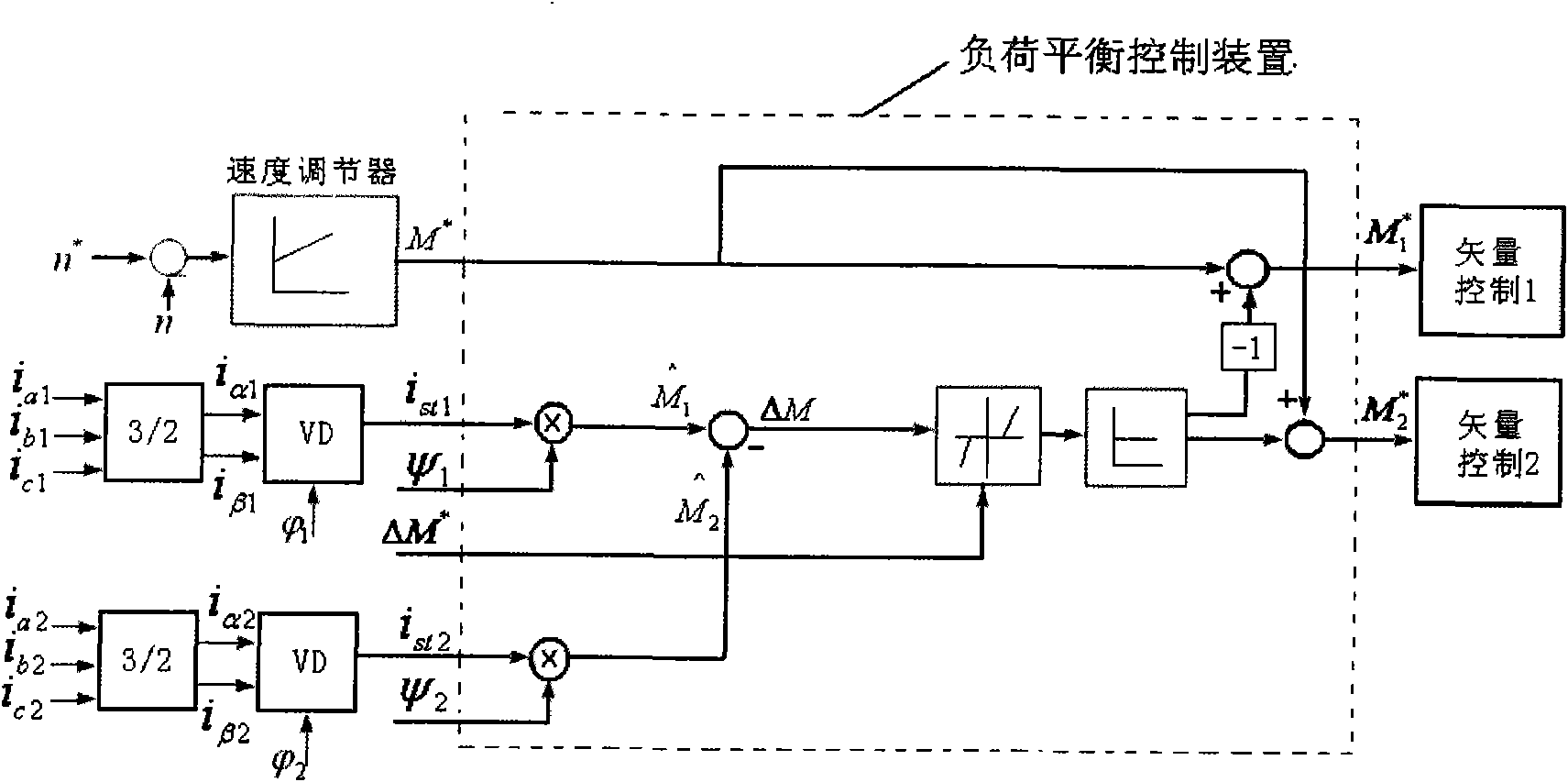

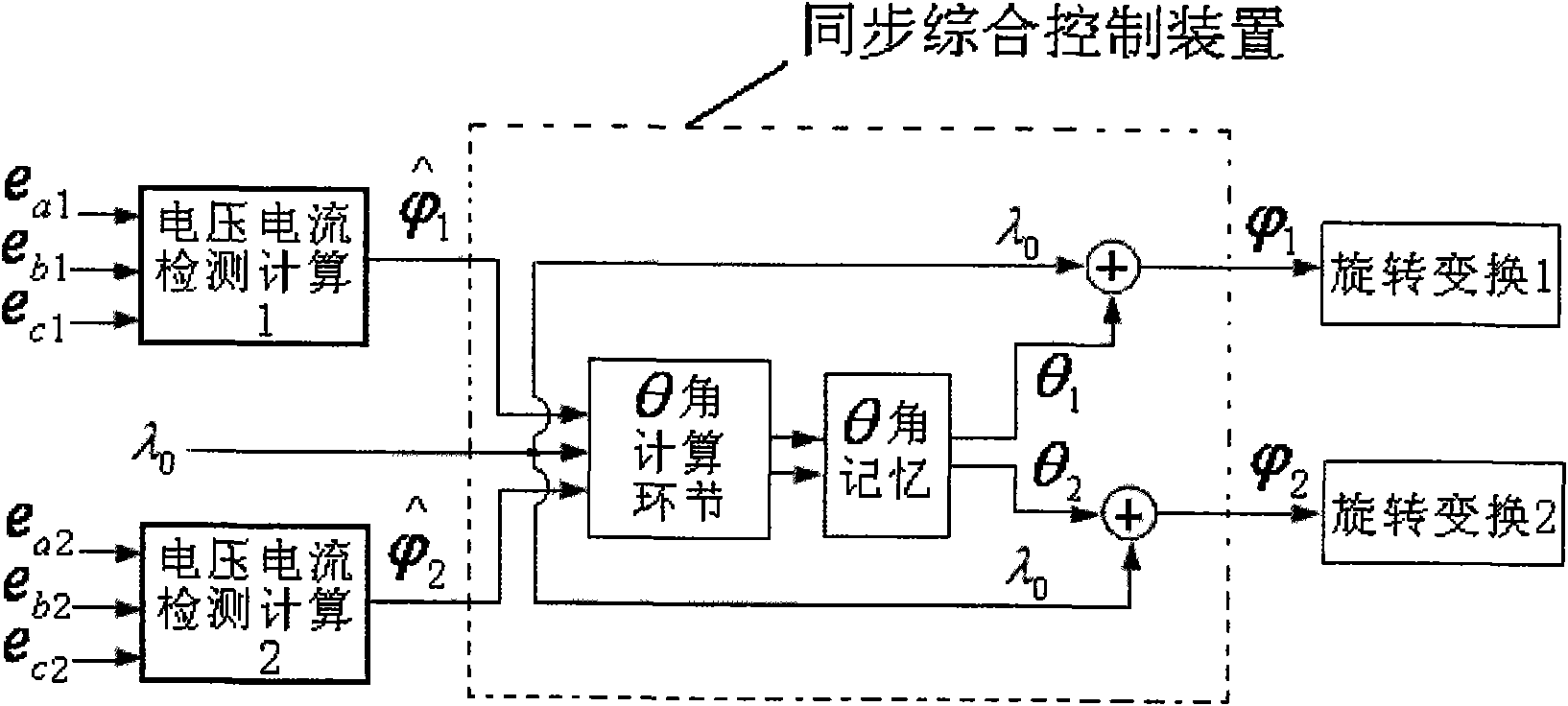

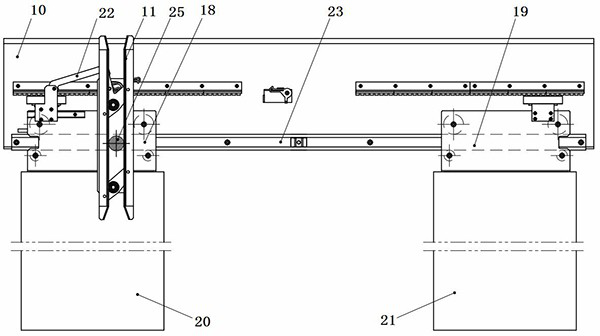

Synchronous and load balancing control system for series operation of a plurality of alternating-current synchronous motors

InactiveCN101577515AEnsure balanceEliminates various problems caused by speed feedback differencesElectronic commutation motor controlAC motor controlFrequency changerSynchronous motor

The invention relates to a synchronous and load balancing control system for the series operation of a plurality of alternating-current synchronous motors, belonging to the technical field of power electron and alternating-current transmission. The synchronous and load balancing control system comprises a speed sensor, a position detector, alternating-current synchronous motors, excitation control devices, transducers, pulse triggering devices, vector control systems, a load balancing control device and a synchronous combination control device and is characterized in that the alternating-current synchronous motors are all coaxially and rigidly connected in series with each other, a shaft is only provided with one position detector and one speed sensor, and the alternating-current synchronous motors are all provided with the independent vector control systems, the independent transducers, the independent excitation control devices and the independent pulse triggering devices. The invention sufficiently utilizes the rapid response characteristics of current loops of the vector control systems and ensures the load balancing and the rapidity among the plurality of coaxial and serial alternating-current synchronous motors.

Owner:BEIJING ARITIME INTELLIGENT CONTROL +1

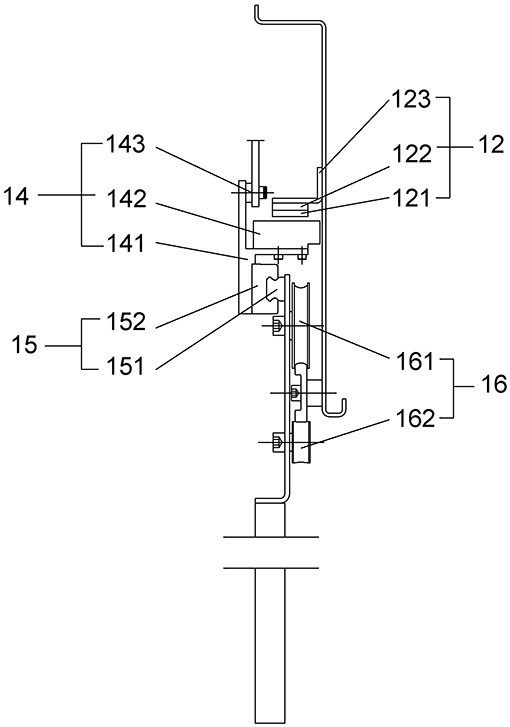

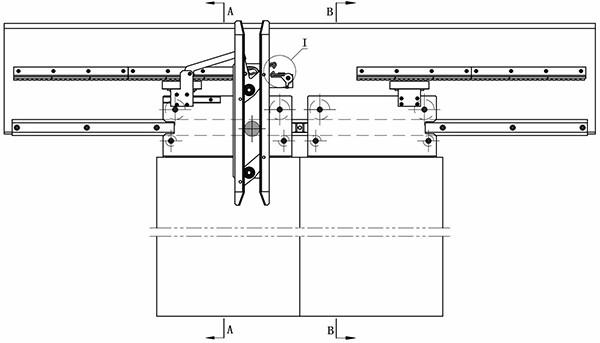

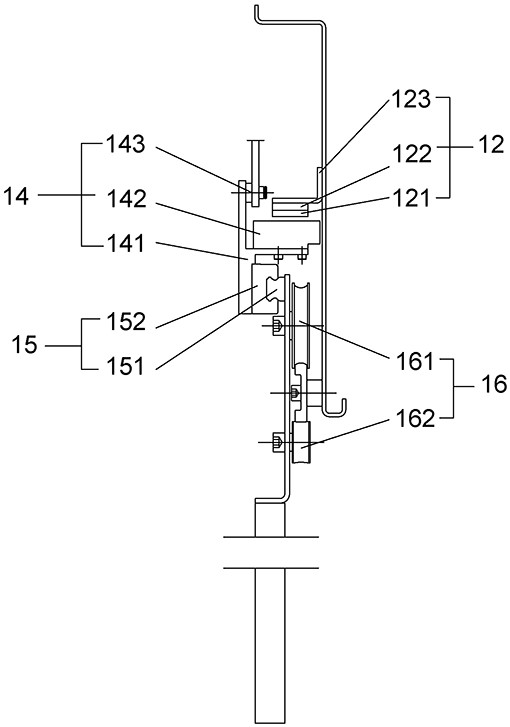

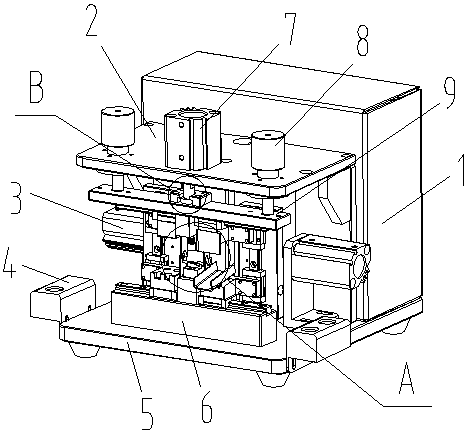

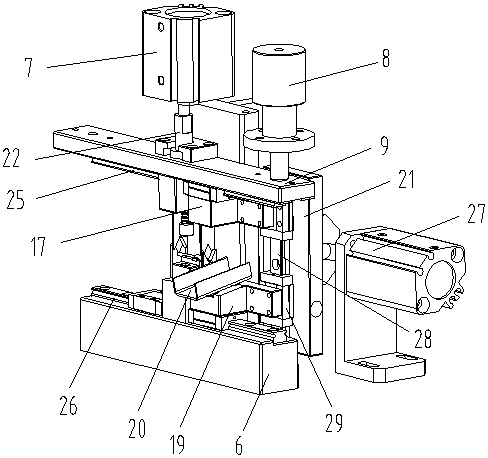

Door motor system based on double linear motors and synchronous motion control method thereof

ActiveCN113023534AGuaranteed to run synchronouslyImprove anti-interference abilityAssociation with control/drive circuitsMultiple dynamo-electric motors speed regulationSynchronous controlControl system

The invention provides a door motor system based on double linear motors and a synchronous motion control method thereof. The door motor system comprises the left linear motor, the right linear motor, a left door plate, a right door plate, a position sensor, a control system and the like. The left linear motor and the right linear motor directly drive the left door plate and the right door plate of a door motor to be opened and closed respectively, and the door motor system has the advantages of being simple in transmission structure, high in efficiency, precision and reliability, space-saving, convenient to maintain and the like. Furthermore, in the aspect of motion control, on the basis that existing double motors are independently controlled by respective controllers, a synchronous controller is additionally arranged, synchronous position error signals of the double linear motors serve as input of the synchronous controller, and then output signals are sent to a main channel of the double linear motors to be adjusted. Therefore, the synchronous operation of the double linear motors is ensured and the anti-interference capability is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

