Grouting combined mould

A combined mold and grouting technology, used in die-casting molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of low grouting molding efficiency, high production cost, low utilization rate of gypsum molds, etc., and achieve good splicing efficiency and connection. Large contact surface and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

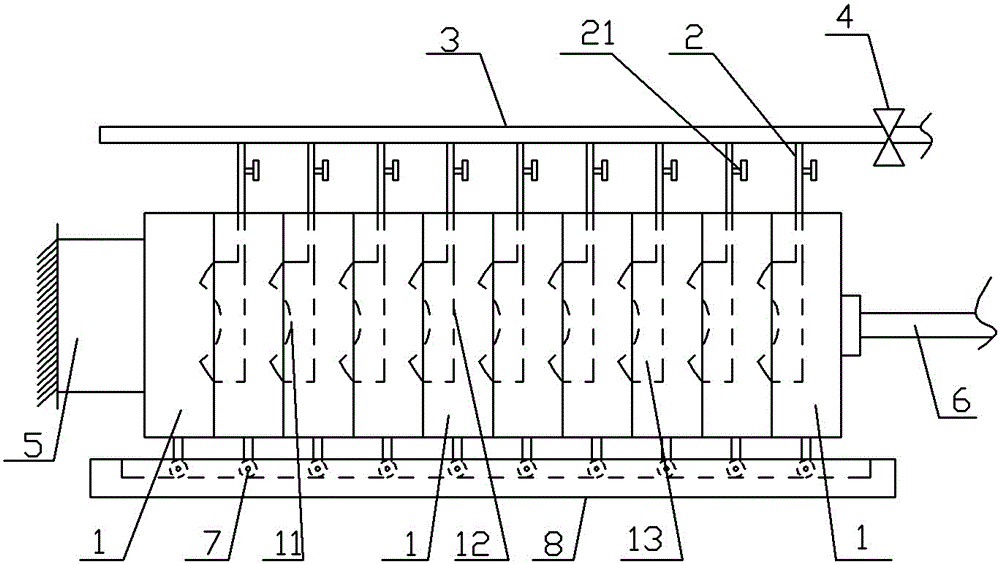

[0014] The reference signs in the drawings of the description include: plaster mold 1, bump 11, groove 12, mud forming cavity 13, grouting branch pipe 2, grouting valve 21, mud pipe 3, mud pump 4, limit block 5, Cylinder output shaft 6, roller 7, guide rail 8.

[0015] Embodiment The grouting combined mold is basically as attached figure 1 Shown:

[0016] The combined plaster mold for grouting includes ten plaster molds 1 that are joined together. Among any two adjacent plaster molds 1, the plaster mold 1 on the left has a bump 11, and the plaster mold 1 on the right has a bump 11. The groove 12 opposite to the bump 11 forms a mud molding cavity 13 between the bump 11 and the groove 12. The plaster mold 1 with the groove 12 is provided with a grouting port communicating with the mud molding cavity 13. The grouting The mouth is connected with the grouting branch pipe 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com