Rubber wheel structure for conveying glass

A rubber wheel and glass technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve problems such as scratches and glass scratches, and achieve the effects of reducing scratches, ensuring quality, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

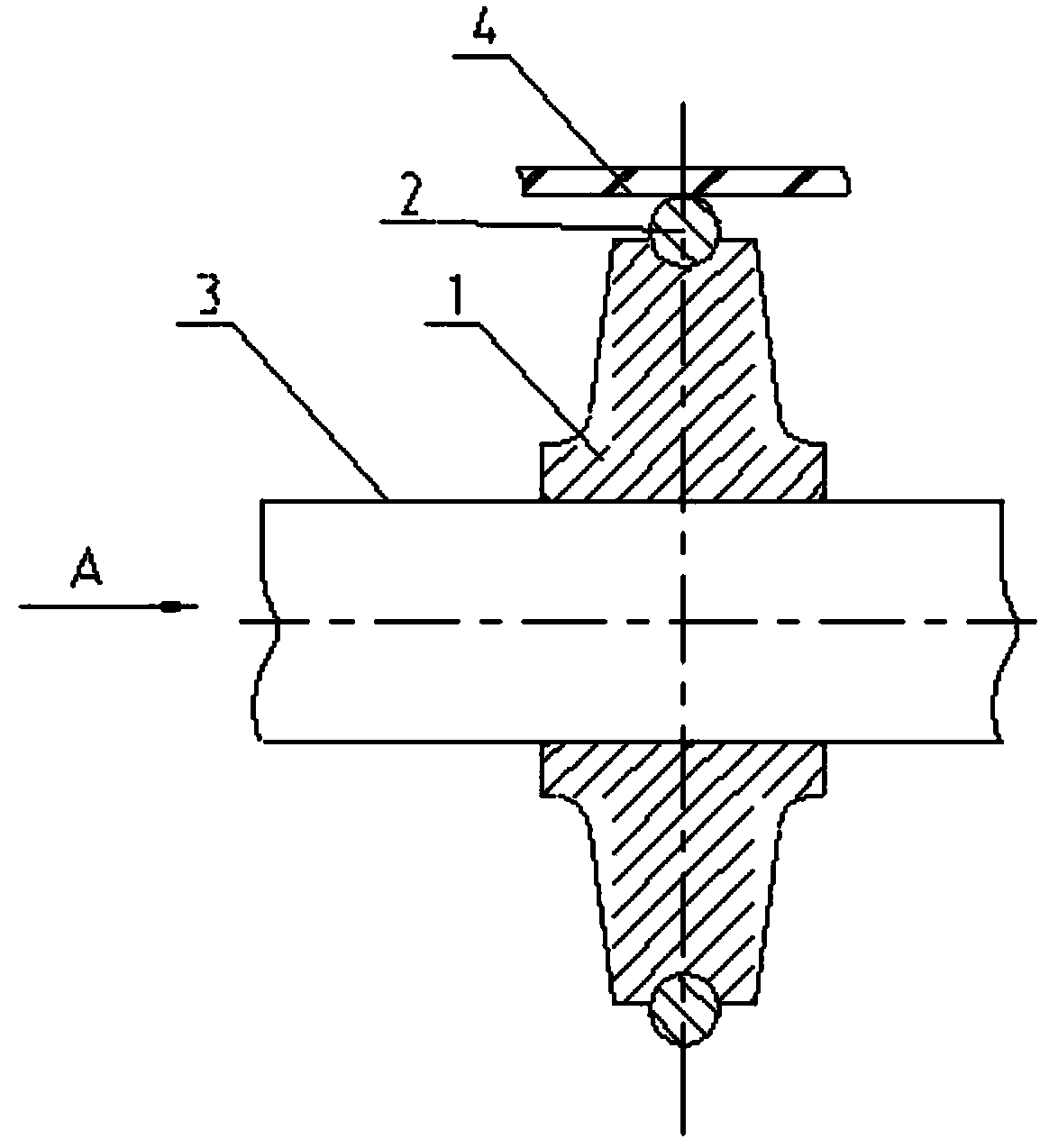

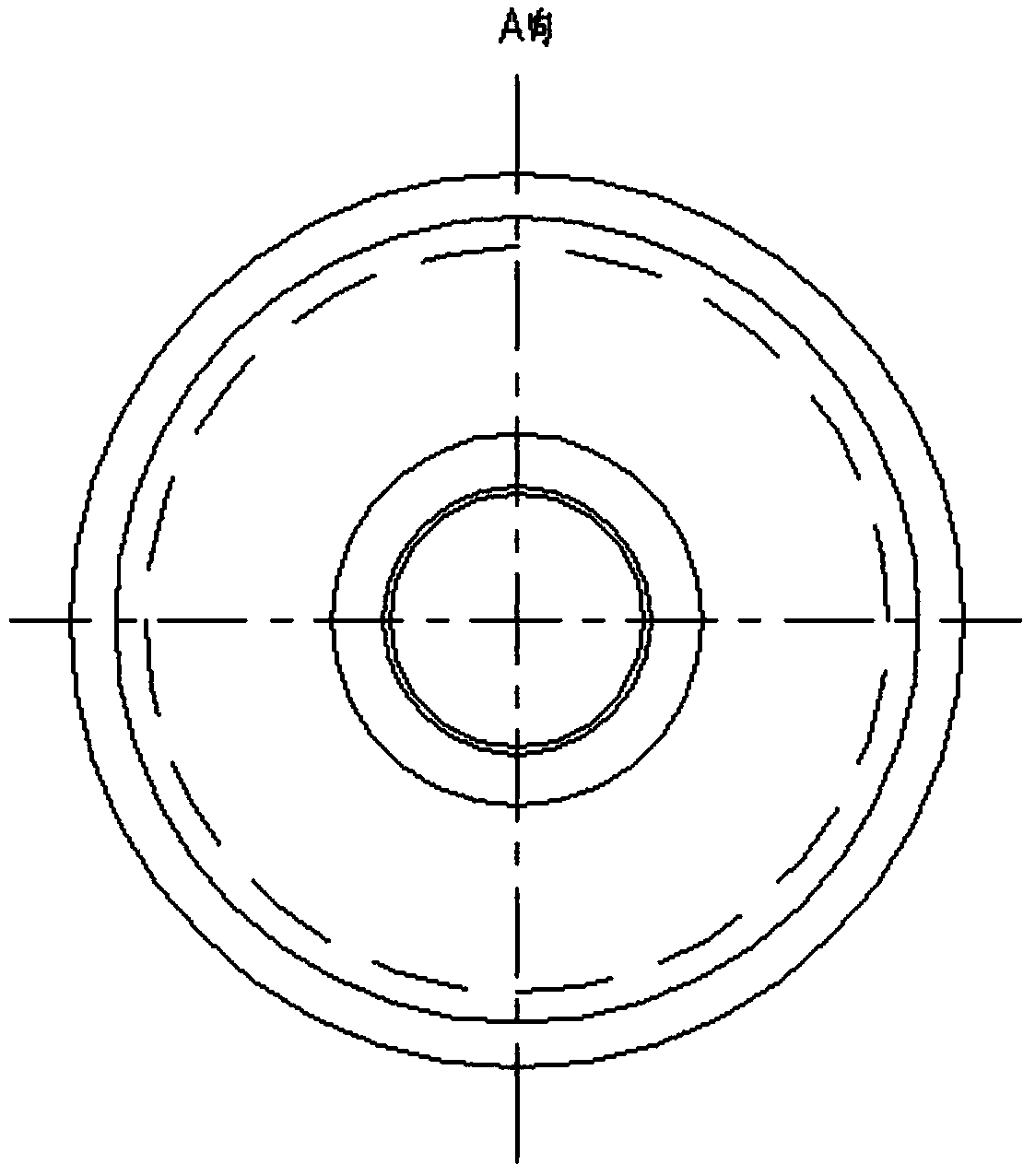

[0021] like figure 1 , figure 2 As shown, the present invention is used in glass production or glass deep processing equipment. The inner core 1 and the mandrel 3 are integrated through the interference fit between the inner core 1 and the mandrel 3. When the mandrel 2 rotates, the rubber wheel is driven to rotate together. So as to play the role of conveying glass.

[0022] The rubber wheel is composed of inner core 1 and outer rubber ring. The inner hole of the inner core 1 is smaller than the shaft diameter, which ensures an interference fit with the mandrel 3. The contact length between the inner hole and the mandrel 3 is wider than the section of the inner core 1, so that There is a sufficient contact surface between the inner core 1 and the mandrel, so as to ensure a sufficiently strong frictional force between the inner core 1 and the mandrel 2 .

[0023] The outer O-ring 2 is processed separately from the inner core 1, so that the two can be made of different materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com