Patents

Literature

88results about "Granulation on conveyor belts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

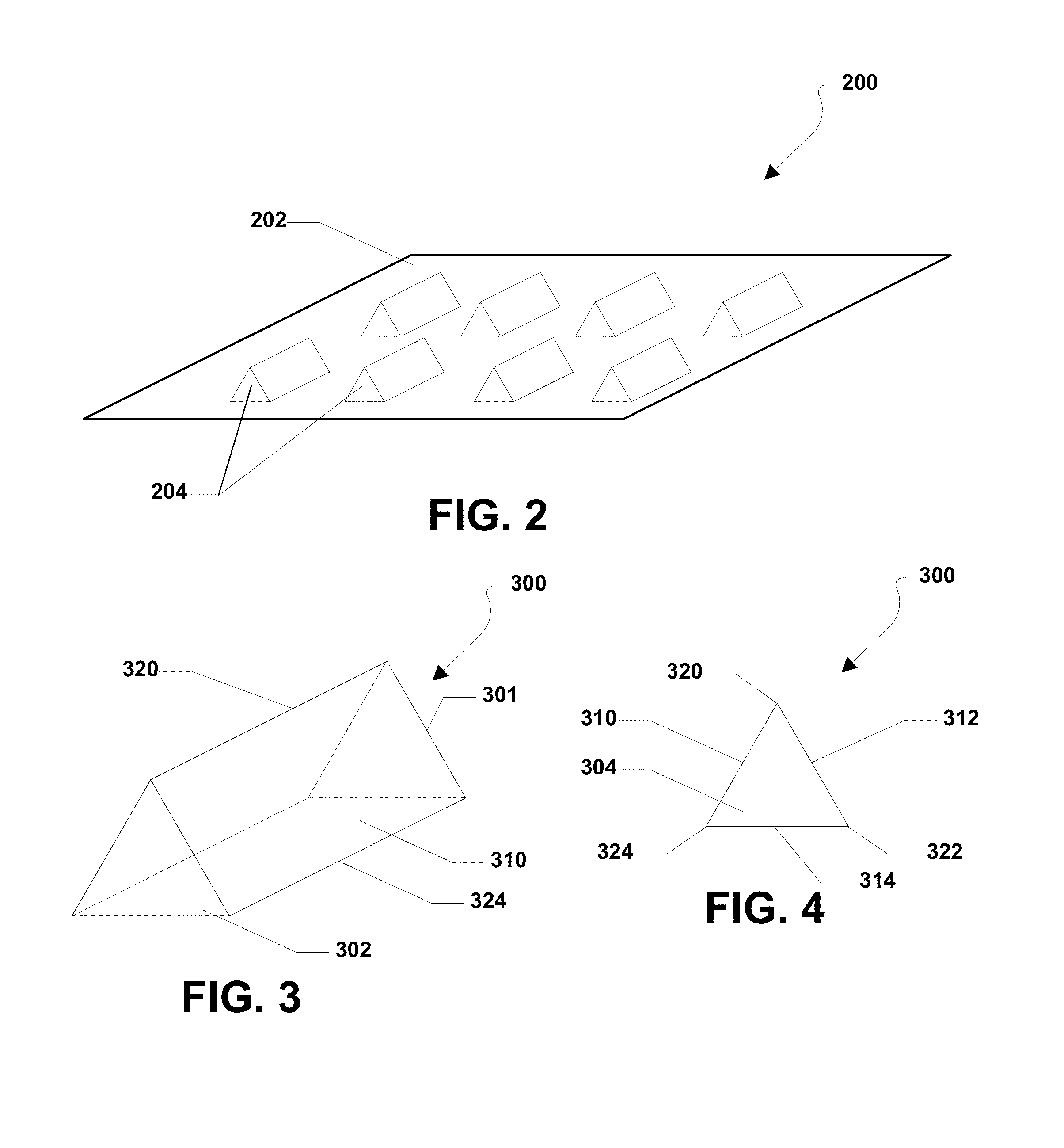

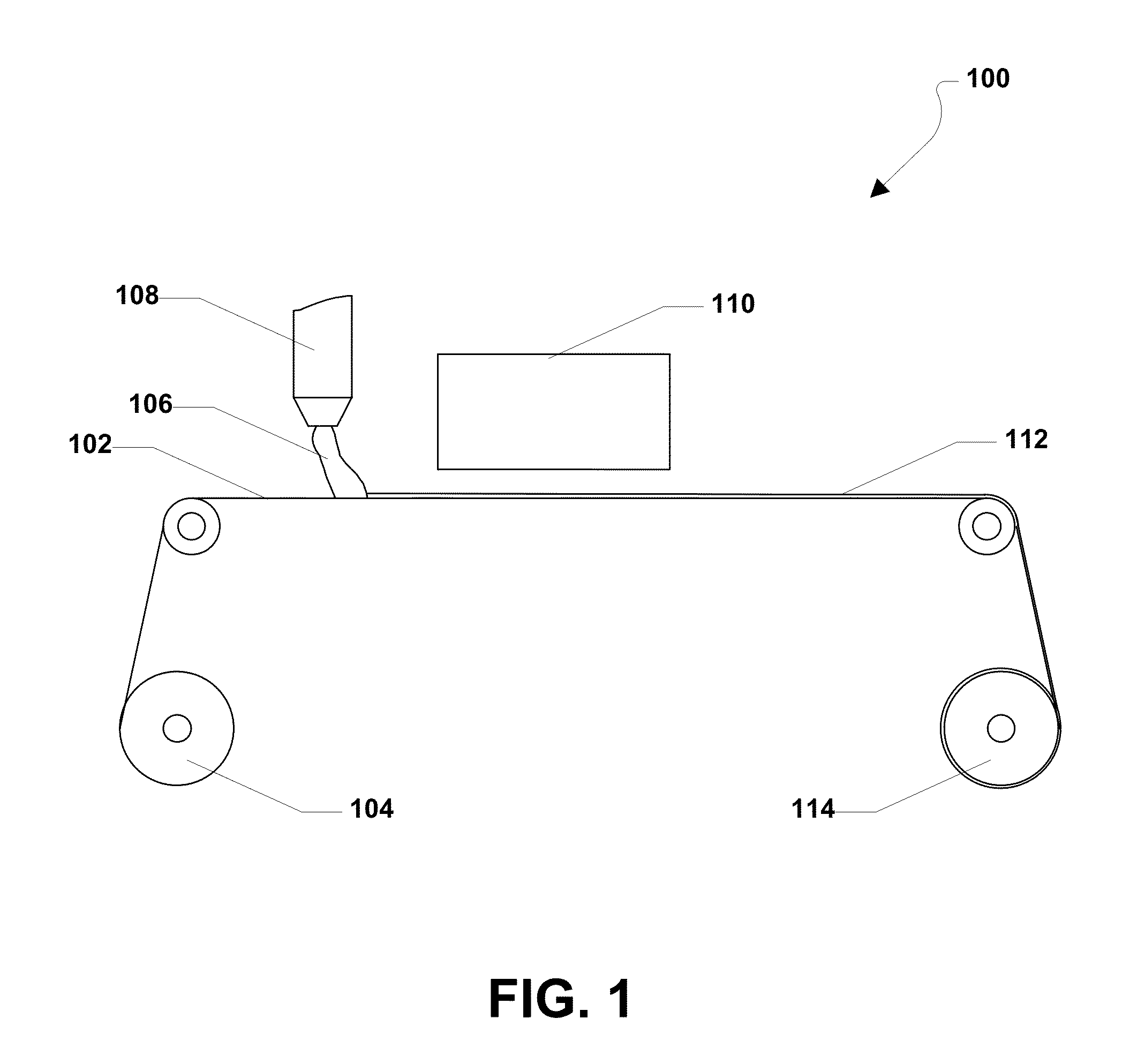

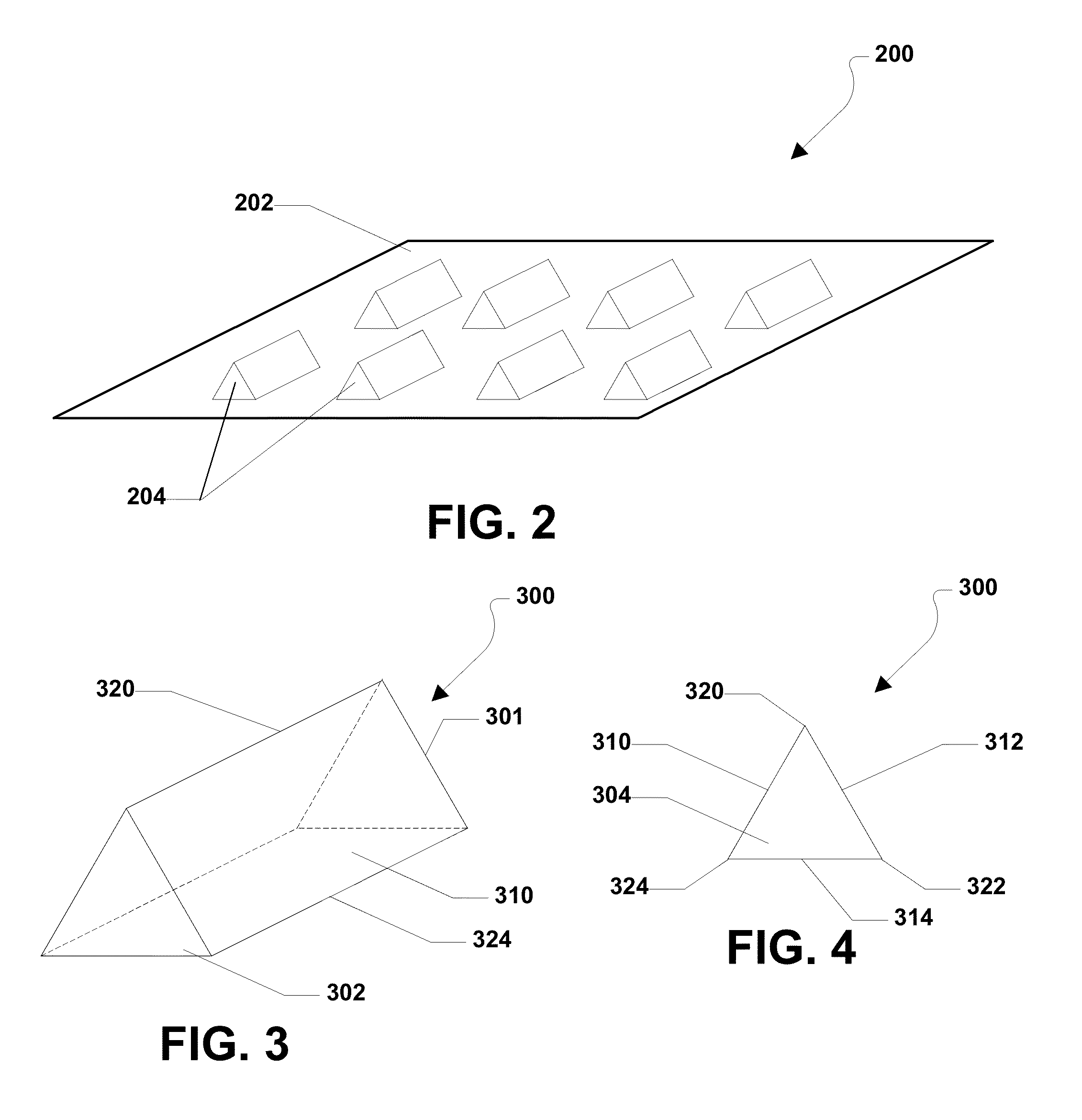

Abrasive particles having complex shapes and methods of forming same

An abrasive grain is disclosed and may include a body. The body may define a length (l), a height (h), and a width (w). In a particular aspect, the length is greater than or equal to the height and the height is greater than or equal to the width. Further, in a particular aspect, the body may include a primary aspect ratio defined by the ratio of length:height of at least about 2:1. The body may also include an upright orientation probability of at least about 50%.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Pastillation of Ammonium Sulfate Nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

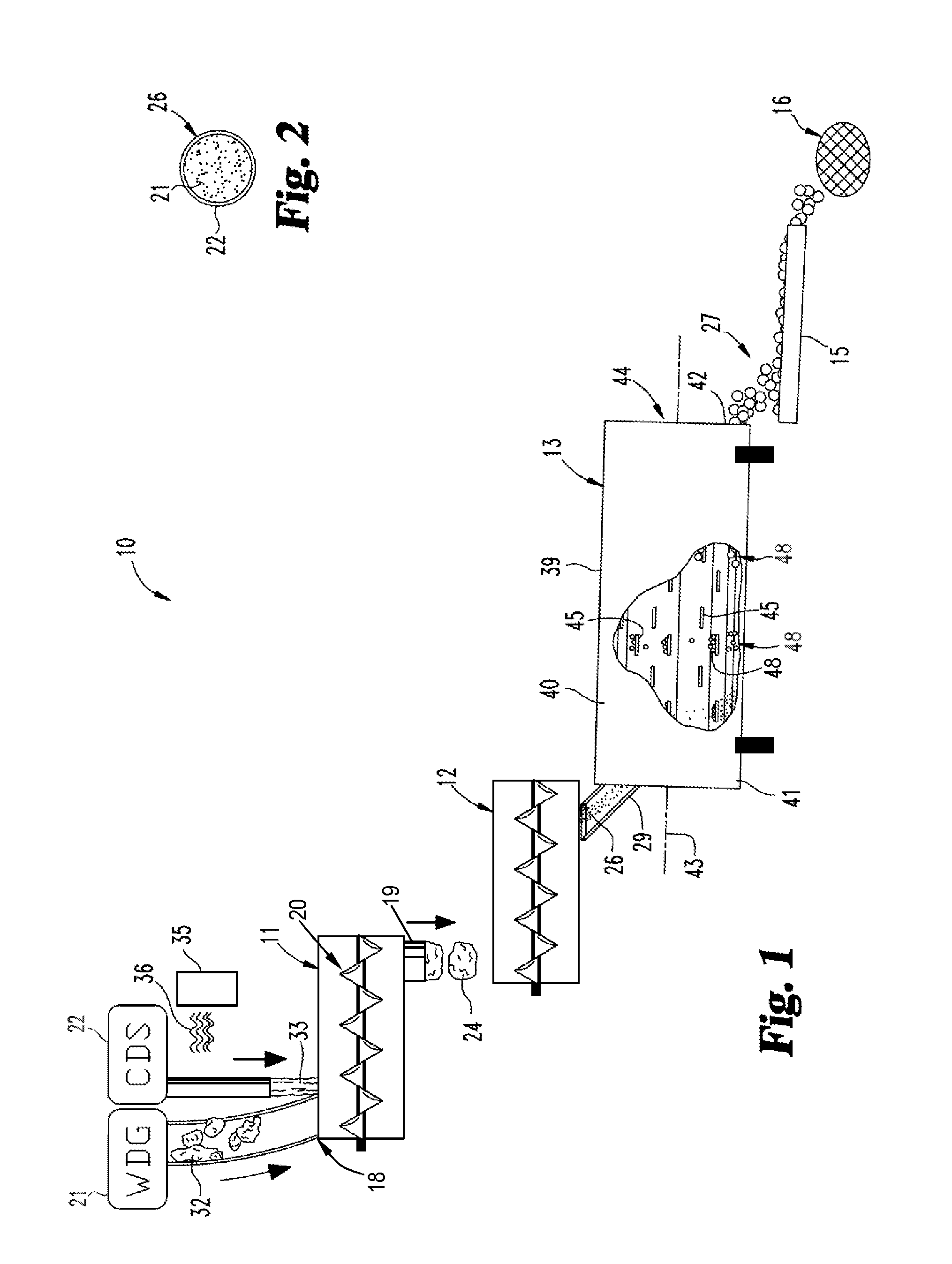

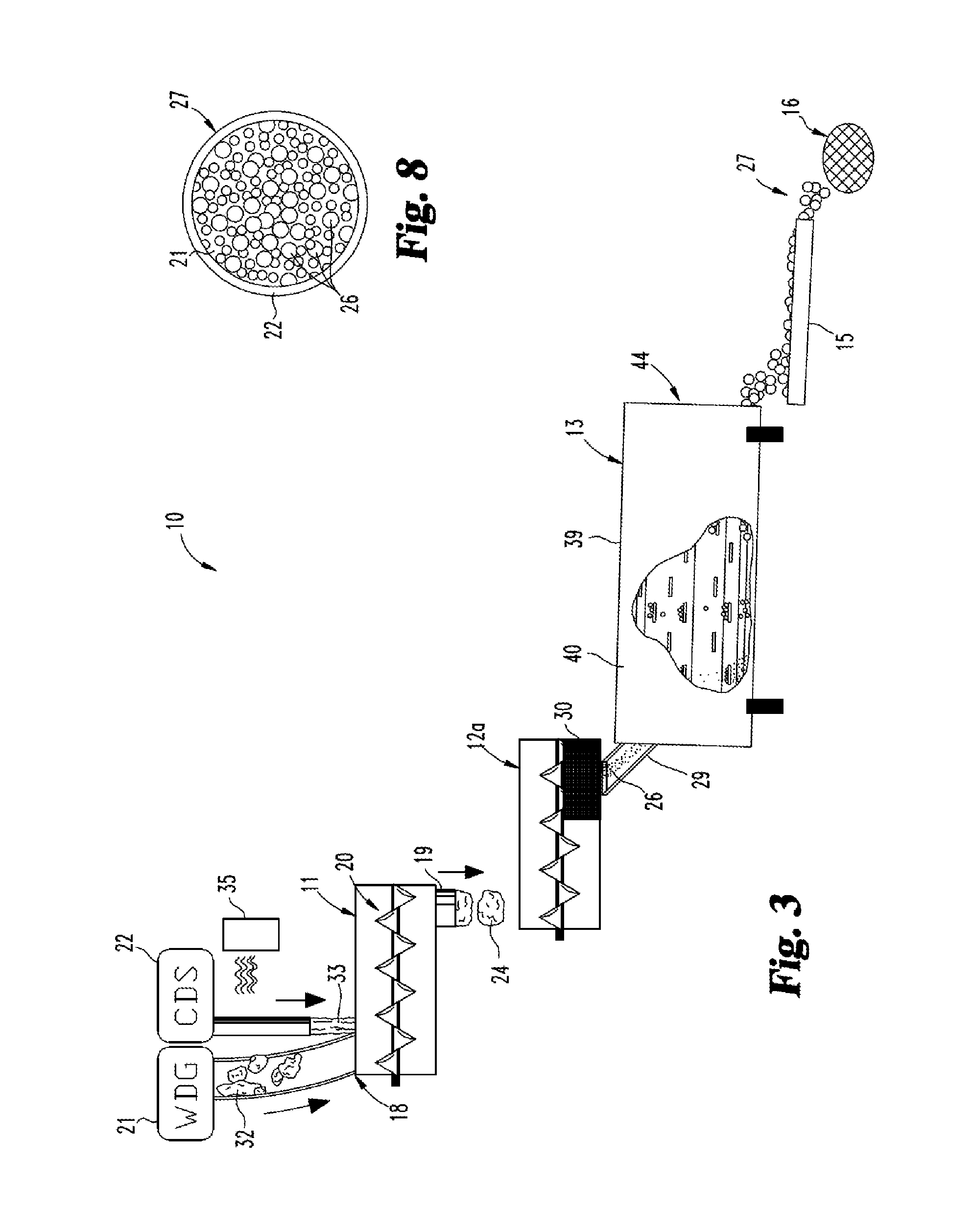

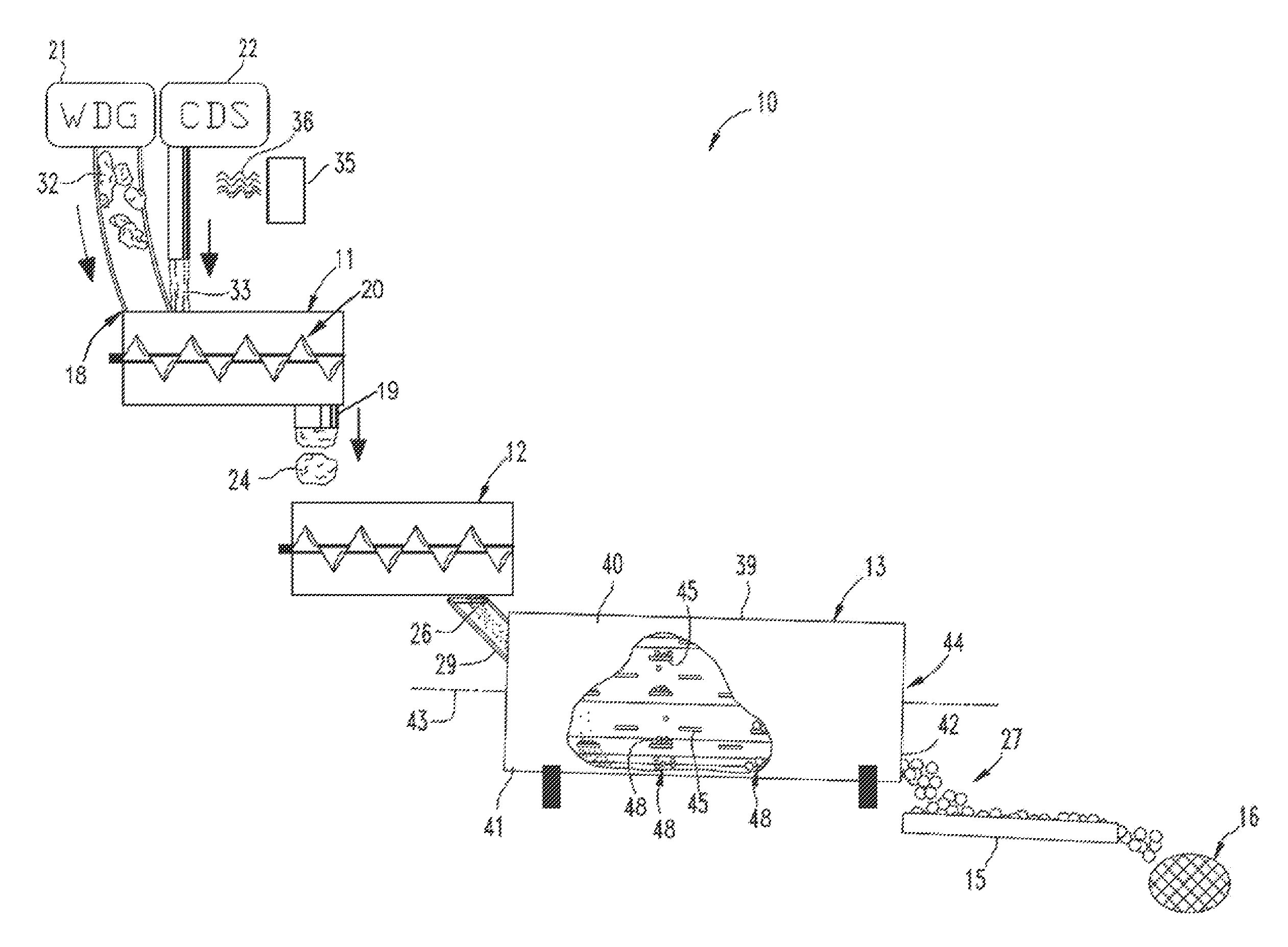

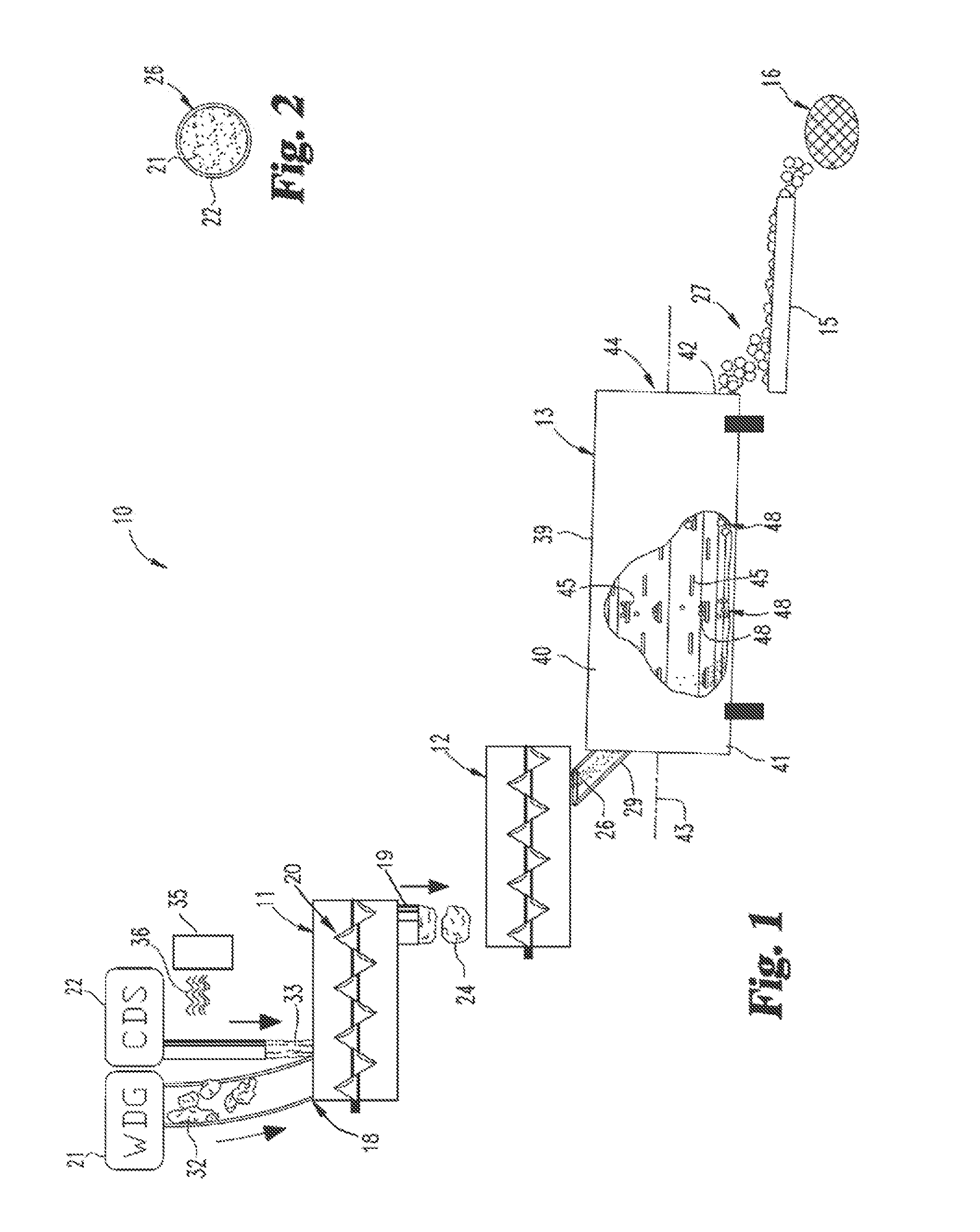

Apparatus and method for producing biobased carriers from byproducts of biomass processing

