An intelligent high-speed gravure printing machine

A kind of gravure printing machine and gravure printing technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems such as difficult to achieve speed, unable to meet large-scale printing, good printing quality, etc., to ensure synchronous operation , to ensure the effect of high-precision overprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

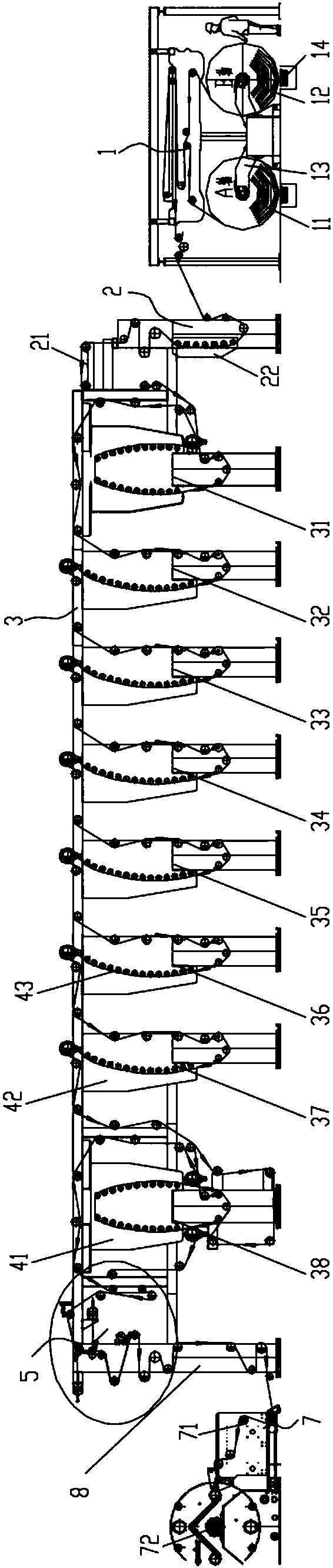

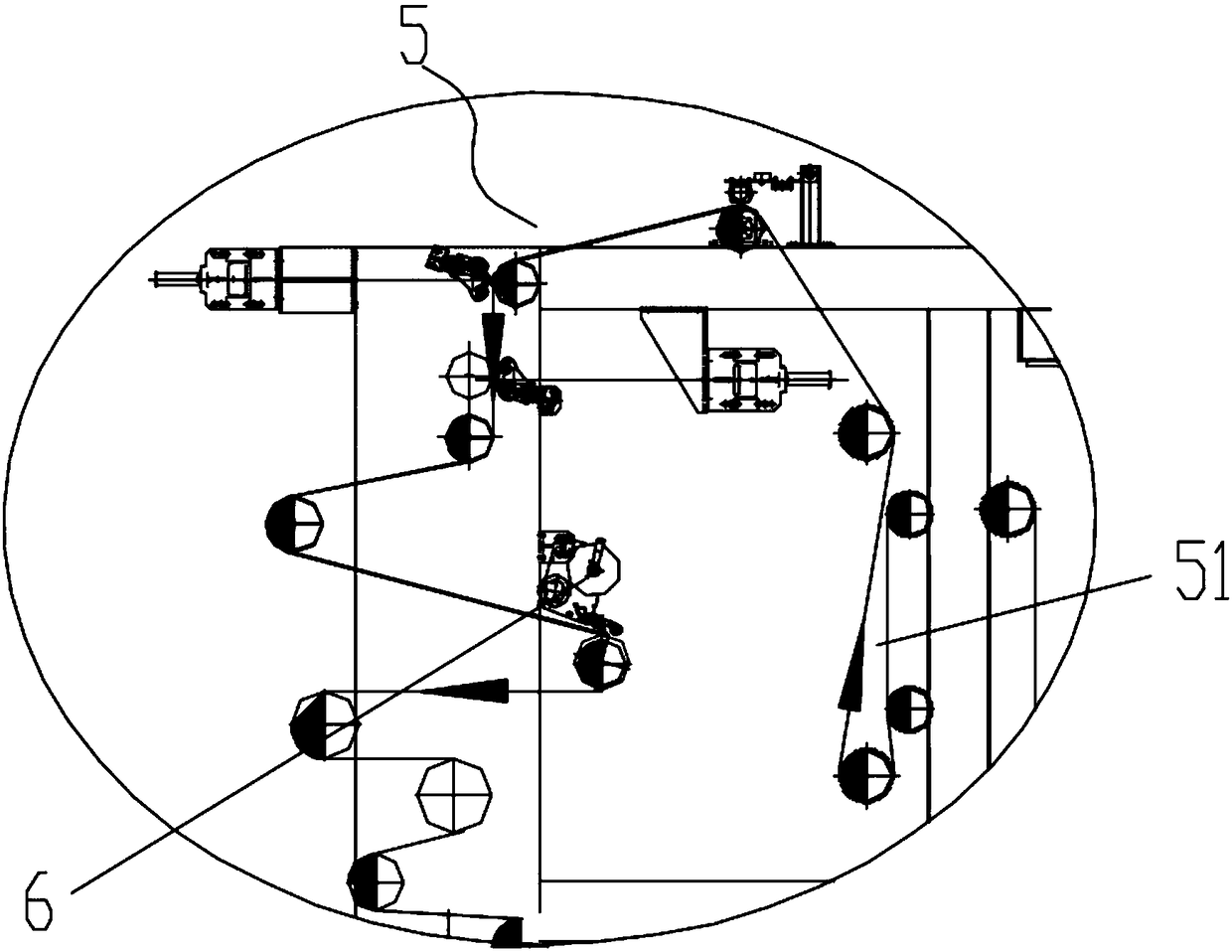

[0021] Examples, see Figure 1 ~ Figure 2 , the intelligent high-speed gravure printing machine provided in this embodiment includes a double-axis unwinding zero-speed docking storage rack 1, an unwinding traction device 2, an 8-color gravure printing device 3, a product inspection device 5, and a labeling device. 6 and traction winding device 7; the 8-color gravure printing device 3 includes the first color group 31, the second color group 32, the third color group 33, the fourth color group 34, the fifth color group 35, The sixth color group 36, the seventh color group 37 and the eighth color group 38, the first color group 31 and the eighth color group 38 are provided with a positive and negative printing oven 41, and the second color group 32 to the seventh color group The group 37 is provided with a positive printing oven 42 ; the inspection device 5 includes a still picture device 51 , and the labeling device 6 is arranged below the inspection device 5 . The inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com