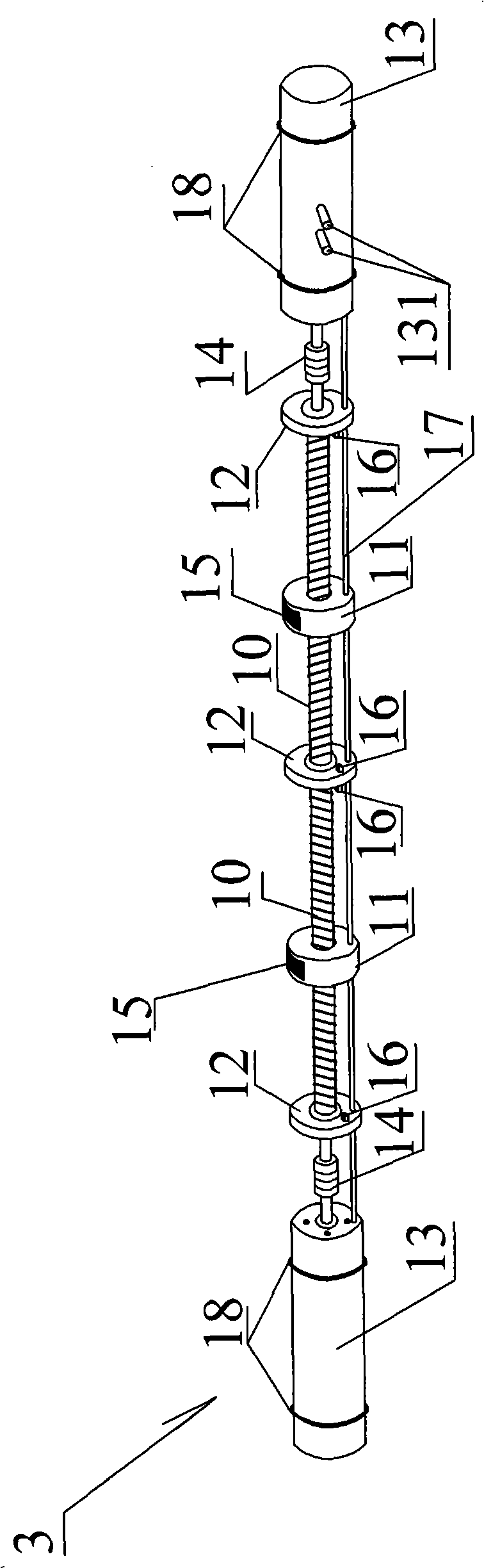

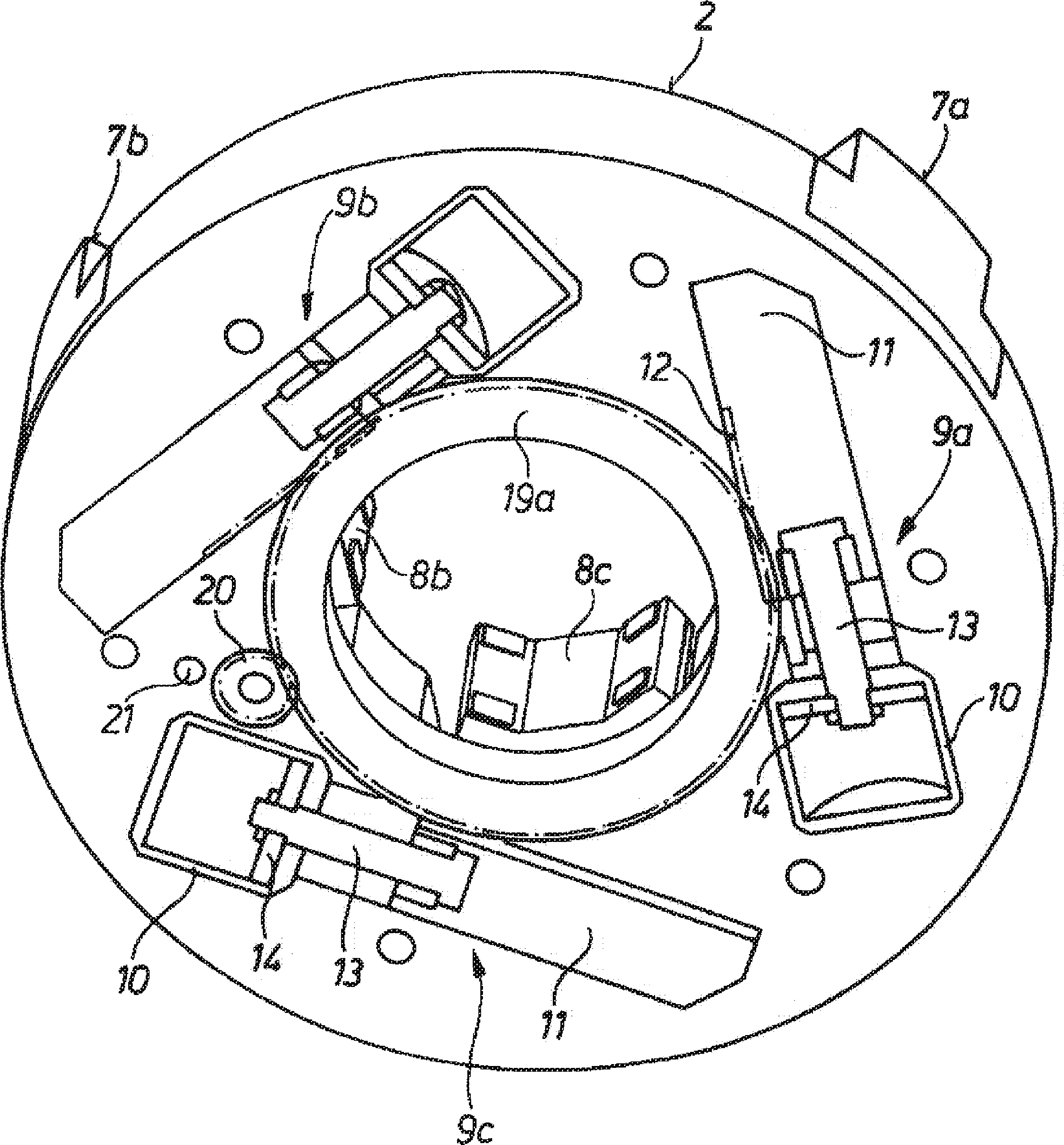

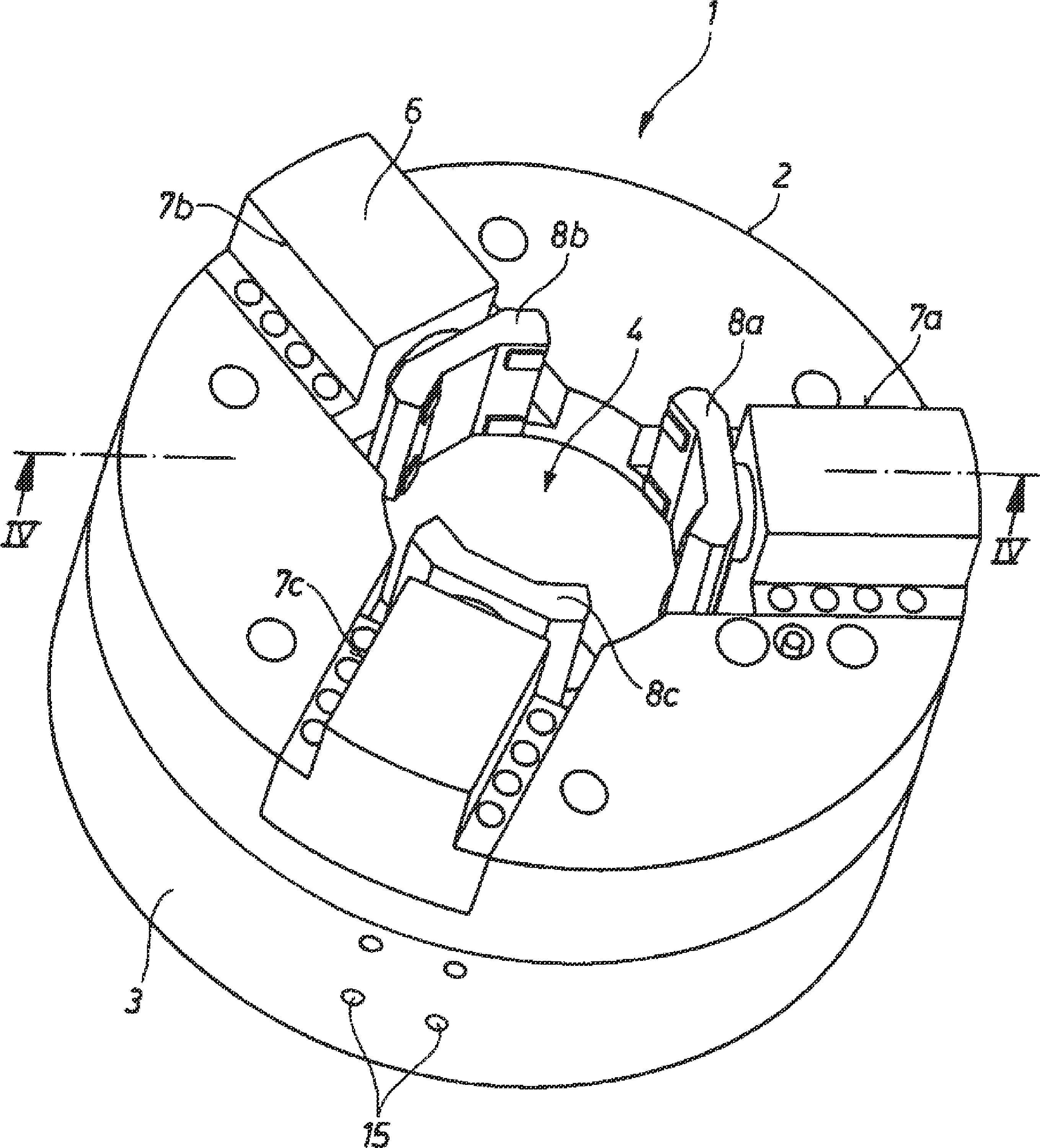

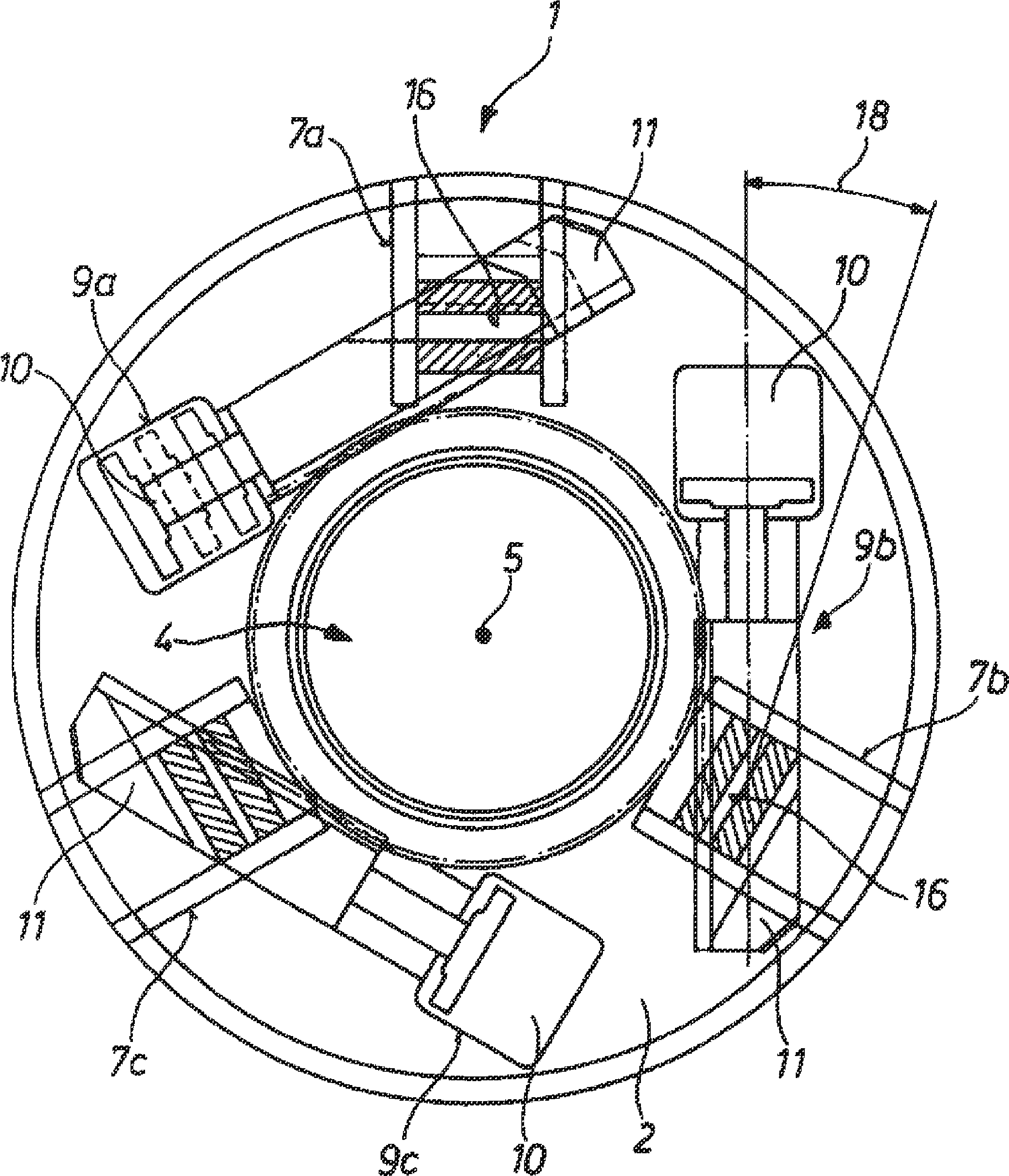

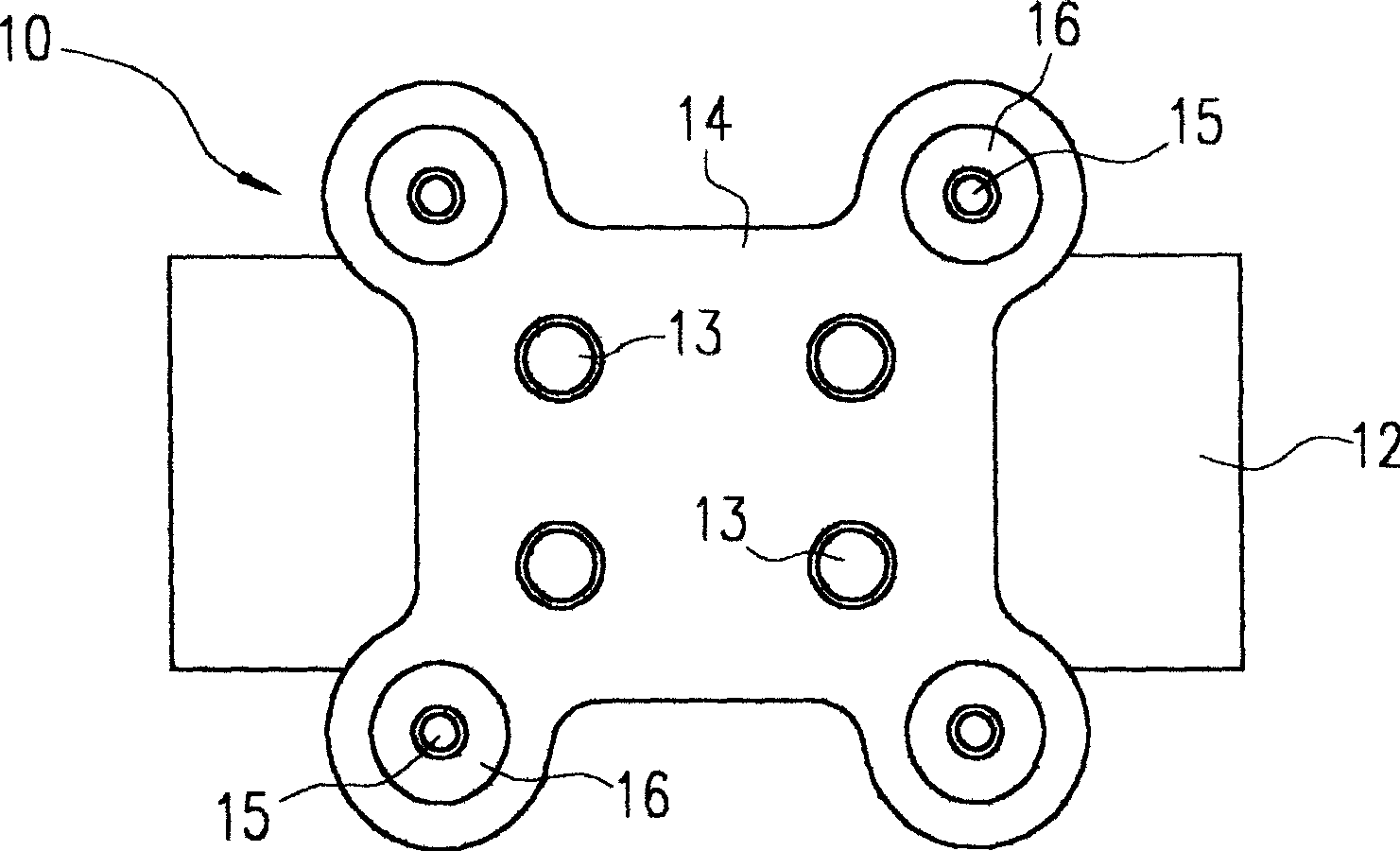

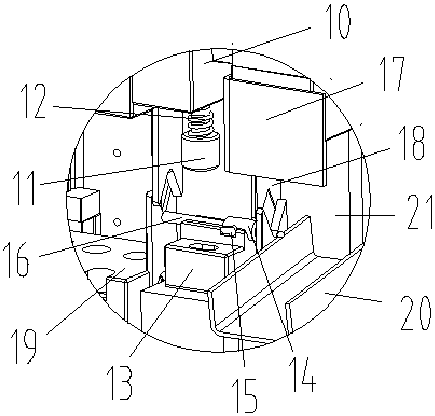

Chuck for a machine tool for machining a tubular, rotating workpiece

InactiveCN103917317AAccurate understandingLight in massSleeve/socket jointsChucksRotational axisCoupling

The invention relates to a chuck (1) for a machine tool for machining a tubular workpiece which rotates about a rotational axis (4) that coincides with the centre of the chuck, comprising at least two chucking slides (7a, b, c) that are designed to be positionable radially with respect to the rotational axis (4) in order to release and chuck the workpiece, are arranged on the end side of and in a manner distributed uniformly around the circumference of a chuck head plate (2), and bear chucking jaws (8a, b, c). The operating characteristics for the central and / or balancing chucking of a tube are improved when each chucking slide (7a, b, c) is assigned firstly transverse slides (9a, b, c) which are provided tangentially to the rotational axis (4) in the head plate (2), are acted upon by an adjusting means and have a slide block (11) formed as a rack (12) on a longitudinal side, and secondly separate toothed wheels (19a, b, c) which mesh with the racks (12), wherein each chucking slide (7a, b, c) is provided on its underside with a driving claw (17) which, in order to deflect the movement of the transverse slide (9a, b, c) in an adjusting movement, extending at right angles to the rotational axis (4), of the chucking slide (7a, b, c), is in engagement with a slot-like guide groove (16) provided in the slide block (11) of the transverse slide (9a, b, c), and wherein the toothed wheels (19a, b, c) are assigned a coupling pinion (20) that can be engaged and disengaged axially with respect to the rotational axis.