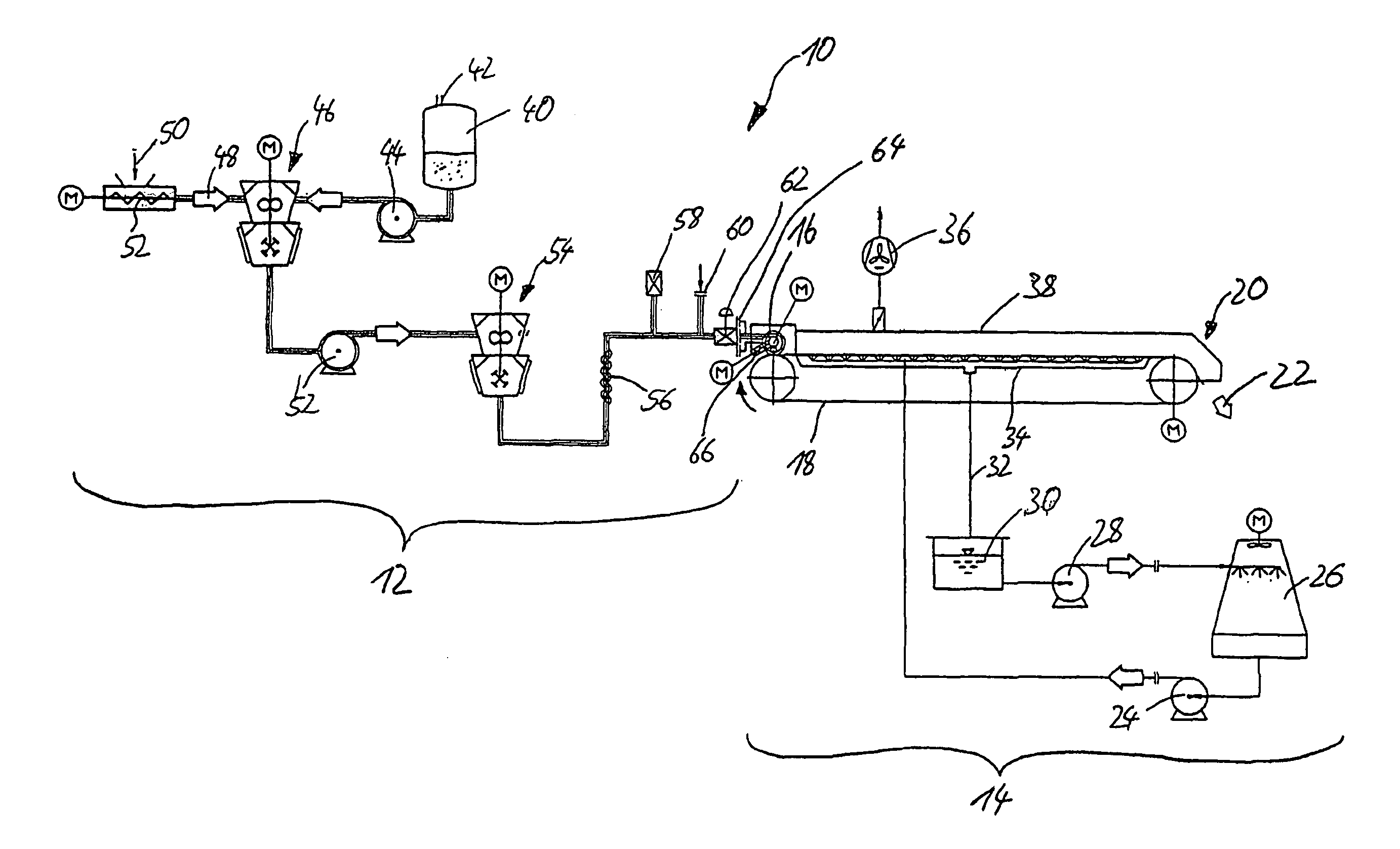

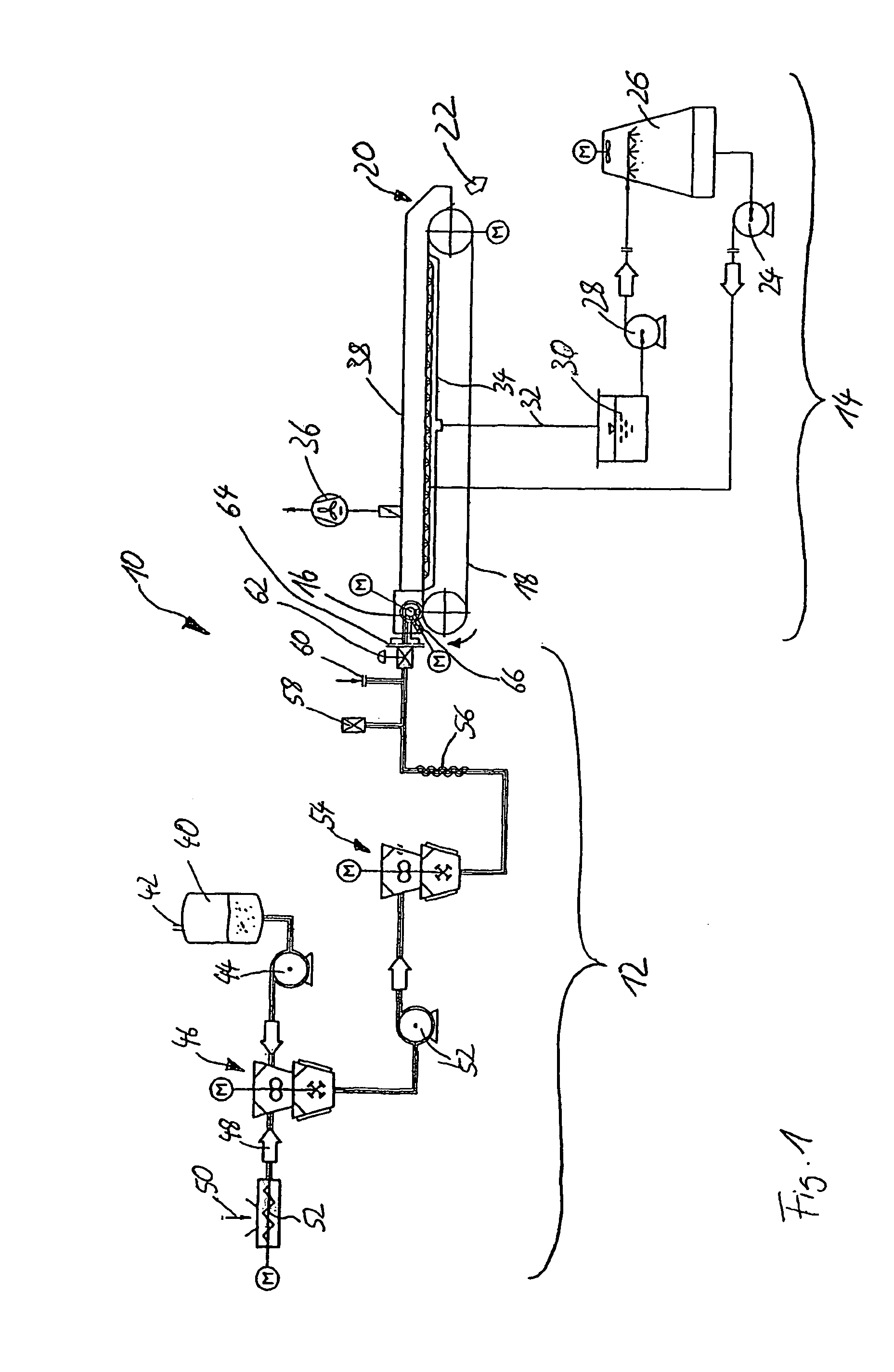

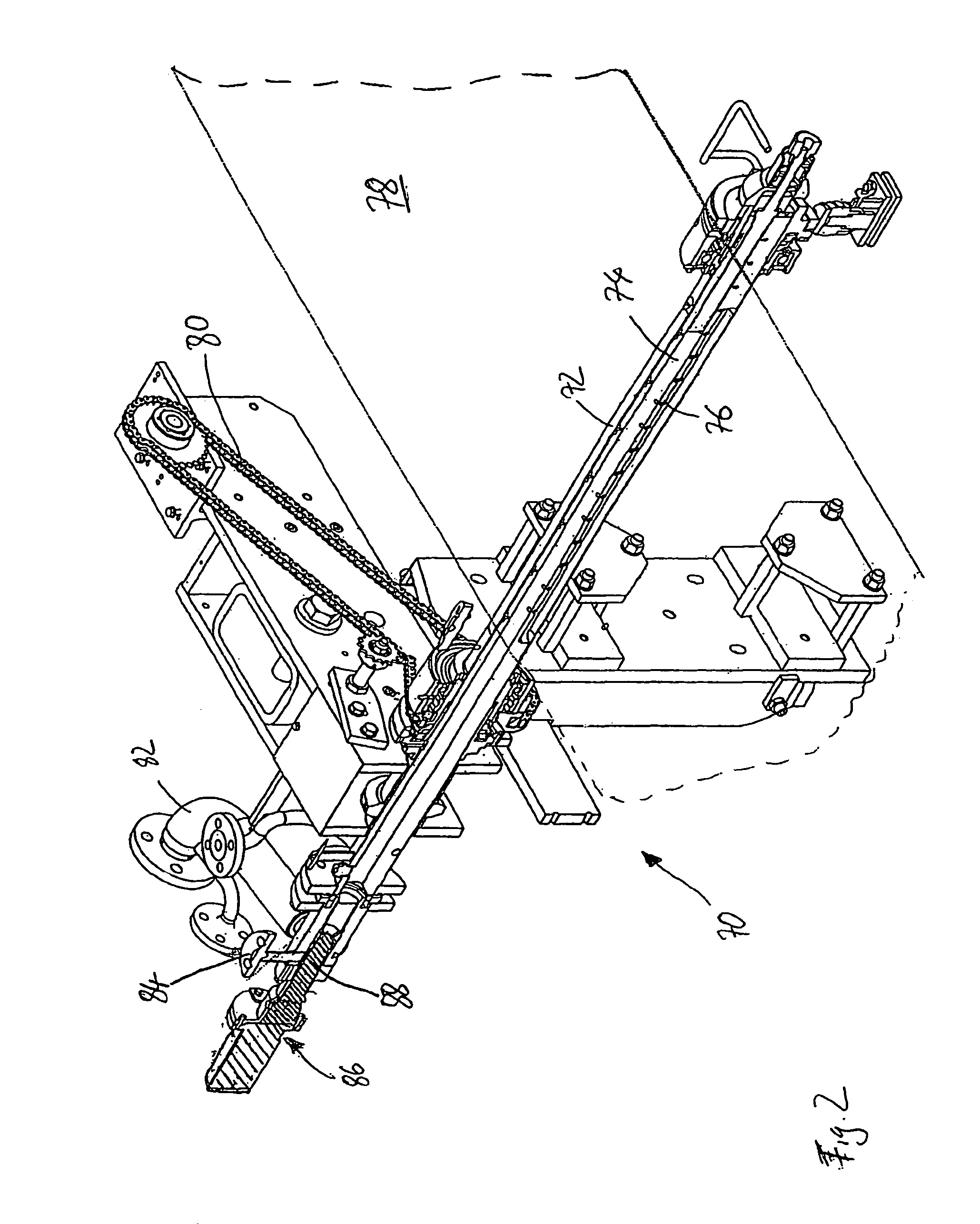

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

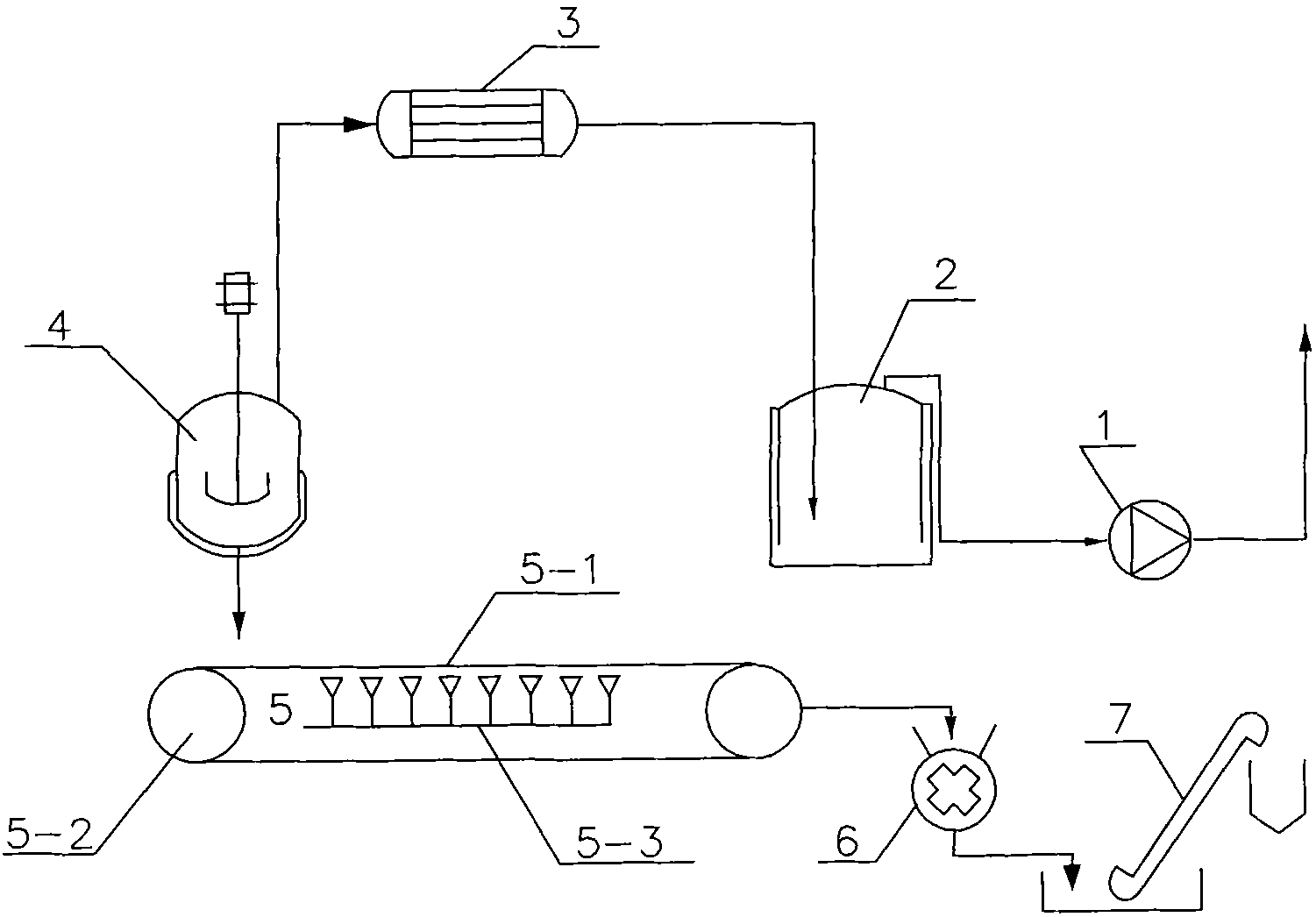

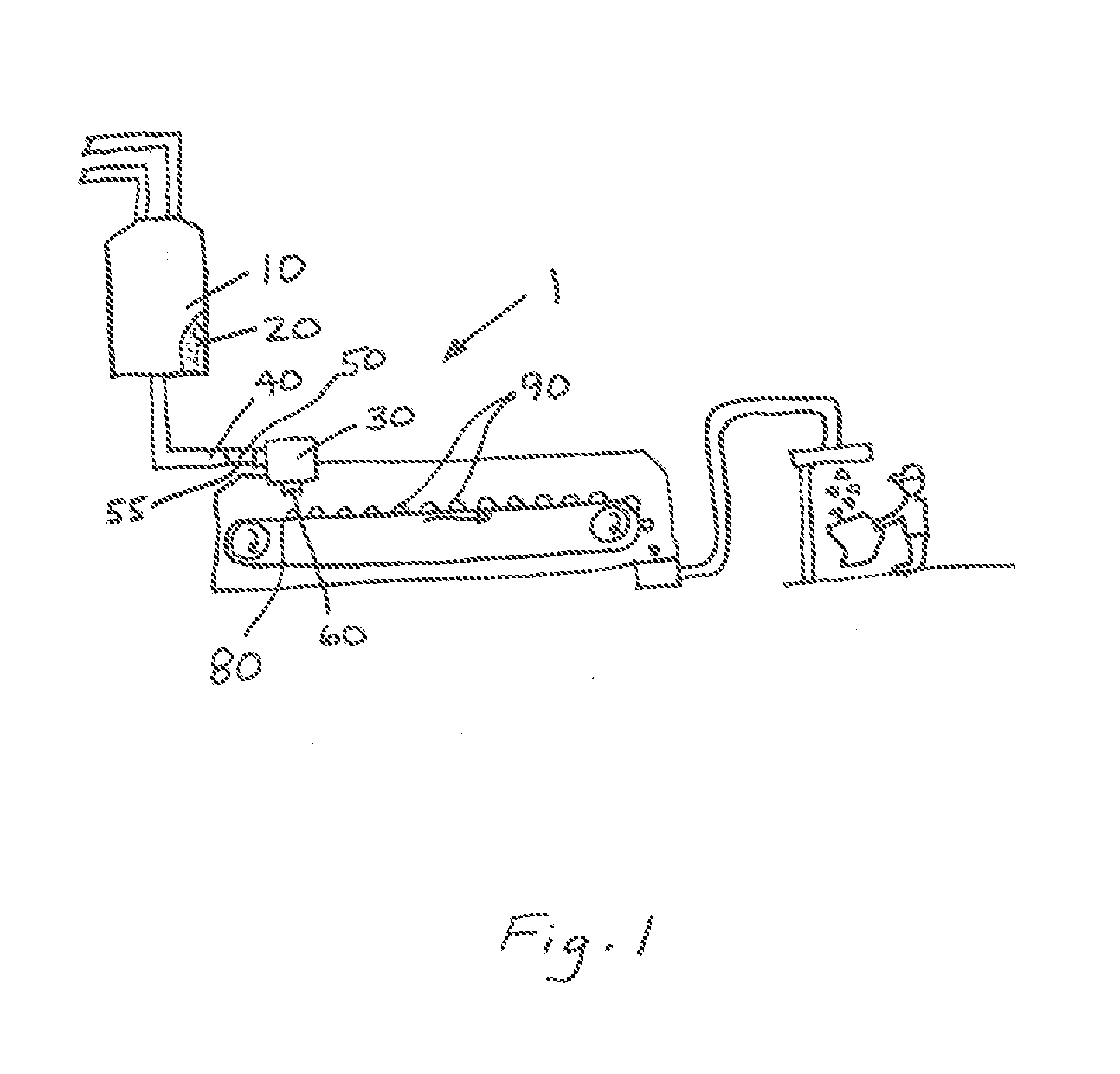

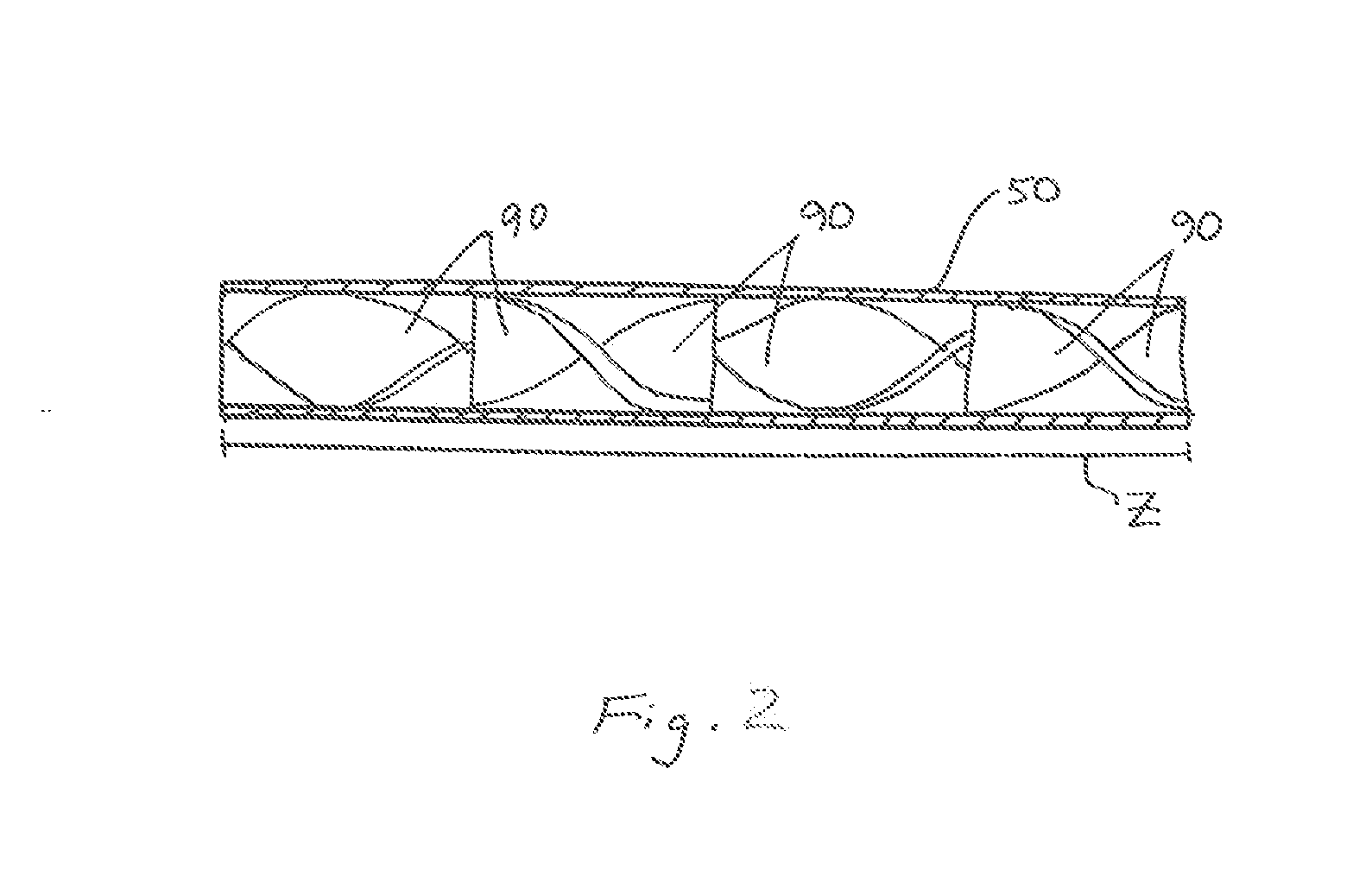

Triglycidyl isocyanurate melting granulating technology and production line thereof

ActiveCN101773806AImprove working environmentSolve environmental problemsOrganic chemistryGranulation on conveyor beltsChemistryTriglycidyl isocyanurate

The invention relates to the technical field of triglycidyl isocyanurate melting granulation, in particular to a triglycidyl isocyanurate melting granulating technology and a production line thereof. In the melting granulating technology, a distillation still is used at different temperatures to carry out atmospheric distillation and reduced pressure distillation, and after an organic solvent is steamed out completely, materials in the distillation still are uniformly put onto a band type cooling conveyer and are ground and screened after being cooled, and the production line consists of the distillation still, a condenser, an organic solvent recovery tank, a vacuum pump, the band type cooling conveyer arranged under the distillation still, a grinder, a screening machine, a packaging machine, a steam pipeline connected with an interlayer of the distillation still and a cooling water pipeline. The invention has the advantages of complete recovery of the organic solvent, working environment improvement, production cost reduction, stable and safe process and high product yield. Because the product density is large, the storage and transportation space is reduced, and the storage and transportation cost is reduced.

Owner:ANSHAN RUNDE FINE CHEM

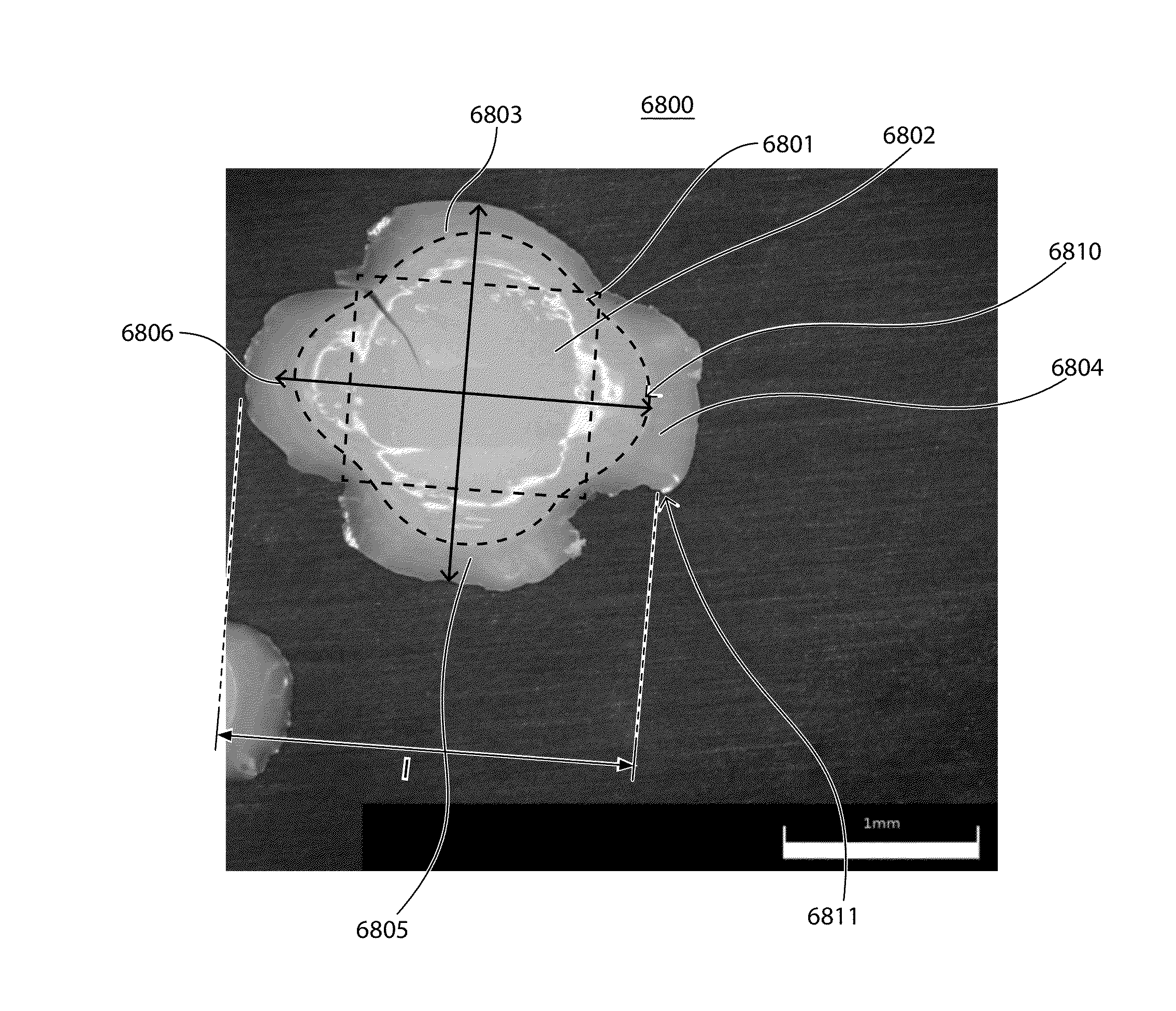

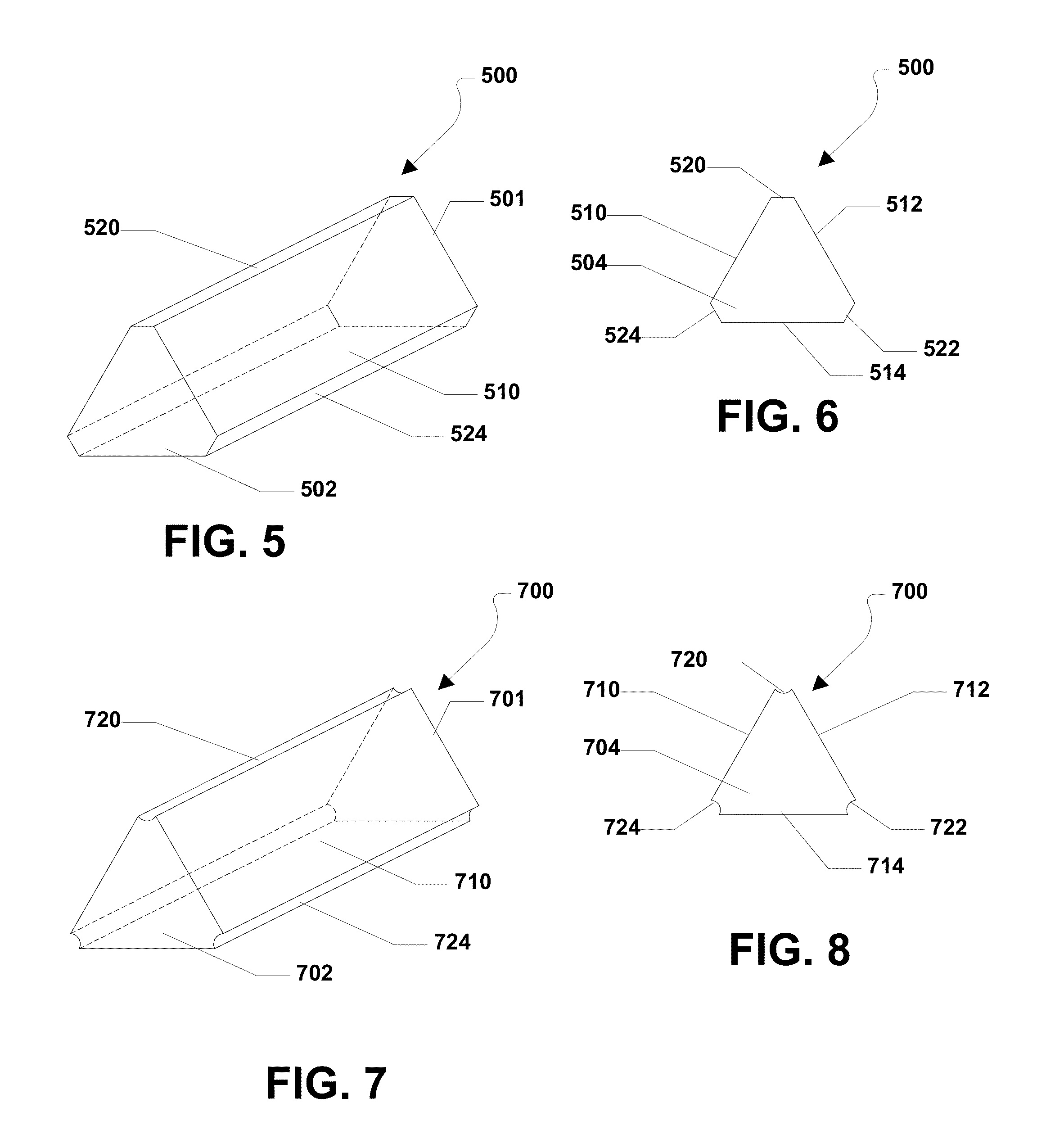

Abrasive particles having complex shapes and methods of forming same

An abrasive grain is disclosed and may include a body. The body may define a length (l), a height (h), and a width (w). In a particular aspect, the length is greater than or equal to the height and the height is greater than or equal to the width. Further, in a particular aspect, the body may include a primary aspect ratio defined by the ratio of length:height of at least about 2:1. The body may also include an upright orientation probability of at least about 50%.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

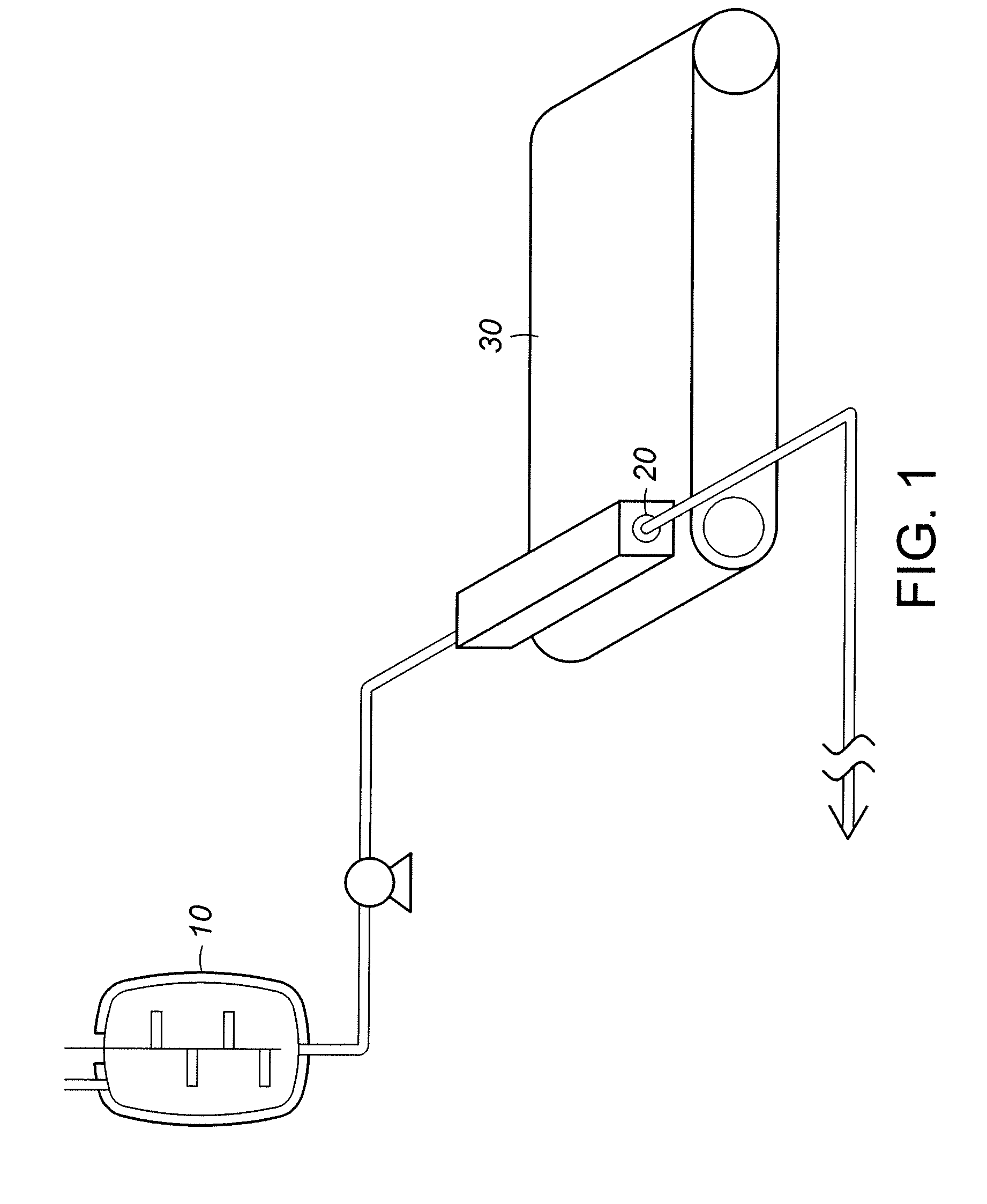

Apparatus and method for harvesting carbon nanotube arrays

An apparatus is provided for harvesting a carbon nanotube array from a substrate. The apparatus includes a peeler that peels the carbon nanotube array from the substrate and a support that receives the carbon nanotube array peeled from the substrate. In addition the apparatus includes a drawing device that simultaneously draws the carbon nanotube array from the substrate onto the support as the carbon nanotube array is peeled from the substrate. The peeler and drawing device are synchronized in operation so that as a given length of carbon nanotube array is peeled from the substrate, that same given length of carbon nanotube array is drawn onto the support.

Owner:UNIV OF KENTUCKY RES FOUND

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

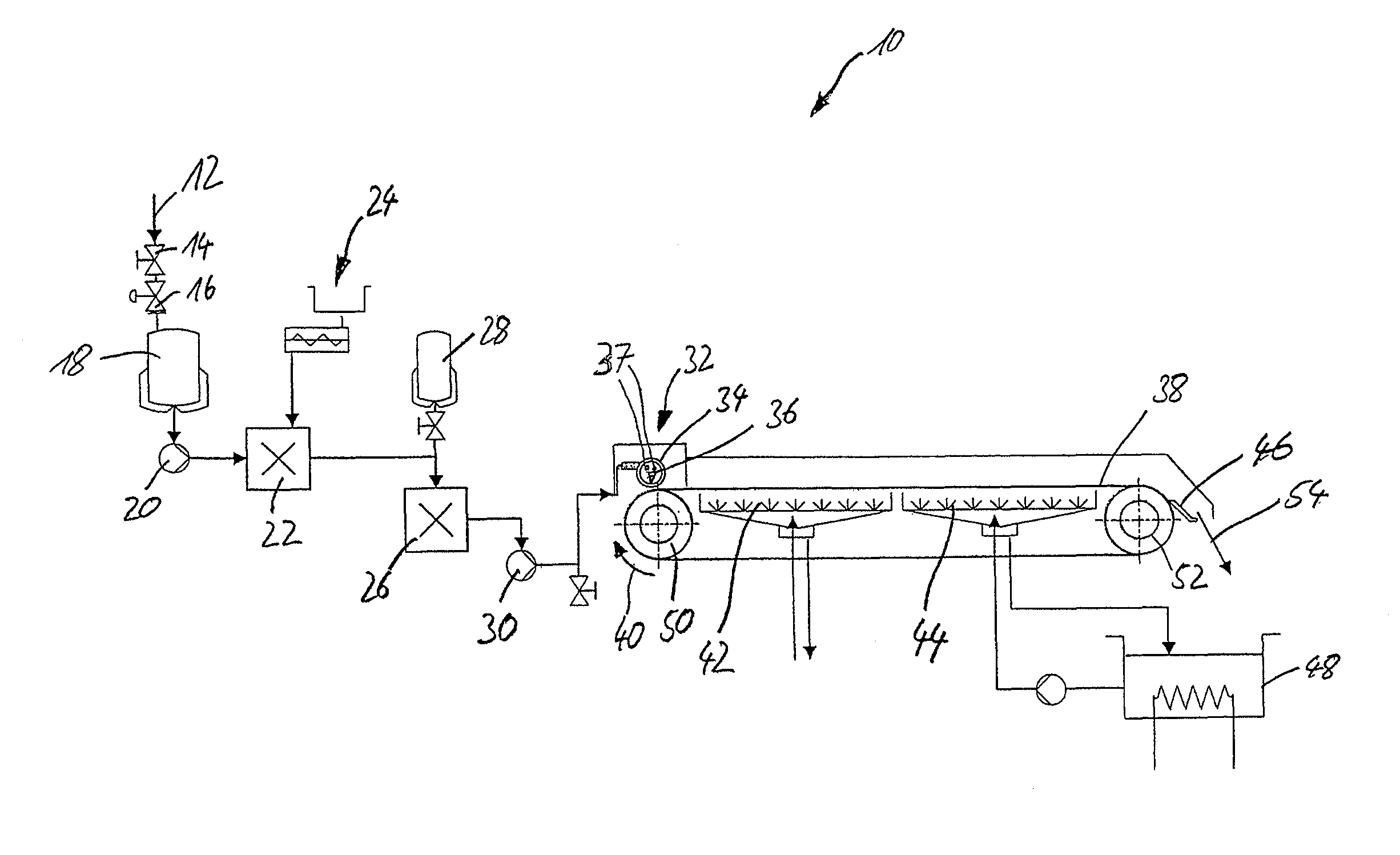

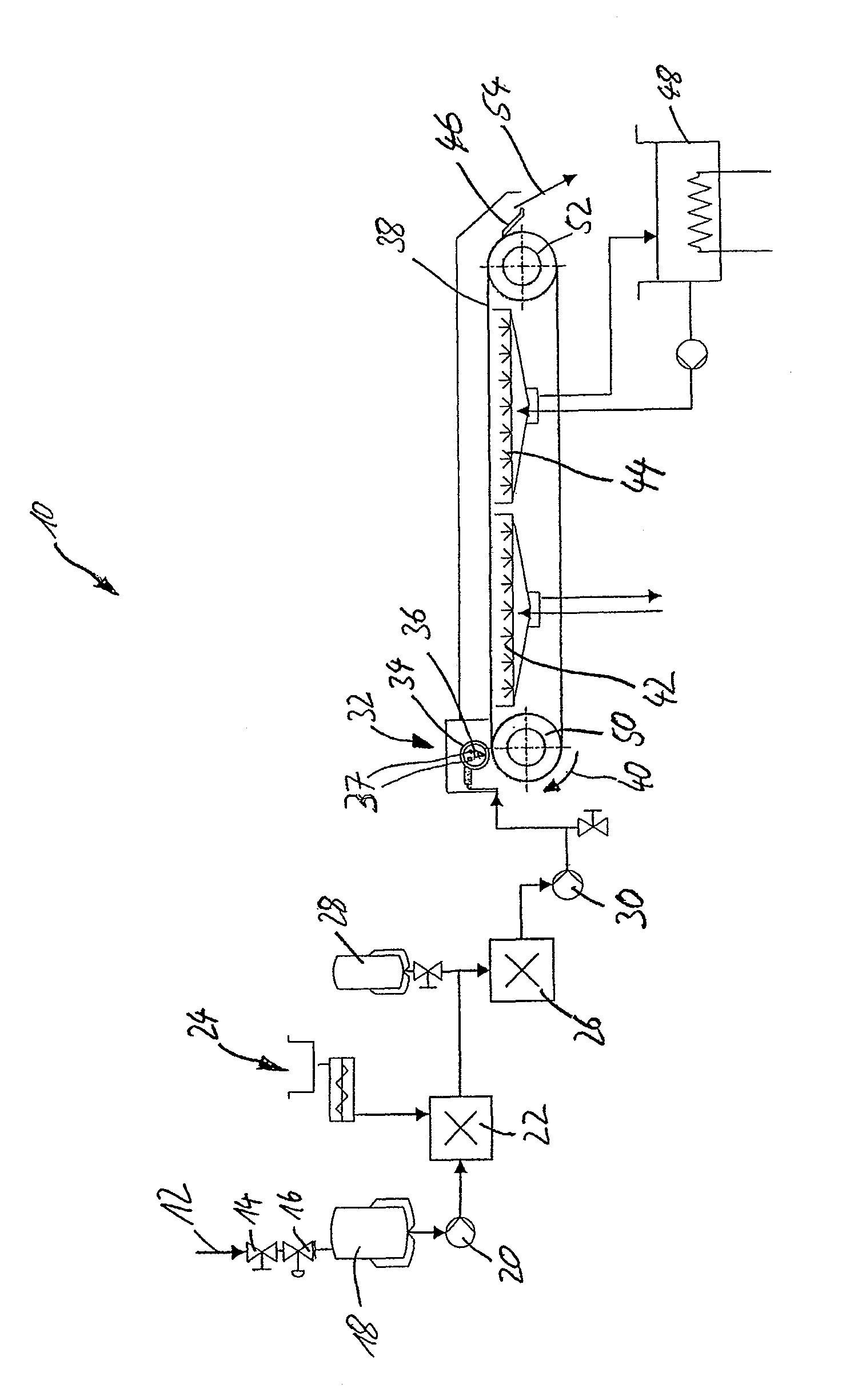

Pastillation of ammonium sulfate nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

Method and apparatus for the production of bitumen blocks

InactiveUS20150166897A1Highly accurate adherenceEnough timeLaminationWorking-up pitch/asphalt/bitumen by meltingEngineeringMechanical engineering

A method and an apparatus for the production of bitumen blocks, with a drop former for generating bitumen drops from molten bitumen, with a belt cooler having a rotating belt for cooling and solidifying the bitumen drops deposited on the rotating belt into tablets, and with a decanting device for decanting the tablets into bags, the tablets being at least partially combined, inside the bags filled with tablets, into a compact bitumen mass.