Owner:SMS MEER

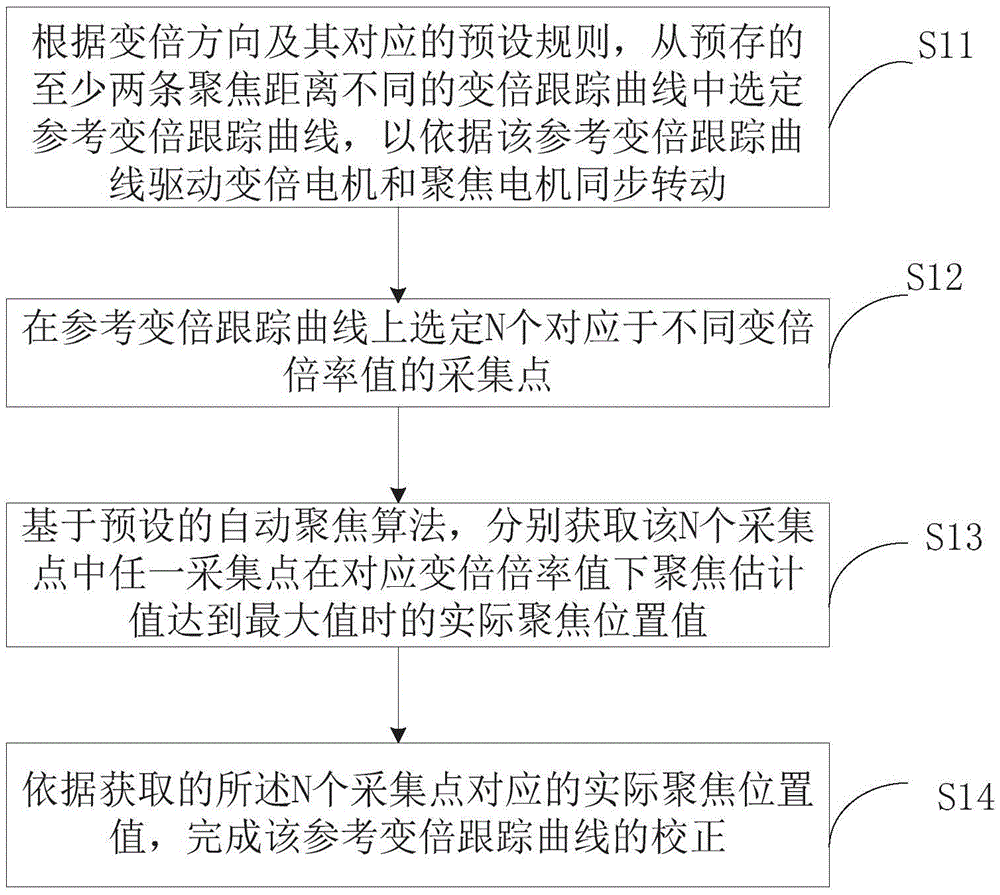

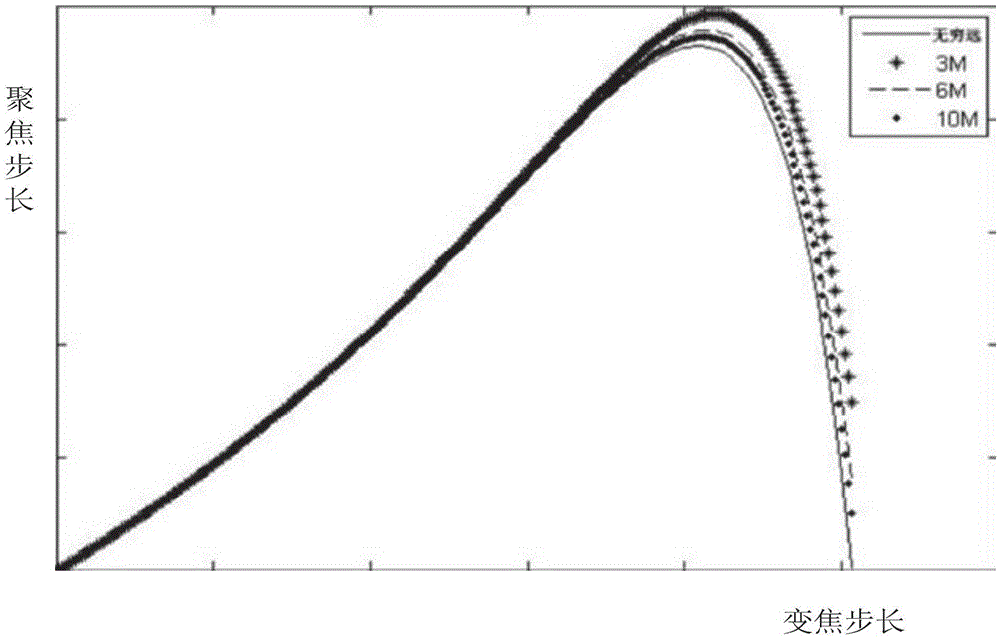

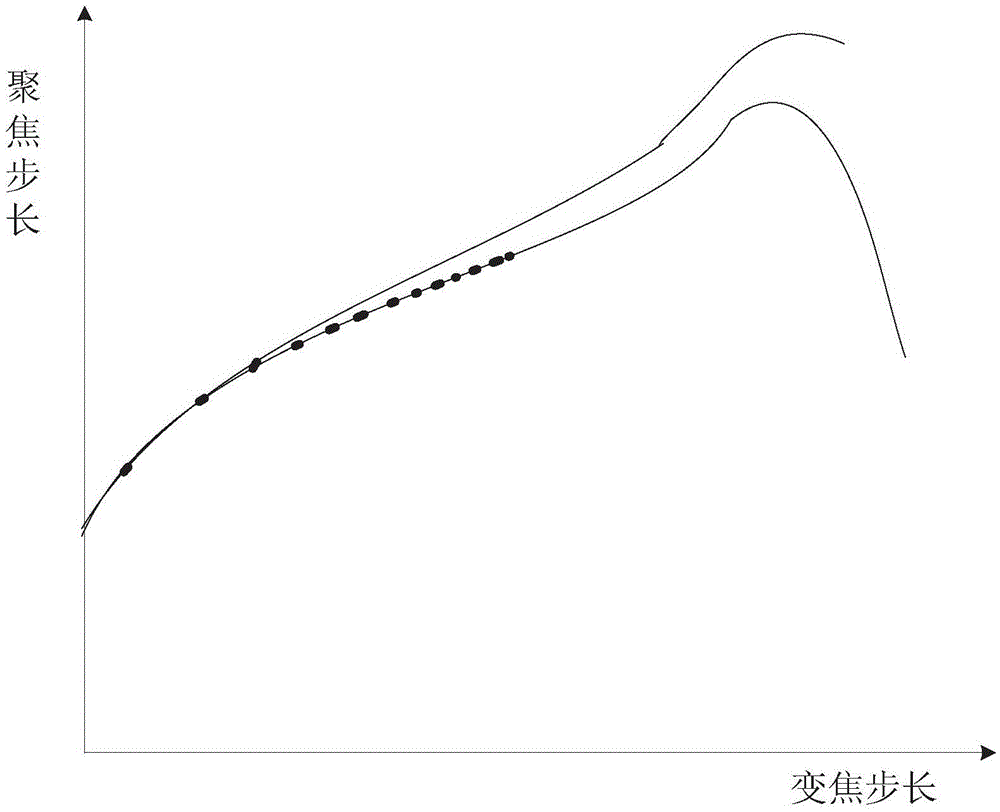

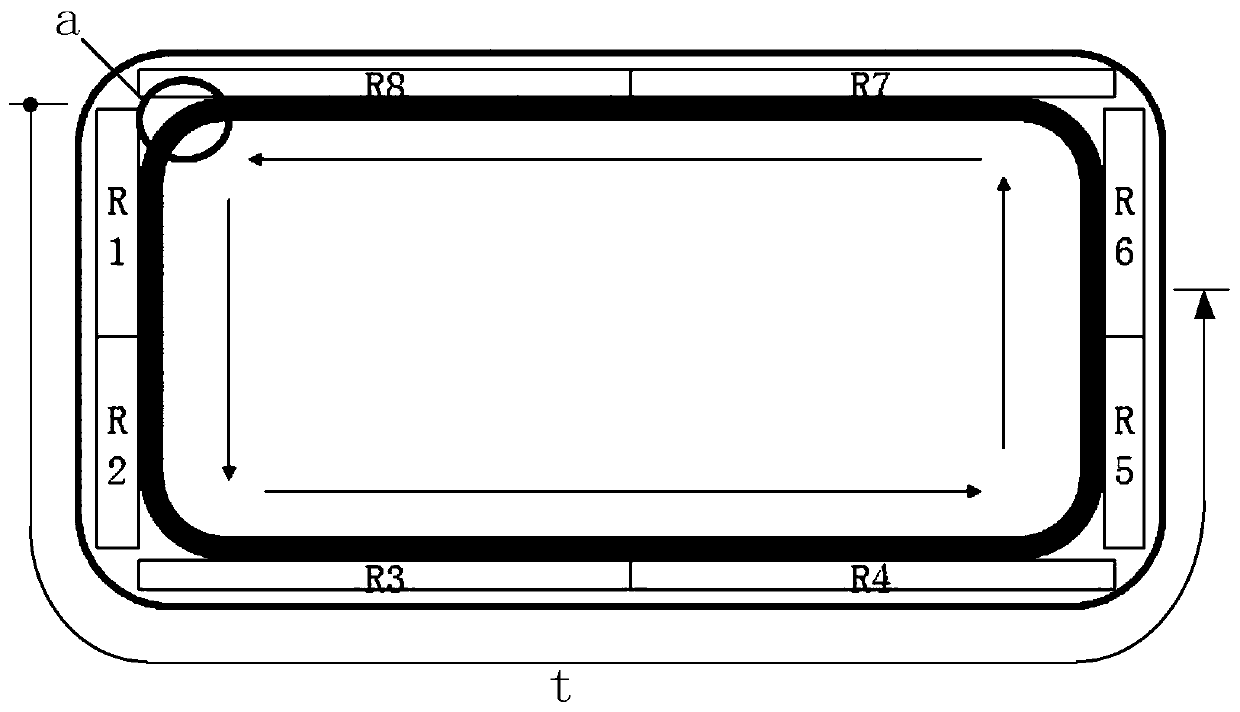

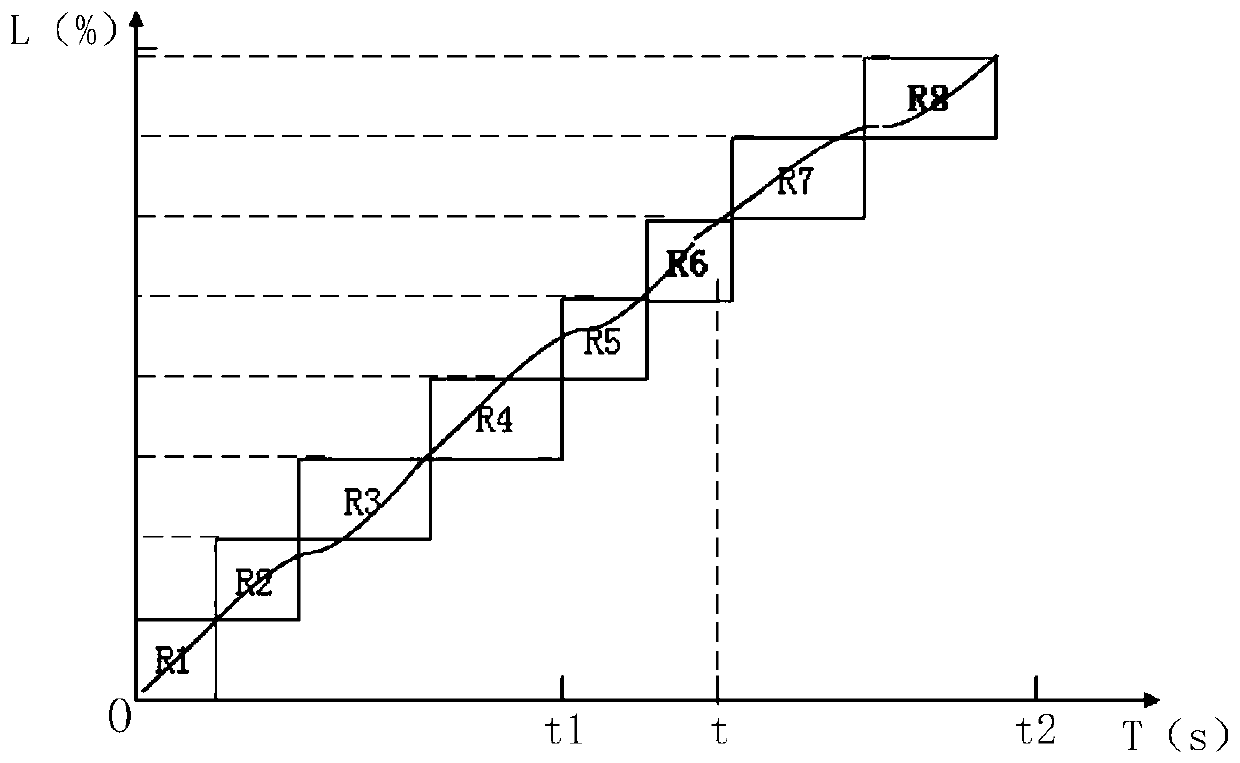

Zoom tracking curve correction method and device

InactiveCN105554387AFocus clearlyGuaranteed to run synchronouslyTelevision system detailsColor television detailsMagnificationCorrection method

The invention relates to the technical field of camera shooting monitor, in particular to a zoom tracking curve correction method and device. The method comprises the following steps: selecting a reference zoom tracking curve from at least two prestored zoom tracking curves with different focus distances according to a zoom direction and a corresponding default rule so as to drive a zoom motor and a focus motor to rotate synchronously with reference to the reference zoom tracking curve; selecting N collection points corresponding to different zoom magnification values on the reference zoom tracking curve; based on a preset automatic focus algorithm, separately acquiring an actual focus position value when a focus estimation value of any one collection point, at the corresponding zoom magnification value, in the N collection points reaches the maximum value; and with reference to the acquired actual focus position values corresponding to the N collection points, completing the correction of the reference zoom tracking curve. Through adoption of the method and the device, an actual zoom tracking curve of each shot can be acquired, so that synchronous operation of follow-up zooming and automatic focus along with the corrected actual zoom tracking curve can be ensured, thereby making the focus of images in a whole zooming process clear.

Owner:BEIJING QIHOO TECH CO LTD +1

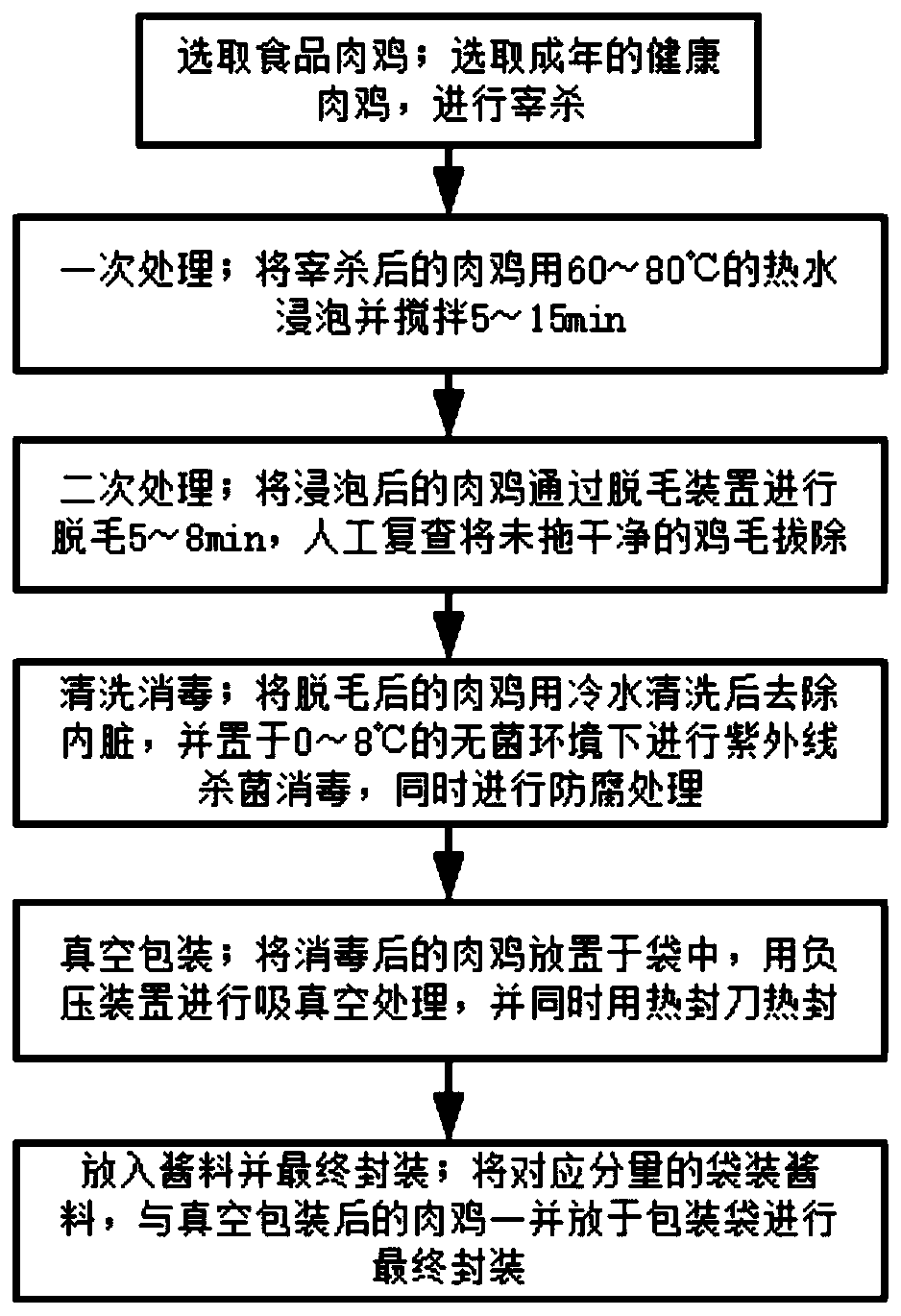

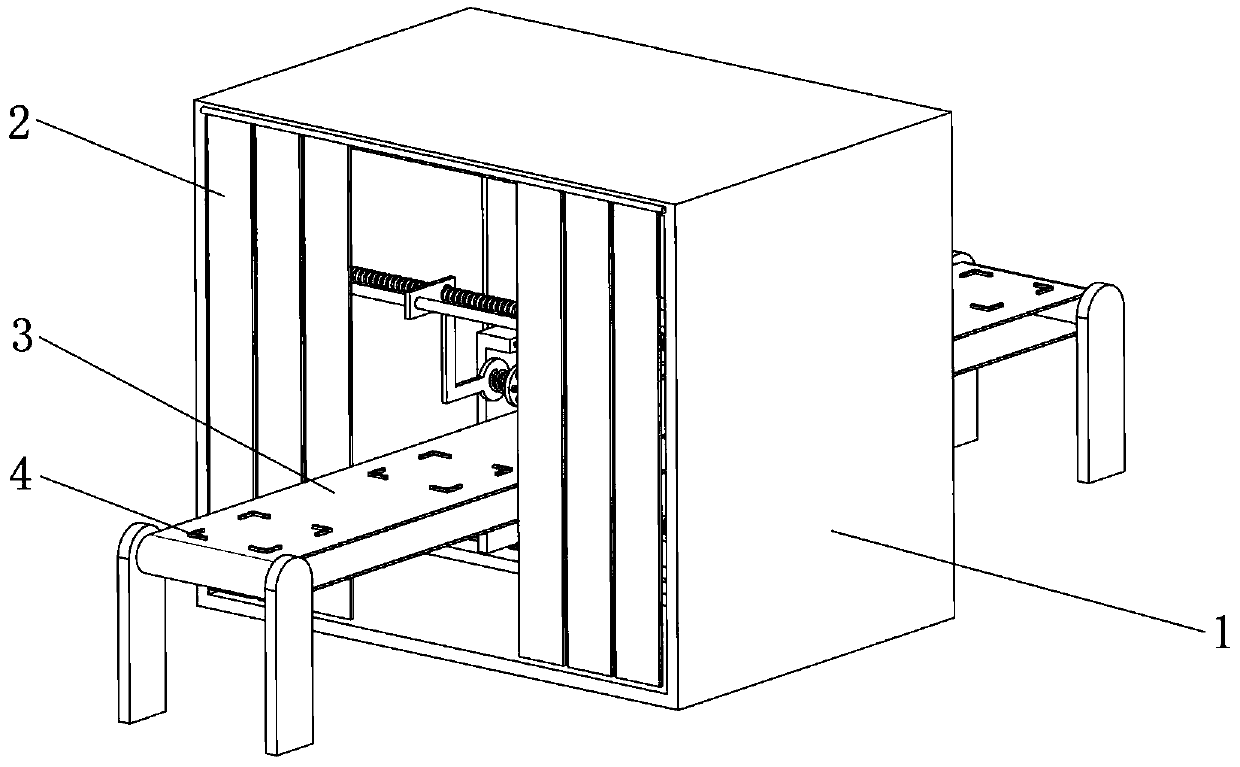

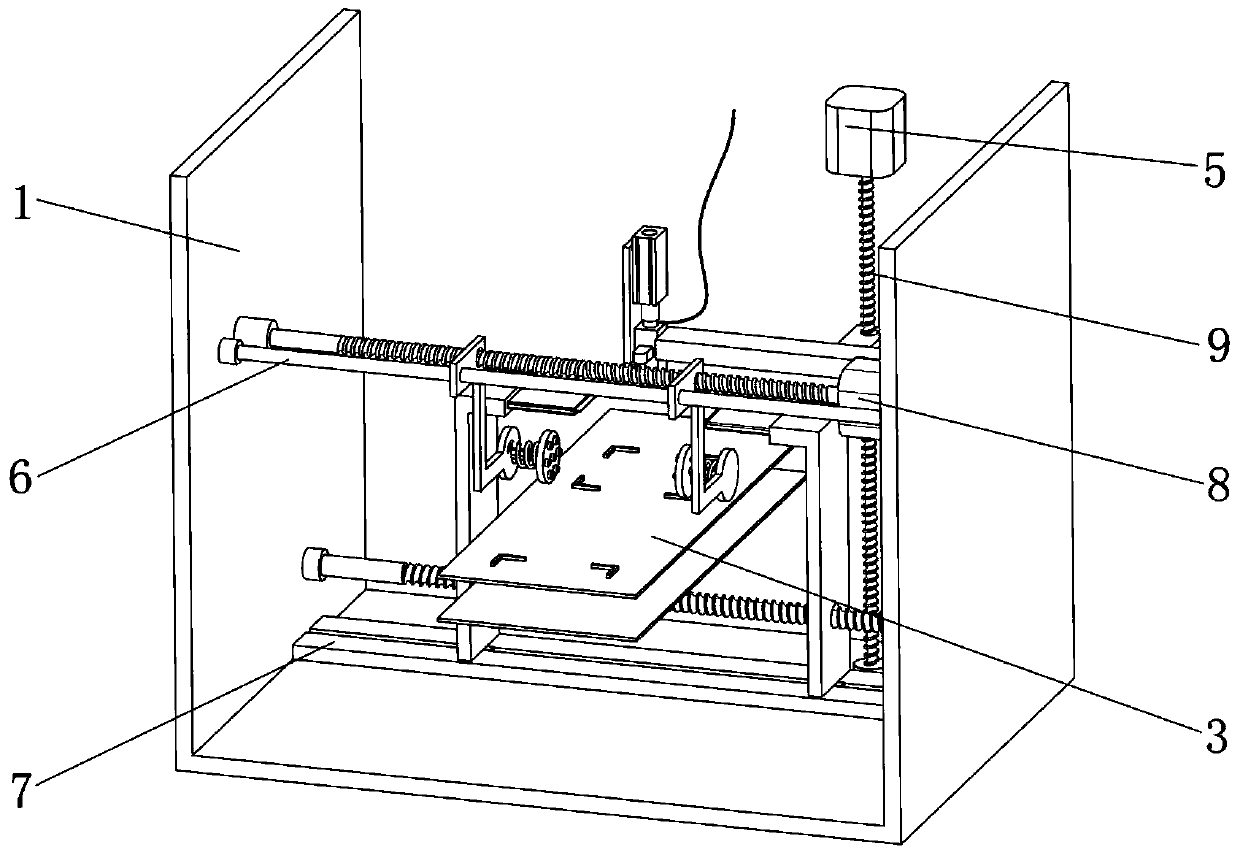

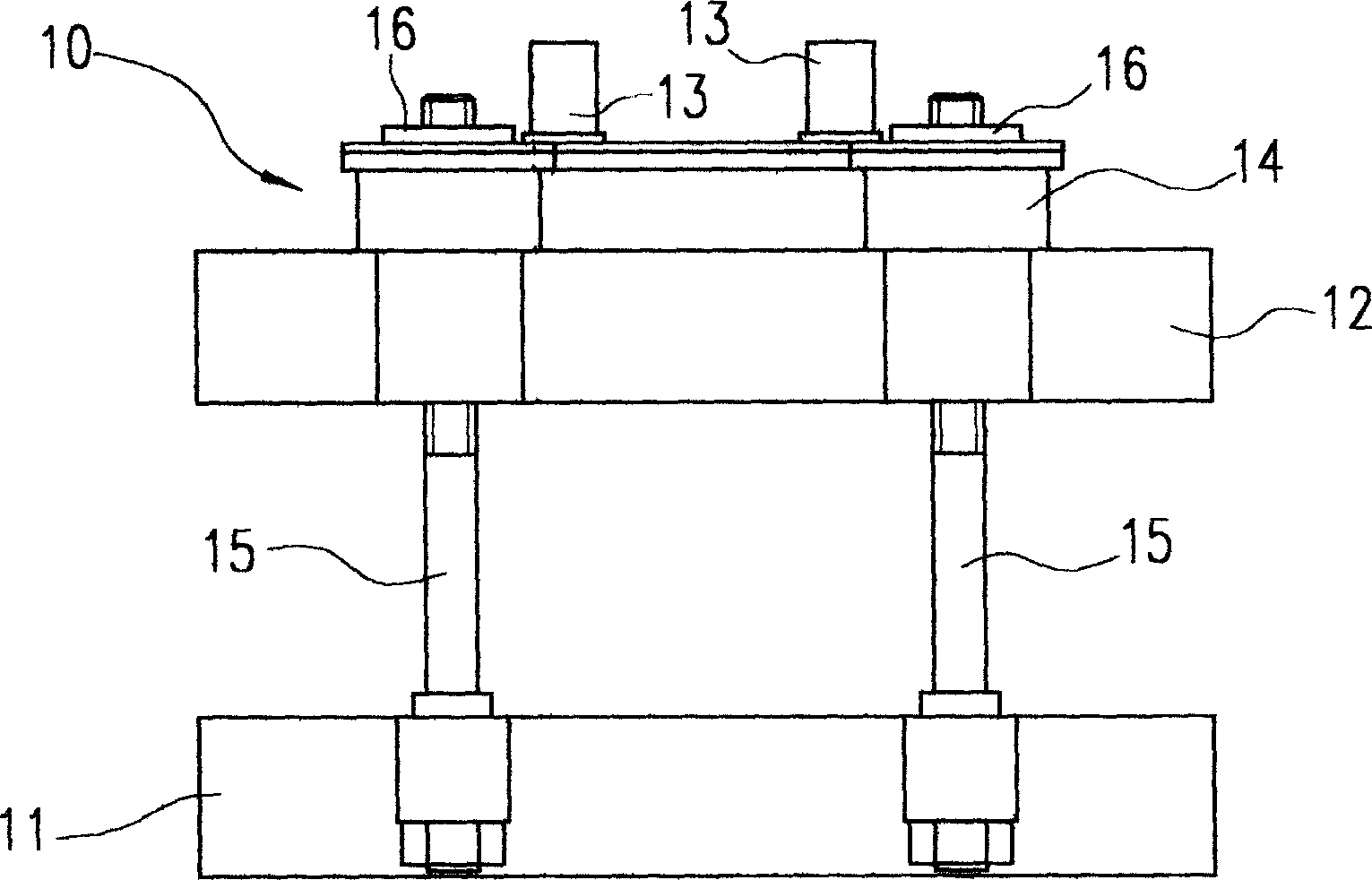

Processing technology and processing device for food broiler chickens

PendingCN111436479AMeet different needsConvenience for follow-up cooking workPoultry plucking mechanismsPackaging by pressurising/gasifyingProcess engineeringBroiler

The invention discloses a processing technology and a processing device for food broiler chickens, and relates to the technical field of food broiler chicken processing. In order to improve the convenience of cooking after purchasing, the processing technology comprises the following steps: selecting the food broiler chickens; selecting adult healthy broiler chickens, and slaughtering the selectedbroiler chickens; performing primary treatment; and soaking the slaughtered broiler chickens in hot water at 60-80 DEG C, and performing stirring for 5-15 minutes. The processing device comprises a packaging chamber, a conveying belt, an opening mechanism, a vacuum suction mechanism and a heat sealing mechanism, the vacuum suction mechanism comprises a vacuum suction motor, a vacuum suction threaded rod, a vacuum suction head and a vacuum suction air cylinder, the inner wall of one side of the packaging chamber is connected with a supporting column through a sliding block, and the inner wallof one side of the supporting column is connected with the outer wall of the vacuum suction threaded rod through threads. According to the method, by arranging the mode that a sauce is added and packaged together with the processed broiler chickens in a separated mode, different requirements of consumers can be met, meanwhile, convenience is provided for subsequent cooking work after purchasing, and time is saved.