Owner:IPCO GERMANY GMBH

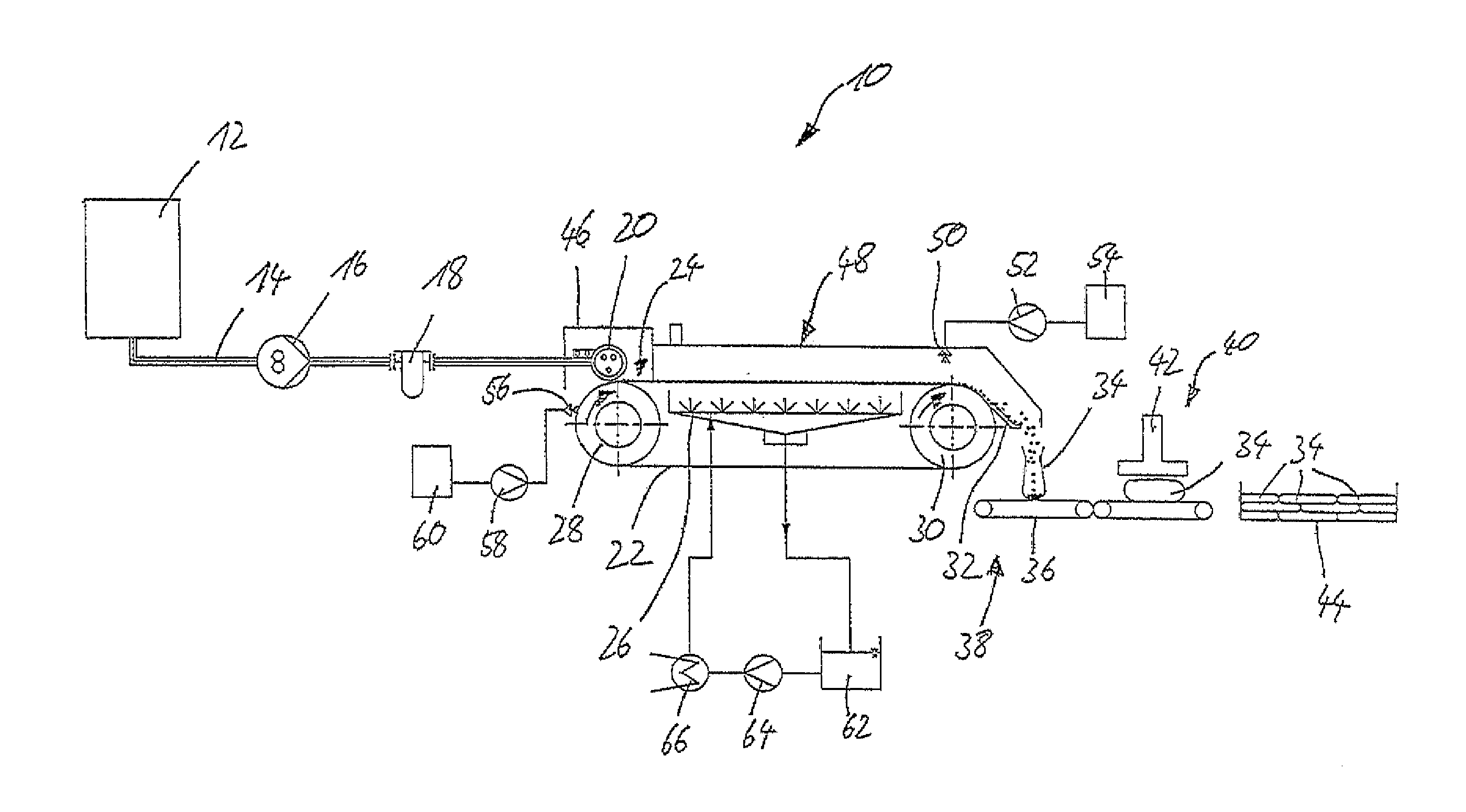

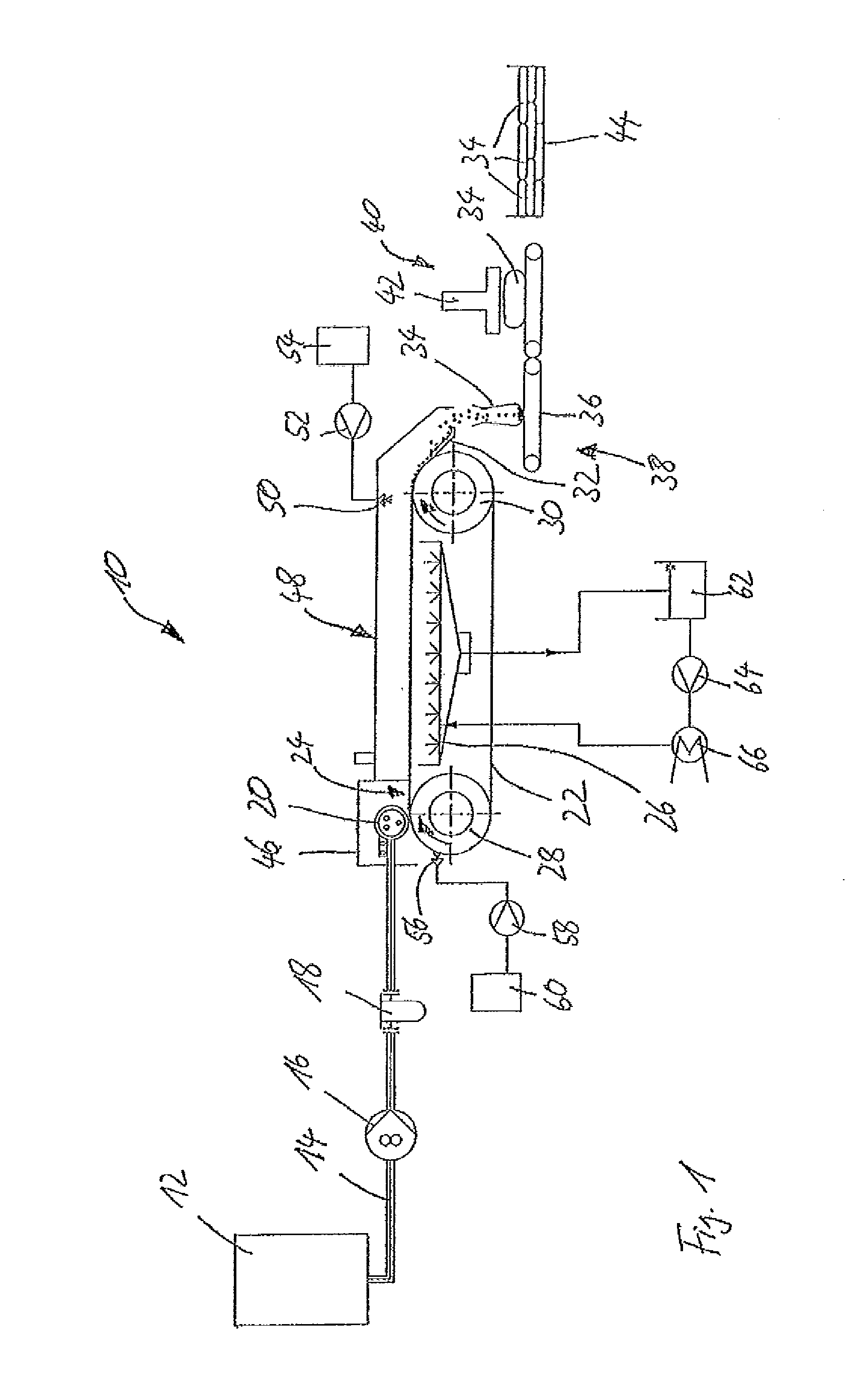

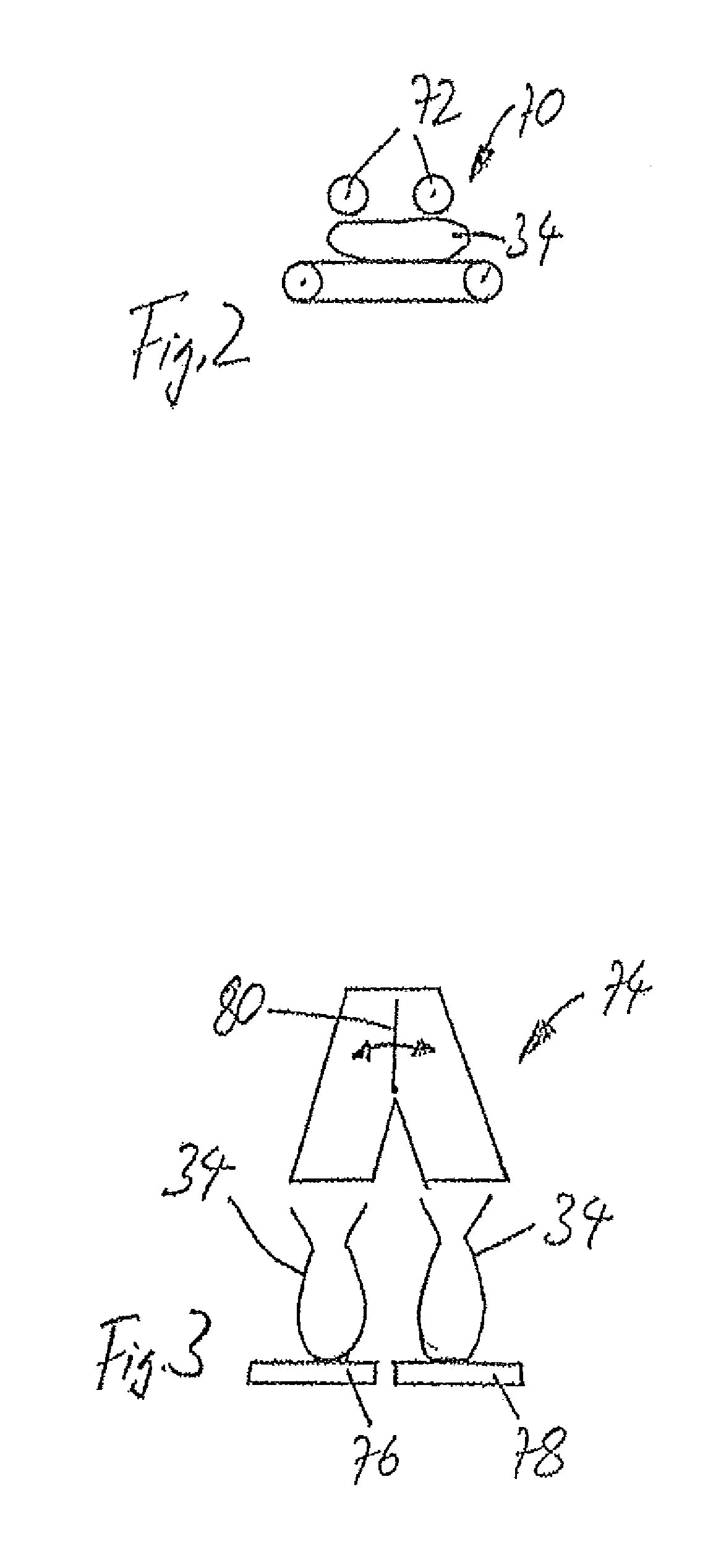

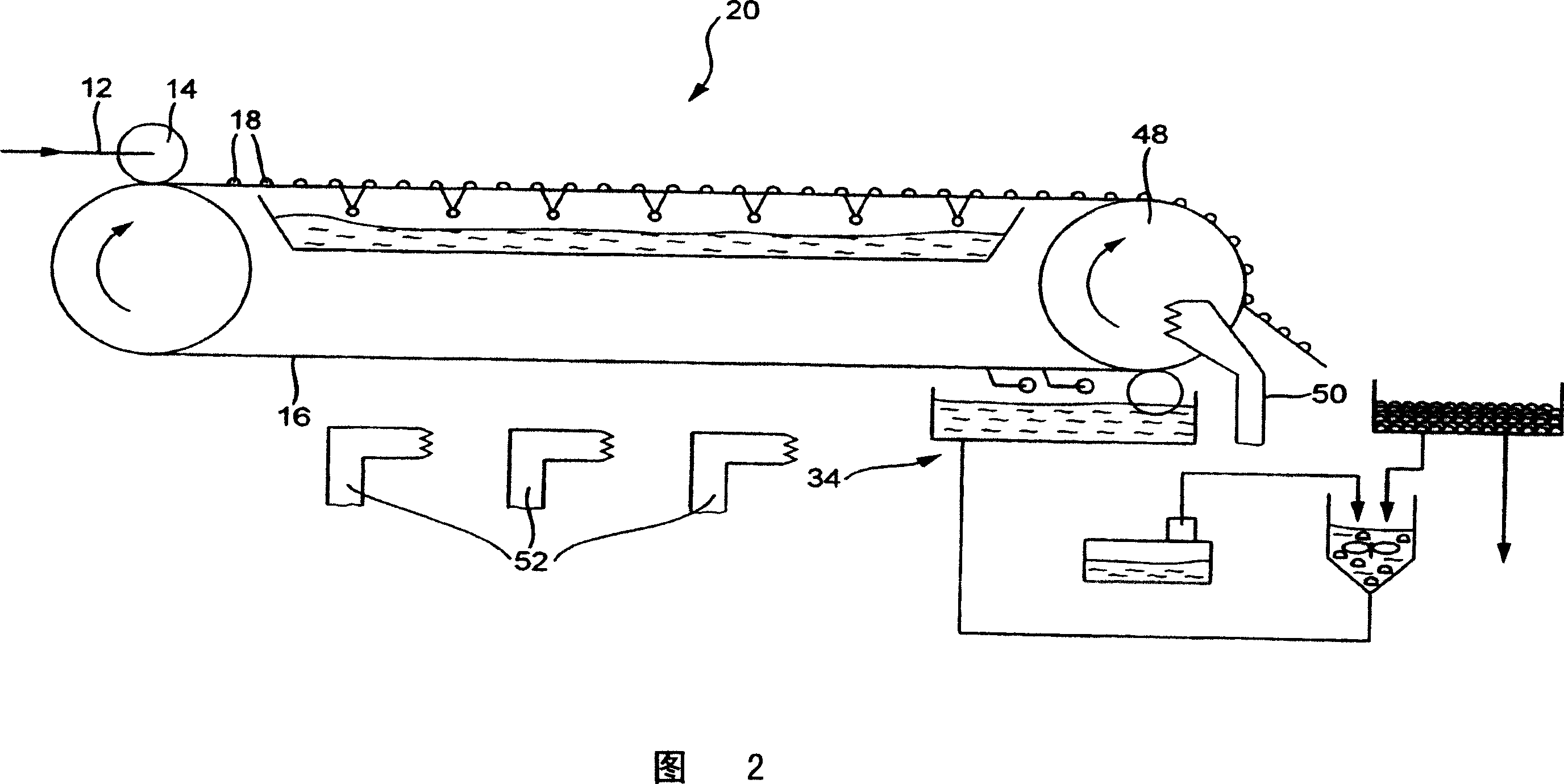

Apparatus and process for forming particles

Owner:THE PROCTER & GAMBLE COMPANY

Belt Conveying Device with Crushing and Dust-proof functions for Agglomerated Finely divided materials

InactiveUS20190344284A1Prevent deviationImprove intelligenceConveyorsLarge containersHydraulic cylinderEngineering

The invention relates to a belt conveying device with crushing and dust-proof functions for agglomerated finely divided materials which includes a base, a rolling bracket, a conveyor belt, a crushing and dust removing mechanism, and a conveyor belt cleaning mechanism. The base includes a fixed seat body, a movable seat body, and a hydraulic cylinder. The rolling bracket includes a supporting plate, a rotating shaft, and supporting rods. The conveyor belt includes a belt-shaped conveyor belt body and induction teeth. The crushing and dust removing mechanism includes an inner sleeve, an outer sleeve, a first air pump, an ion fan, and a mixing chamber. The conveyor belt cleaning mechanism includes a cylinder, a stencil, a cleaning mechanism, and a second air pump. It has advantages of having simple and reasonable structure, easy to use, high degree of intelligence, automatically correcting deviation of conveyor belt and cleaning the conveyor belt and good dust-proof effect, which effectively solves the problem of jeopardizing the health of workers due to the dust caused at the time of conveying finely divided materials.

Owner:WANG XIAOMIN

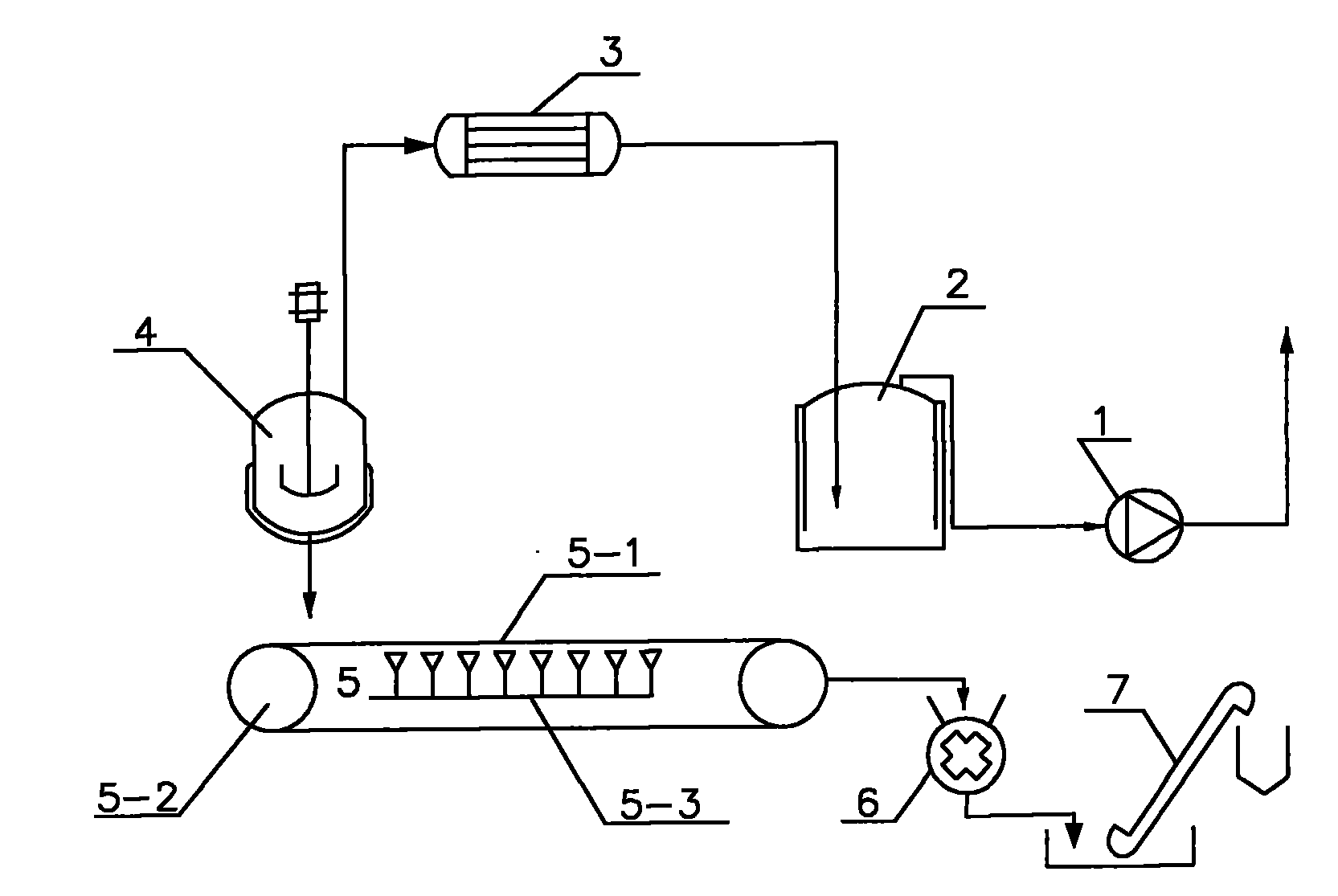

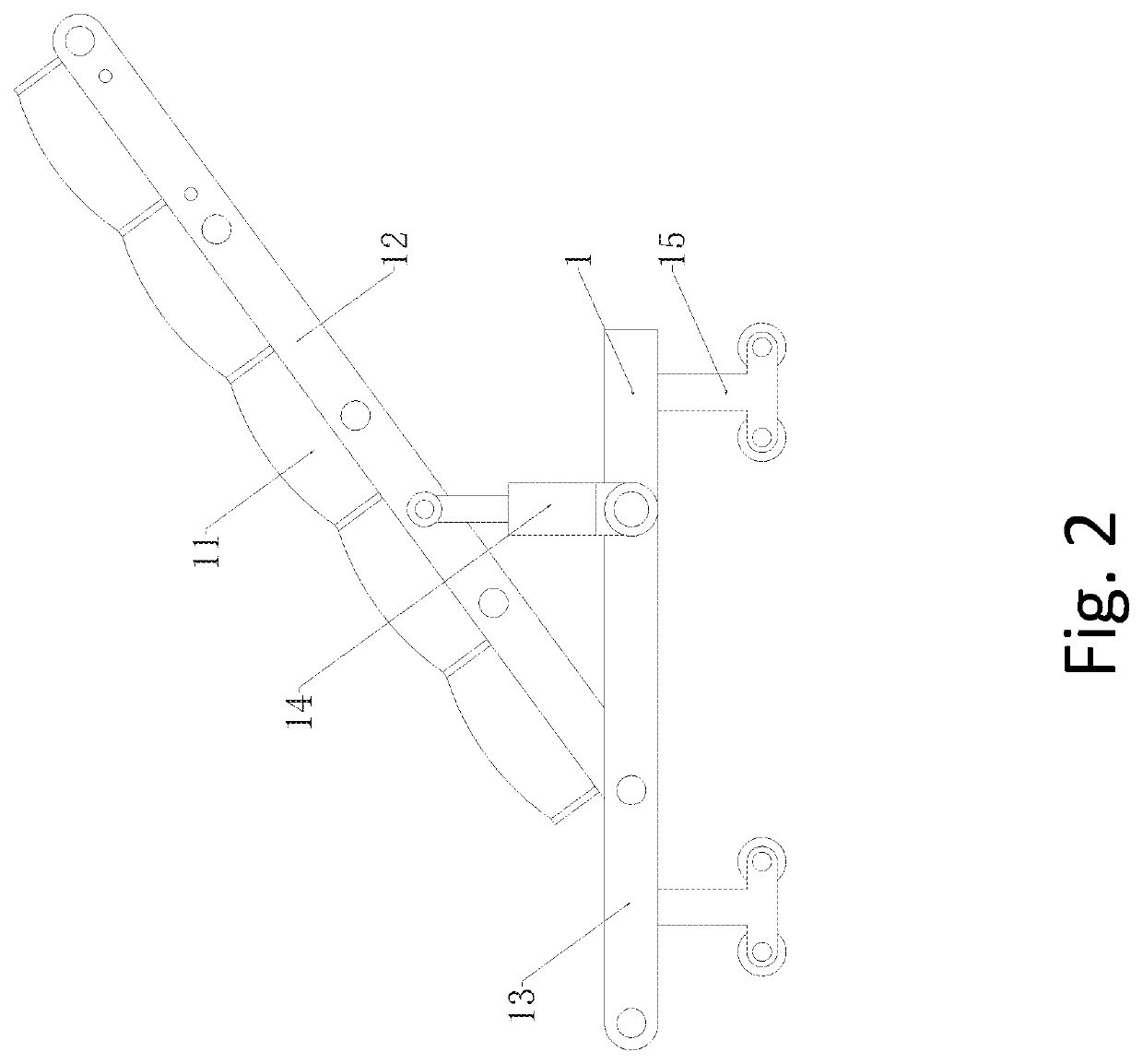

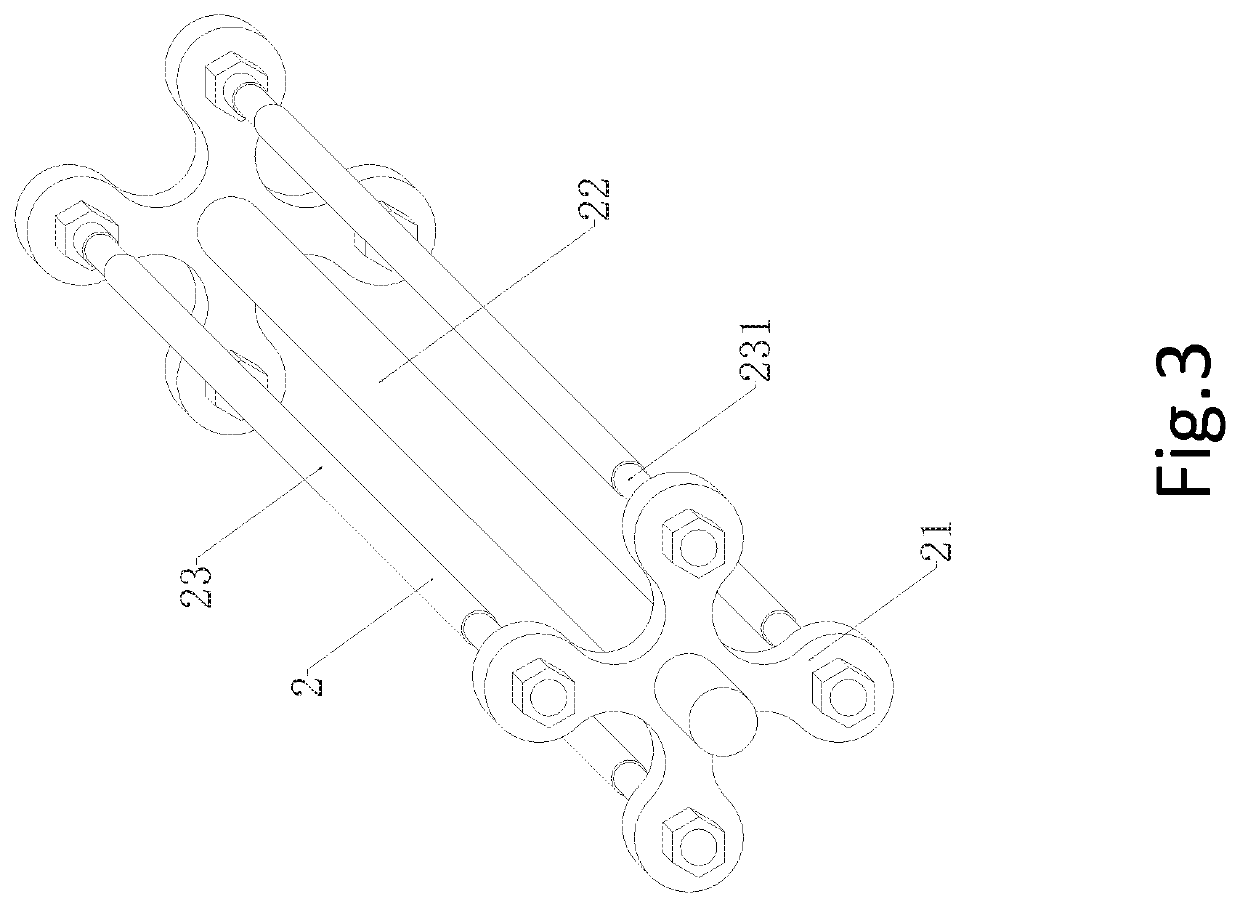

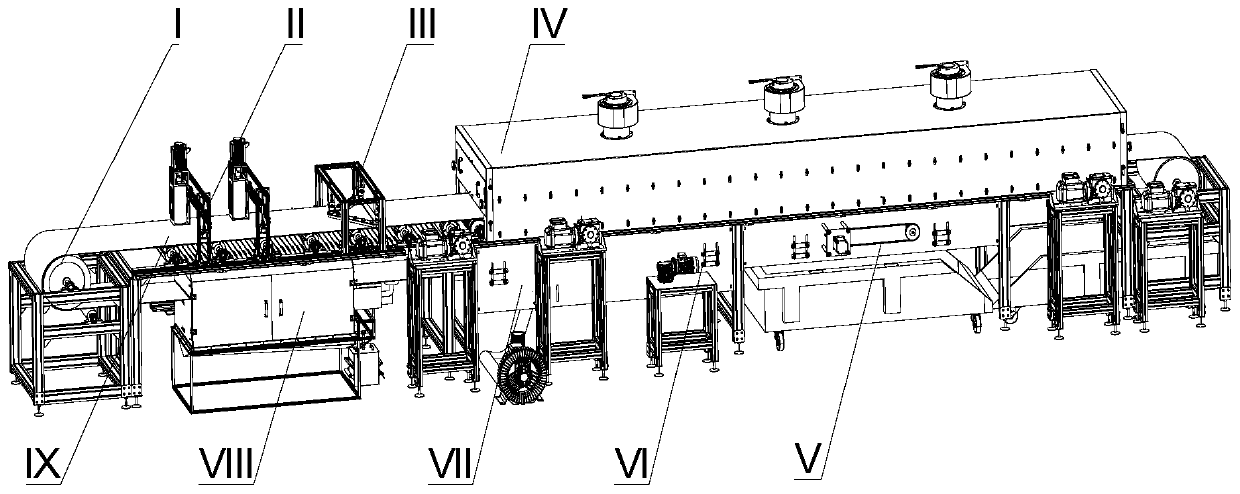

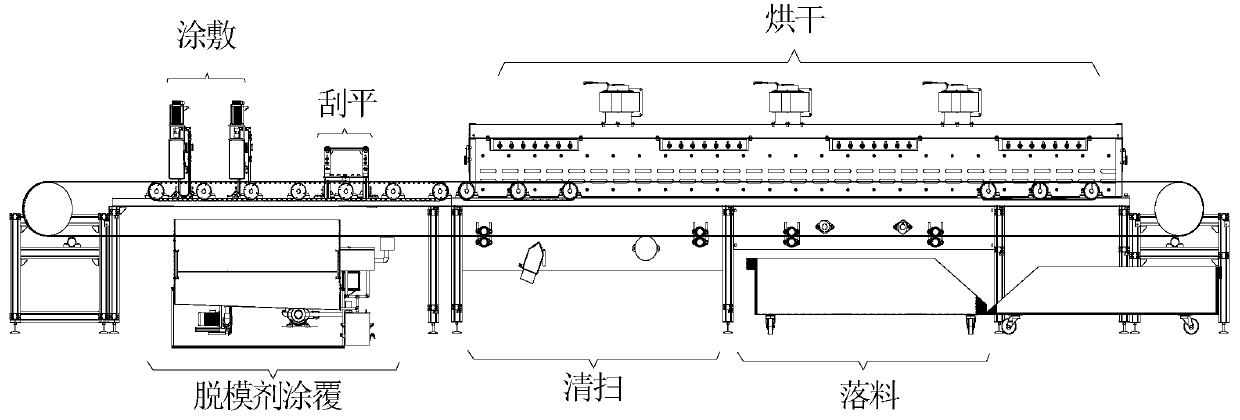

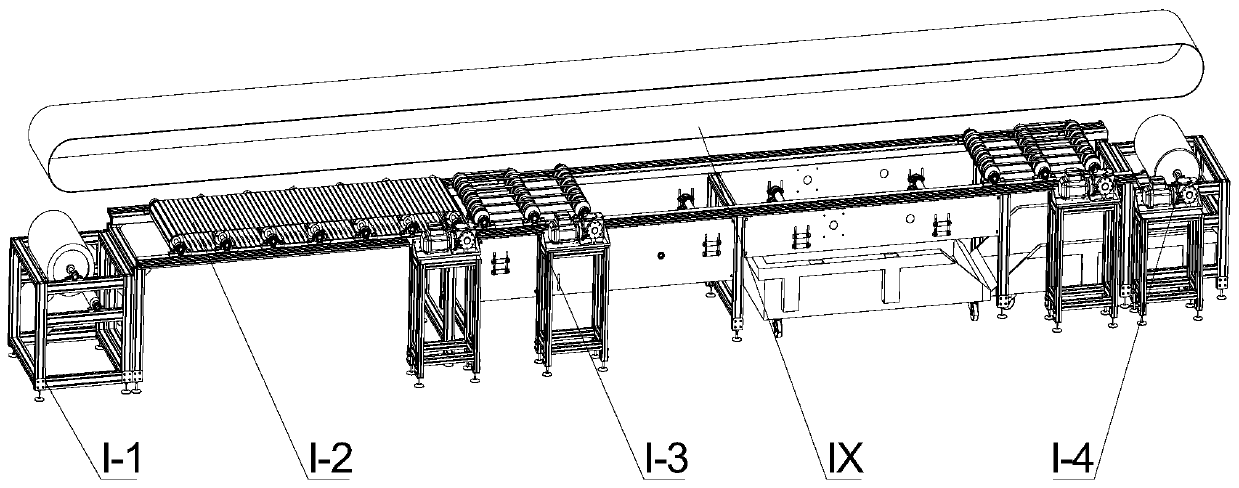

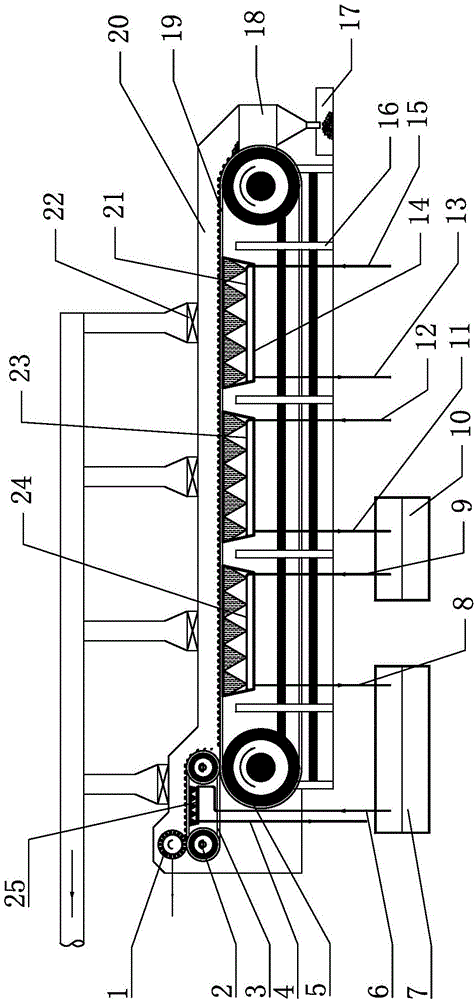

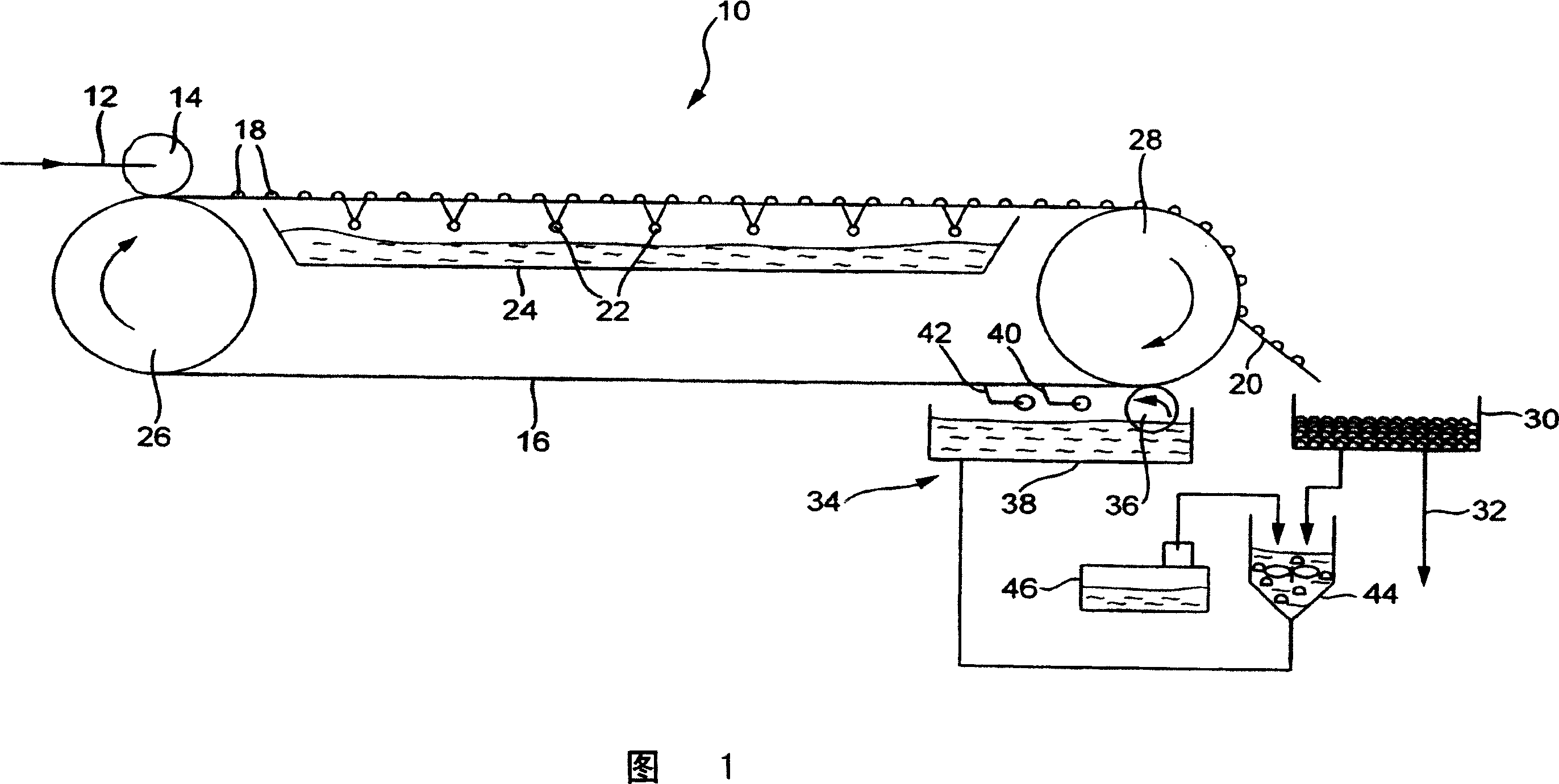

Production line of CA grinding material

InactiveCN110549260ARealize a high degree of automationReduce manufacturing costGranule coatingOther chemical processesProduction lineSlurry coating

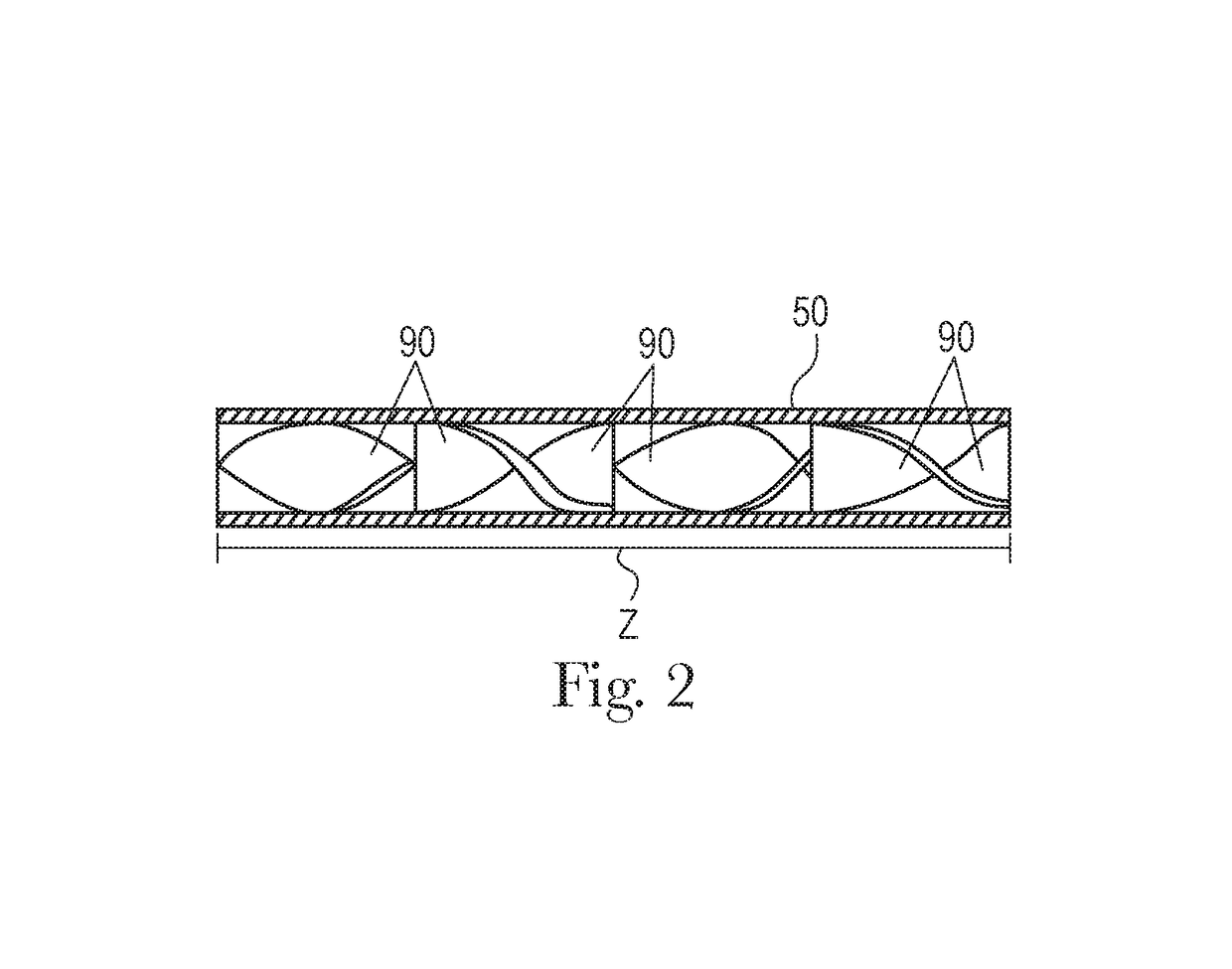

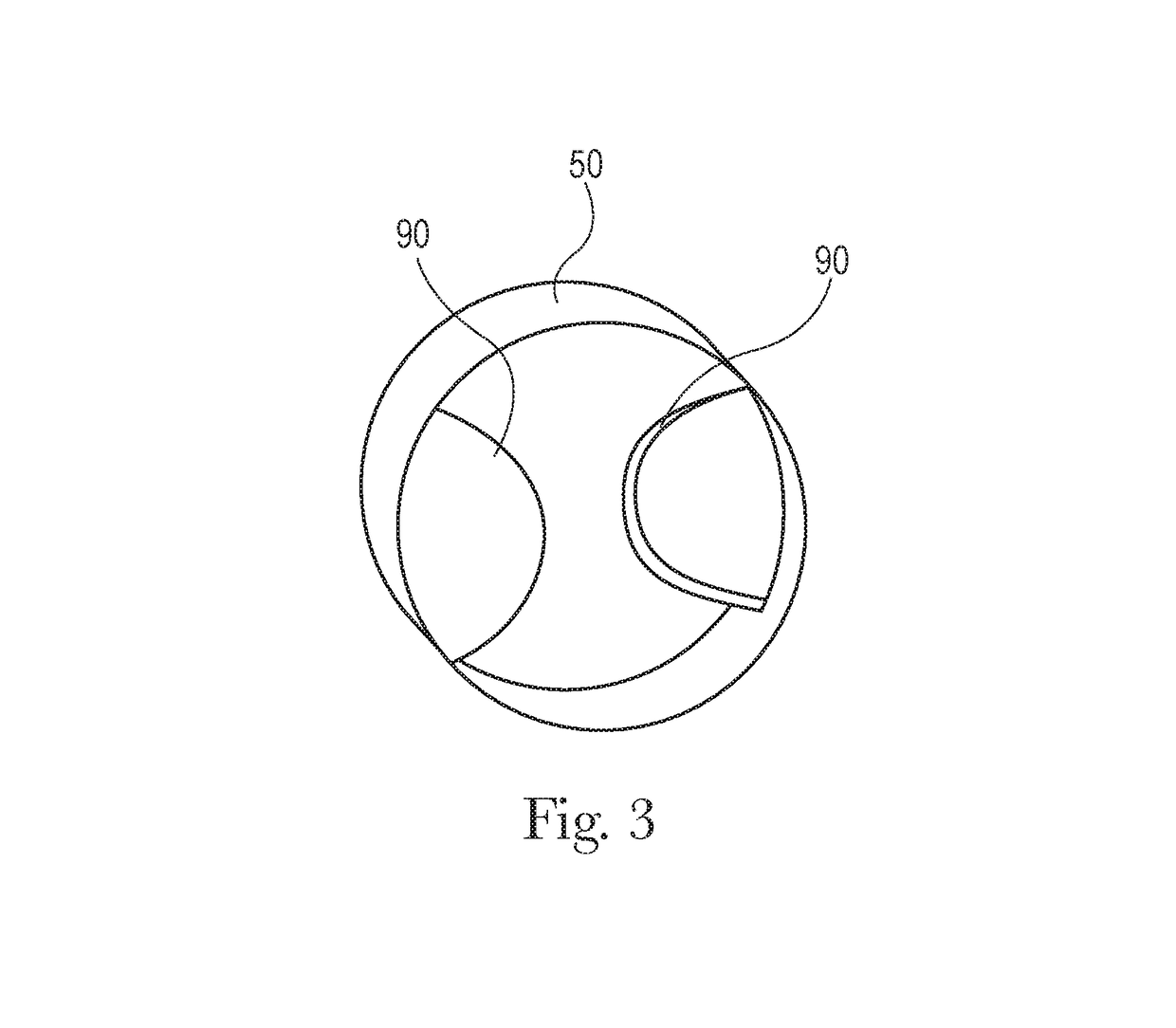

The invention discloses a production line of a CA grinding material. The production line comprises a belt mold, a transmission device, a slurry coating mechanism, a slurry scraping mechanism, a dryingmechanism, a material falling mechanism, a sweeping mechanism and a release agent coating mechanism, wherein the belt mold is provided with a cavity, the transmission device is used for driving the belt mold to run, the slurry coating mechanism is used for coating the surface of the belt mold and the inner part of the mold cavity with slurry, the slurry scraping mechanism is used for scraping theslurry coated on the surface of the belt mold into the cavity, the drying mechanism is used for drying the belt mold to enable the slurry to be dried and solidified to form grinding particles, the material falling mechanism is arranged below the drying mechanism and used for falling the abrasive particles in the belt mold cavity in an vibrating mode, the sweeping mechanism is used for sweeping slurry fragments of the belt mold after the material falls, and the release agent coating mechanism is used for spraying a release agent in a covering mode to the swept belt mold. According to the production line, six procedures such as the slurry coating, slurry scraping, drying, material falling, sweeping and release agent spraying are sequentially carried out, so that a set of circulating production line is formed, and the high automation of CA grinding particles production is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