Owner:江苏华斯达食品有限公司

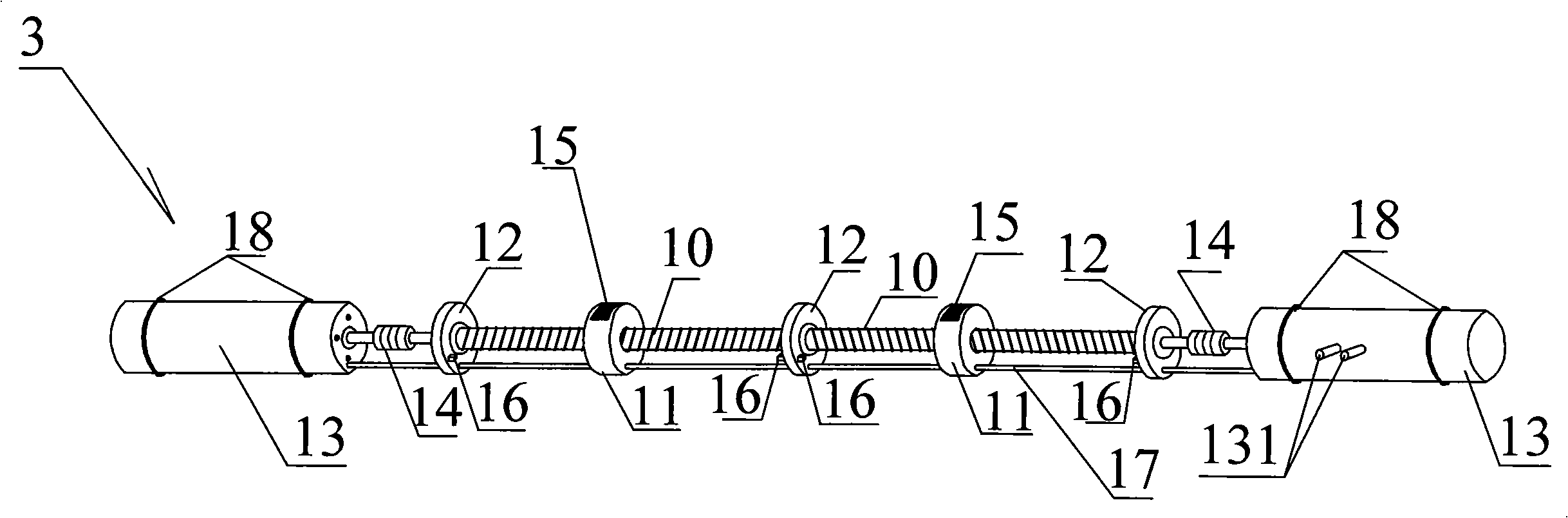

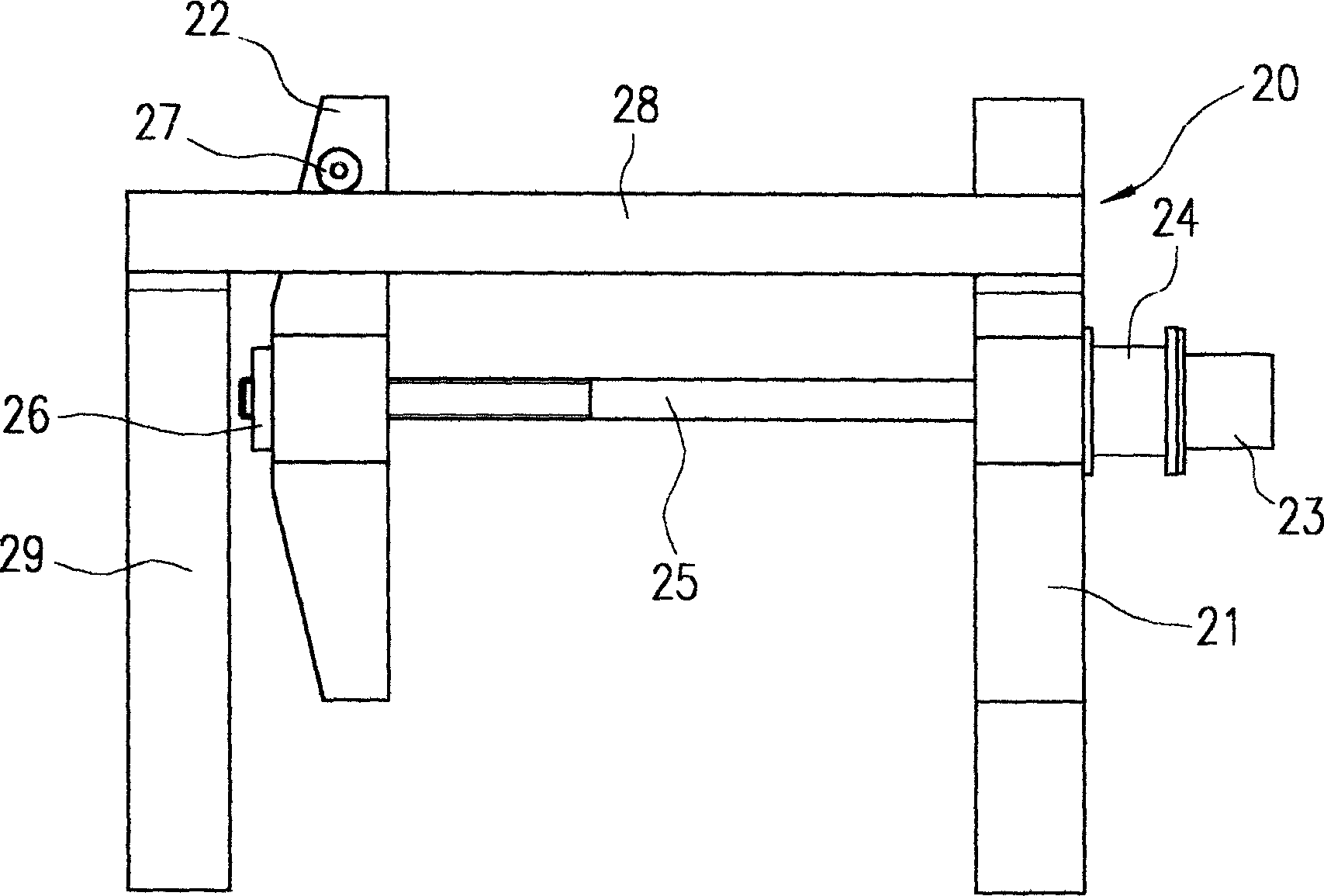

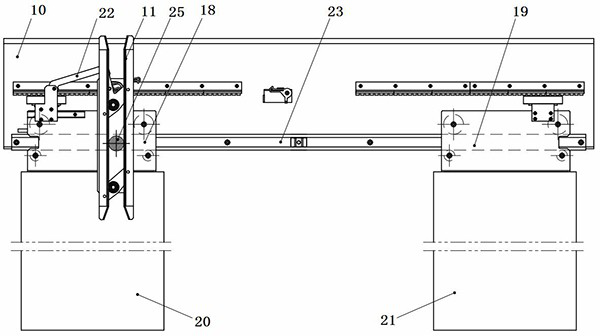

Tightening mechanism for opening and closing filter press

InactiveCN1762534AIncrease the itineraryImprove carrying capacityFiltration separationPull forceEngineering

The invention relates to the field of dissociating the solid and liquid, which in detail relating to an open and close tensioning mechanism of the pressing filter. The open and close tensioning mechanism comprises: bearing plate with a fixed position, exerting plate which can move out and back in relative with the bearing plate, actuating mechanism with prime motor, and screw pair possessing bolt and cover nut and driven by the actuating mechanism. The said screw pair are installed on the two sides of the bearing plate and exerting plate in pair, the two ends of the blot are connected with the bearing plate and exerting plate respectively. The said exerting plate can be droved by the screw pair to move out and back. When starting the open and close tensioning mechanism, opening the filtering board or closing it, pressing the filtering board in the form of pulling, the bolt bearing the pull force when the filtering board is pressed. The invention is characterized by the integrating the functions of pull off the filtering board, closing the filtering board, pressing the filtering board and locking the position of the filtering board; the length of travel of the filtering board closing is large and fast; the great bearing capability of the bolt after the filtering board being pressed; and the simple and compact structure.

Owner:宋家骏

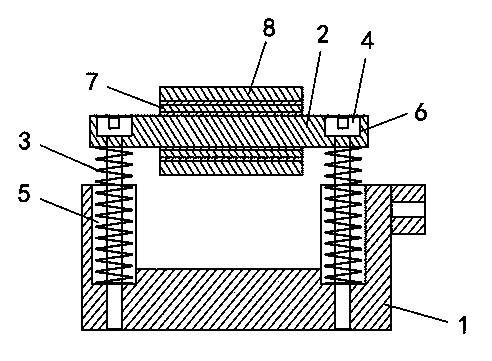

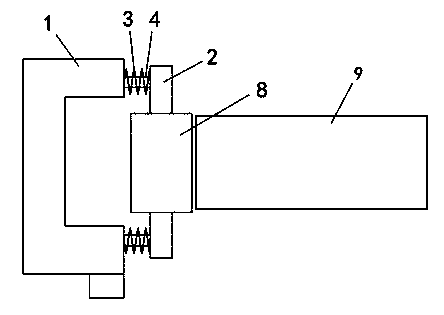

Novel knitting machine driving belt tensioning device

InactiveCN104235290AGuaranteed stabilityGuaranteed to run synchronouslyGearingEngineeringMechanical engineering

The invention discloses a novel knitting machine driving belt tensioning device. The novel knitting machine driving belt tensioning device is characterized by comprising a supporting base, a rolling wheel shaft, springs and connecting shafts. Spring grooves are formed in the supporting base; connecting shaft holes are formed in the rolling wheel shaft; the connecting shafts penetrate through the connecting shaft holes and the springs and then are locked on the supporting base; a bearing is arranged in the middle of the rolling wheel shaft; a rolling wheel is arranged outside the bearing. Compared with the prior art, the device has the advantages that acting force of the springs is utilized for enabling the rolling wheel to tension a mechanical driving belt all the time, it is ensured that the driving belt is not loosened, and is stable in running, and the device is simple in structure, reasonable in design and high in practicability.

Owner:黄钗水

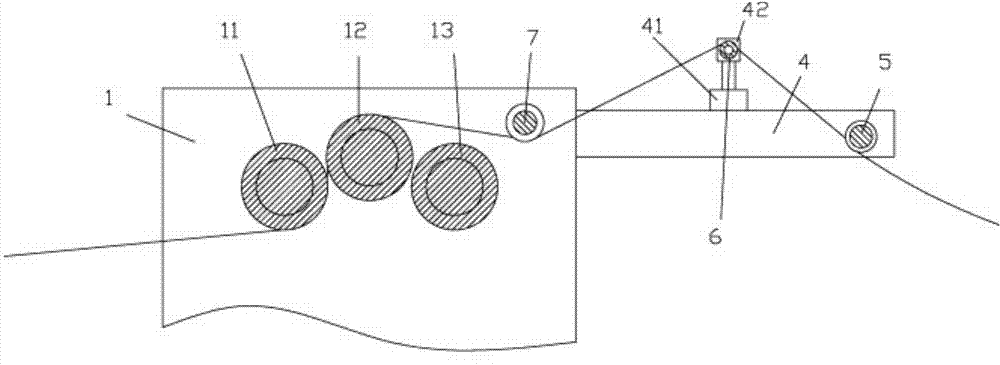

Transmission device for folding machine

InactiveCN103787113AKeep shippingPreventing blocked shipmentsFolding thin materialsWebs handlingGear wheelCoupling

The invention discloses a transmission device for a folding machine. The transmission device comprises two vertical supporting plates. The two ends of a first transmission roll, the two ends of a second transmission roll and the two ends of a third transmission roll are hinged to the upper portions of the two vertical supporting plates respectively. The ends of the same sides of the first transmission roll, second transmission roll and third transmission roll stretch out of the outer side walls, hinged to the vertical supporting plates, of the first transmission roll, second transmission roll and third transmission roll and are arranged in a protection cover fixed to the outer walls of the vertical supporting plates. A duplicate gear is fixed to the middle of the end, connected with an output shaft of a drive motor through a coupling, of the stretching side of the second transmission roll, the drive motor is fixed into the protection cover, a transmission gear is fixed to the end of the stretching side of the first transmission roll and meshed with a first gear of the duplicate gear, and a connecting gear fixed to the end of the stretching side of the third transmission roll is driven by a second gear of the duplicate gear through a transmission chain to rotate. Because the drive motor drives the three transmission rolls to rotate, the synchronization effect is good, and the cloth conveying effect is improved.

Owner:HUNAN JICHANG SILK

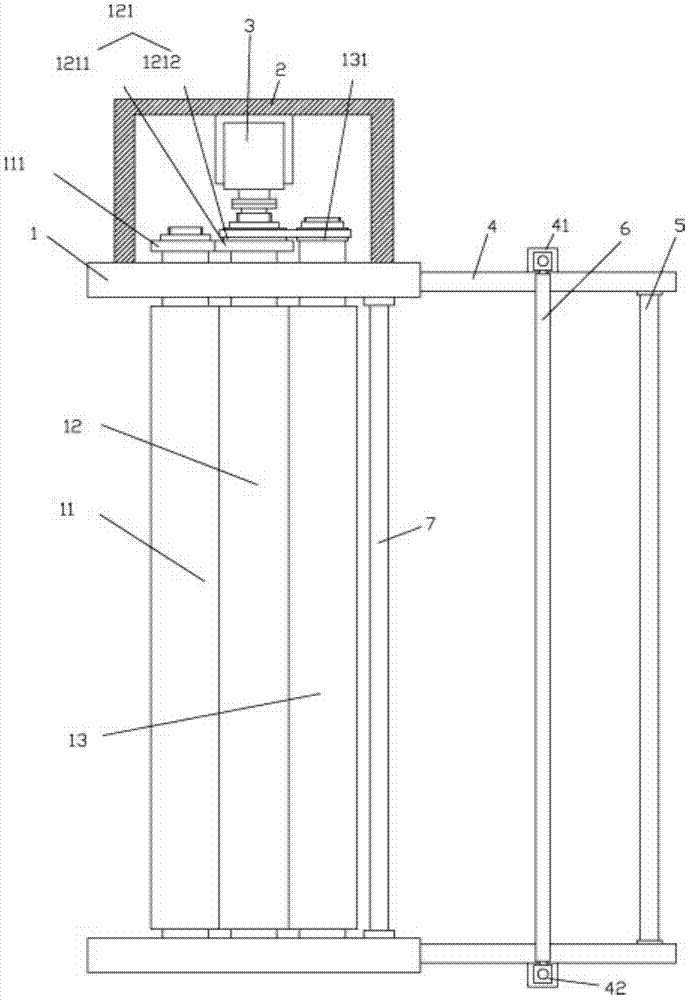

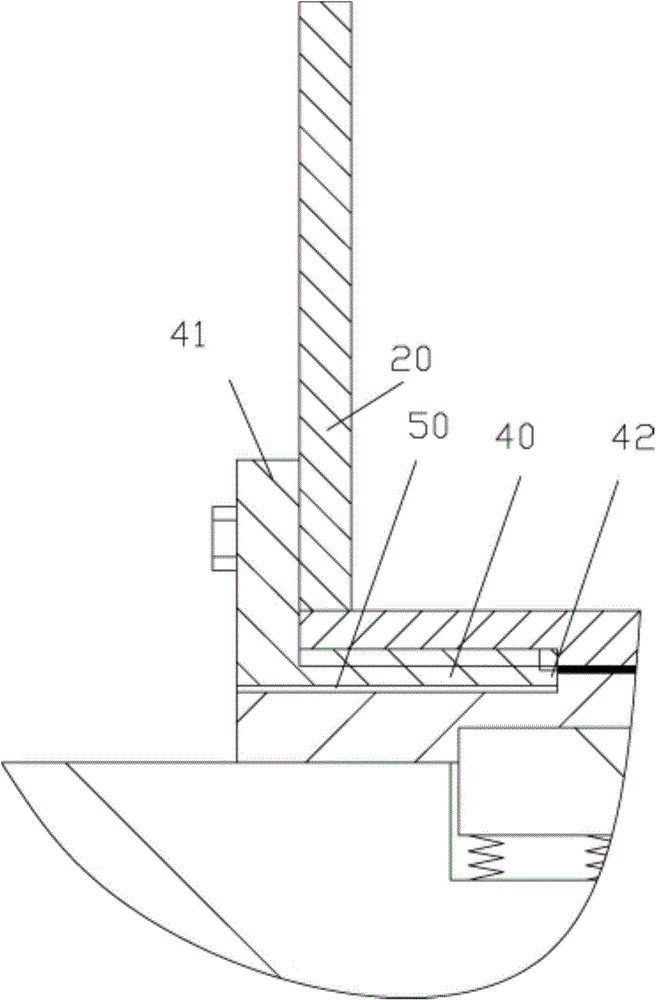

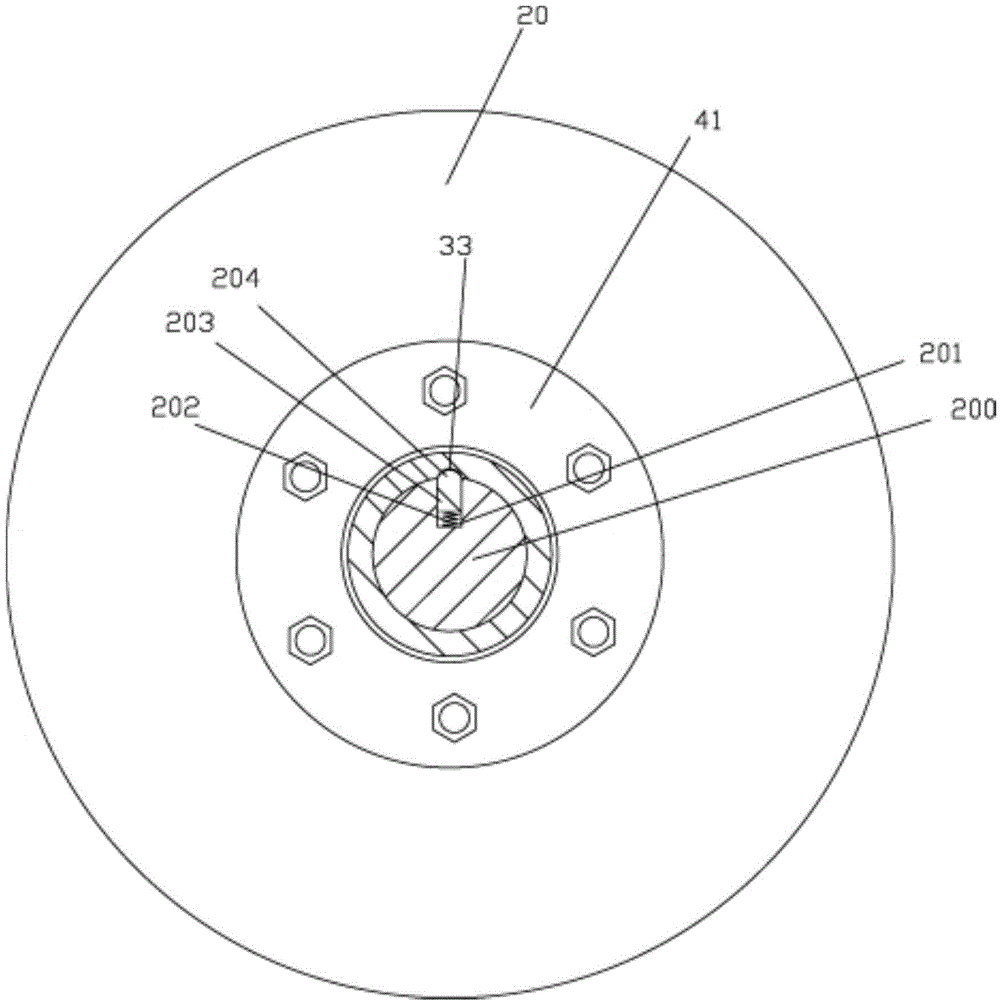

Detachable warp knitting machine pan head

ActiveCN104805562AGuaranteed to run synchronouslySo as not to damageOther manufacturing equipments/toolsTextiles and paperEngineeringWarp knitting

The invention discloses a detachable warp knitting machine pan head. The detachable warp knitting machine pan head comprises a pan head body; the pan head body comprises a winding reel, annular retaining sides sleeve the outer walls of the two ends of the winding reel in an insertion manner, a rotating shaft sleeve is arranged in the winding reel in inserting and sleeving manners, radially extending protruded drum part is arranged on the outer wall of the middle part of the rotating shaft sleeve, a friction sleeve is fixed on the outer wall of the protruded drum part, the outer wall of the friction sleeve is pressed on the inner side wall of the middle part of the winding reel, the two end part connecting sleeves are spirally connected with the two ends of the winding reel, the inner end face of each end part connecting sleeve is pressed on the end face of the protruded drum part, an oblong groove with a cambered-surface section is formed in the inner side wall of the rotating shaft sleeve, an insertion slot is formed in the outer wall of a beam, an elastic mechanism is fixed at the bottom surface of the insertion slot, a limit block is arranged in the insertion slot in the inserting and sleeving manners, and an arc-shaped end part of the limit block is arranged in the oblong groove in the inserting and sleeving manners. The detachable warp knitting machine pan head has the advantages that the maintenance cost is low; the telescopic limit block is arranged on the beam, so that the synchronous operation of the beam and the pan head is ensured; furthermore, when the pan head and the beam are clamped, the pan head and the beam generate relative sliding.