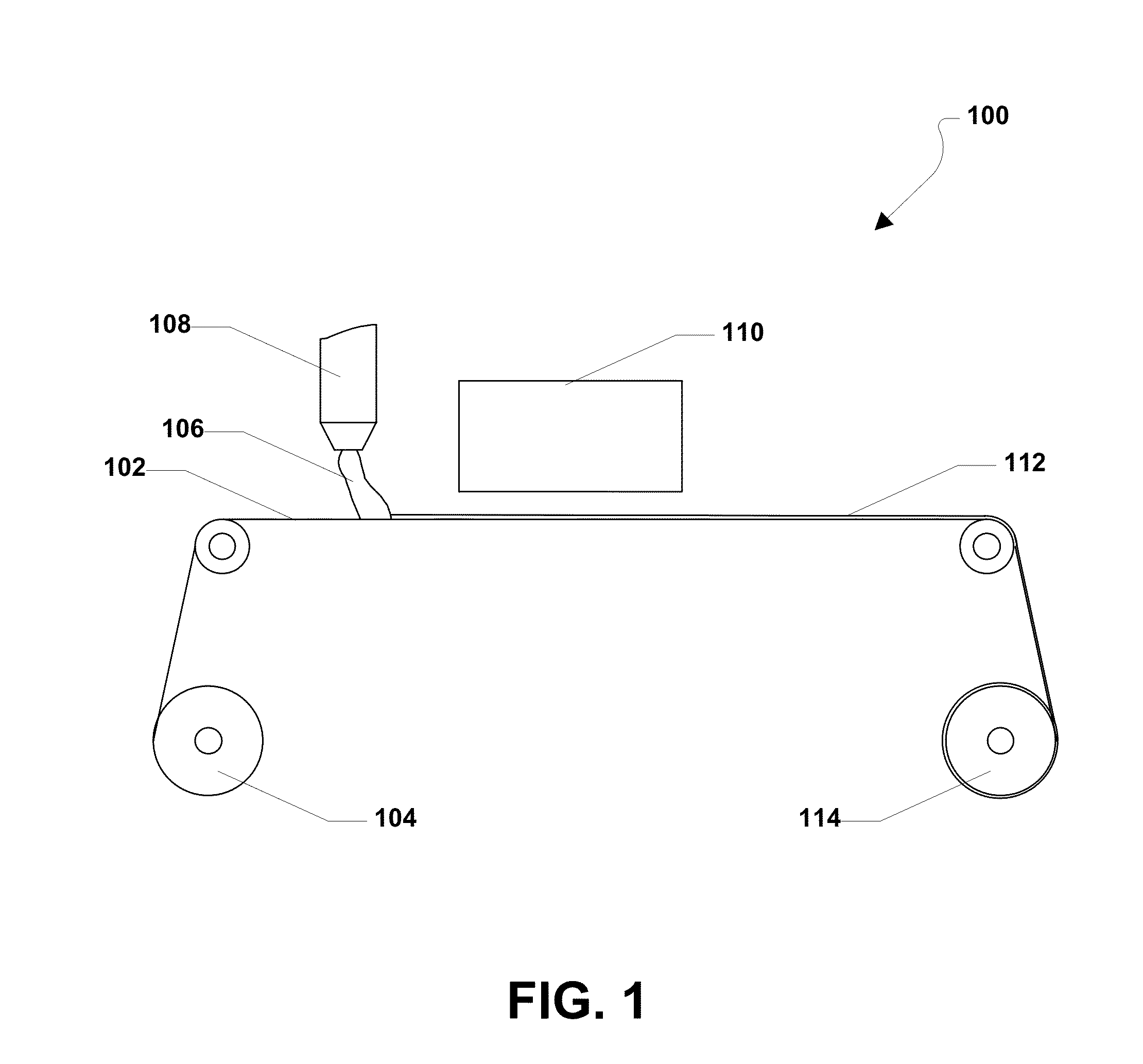

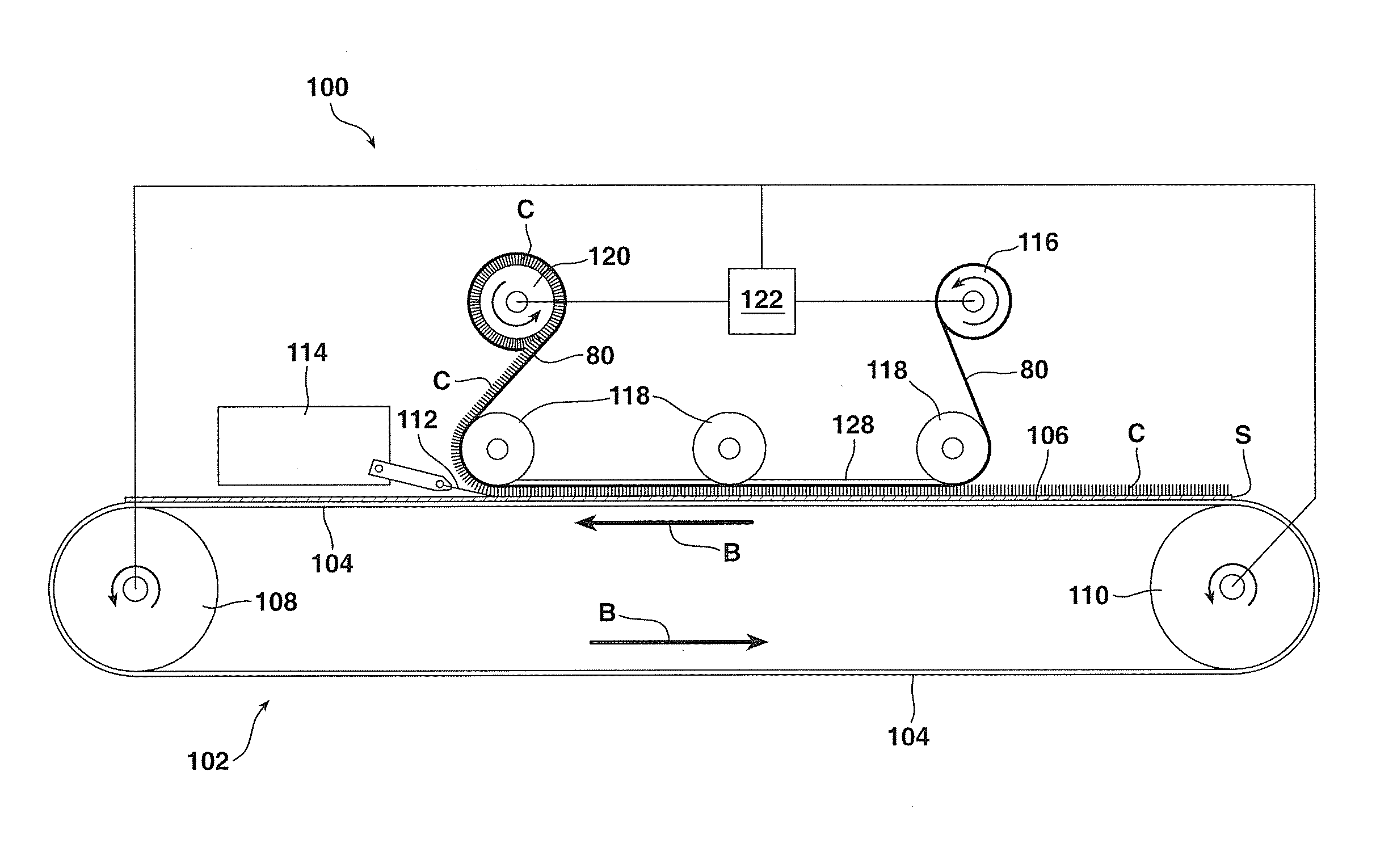

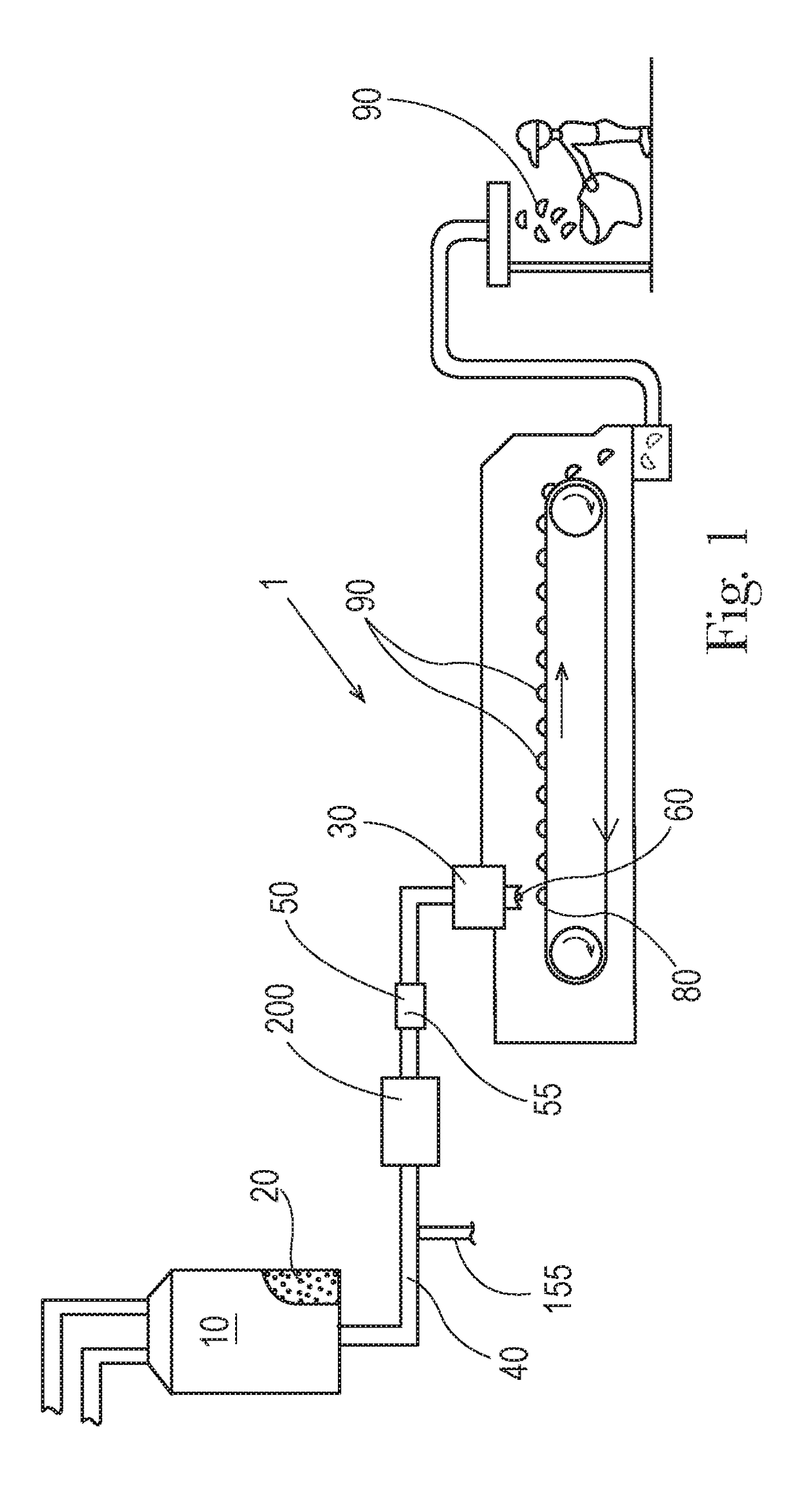

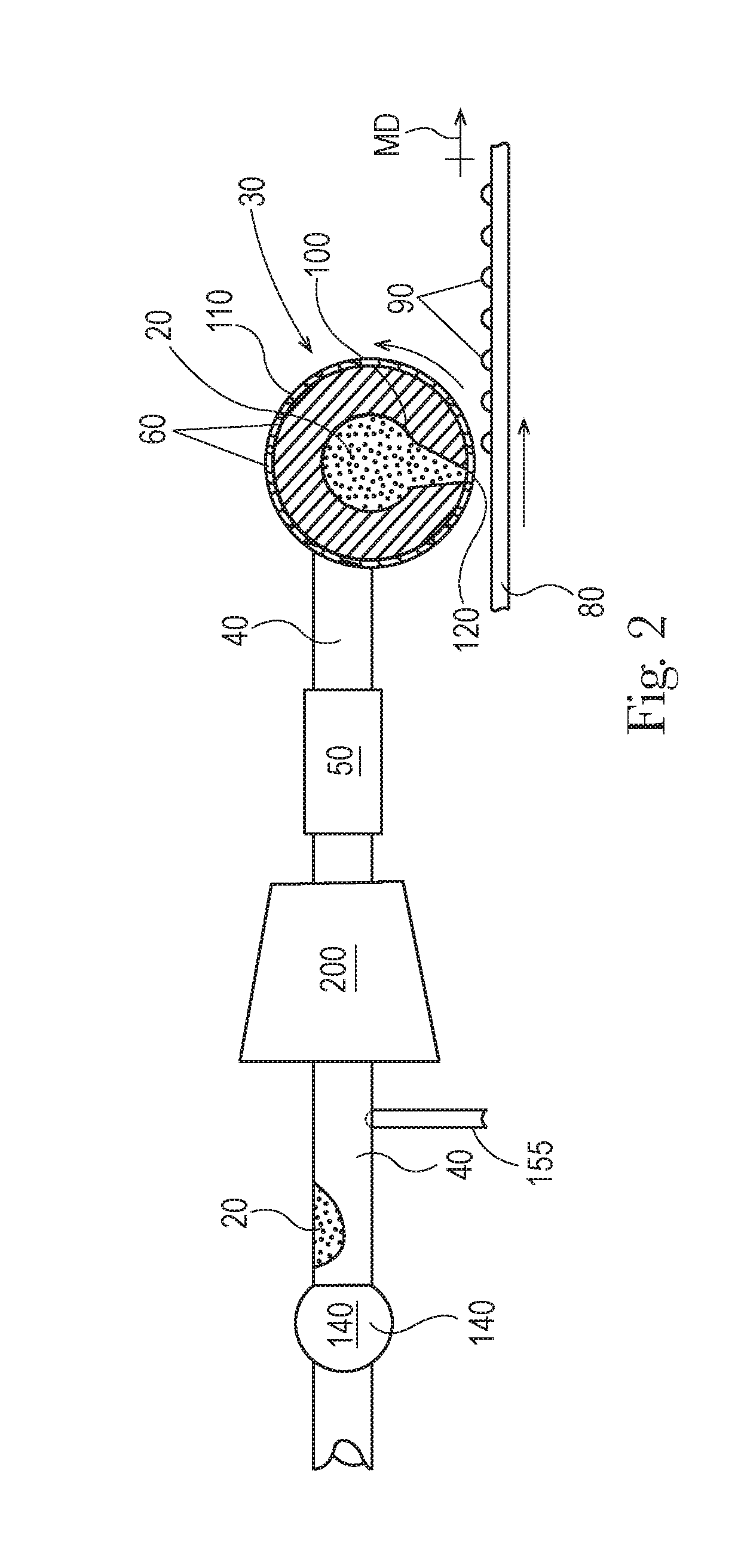

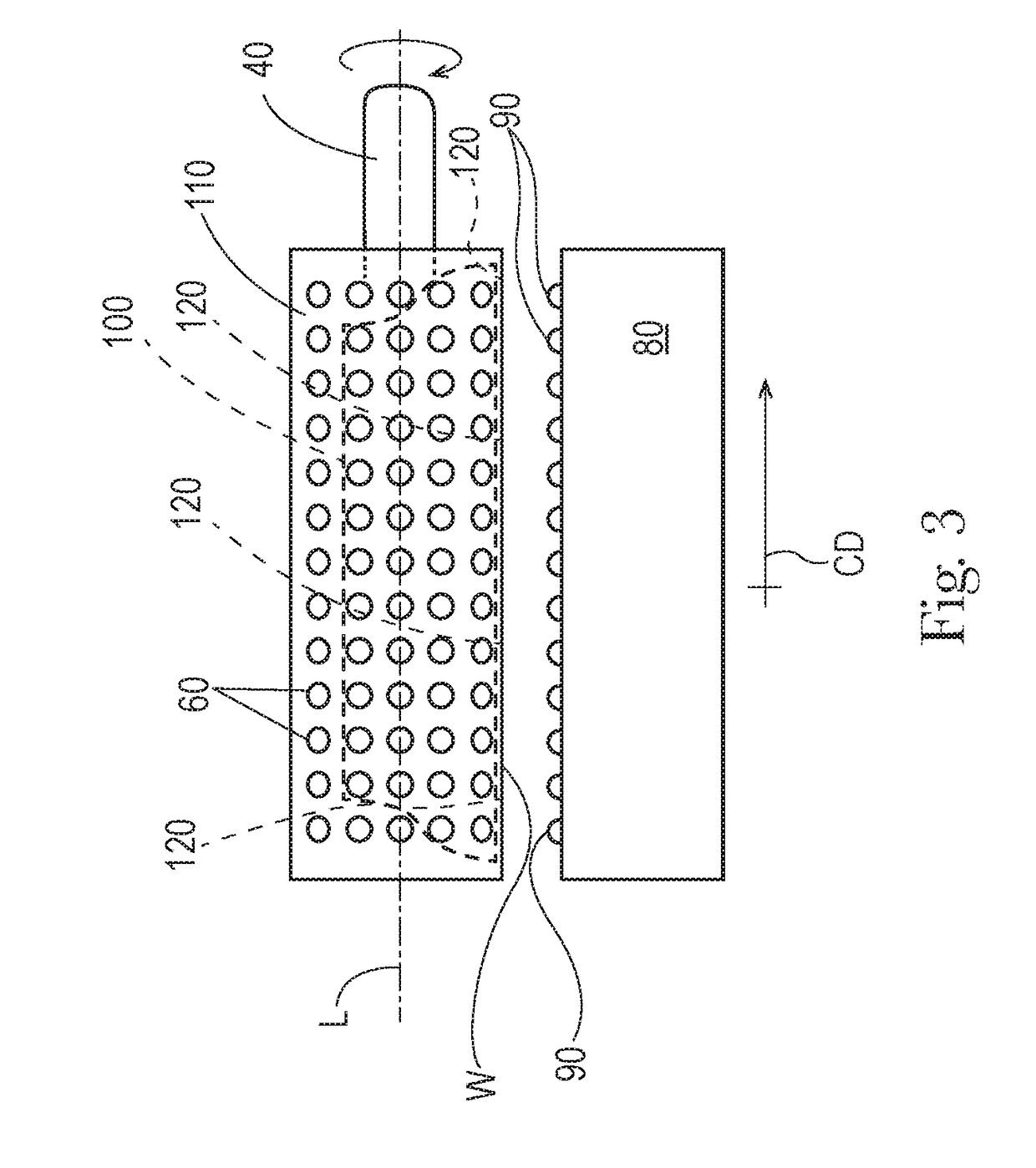

Apparatus and process for forming particles

ActiveUS9878467B2Detergent mixture composition preparationGranulation by liquid drop formationMaterials science

Owner:THE PROCTER & GAMBLE COMPANY

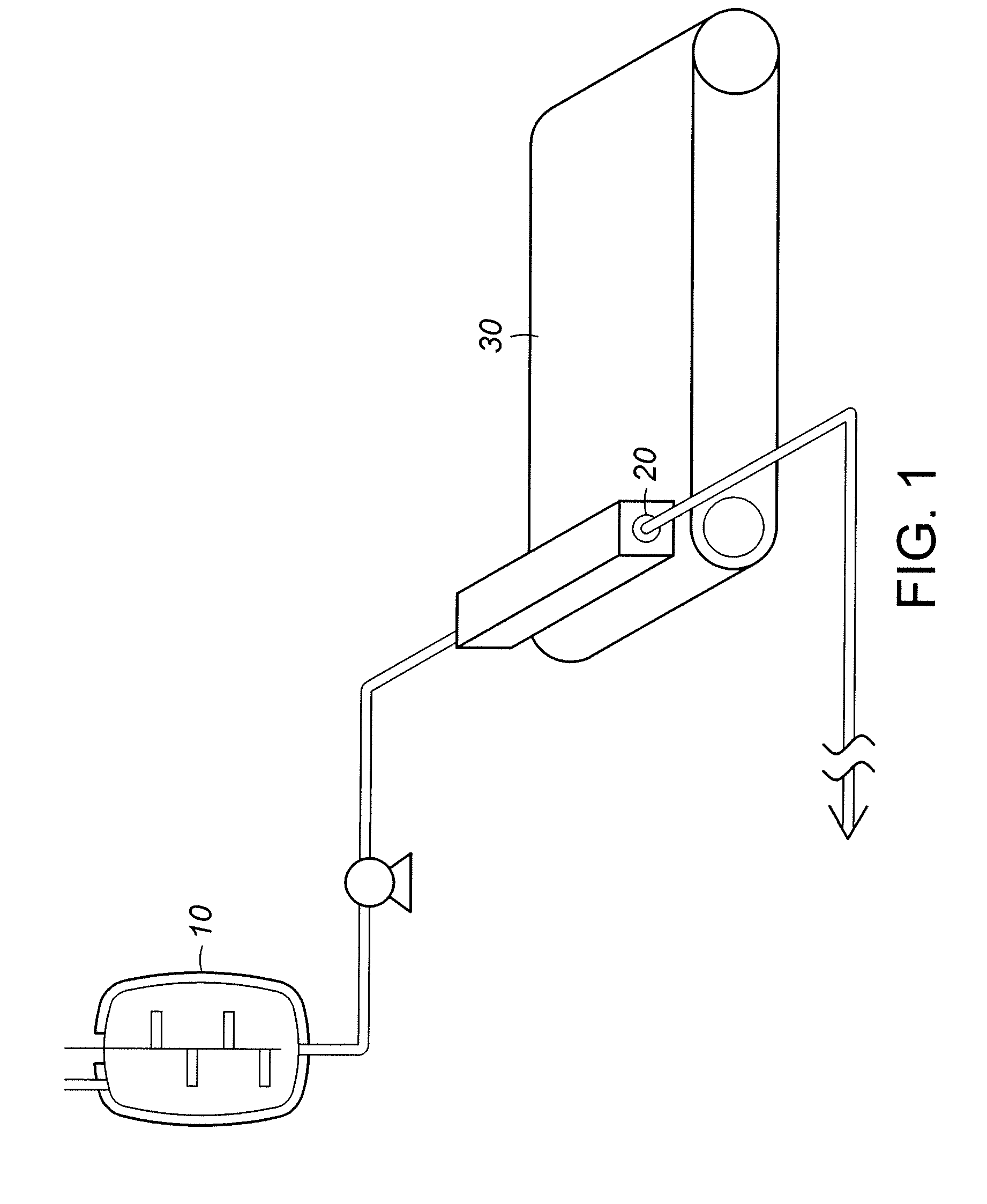

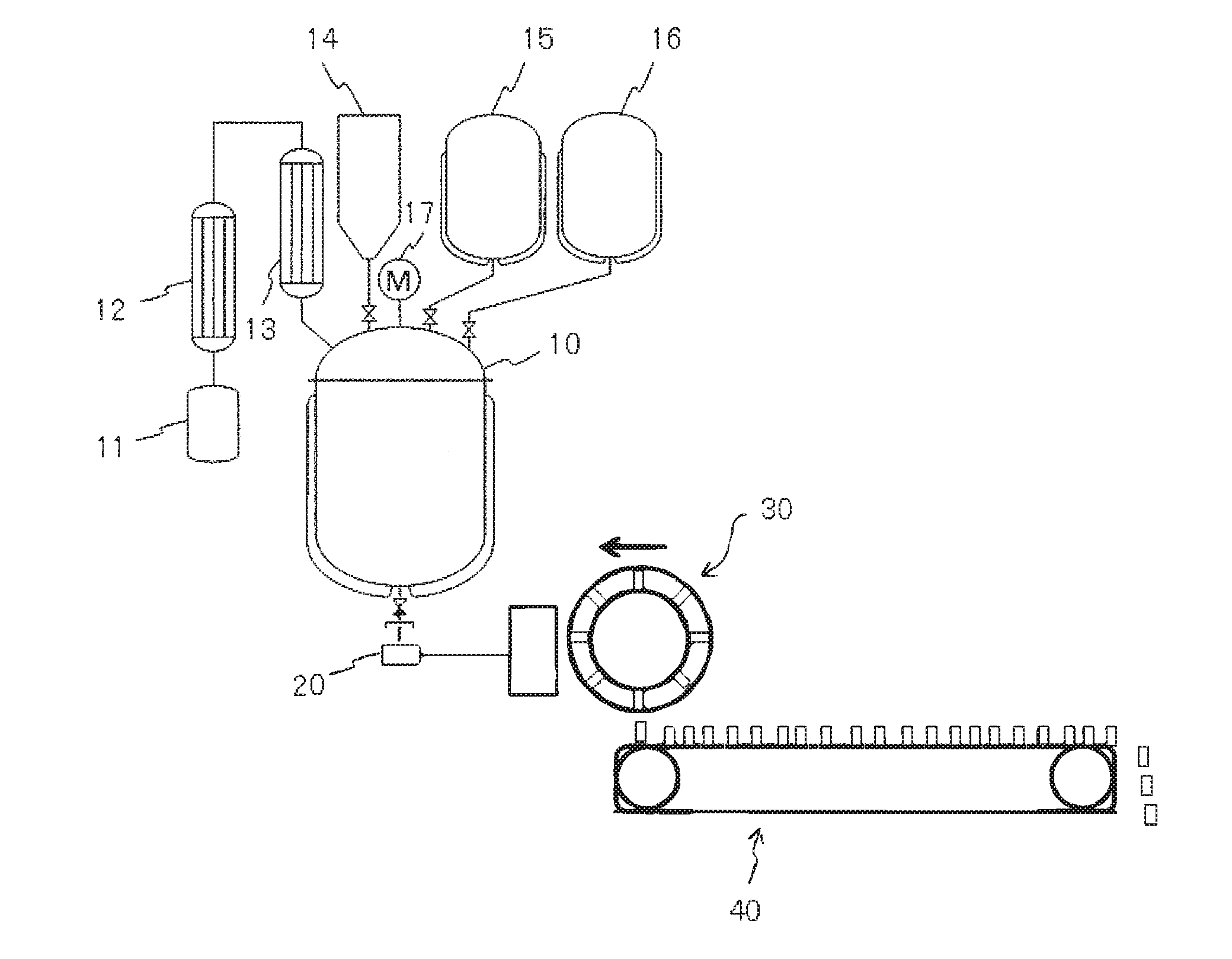

Method for producing tablets containing ammonium nitrate

ActiveUS9366485B2Wide rangeSustained product qualityCalcareous fertilisersAmmonium nitrate fertilisersEngineeringConveyor belt

A method for producing tablets containing ammonium nitrate, including dripping a product melt containing ammonium nitrate with a drop former having a rotating, pierced drum and a nozzle strip contacting an inner face of the pierced drum, so that the product melt is pressed through openings of the pierced drum. The method additionally includes placing the product drops on a circulating cooling conveyor belt, and solidifying the product drops during the transport on the cooling conveyor belt by cooling and removing the solidified product drops from the cooling conveyor belt.