Owner:浙江新铭龙经编织物有限公司

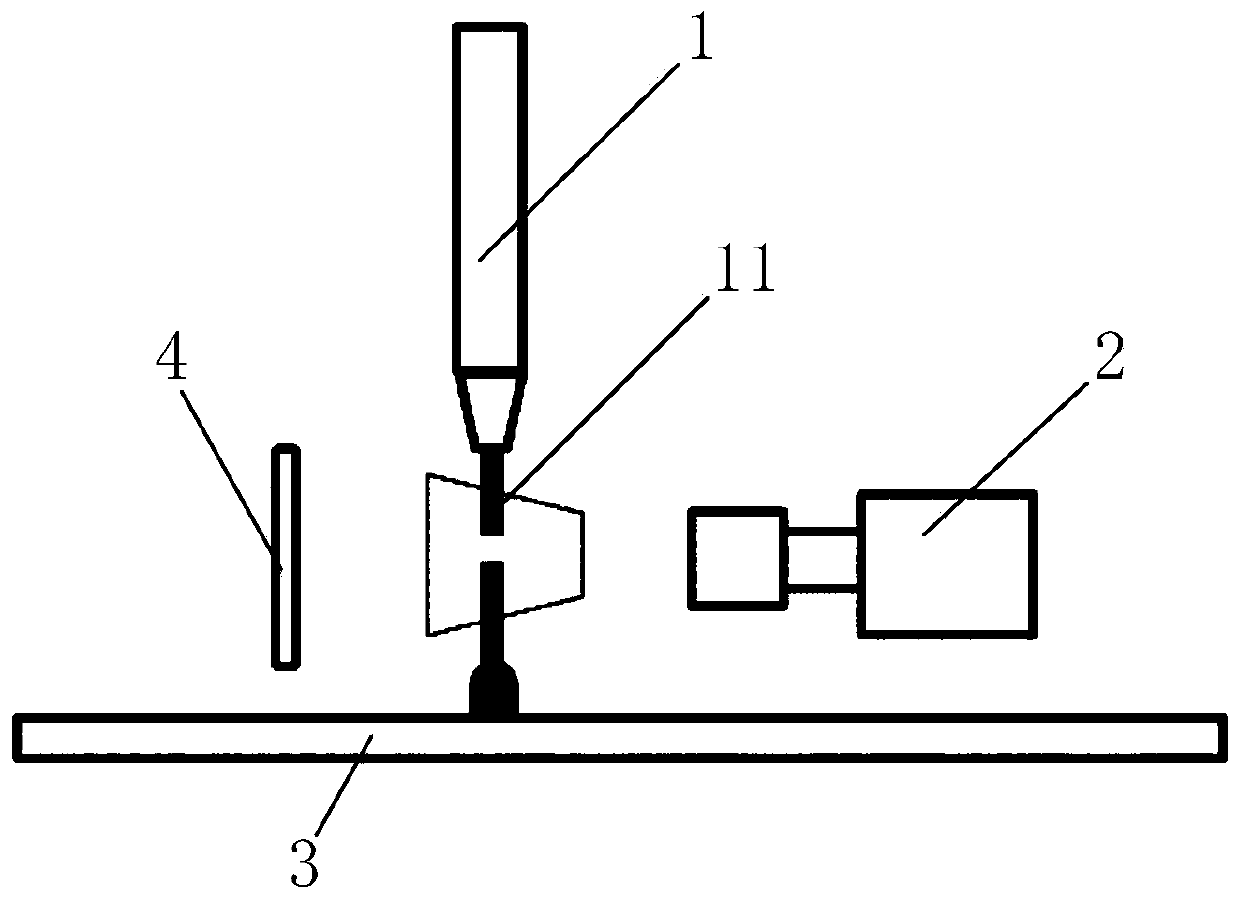

Coating equipment monitoring system and control method for coating equipment

ActiveCN109926275AReal-time monitoring of glue output statusGuaranteed to run synchronouslyLiquid surface applicatorsMaterial analysis by optical meansAbnormal positionsMonitoring system

The invention belongs to the technical field of coating equipment, particularly provides a coating equipment monitoring system and a control method for coating equipment, and aims at solving the problems of the extending of the operation time of a whole coating working procedure by an existing coating detecting method and low operation efficiency. The system comprises an image collecting device, acontrol device and an alarming device which are arranged on the coating device, wherein the image collecting device can collect glue discharging images of the coating device, whether or not there exists abnormality in the glue discharging images can be judged by the control device, and the alarming device can be controlled to send an alarm when there exists abnormality in the glue discharging images. By means of device, the glue discharging state of the coating equipment can be monitored in real time by the monitoring system, a glue abnormal position can be discovered in the coating process,coating checking steps do not need to be conducted after coating, and the whole operation efficiency of the coating working procedure is improved.

Owner:NIO ANHUI HLDG CO LTD

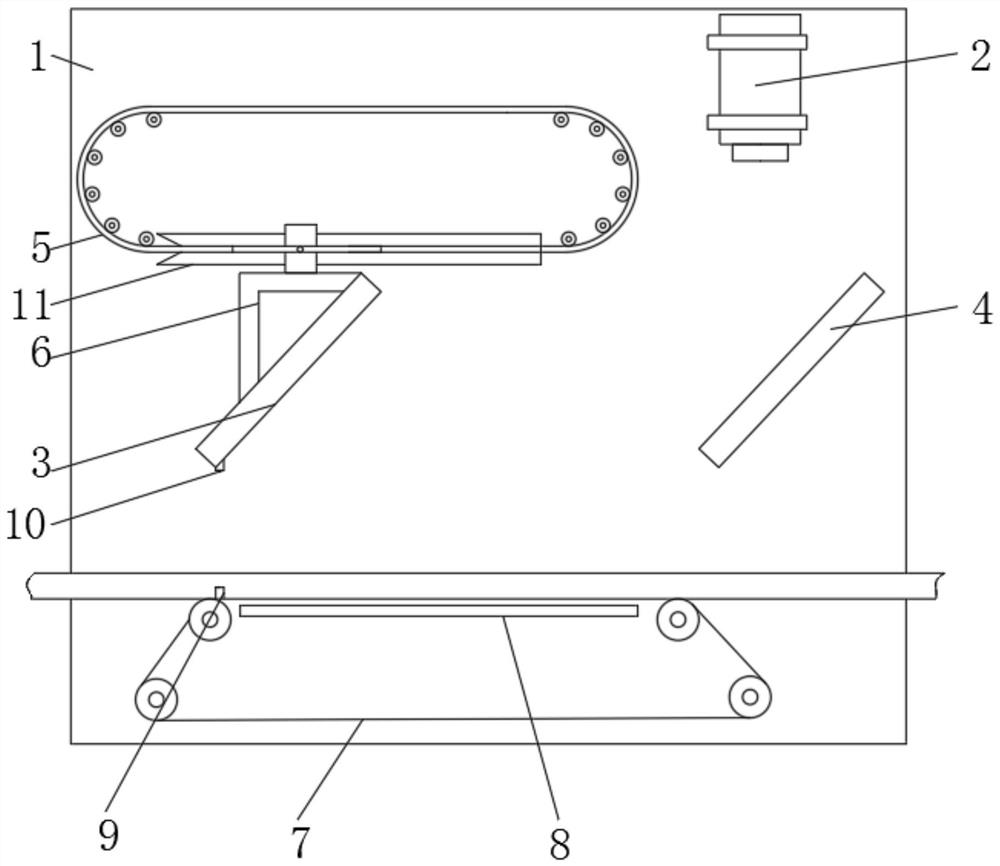

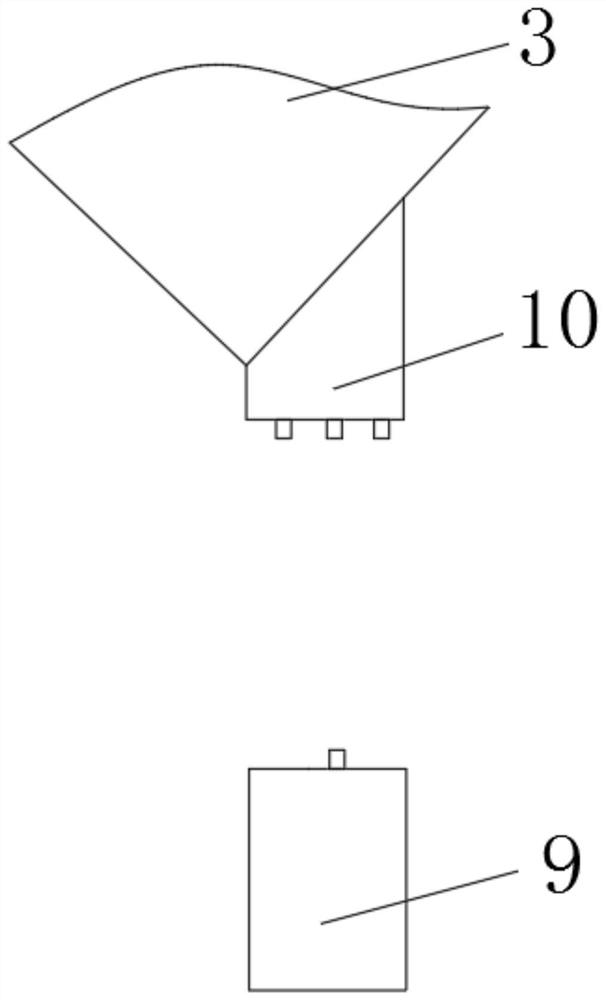

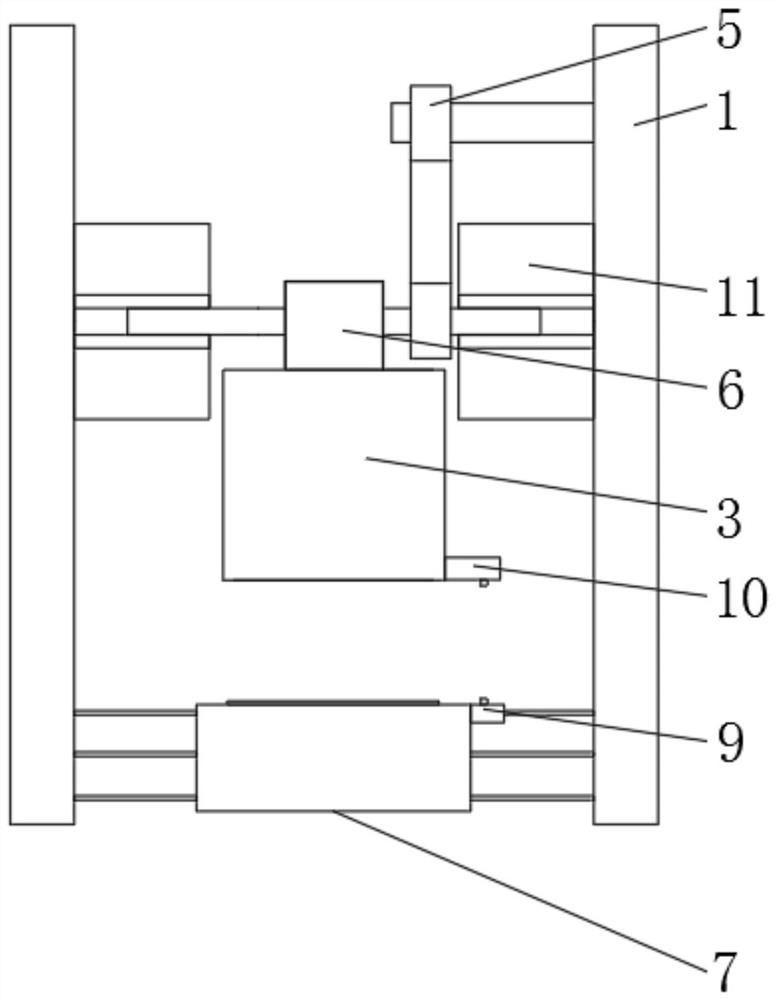

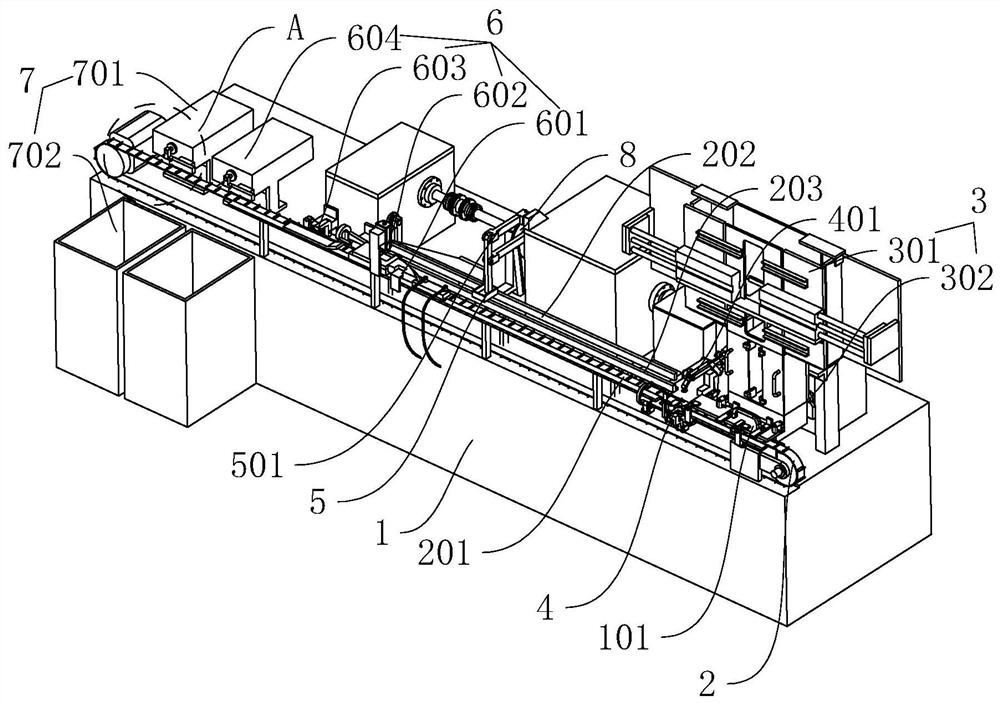

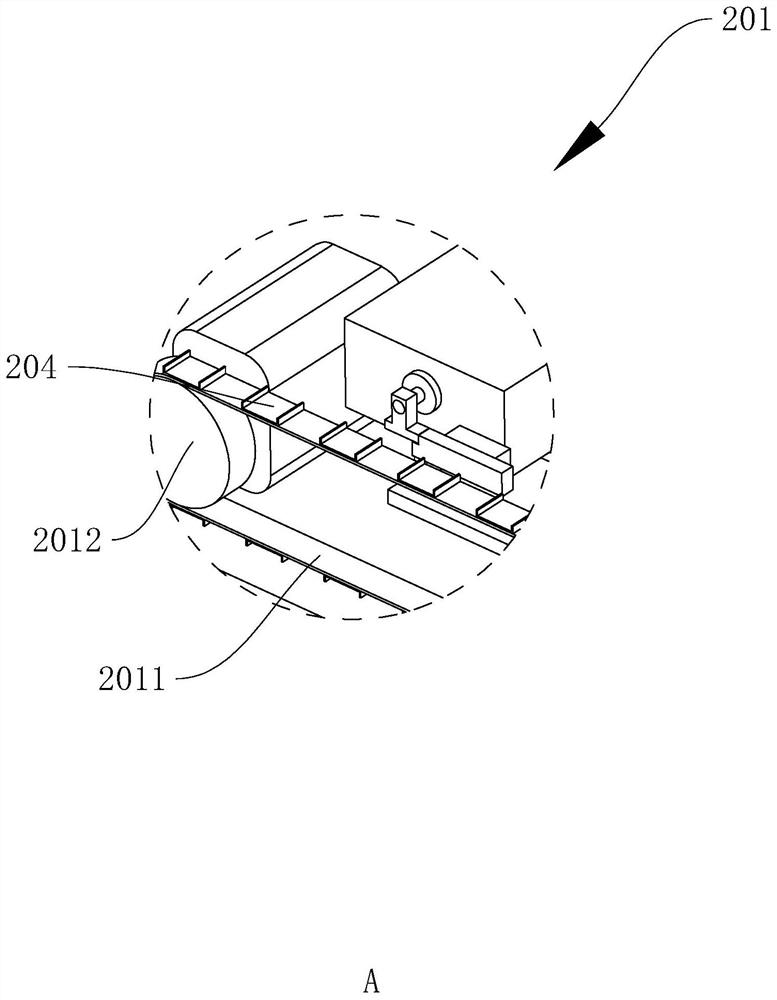

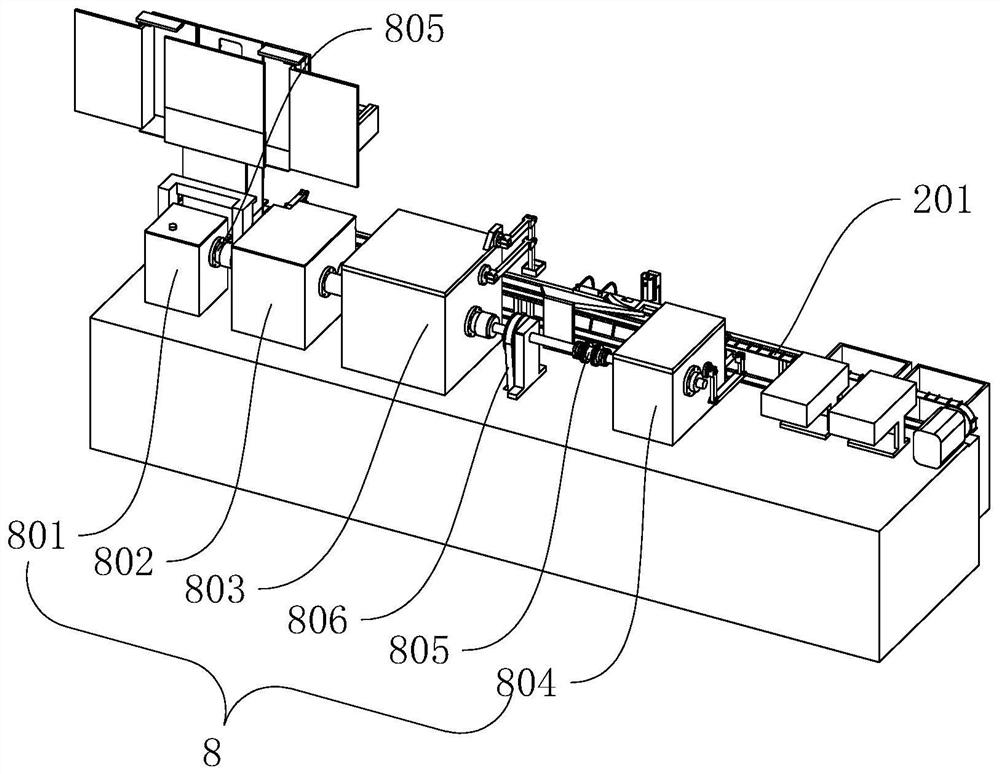

Printed matter detection device based on area-array camera

The invention relates to the technical field of printing equipment, and discloses a printed matter detection device based on an area-array camera. The device comprises a support frame, a camera is fixedly mounted on the support frame, and a movable reflector and a fixed reflector are arranged on the support frame in the moving direction of paper. According to the printed matter detection device based on the area-array camera, the moving speed of the movable reflector is kept consistent with the speed of paper, then images shot by the camera are kept unchanged, and damage to the camera is small; secondly, an alignment piece A, an alignment piece B and an speed measuring piece are matched, the speed of a driving chain and a conveying belt and the speed of the conveying belt and printing are fed back, then adjustment is carried out, and operation at the same speed is ensured; and the paper is always attached to the conveying belt through electrostatic adsorption, the level of the paper during shooting is guaranteed, and the imaging quality is improved. Meanwhile, a friction force between the conveying belt and the paper ensures synchronous operation of the paper and the conveying belt, and the speed difference between the conveying belt and the printing speed can be eliminated.

Owner:何峰

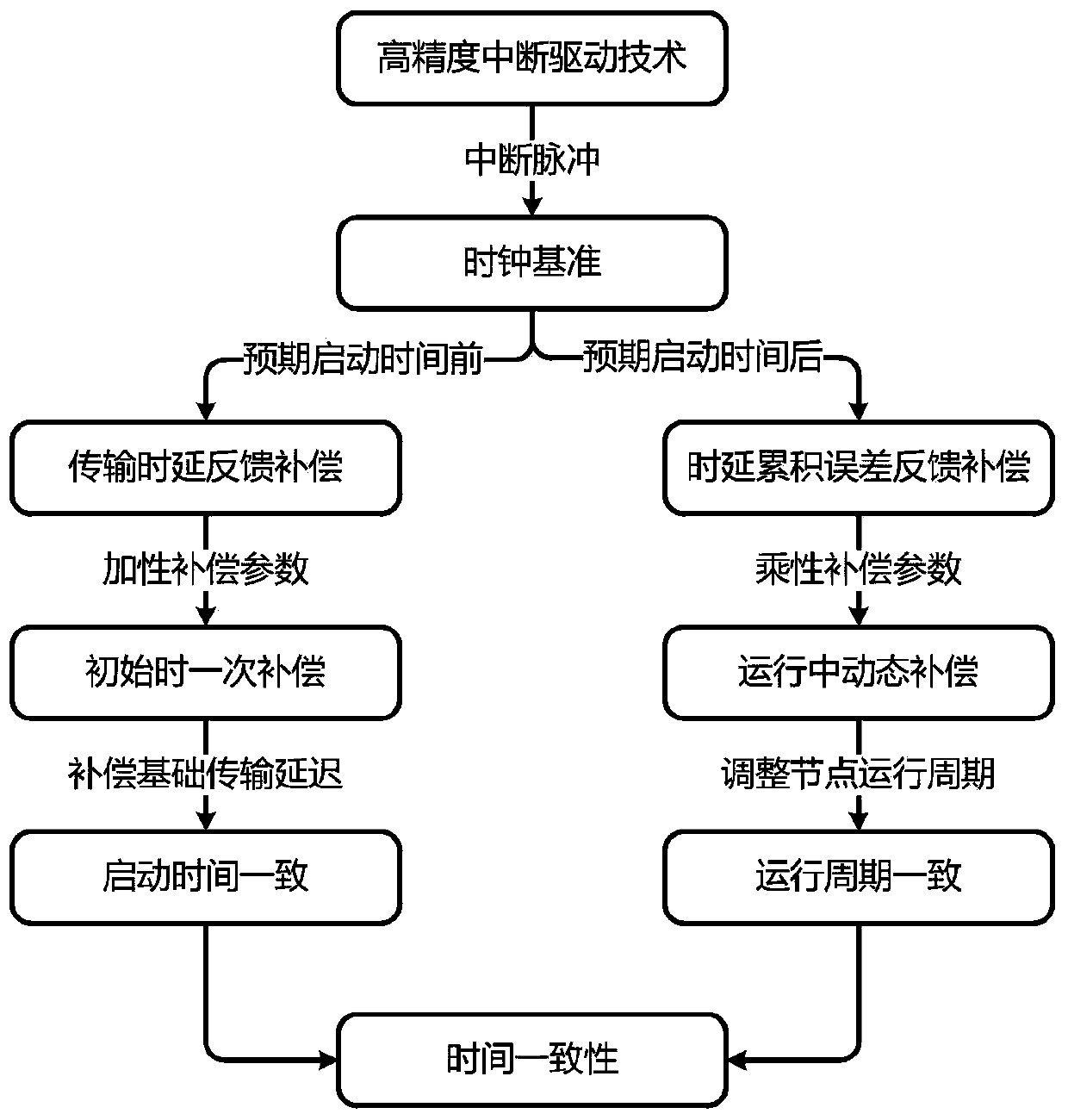

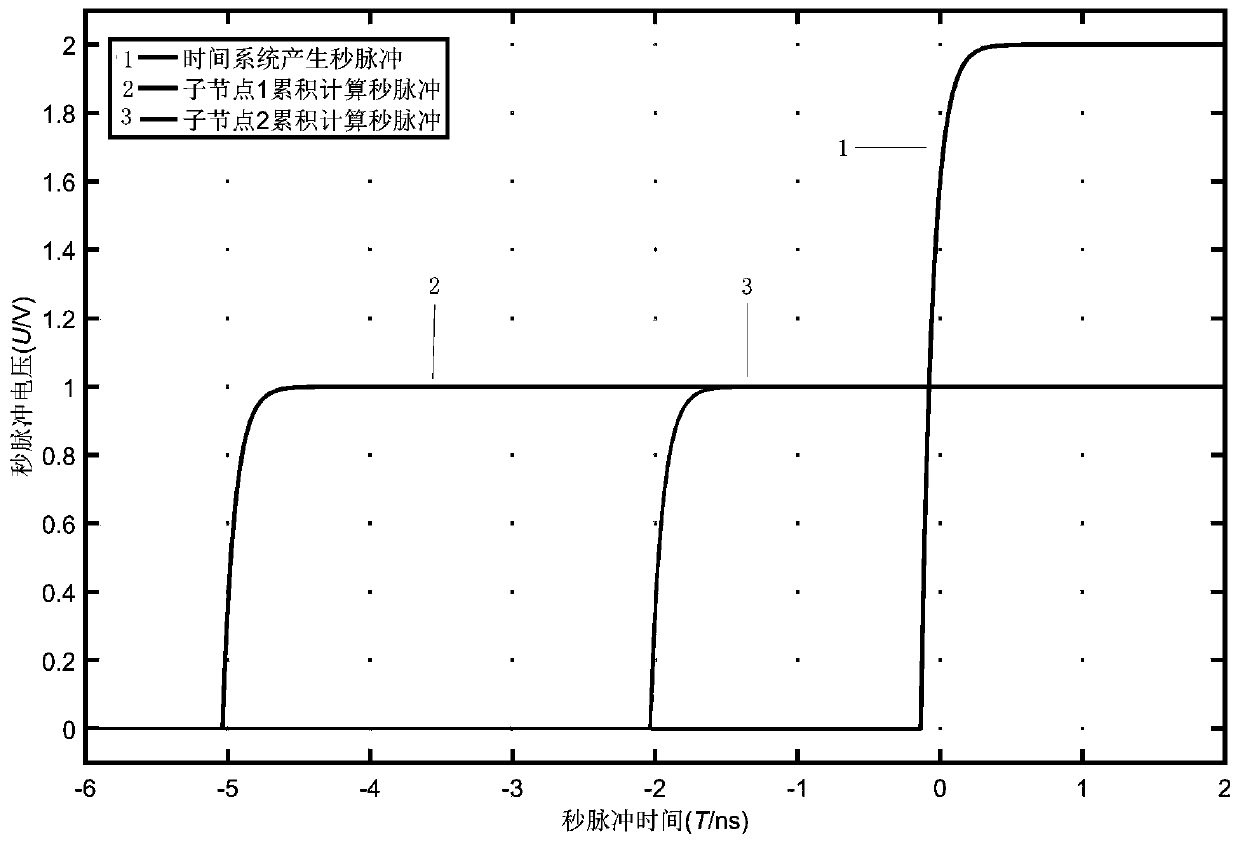

Time consistency control method oriented to cooperative guidance simulation system

ActiveCN110375596AImprove the consistency of the starting stateImprove cycle state consistencySelf-propelled projectilesData transmissionTransmission delay

The invention provides a time consistency control method oriented to a cooperative guidance simulation system. On the basis of the existing time system, the technologies of high-precision interrupt drive, data transmission delay feedback compensation, and delay accumulative error feedback compensation are added. The time consistency control method comprises the following steps: at first, the high-precision interrupt drive technology is utilized to introduce a high-precision clock signal and an interrupt pulse into the cooperative guidance simulation system to drive nodes in the system to operate synchronously; then, unexpected delay of a command in an optical fiber transmission network is taken into consideration, and data transmission delay feedback compensation is introduced to realize one-time compensation of transmission delay and fluctuation; and finally, aiming at the residence time error problem, dynamic delay accumulative error feedback compensation is put forward, and intervalmeasurement and multiframe compensation are utilized to finish the state elastic propulsion during the operating process of the system. With adoption of the time consistency control method, the existing cooperative guidance simulation system is enhanced, nanosecond-grade time control precision between the nodes of the simulation system can be realized, and the problem about time consistency control in the cooperative guidance simulation system is solved.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

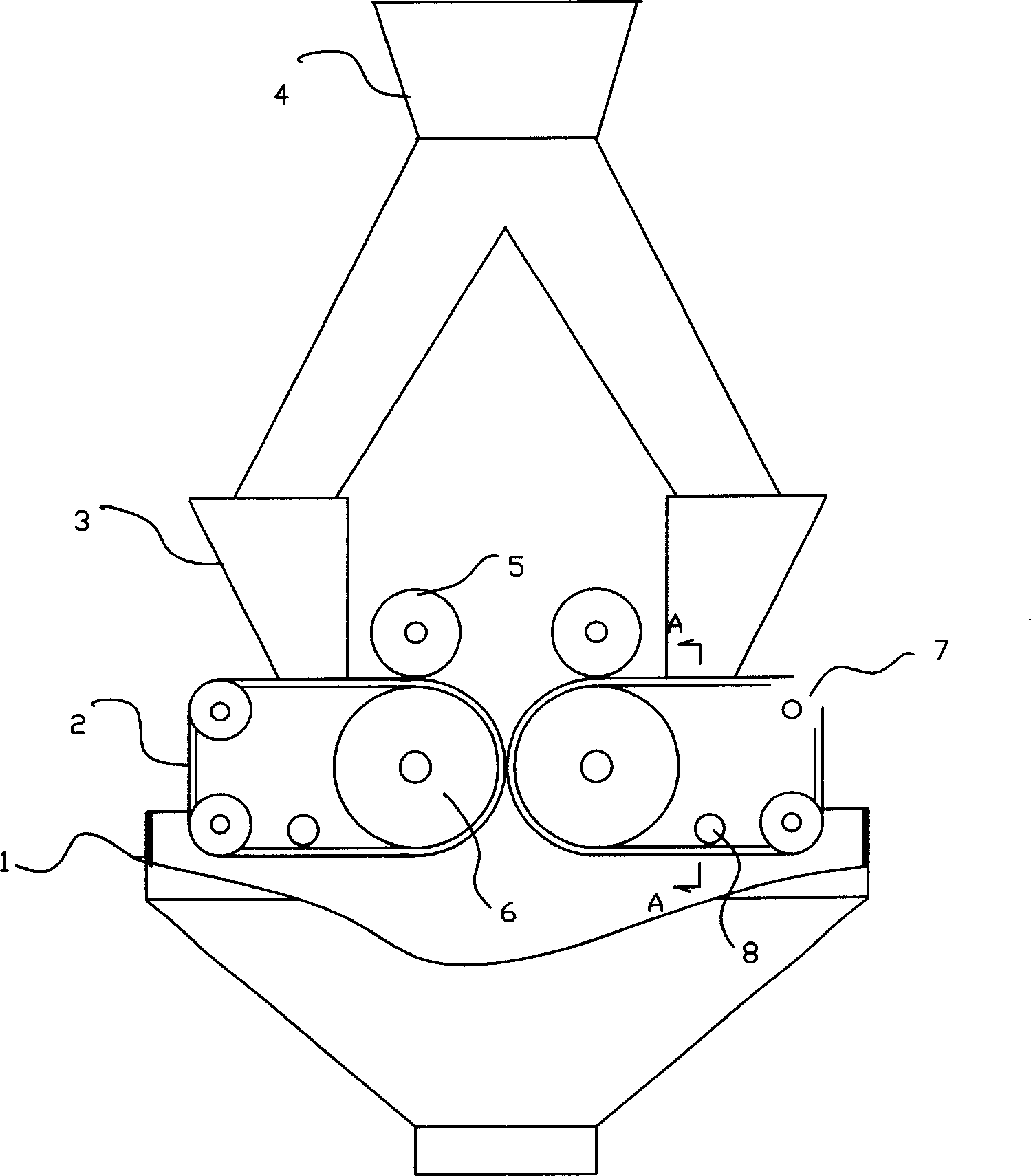

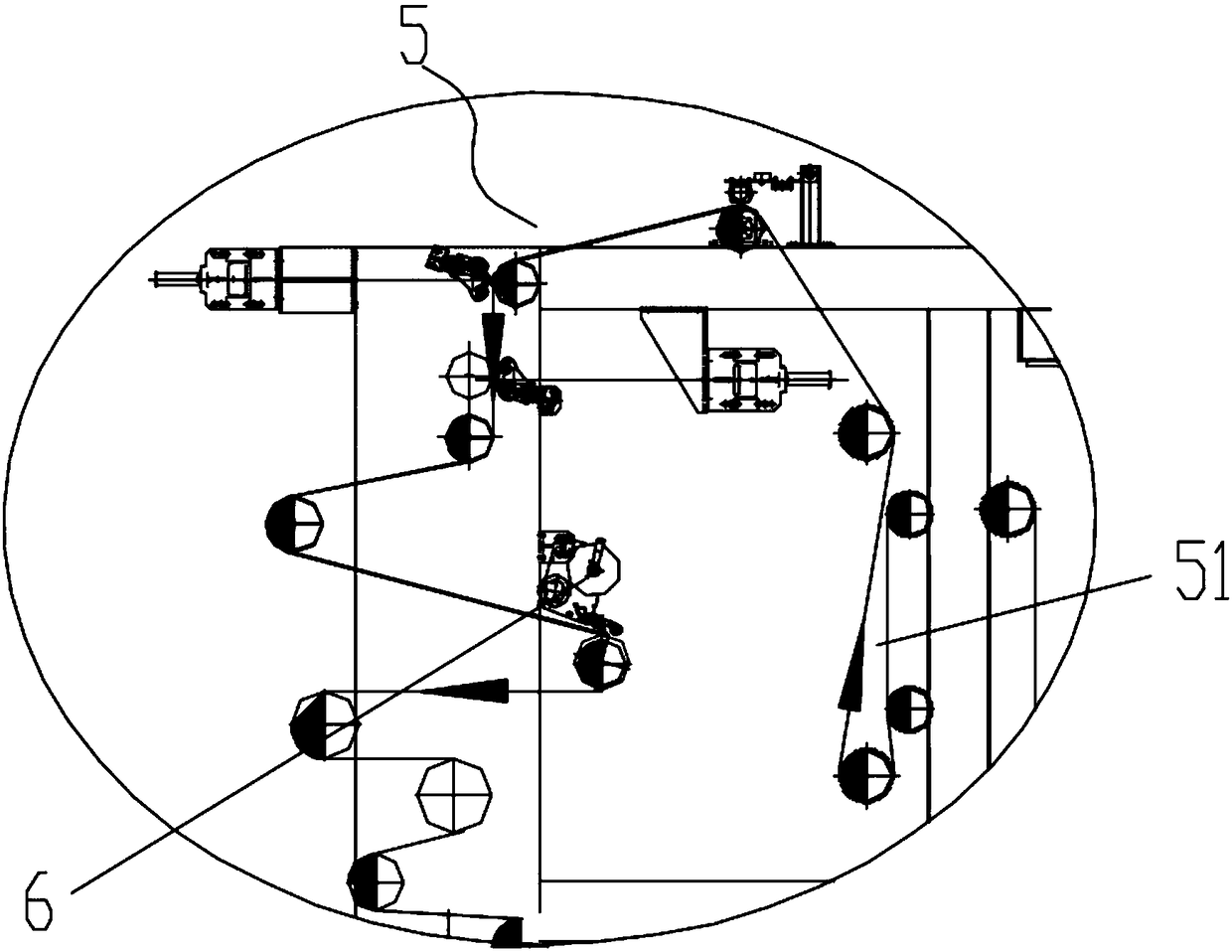

Balling device

InactiveCN1695782AGuaranteed to run synchronouslyHighlight substantive featuresGranulation by pressingGranulation on conveyor beltsElectric machineryEngineering

A pelletizer is composed of feeding cabin, distributing cabin, a pair of rollers driven by motor and speed reducer, and discharging collector.It features that two band-shaped elastic flexible die plates are used for two rollers and supported by said roller and at least one guide roller. Each die plate has a pressing roller and a vibrator.

Owner:SHANDONG IRON & STEEL CO LTD +1

Door machine system based on double linear motors and its synchronous motion control method

ActiveCN113023534BGuaranteed to run synchronouslyImprove anti-interference abilityAssociation with control/drive circuitsMultiple dynamo-electric motors speed regulationSynchronous controlControl system

The invention provides a door machine system based on double linear motors and a synchronous motion control method thereof. The door machine system includes left and right linear motors, left and right door panels, position sensors and control systems. The invention adopts the left and right linear motors to directly drive the left and right door panels of the door operator to open and close respectively, and has the advantages of simple transmission structure, high efficiency, high precision, high reliability, space saving and convenient maintenance. Further, in terms of motion control, the present invention also adds a synchronous controller on the basis that the existing dual motors are independently controlled by their respective controllers, and uses the synchronous position error signal of the dual linear motors as the input of the synchronous controller, and then The output signal is sent to the main channel of the double linear motor for adjustment, so as to ensure the synchronous operation of the double linear motor and improve the anti-interference ability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

An automatic wire stripping machine

ActiveCN106816801BPlay a supporting roleGood stripping effectLine/current collector detailsApparatus for removing/armouring cablesDistribution controlMechanical engineering

The invention relates to an automatic wire-stripping machine comprising a support frame fixed by a mounting block. A power distribution control box is arranged at the back side of the support frame; the mounting block is arranged at the front side; and a loading block cooperating with a cable is arranged at the mounting block. A top plate is arranged at the power distribution control box; a compressing device cooperating with the loading block is arranged in the middle of the top plate; clamping cylinders are arranged at the two sides of the top plate and are connected with a lifting block; and wire stripping devices are arranged below the lifting block. The wire stripping devices include upper moving blocks and lower moving blocks; the upper moving blocks cooperate with an upper sliding rail arranged below the lifting plate; the lower moving blocks cooperate with a lower sliding rail arranged below the mounting block; and clamp blocks are arranged at the upper moving blocks and the lower moving blocks; and the upper moving blocks and the lower moving blocks are connected to a synchronous pulling device. According to the automatic wire-stripping machine, because the clamp blocks cooperating with the cable are arranged at an upper direction and a lower direction of the end portion of the cable, a support effect is realized during the pulling and wire stripping process; the stripping is done completely and the wire stripping effect is good; the operation becomes simple; and the wire stripping efficiency can be improved.

Owner:深圳市艾美迪电子科技有限公司

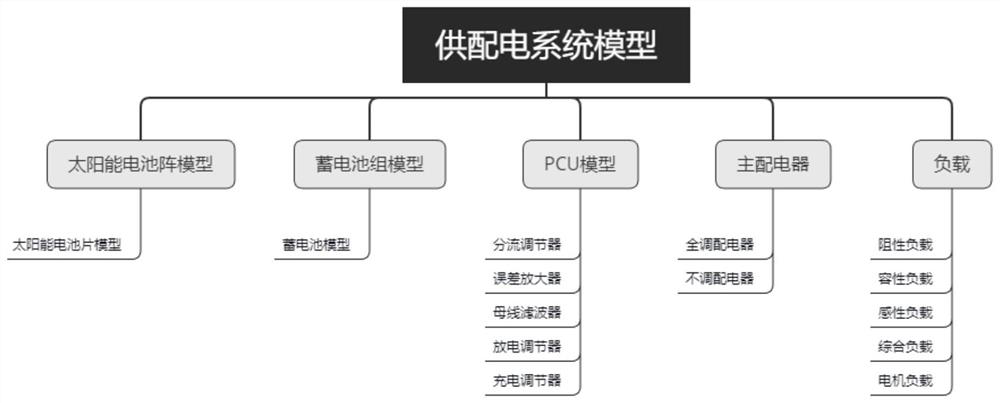

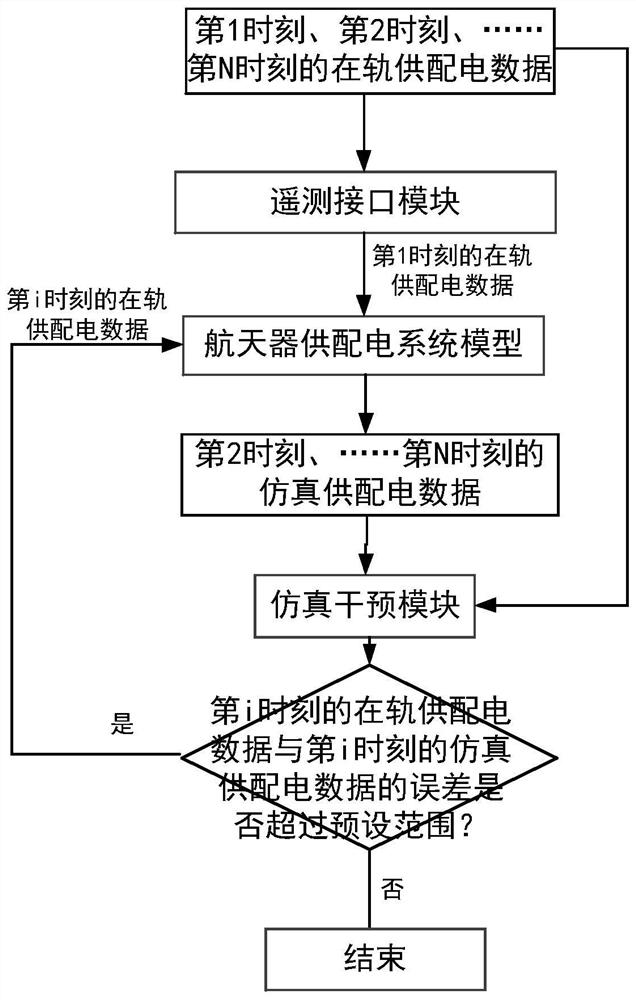

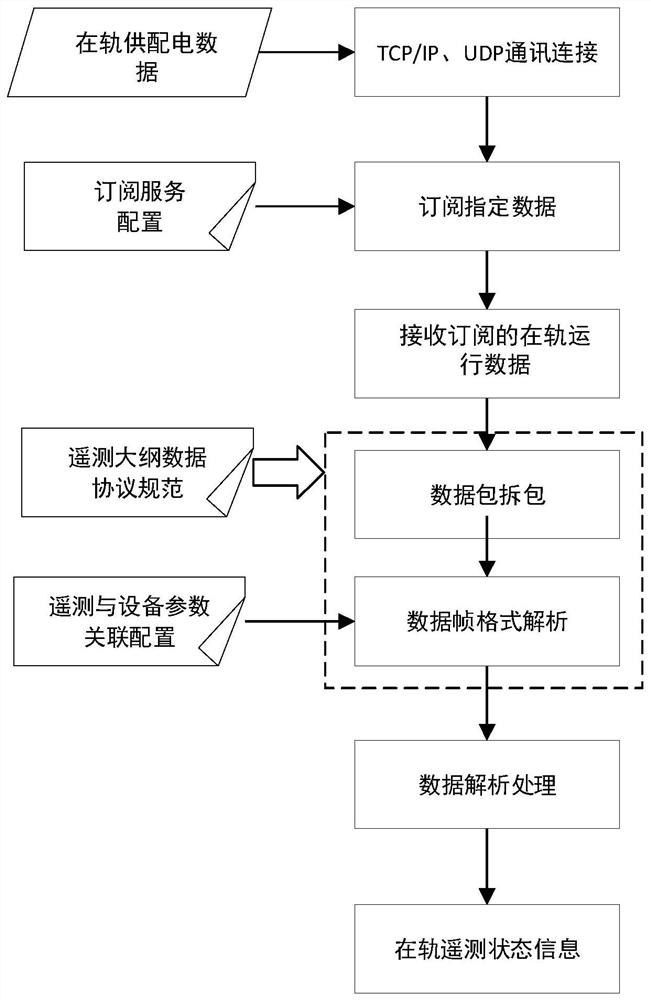

Ground flight accompanying device of spacecraft power supply and distribution system

PendingCN112613187AGuaranteed to run synchronouslyEnsure consistencyDesign optimisation/simulationSpecial data processing applicationsElectricity distribution systemsTelemetry

The invention belongs to the related technical field of spacecraft power supply and distribution systems, and discloses a ground flight accompanying device of a spacecraft power supply and distribution system, which comprises a telemetry interface module used for acquiring on-orbit power supply and distribution data of a spacecraft in real time; and transmitting the on-orbit power supply and distribution data at the initial moment to a spacecraft power supply and distribution system model as an initial value for simulation; a spacecraft power supply and distribution system model used for simulating a power supply and distribution system of the spacecraft according to the received on-orbit power supply and distribution data to obtain simulated power supply and distribution data; and a simulation intervention module used for comparing the on-orbit power supply and distribution data with the corresponding simulation power supply and distribution data, and taking the on-orbit power supply and distribution data at the corresponding moment as an initial value of the spacecraft power supply and distribution system model to perform simulation calculation if an error between the two data exceeds a preset range. The invention can achieve the precise simulation of the non-measurement-and-control arc segment, and meets the monitoring requirements of the non-measurement-and-control arc segment.