Owner:IPCO GERMANY GMBH

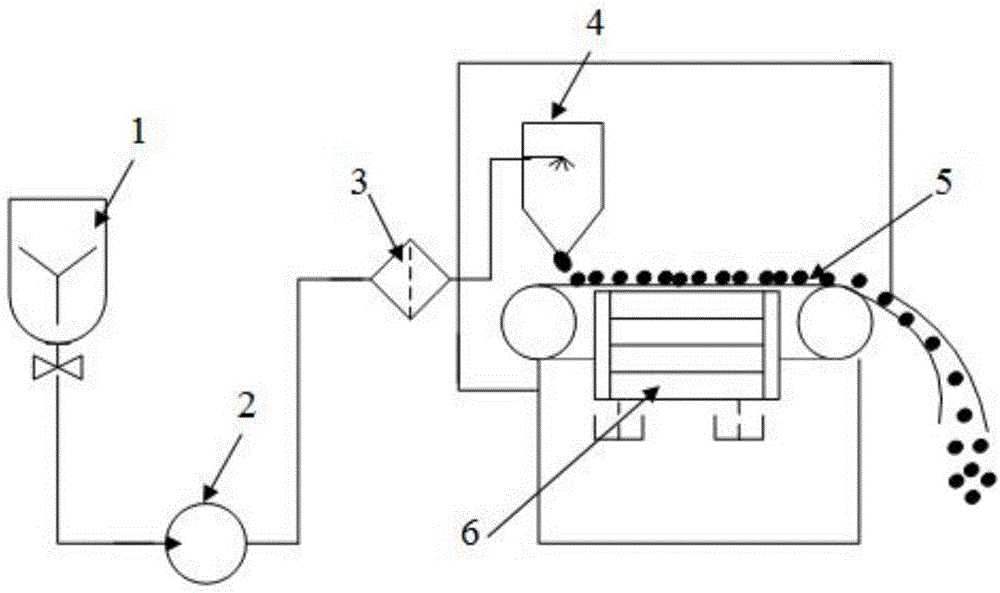

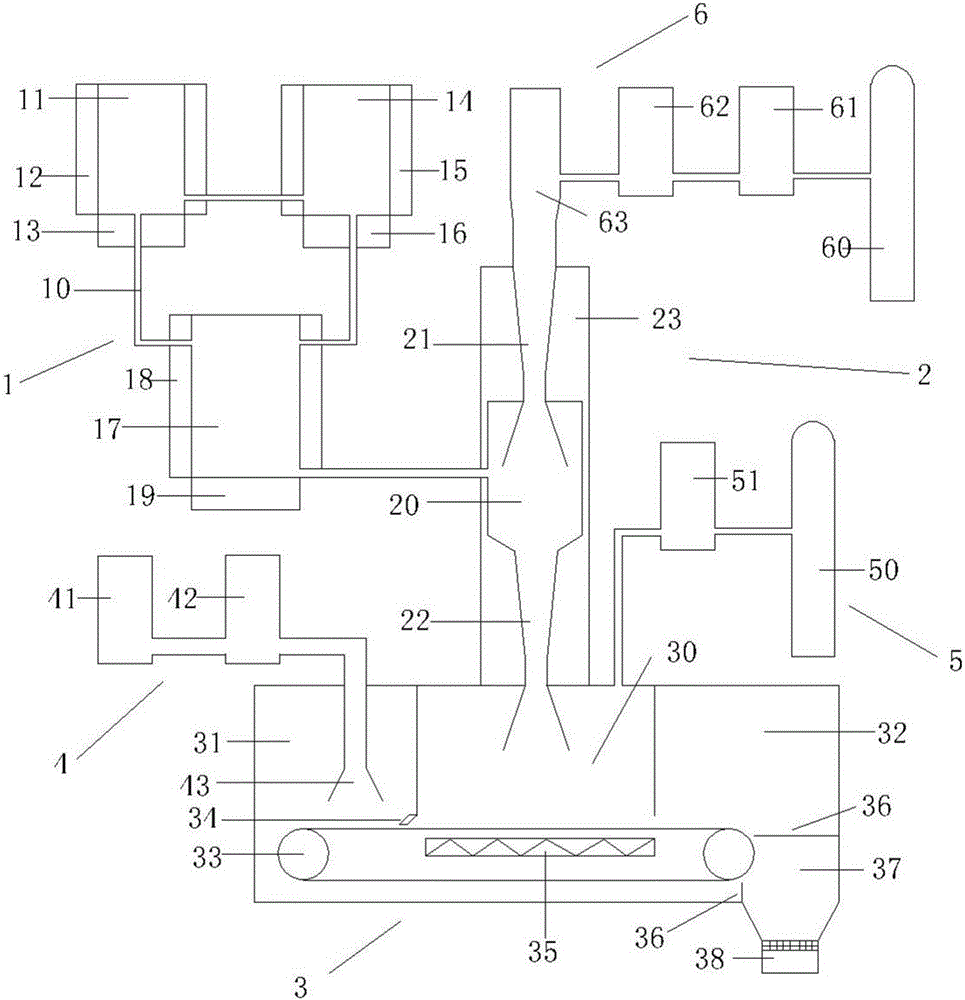

Granulation device

InactiveCN106179121AExtended service lifeLow maintenanceGranulation on conveyor beltsSurface layerEngineering

The invention discloses a granulation device which comprises a fusion mixing groove, a distribution groove, a conveying belt and a cooling spraying device. A raw material pump and a filter are arranged between the fusion mixing groove and the distribution groove. The raw material pump is connected to the outlet end of the fusion mixing groove, fused raw materials are pumped by the raw material pump to the filter and filtered by the filtered and enter the distribution device from a feed inlet, the distribution device divides the fused materials fed from the feed inlet into drops and enables the drops to be dropwise distributed on the conveying belt, and the conveying belt comprises a conveying belt body and a super-hydrophobic oleophobic surface layer arranged on the surface of the conveying belt body. Super-hydrophobic oleophobic treatment is carried out on the surface of the conveying belt, the fused material drops can be automatically shrunk into spheres, the chain type stainless steel conveying belt is used for replacing a steel belt, and therefore granules in an approximate sphere shape can be produced; in addition, due to the fact that the chain type conveying belt replaces the steel belt, basically no stress is produced during operation, the service life is greatly prolonged, and the maintenance cost is low.

Owner:SHENZHEN DAXITA TECH CO LTD

Method of agglomerating silicon/silicon carbide from wiresawing waste

The process of the present invention begins with a source of silicon and silicon carbide from wafer production. The silicon / silicon carbide waste material is dewatered as need be and passed to a mixer where the waste material is agglomerated. A binder is applied to the waste material either during agglomeration or during pelletizing. A variety of organic binders may be used such as polyvinyl alcohol, molasses, sodium silicate and polyethylene glycol; however, the preferred binder is a lignosulsulfonate. The amount of binder used will depend upon the particular binder and the feed material used. The silicon / silicon carbide-containing waste material is pelletized. The invention also provided silicon / silicon carbide-containing pellets that may be used as reduction material in smelting furnaces for the production of metals and alloys.

Owner:ALTERNATIVE CHARGE MATERIALS

Apparatus and process for forming particles

Owner:THE PROCTER & GAMBLE COMPANY

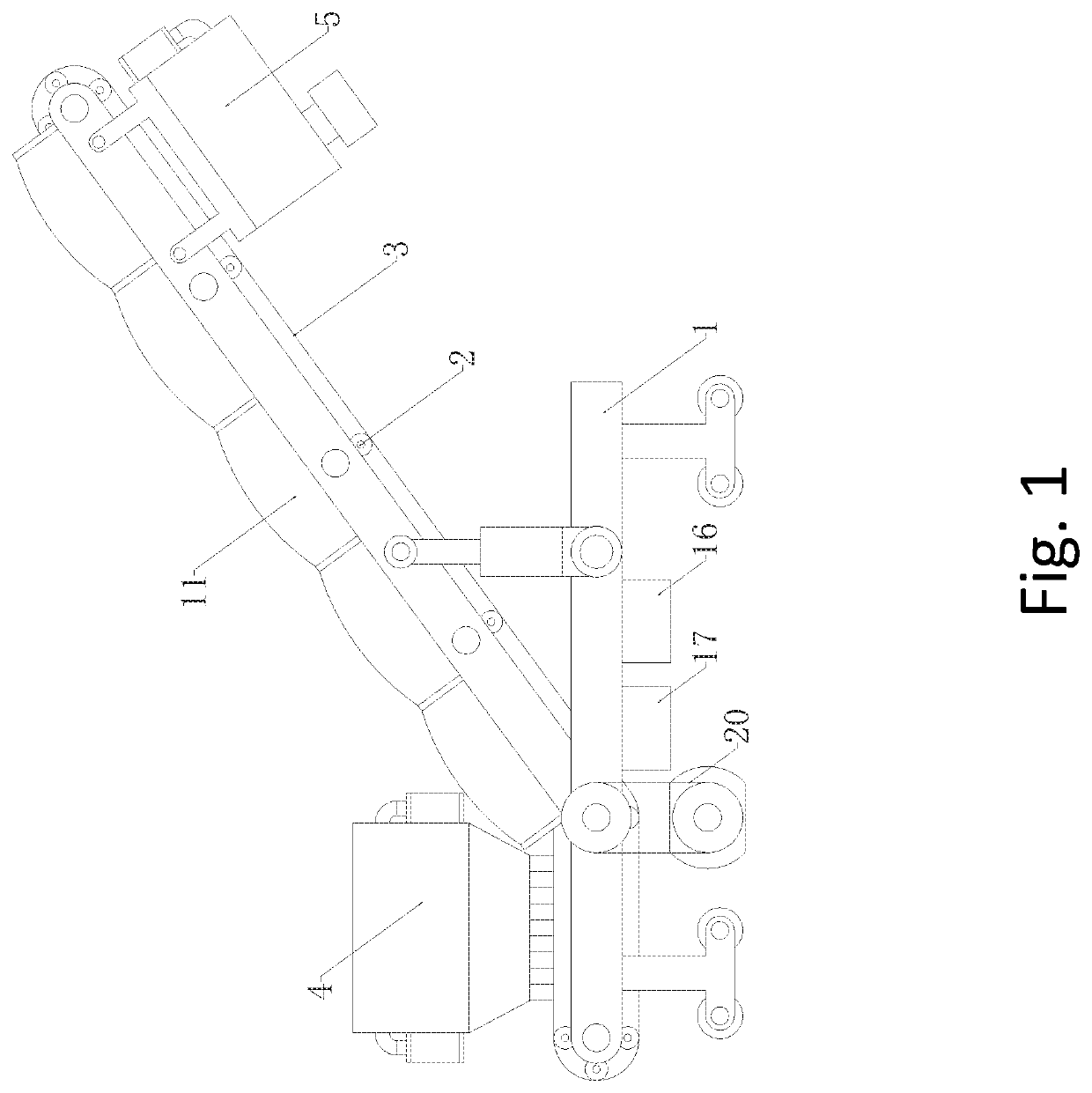

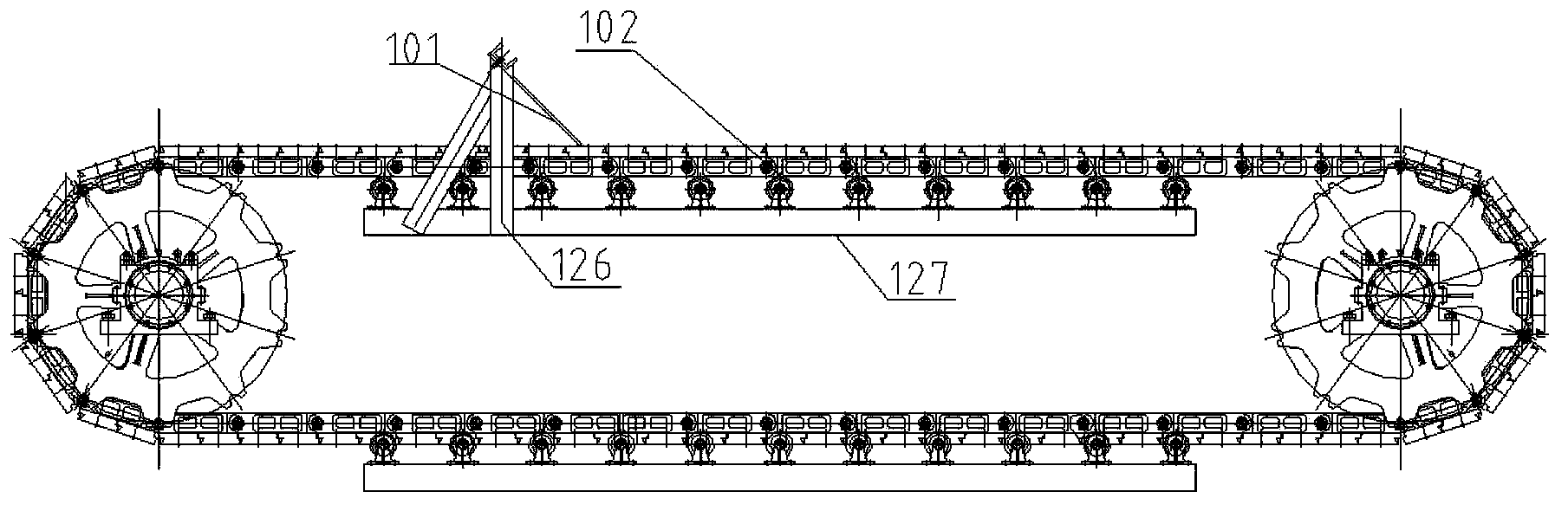

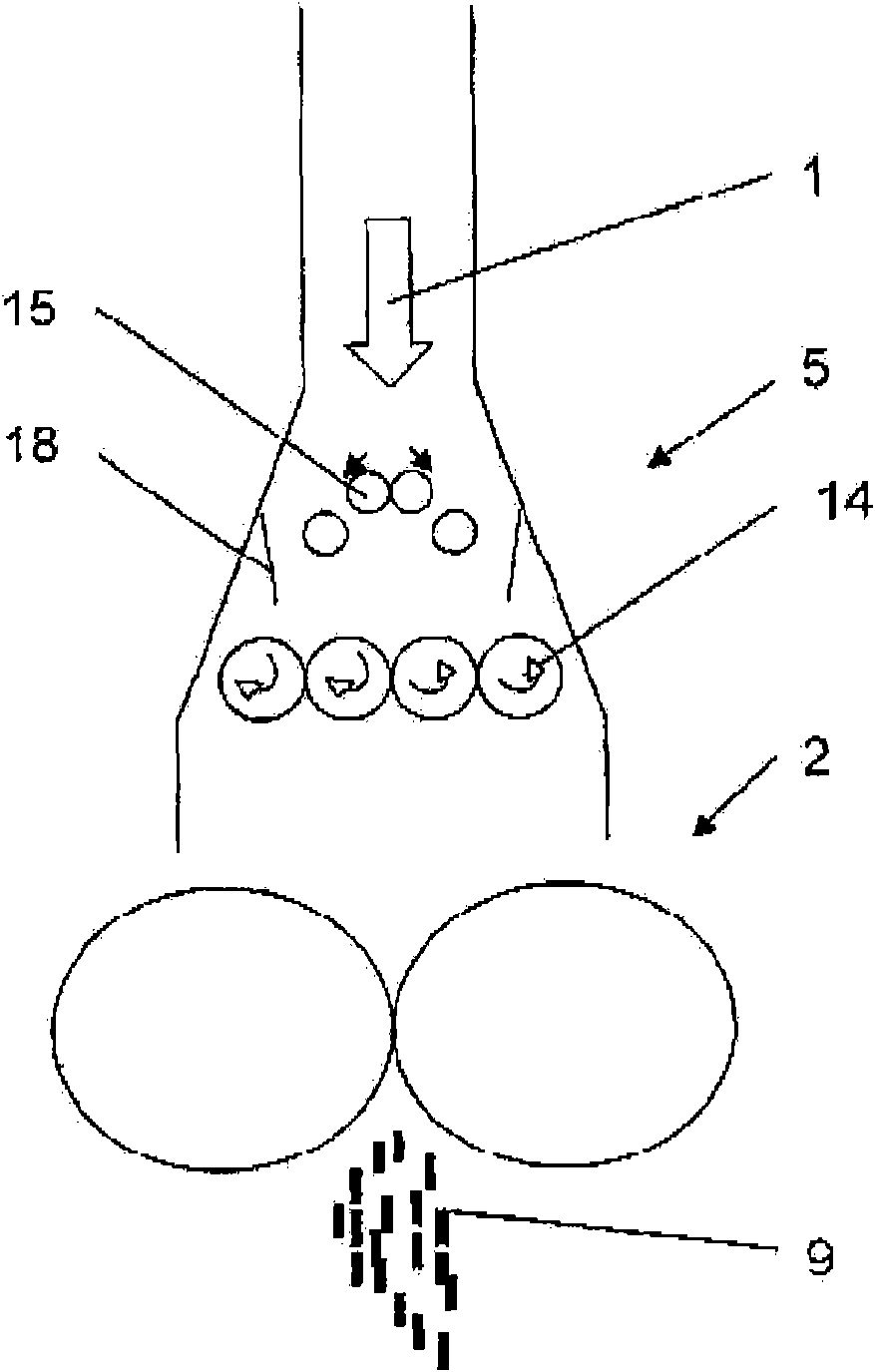

Chain belt type granulator for rapid one-step molding of high temperature liquid calcium carbide

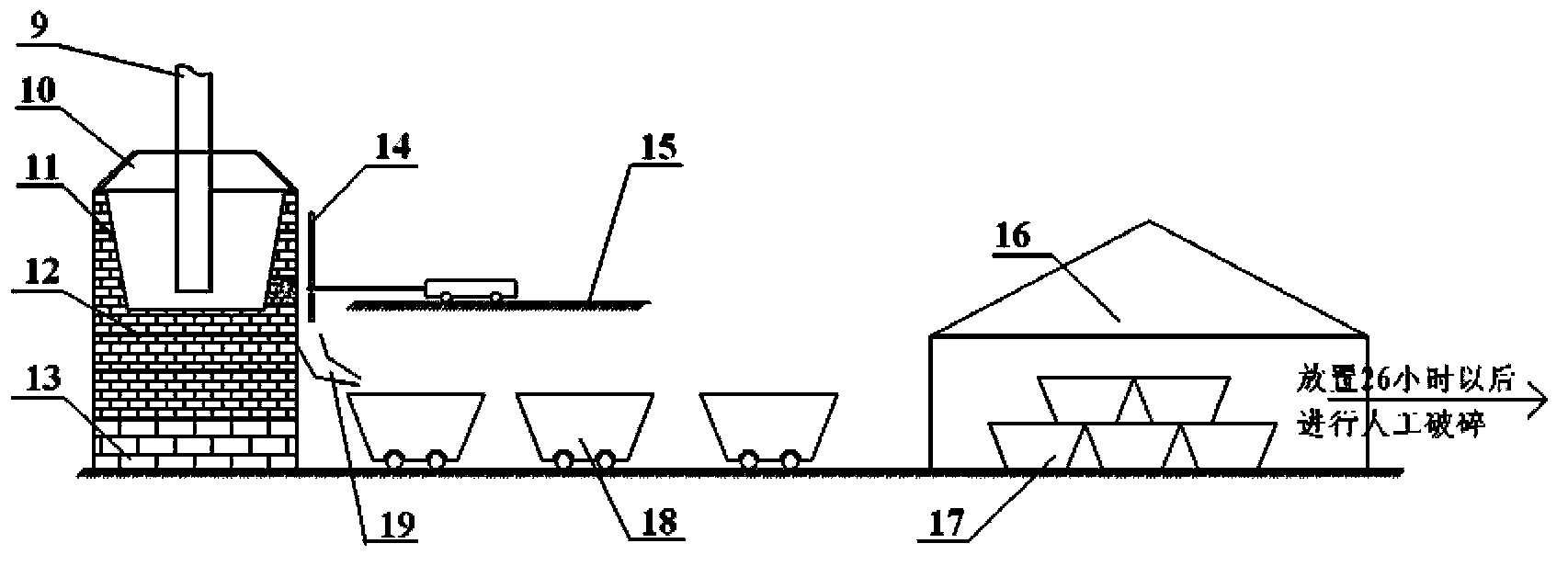

InactiveCN104289155AShorten the timeReduce wasteEnergy inputCalcium carbideLiquid stateMaterial resources

The invention provides a chain belt type granulator for rapid one-step molding of high temperature liquid calcium carbide. The chain belt type granulator is provided with a conveying chain belt, which is provided with a plurality of calcium carbide dies and a calcium carbide scraping plate. Each of the calcium carbide dies is formed by back-to-back arrangement of two identical half dies. The calcium carbide scraping plate is used for strickling the high temperature liquid calcium carbide constantly, so that the high temperature liquid calcium carbide uniformly flows into the calcium carbide dies, and along with continuous conveying by the conveying chain belt, the high temperature liquid calcium carbide in the calcium carbide dies quickly cools into a solid calcium carbide block. The chain belt type granulator provided by the invention can efficiently break calcium carbide, omits a breaking process in a downstream PVC production process, avoids formation of powder caused by manual breaking of calcium carbide, and greatly reduces the waste of materials. In addition, as the volume of the calcium carbide block is greatly reduced, the surface area is increased, the heat dissipation rate is quickened, the calcium carbide cooling time is shortened, and workshop manpower and material resources, and floor occupation are saved.

Owner:BEIJING SNTA ENERGY SAVING ELECTRICAL

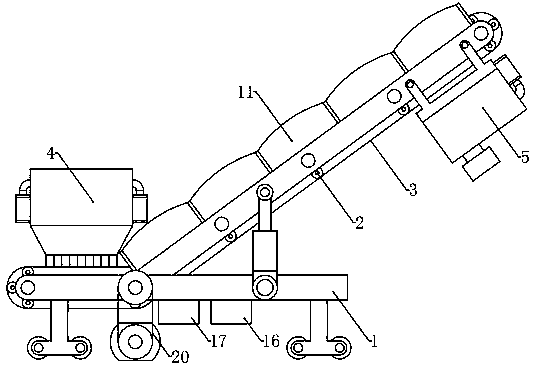

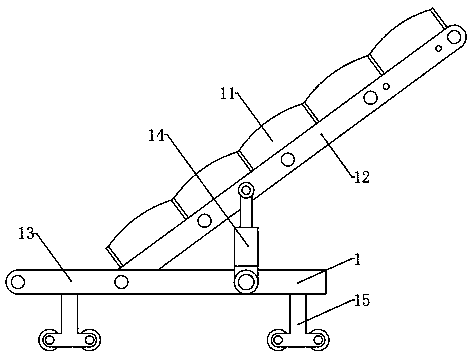

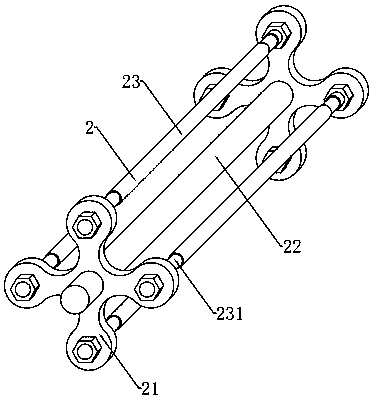

Belt-type crushing dustproof conveying device for agglomerated finely-crushed materials

ActiveCN108750708APrevent deviationReasonable structureConveyorsLarge containersHydraulic cylinderEngineering

The invention discloses a belt-type crushing dustproof conveying device for agglomerated finely-crushed materials. The belt-type crushing dustproof conveying device comprises a base with a frame structure, a rolling bracket, a conveyor belt, a crushing dustproof mechanism and a conveyor belt cleaning mechanism. The base comprises a fixed base body, a movable base body and a hydraulic cylinder; therolling bracket comprises supporting plates, a rotating shaft and supporting rods; the conveyor belt comprises a conveyor belt body and inductive teeth; the crushing dustproof mechanism comprises aninner sleeve, an outer sleeve, a first air pump, an ion fan and a mixed bin; and the conveyor belt cleaning mechanism comprises a tube, a mesh board, a sweeping mechanism and a second air pump. The belt-type crushing dustproof conveying device for the agglomerated finely-crushed materials is reasonable in structure and has the advantages of being simple in structure, convenient to use, high in intellectualization degree, capable of automatically regularizing the deviated conveyor belt and automatically cleaning the conveyor belt, good in dustproof effect and the like, and the problem that flying dust endangers the health of workers during finely-crushed material conveying is effectively solved.