Owner:HUAZHONG UNIV OF SCI & TECH +1

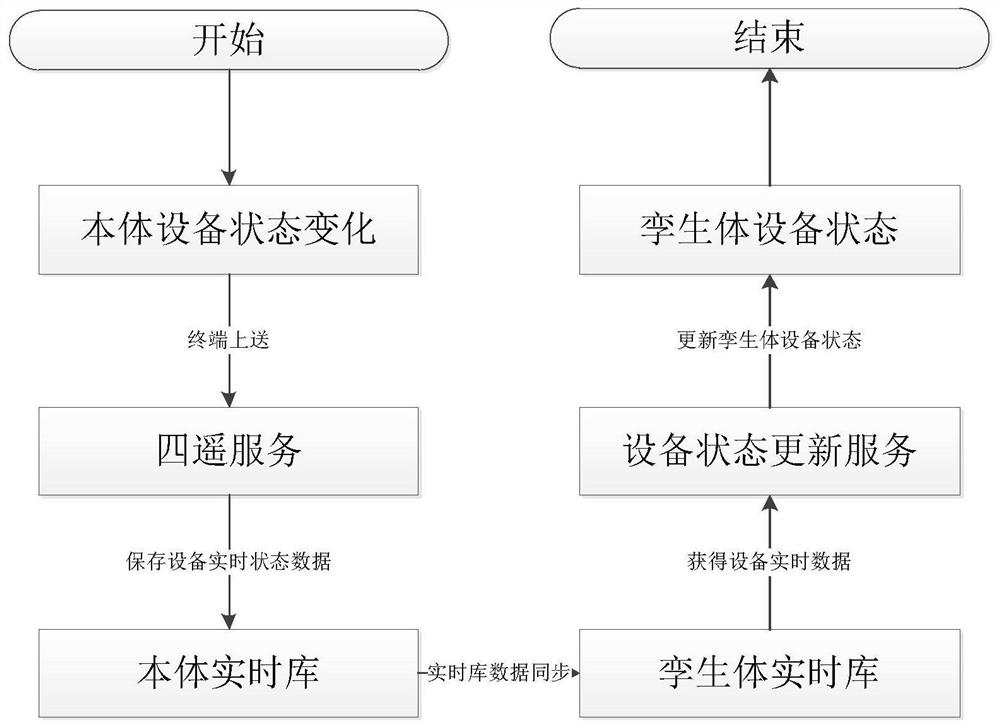

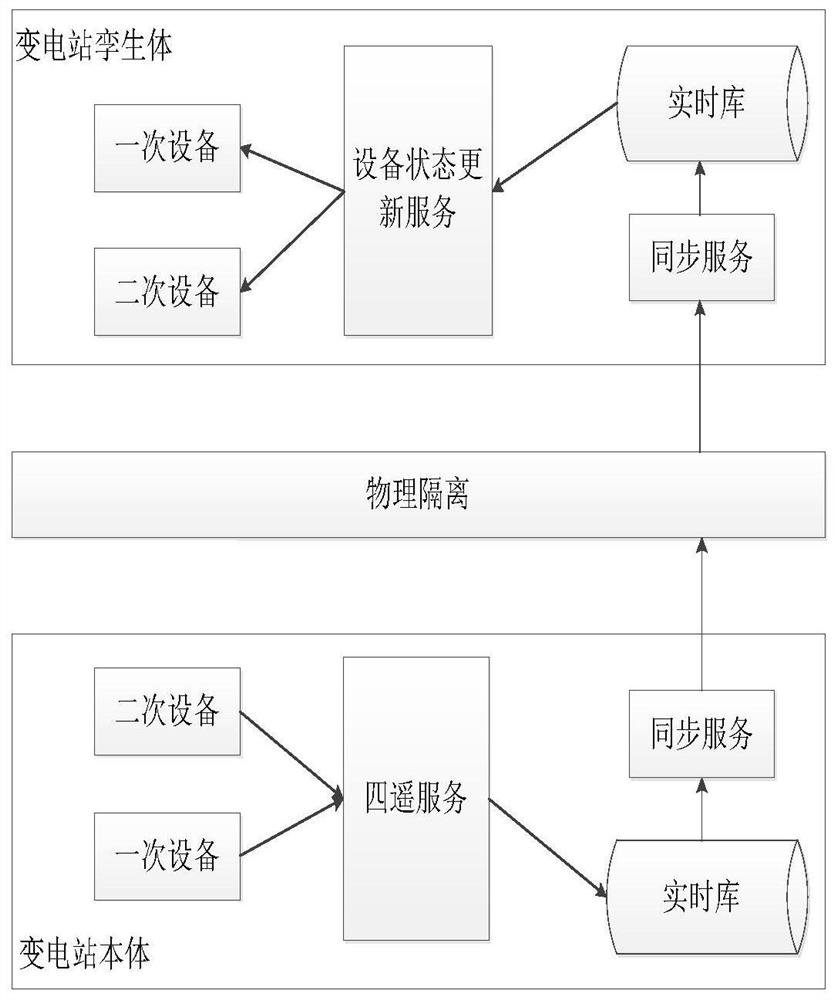

Virtual-real synchronous operation method and device for digital twin transformer substation

PendingCN113837586AStrong consistencyGuaranteed to run synchronouslyDatabase management systemsResourcesTime markTransformer

The invention relates to a virtual-real synchronous operation method and device for a digital twin substation, and the method comprises the steps: marking a time mark on the real-time operation state data of equipment, storing the real-time operation state data in a body real-time library, and synchronizing the real-time operation state data to a twin real-time library, so as to update the state of twin equipment according to the data with the time mark. According to the technical scheme provided by the invention, the equipment states of the transformer substation body and the twin body are synchronized through the time marks of the data, the defects of complex configuration, high operation and maintenance cost and complex configuration logic in the prior art are overcome, and strong consistency of the data is realized through a simple mode, so that synchronous operation of the transformer substation twin body and the transformer substation body is ensured.

Owner:XUCHANG XJ SOFTWARE TECH

Side opening type cigarette case packaging machine

ActiveCN113548225AImprove packaging efficiencyGuaranteed to run synchronouslyPackaging cigarettePackaging automatic controlAluminium foilStructural engineering

The invention discloses a side opening type cigarette case packaging machine. The side opening type cigarette case packaging machine comprises a rack, the rack is provided with a transferring station, a feeding station, a cover turning station, a cigarette feeding station, a screening station, a discharging station and a driving station, and the cover turning station comprises a cover opening assembly used for opening a cigarette cover of a cigarette case from a closed state to an open state; the screening station comprises a film removing assembly used for opening lining aluminum-foil paper on a cigarette group; and the driving station drives all the stations to operate, the film removing assembly comprises a negative pressure suction plate and a guide plate, the negative pressure suction plate is arranged on one side of a conveying belt set and located above the cigarette cases, the guide plate is located on the rear side of the negative pressure suction plate, and the guide plate is provided with a first guide arc face extending in the direction of a positioning sliding plate. The side opening type cigarette case packaging machine has the effects that automatic packaging and automatic screening of cigarette groups are achieved through the combined action of all the stations, and the packaging efficiency is effectively improved.

Owner:浙江金龙烟草机械有限公司

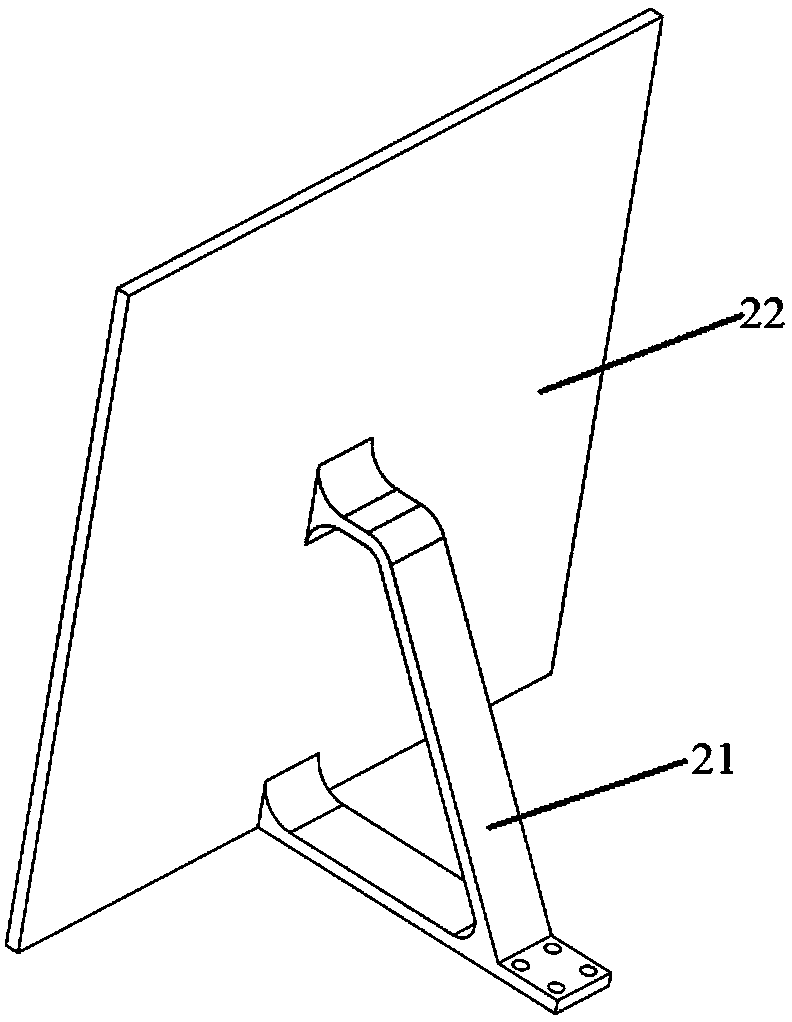

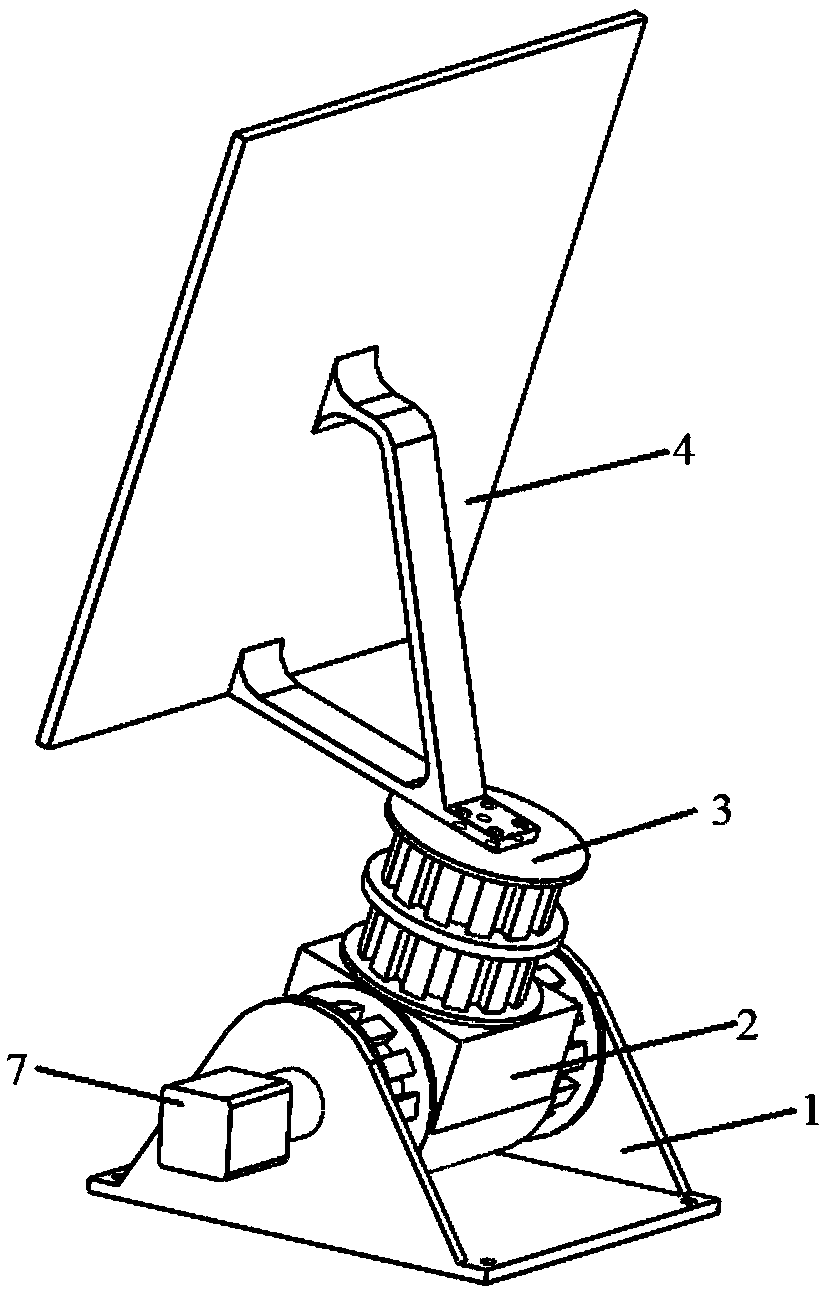

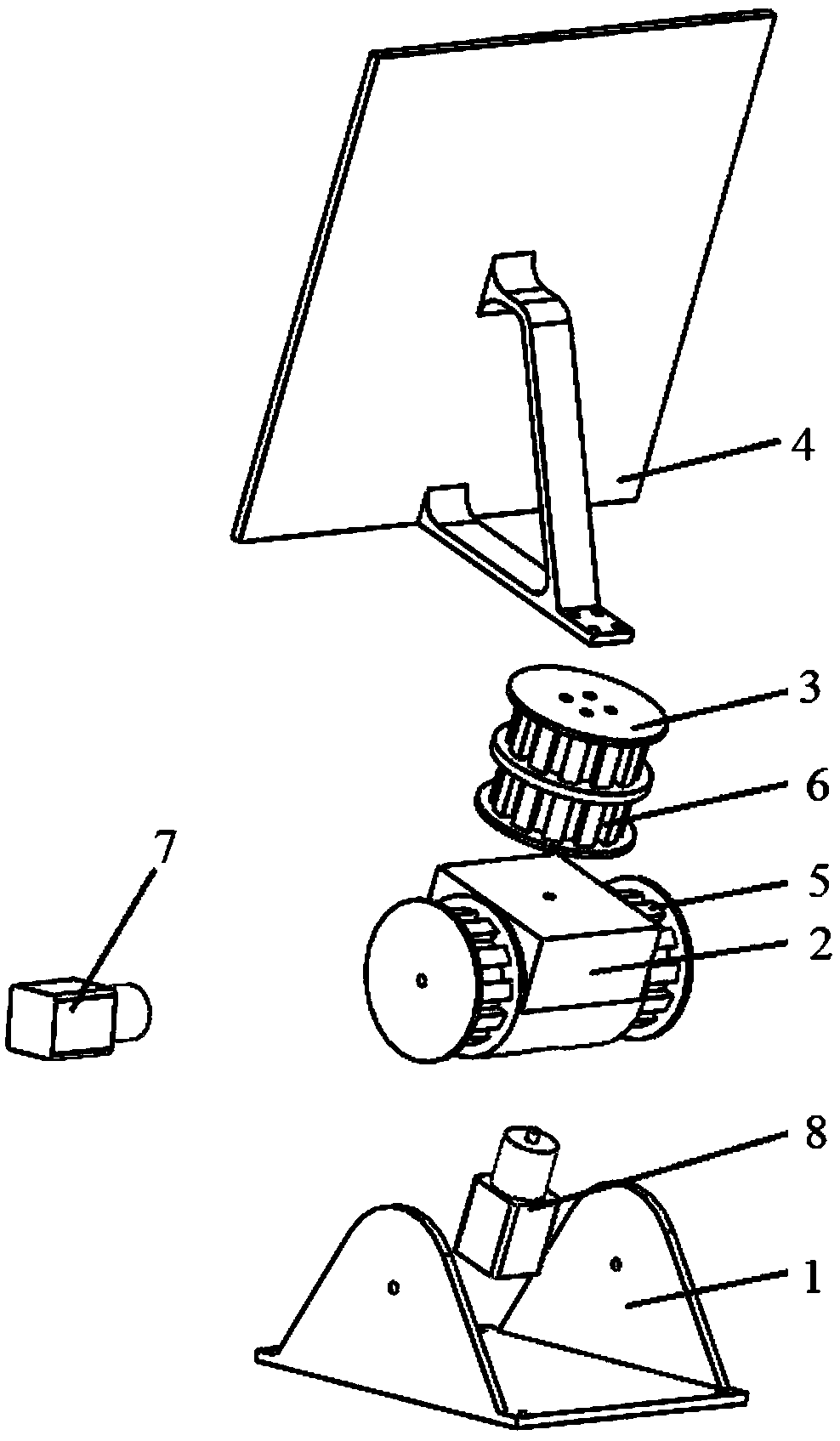

Matrix type solar cell panel direction adjusting system

PendingCN108566150AReduced drive mechanismLow costPhotovoltaic supportsSolar heating energyAerospace engineeringSunlight

The invention discloses a matrix type solar cell panel direction adjusting system, and belongs to the photovoltaic field. The system comprises a plurality of solar cell systems. Each solar cell systemcomprises a base, a pitching base, a rotating base and a solar cell panel, the pitching bases are hinged to the bases, and at least one pitching synchronizing mechanism is arranged on each pitching base; the pitching synchronizing mechanisms of at least two solar cell systems are connected with each other, and the rotating bases are hinged to the pitching bases, and at least one rotating synchronizing mechanism is arranged on each rotating base; the rotating synchronizing mechanisms of at least two solar cell systems are connected with each other; the rotating bases are connected with the solar cell panels; the pitching base of at least one solar cell system is connected with a pitching driving mechanism, and the rotating base of at least one solar cell system is connected with a rotatingdriving mechanism. According to the system, the posture of a solar cell panel array can be synchronously adjusted along with the sunlight incident angle, a large number of driving mechanisms are omitted, and the cost is reduced.

Owner:SHANDONG UNIV

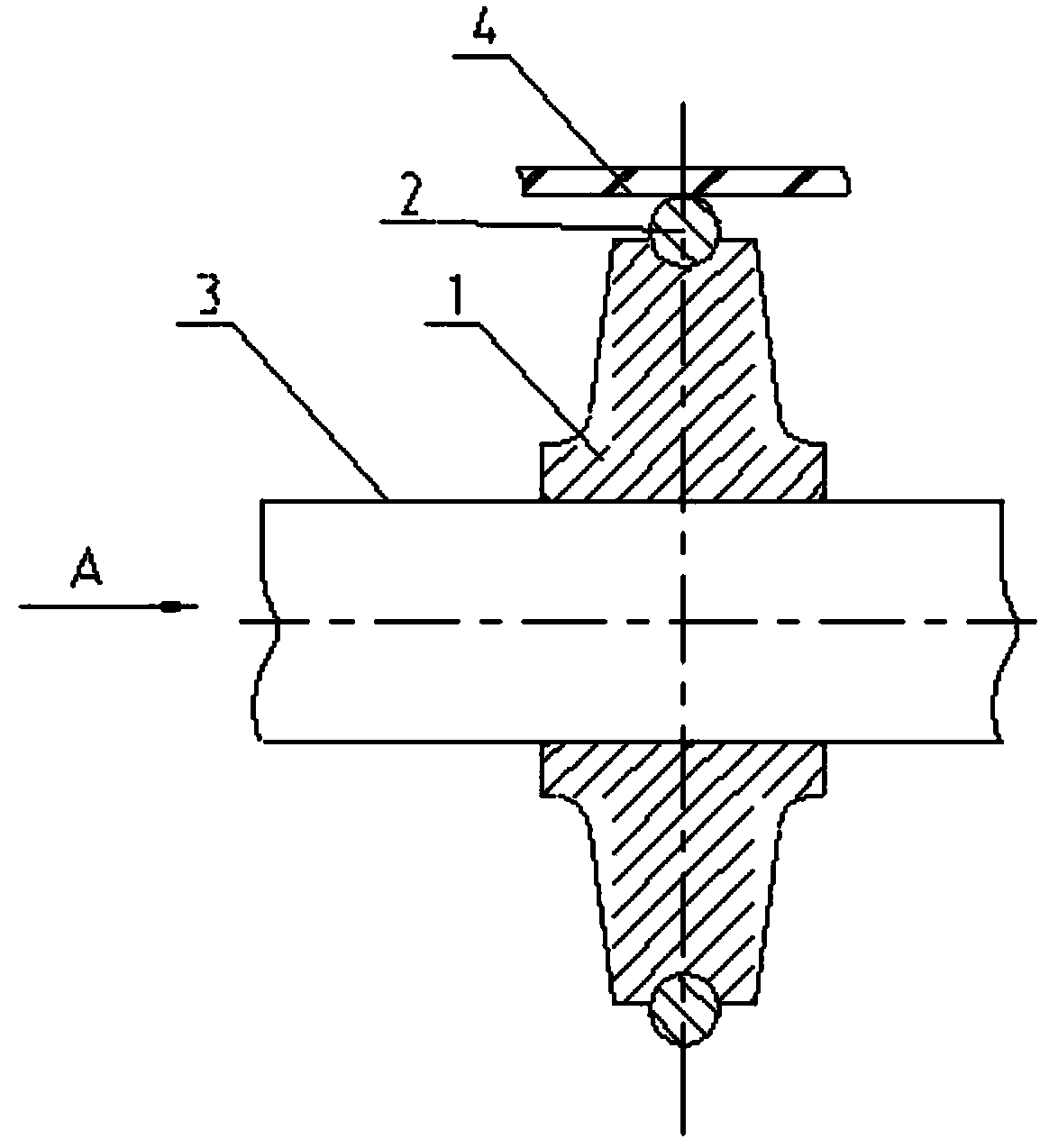

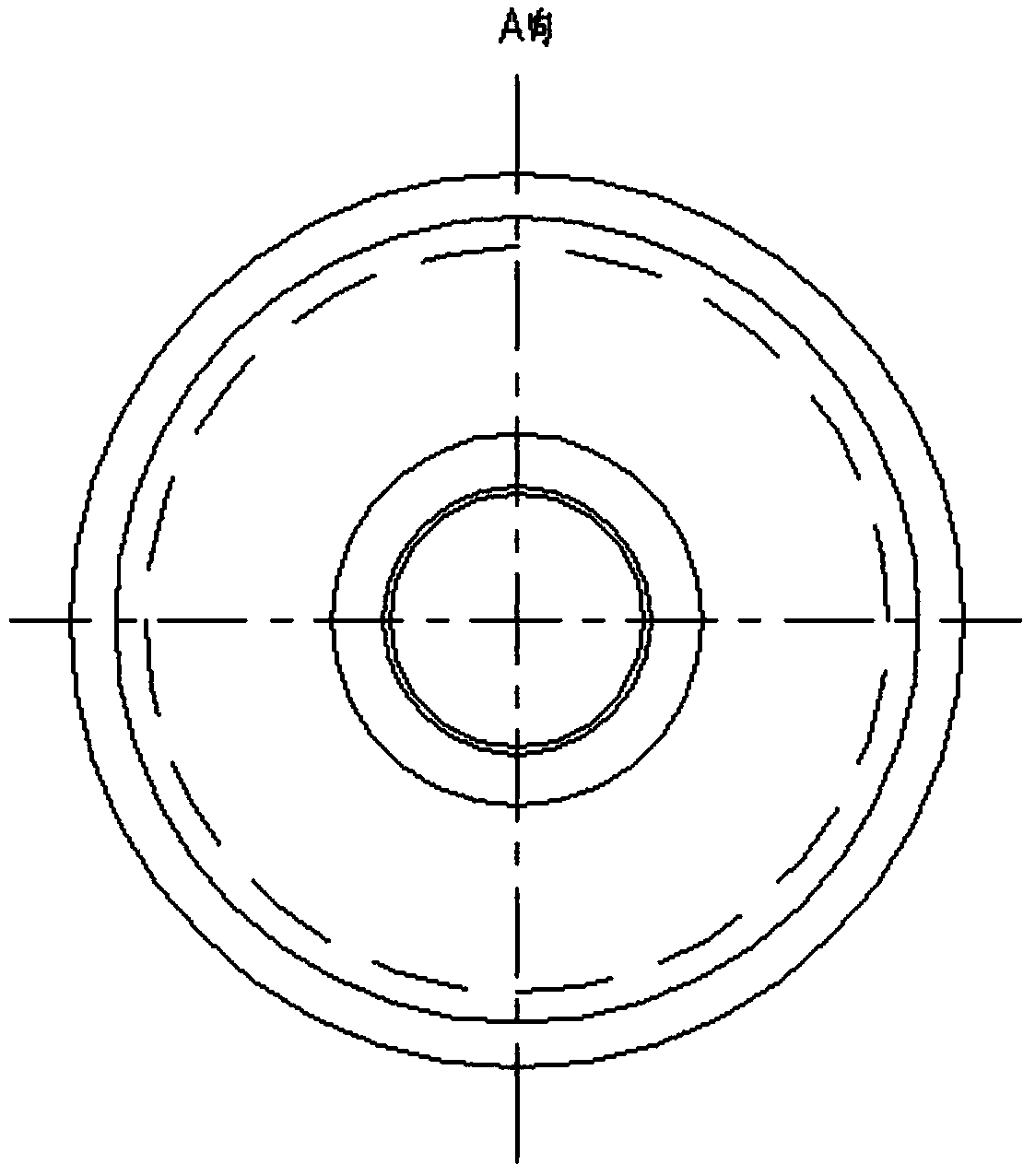

Rubber wheel structure for conveying glass

InactiveCN103466281ALarge contact surfaceGuaranteed to run synchronouslyRollersInterference fitEngineering

The invention relates to the technical field of glass production and glass deep processing, in particular to a rubber wheel structure for conveying glass. The rubber wheel structure for conveying the glass consists of an inner core and an external O-shaped ring, wherein the inner core is in interference fit with a mandrel to form a whole, and the mandrel is in linkage with the rubber wheel structure. The rubber wheel structure for conveying the glass is characterized in that the hole diameter of the inner core is smaller than the diameter of the mandrel, a cross section of the inner core is trapezoid, and the contact length between the inner core and the mandrel is larger than the width of the trapezoid cross section. Compared with the prior art, the rubber wheel structure for conveying the glass has the advantages that the inner core is of a trapezoid structure, so that the strength of a rubber wheel is enhanced, meanwhile materials are also saved, the cost is low, and the performance cost ratio is high; the inner core is in interference connection with the mandrel, so that enough friction force and the large contact face are formed between the mandrel and the inner core; the inner core and the external O-shaped ring are separated, so that different materials can be adopted, and only the external O-shaped ring is required to be replaced after being abraded; only the external O-shaped ring of the whole rubber wheel is in contact with the glass, glass scratching is decreased, and the quality of conveyed glass is ensured.

Owner:CHINA TRIUMPH INT ENG

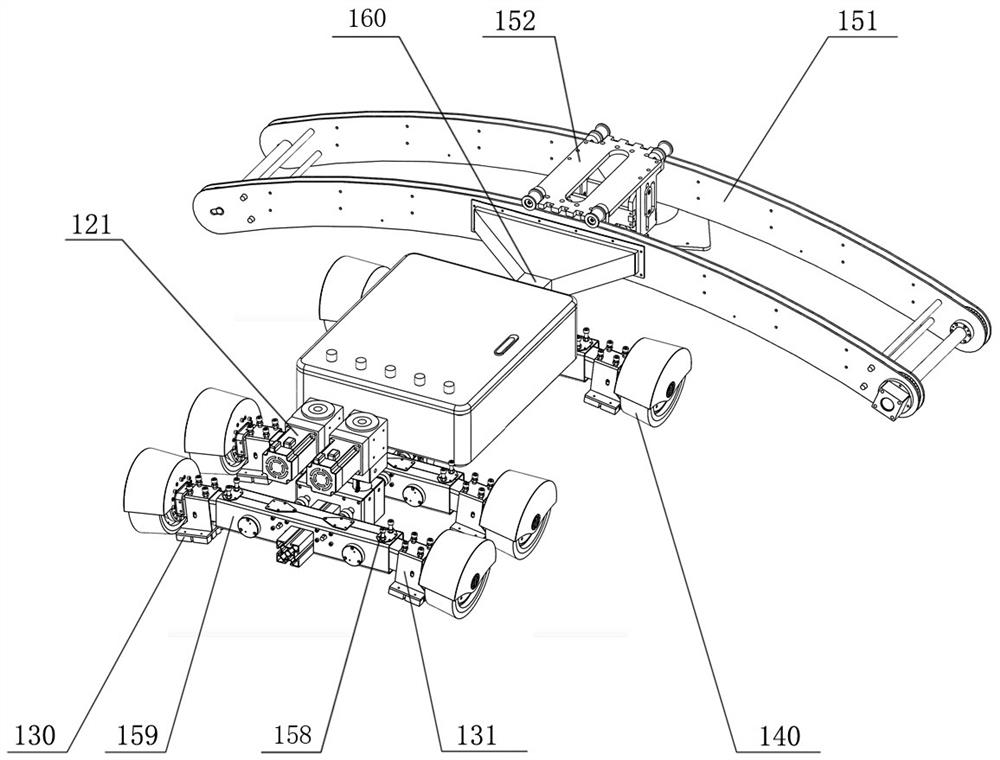

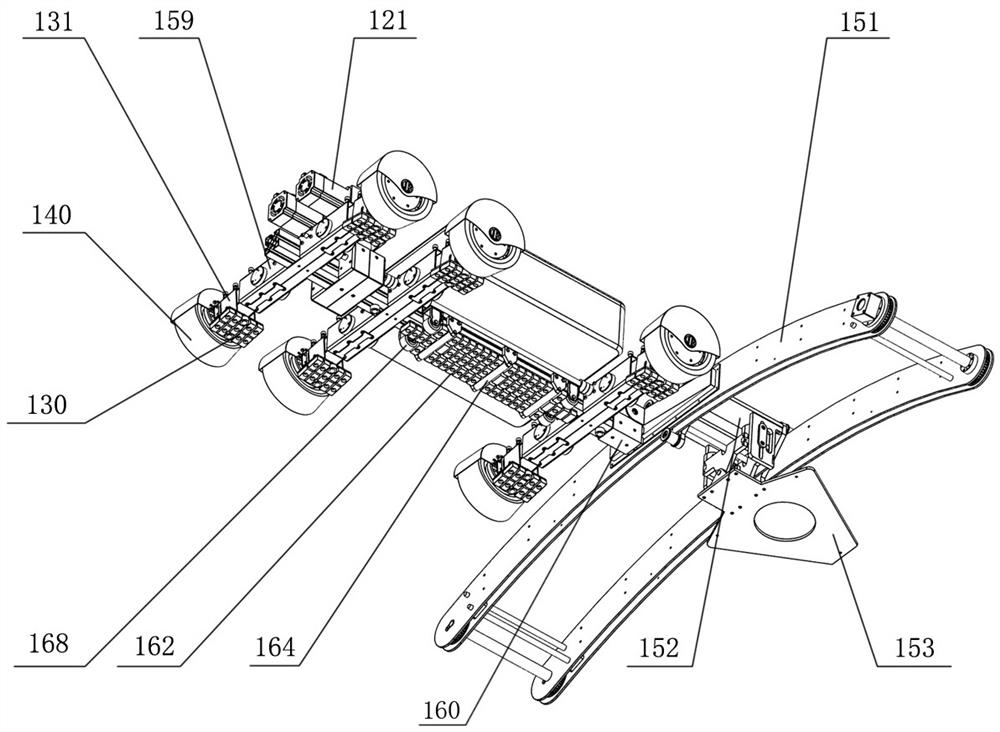

Wall-climbing robot suitable for cleaning fan tower

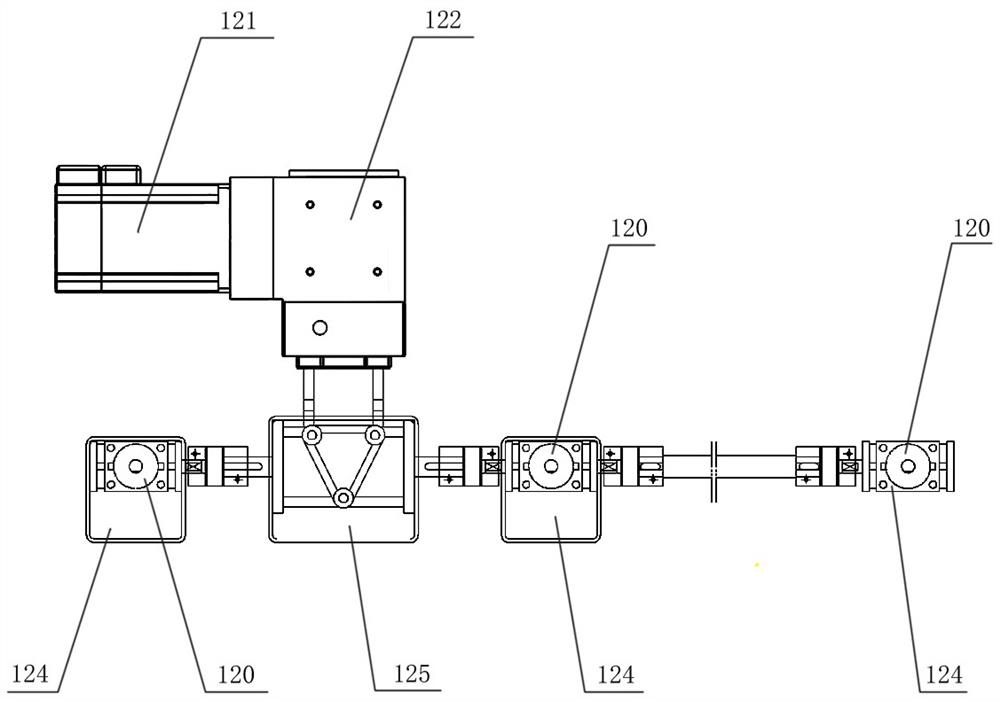

PendingCN111878327AGuaranteed to run synchronouslyReduce the number of configurationsMachines/enginesWind energy generationMotor speedReduction drive

The invention relates to a wall-climbing robot suitable for cleaning a fan tower. The wall-climbing robot structurally comprises a rack, a walking driving system, movable supporting arms and a magnetic chuck; the walking driving system comprises a motor speed reducer and a universal shaft; power output shafts are connected to the two output ends of the motor speed reducer respectively, each poweroutput shaft is connected with a commutator, and the output ends of the commutators are connected with wheel assemblies on the same side of the robot through the universal shaft, so that wheels on thesame side of the wall-climbing robot are driven by one motor speed reducer to operate synchronously; and the movable supporting arms comprise supporting arm assemblies and the wheel assemblies, harmonic speed reducers are installed in the wheel assemblies, and the universal shaft is connected with the harmonic speed reducers through fasteners. According to the wall-climbing robot, the movable supporting arms on the same side of the robot are driven and controlled by one motor speed reducer, a multi-stage speed reduction driving manner can be formed, the configuration number and dead weight ofthe motor speed reducers are reduced, and the loading capacity and working characteristics of the wall-climbing robot can be improved.

Owner:温广胜 +1

Hydraulic system of tuna fishing machine

ActiveCN103392680AGuaranteed to run synchronouslyAvoid destructionOther angling devicesBall valveEngineering

The invention discloses a hydraulic system of a tuna fishing machine. The hydraulic system of the tuna fishing machine comprises a rope coiling machine hydraulic motor and a rope throwing machine hydraulic motor. An oil supplement pipeline is connected between the rope coiling machine hydraulic motor and the rope throwing machine hydraulic motor, is divided into two paths after starting off from a rope throwing machine hydraulic pipeline, and is respectively connected into an oil inlet and an oil outlet of the rope coiling machine hydraulic motor through one-way valves, two pressure release valves are arranged between the two ends of the oil inlet and the oil outlet of the rope throwing machine hydraulic motor in parallel and are opposite in direction, and a high pressure ball valve is connected between the oil inlet and the oil outlet of the rope throwing machine hydraulic motor. The hydraulic system can prevent the pipelines from being damaged when an emergency brake is carried out on a rope coiling machine, can prevent the rope coiling machine from rotating and from being damaged without hydraulic oil when a rope throwing machine operates, and can guarantee synchronous operation of the rope cooling machine and the rope throwing machine.

Owner:中创海洋科技股份有限公司

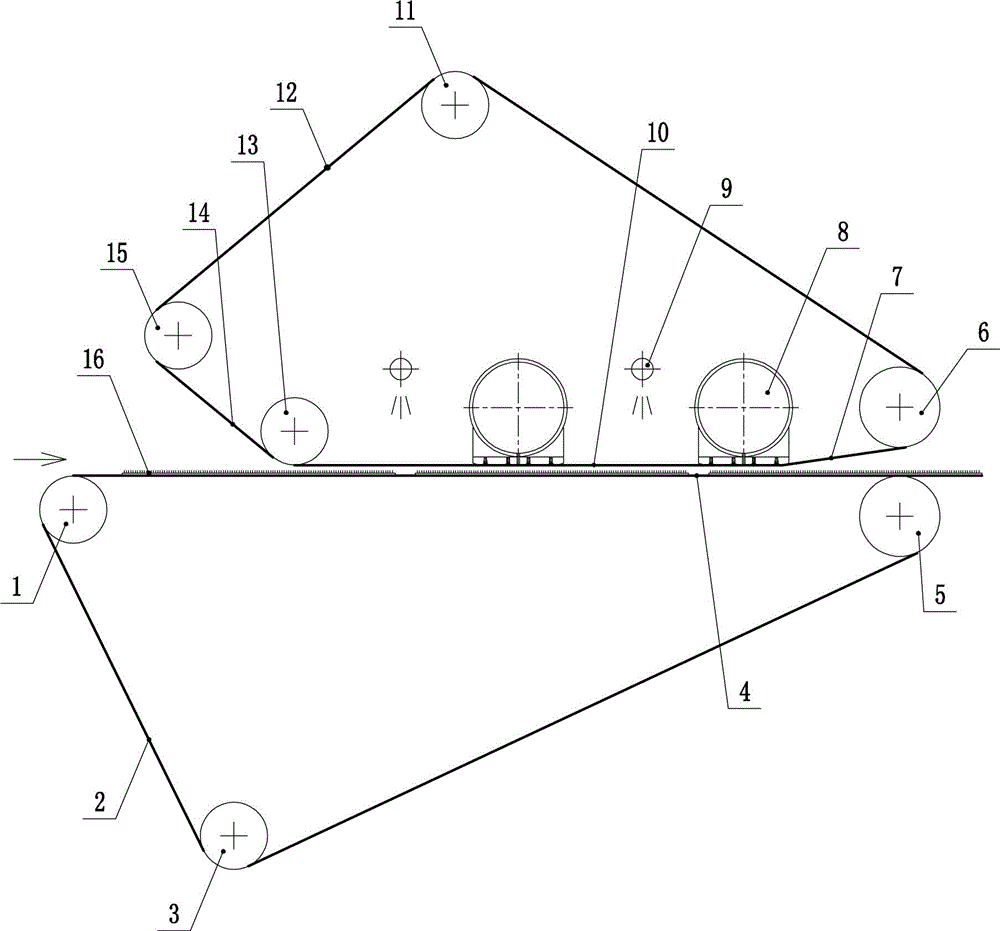

Tufted carpet fabric dual-net-belt clamped washing structure

InactiveCN104924751ARealize continuous production operationGuaranteed to run synchronouslyPrinting press partsEngineeringWater spray

A tufted carpet fabric dual-net-belt clamped washing structure comprises an upper drive operating system and a lower drive operating system which are independent, wherein the lower drive operating system comprises a lower first drive roller and a lower second drive roller which are horizontally arranged, the lower first drive roller and the lower second drive roller perform joint drive and are provided with a lower drive net belt, and the lower drive net belt located on the upper sides of the lower first drive roller and the lower second drive roller is a lower clamping section. An upper drive operating system comprises an upper first drive roller and an upper second drive roller which are horizontally arranged, the upper first drive roller and the upper second drive roller perform joint drive and are provided with an upper drive net belt, and the upper drive net belt located on the upper sides of the upper first drive roller and the upper second drive roller is an upper clamping section. An upper clamping discharge section and a lower clamping discharge section are vertically and correspondingly arranged, the upper drive net belt operates with respect to the lower drive net belt in the reverse direction, and a clear water spraying pipe and a vacuum water suction pipe are arranged above the upper clamping discharge section in a front-rear mode. A gap is reserved between the upper clamping discharge section and the lower clamping discharge section.

Owner:山东源丰印染机械有限公司

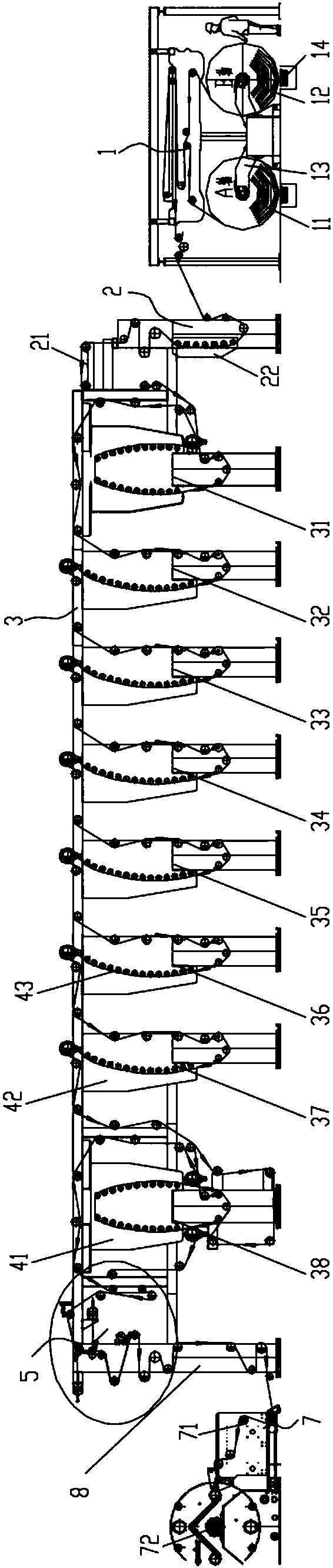

An intelligent high-speed gravure printing machine

InactiveCN106142819BGuaranteed to run synchronouslyEnsure high precision overprintRotary intaglio printing pressPrinting press partsProduct inspectionPrinting press

The invention discloses an intelligent high-speed gravure printing machine. The machine comprises a double-shaft unwinding and zero-speed butt-jointing storage frame, an unwinding traction device, an eight-color gravure printing device, a product inspection device, a labeling device and a winding traction device which are arranged sequentially, wherein the product inspection device comprises a still picture device; and the labeling device is arranged below the product inspection device. According to the machine, during unwinding, two hydraulic lifting arms with hydraulic lifting single-stations are adopted for zero-speed receiving in a non-stop manner, preheating is performed by the aid of a preheating drying oven of the unwinding traction device, transverse plate deviation is avoided by the aid of an advancing deviation correction device, various electronic printing plate shafts are driven by servo motors of color groups of the eight-color gravure printing device separately, reliable and high-speed data communication of various servo controllers is realized by the aid of field buses, and high-precision overprinting is guaranteed; products are monitored on line by the aid of the still picture device of the product inspection device; and non-stop horizontal pushing press roller winding is performed by the aid of a horizontal pushing press roller receiving mechanism.

Owner:广东顺德德力印刷机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com