Owner:常熟市天和砼有限公司

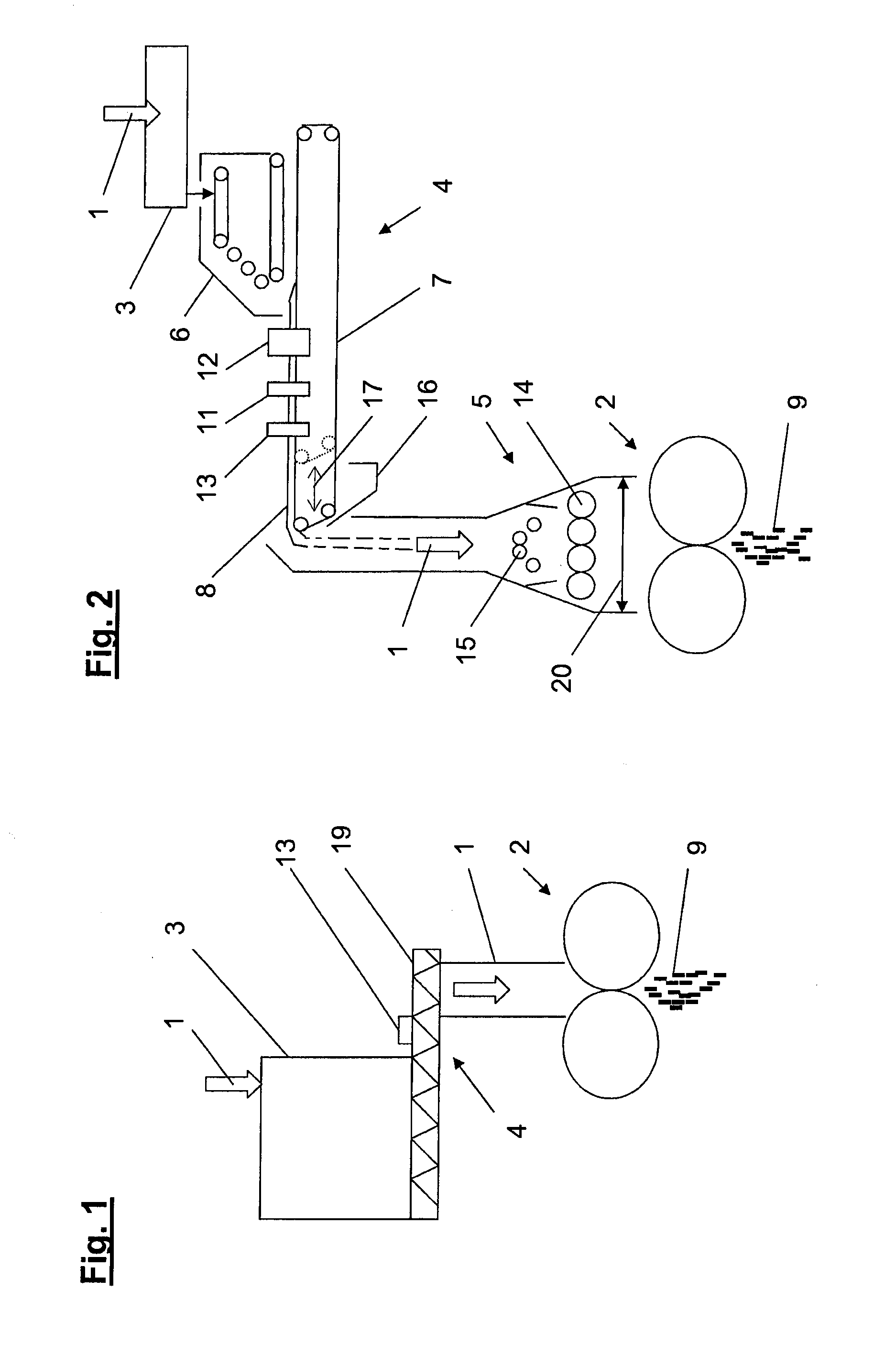

Method and drop former for producing tablets and method for producing a sulfurous fertilizer

InactiveUS8349229B2Increase the areaMaterial composition is uniformSulfur compoundsAuxillary shaping apparatusSteel beltMaterials science

A method for producing tables made of mixtures of a plurality of materials, and a method for producing a sulfurous fertilizer. A method for producing tablets made of mixtures of a plurality of materials, particularly urea mixtures, having the following steps:—producing a liquid melt of a first material,—adding at least one further material in solid or liquid form to the melt for producing a mixture,—output of drops of the mixture onto a steel belt by means of a drop former having a rotating, perforated outer drum,—solidification of the drops of the mixture on the steel belt into tablets, wherein the at least one additional material is mixed into the liquid melt in liquid form immediately before the drop former or into the liquid melt in solid. form upstream of a two-stage heated grinding and mixing unit.

Owner:IPCO GERMANY GMBH

Preparation technology of BPEF (4, 4'-(9-fluorenylidene) bis (2-phenoxy-ethanol)) with high bulk density

InactiveCN103317746AHigh bulk densityImprove liquidityGranulation by pressingShaping pressMolten state9-fluorenylidene

The invention discloses a preparation technology of BPEF (4, 4'-(9-fluorenylidene) bis (2-phenoxy-ethanol)) with high bulk density. Powdery BPEF is subjected to dry powder tableting by a hydraulic machine or granulation by a roller dry-technique granulator or fusing granulation to prepare a space structure of BPEF with the high bulk density, wherein powdery BPEF is subjected to dry powder tableting by the hydraulic machine and is directly compressed into cylindrical, square and half-moon-shaped space structures; the powdery BPEF is directly compressed into ingot-shaped, grain-shaped and strip-shaped space structures by the roller dry-technique granulator; and the fusing granulation comprises the steps as follows: the BPEF is heated to be in a fusing state, then the BPEF in the fusing state is uniformly distributed on a steel belt of a rotation belt type condensation granulator, is cooled in a continuous spraying manner, and finally is used for producing hemispherical, strip-shaped and sheet-shaped space structures with the forms of intermittent dipping, continuous strip discharging and full-width cloth overflowing. The technology is simple and convenient, and can effectively increase bulk density and fluidity of BPEF, so that not only is the production efficiency improved, but also the environment pollution is prevented.

Owner:JIANGSU EVER GALAXY CHEM CO LTD

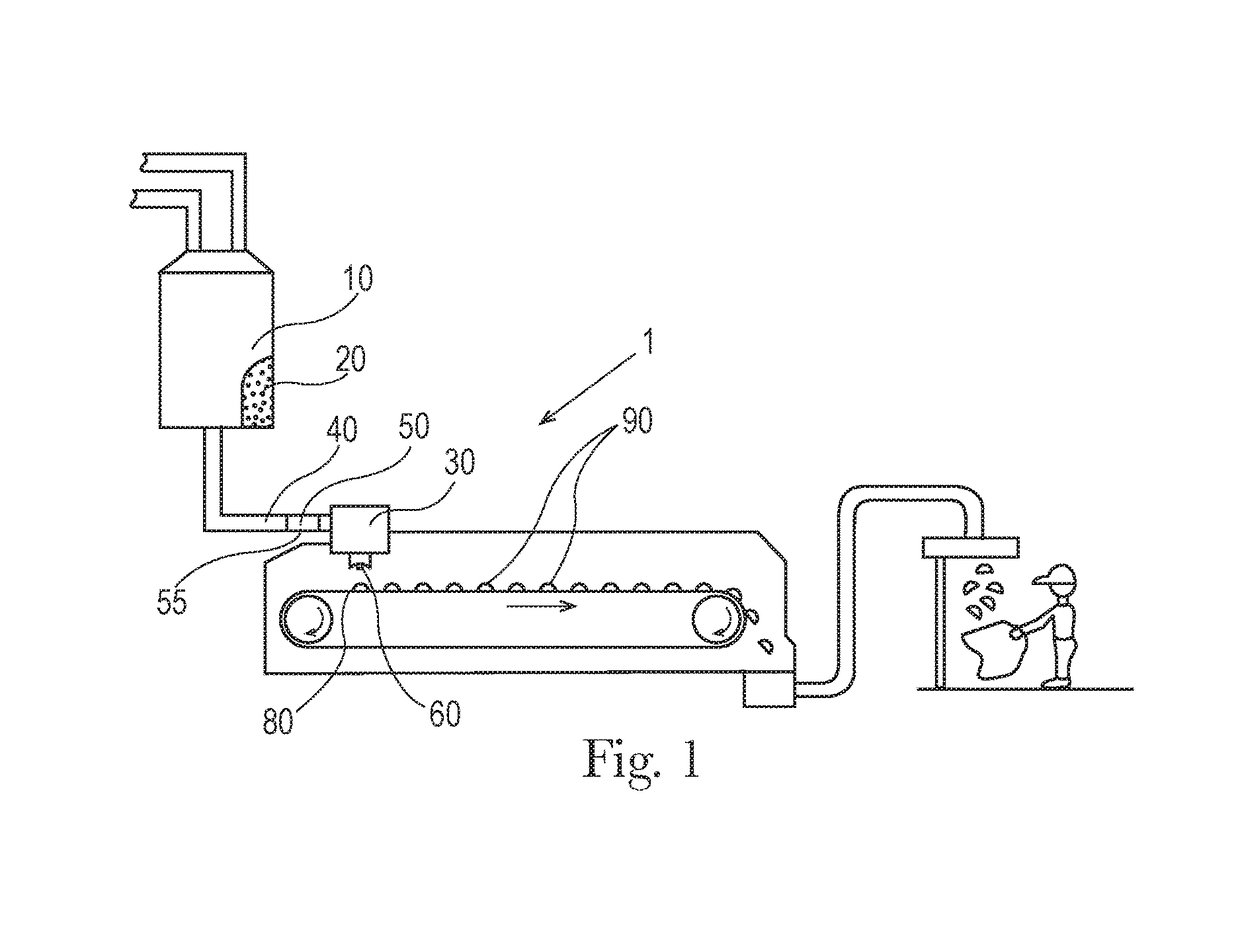

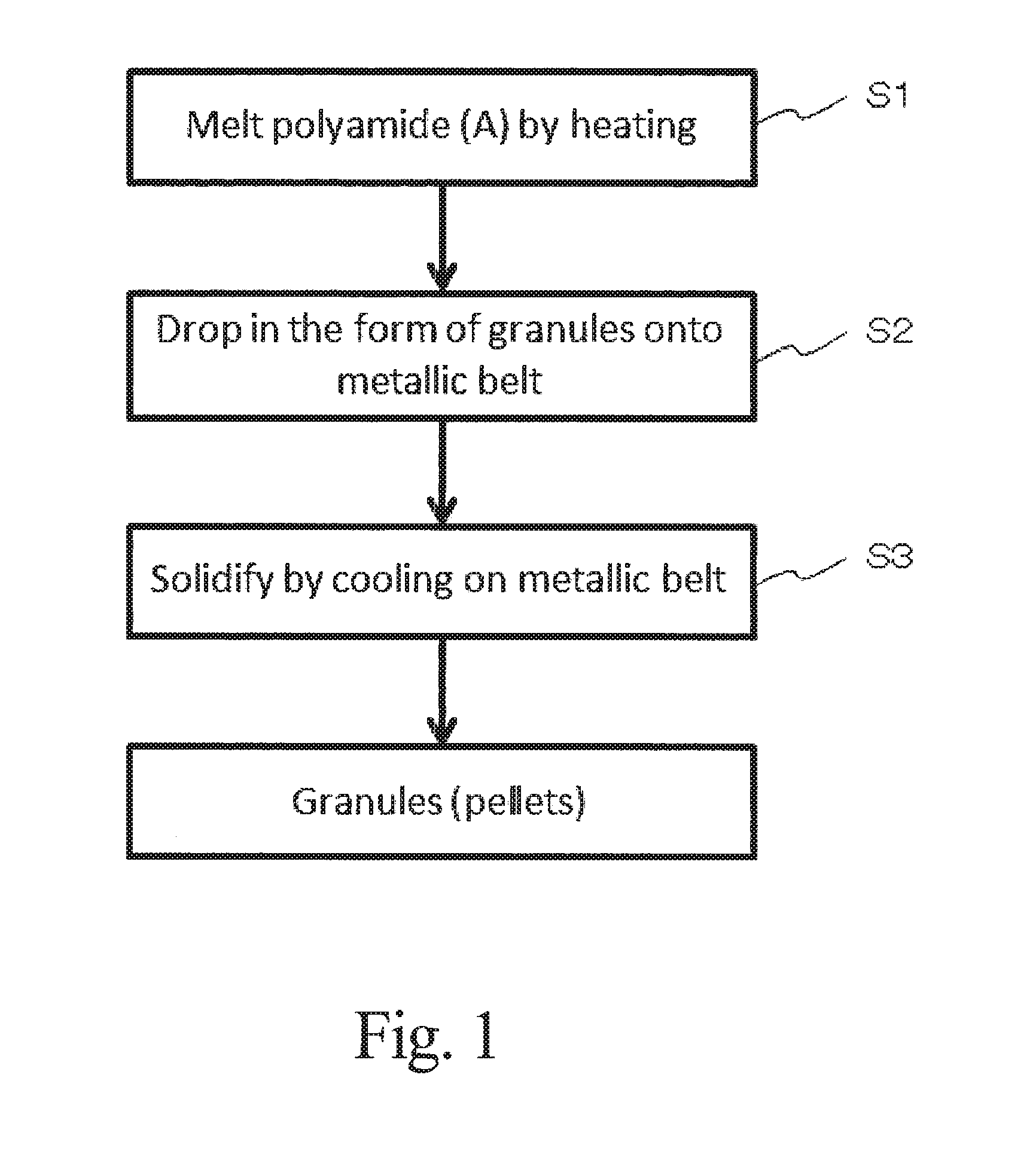

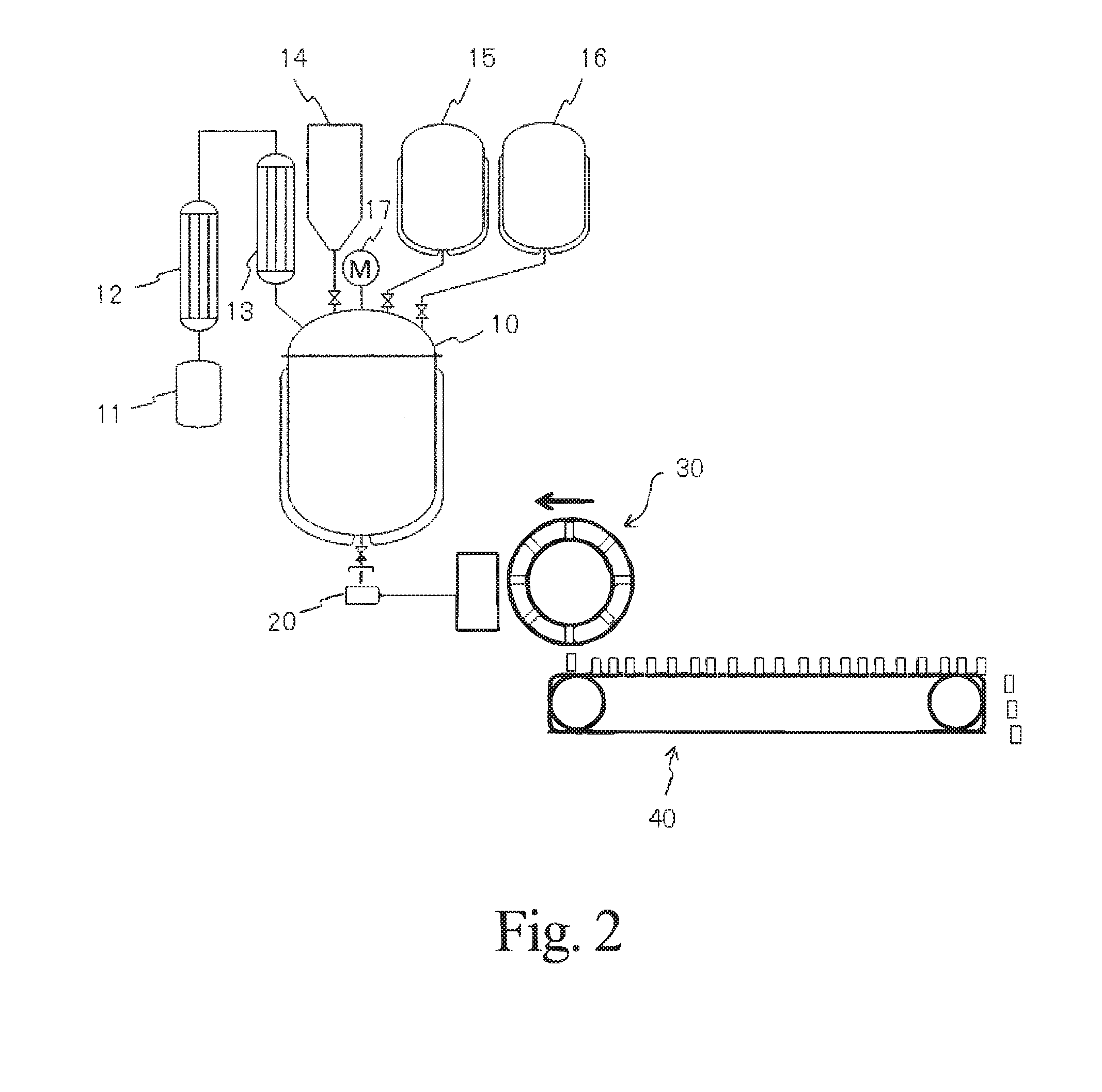

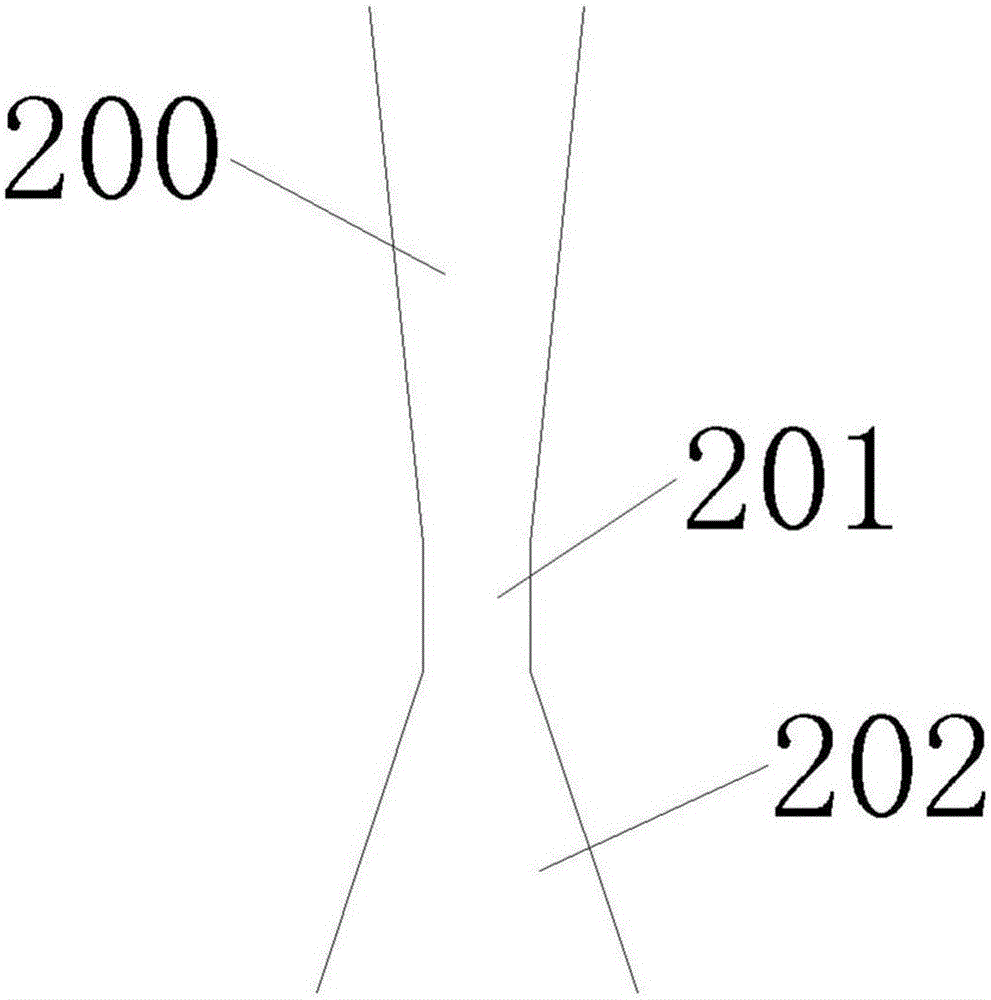

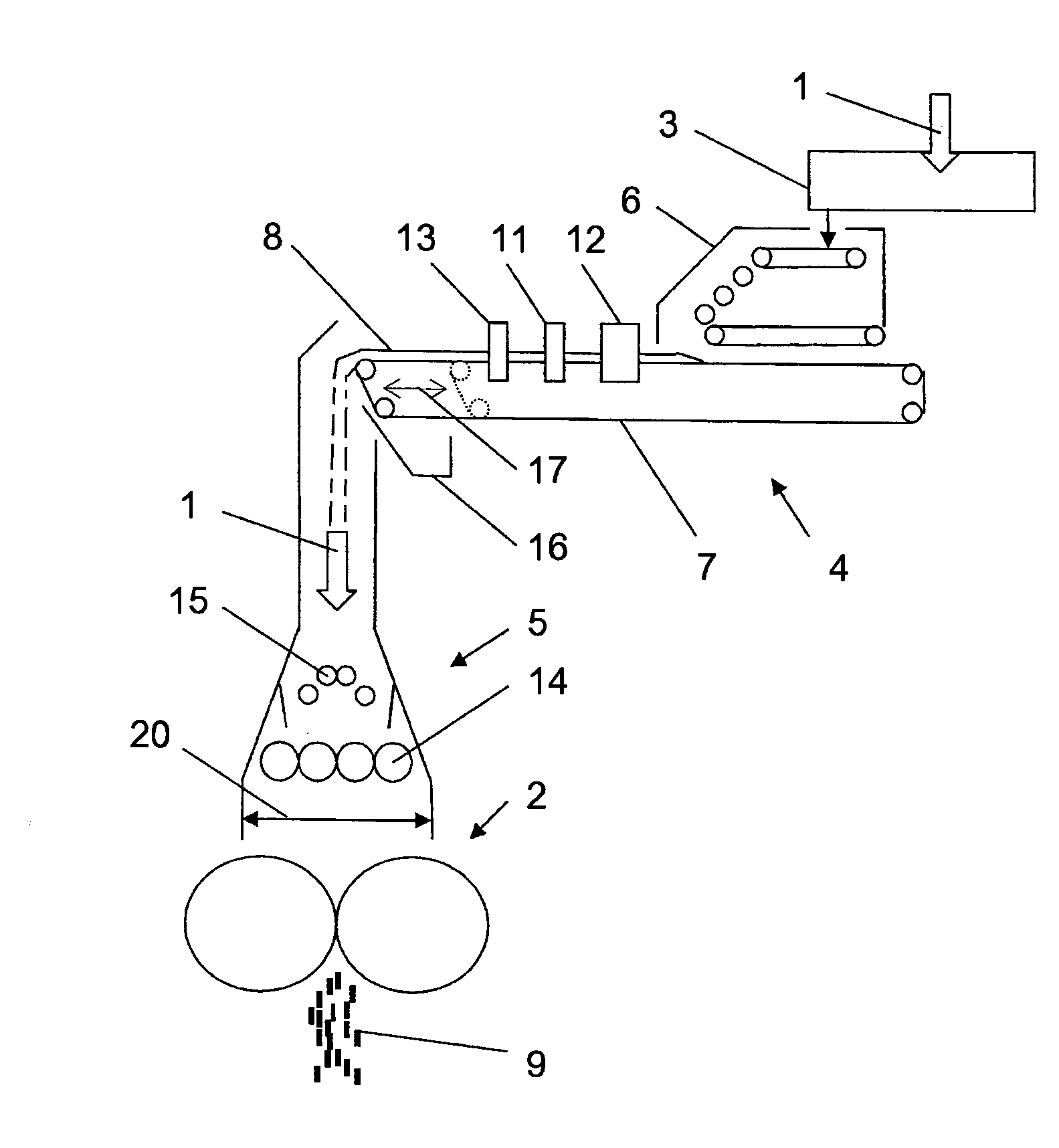

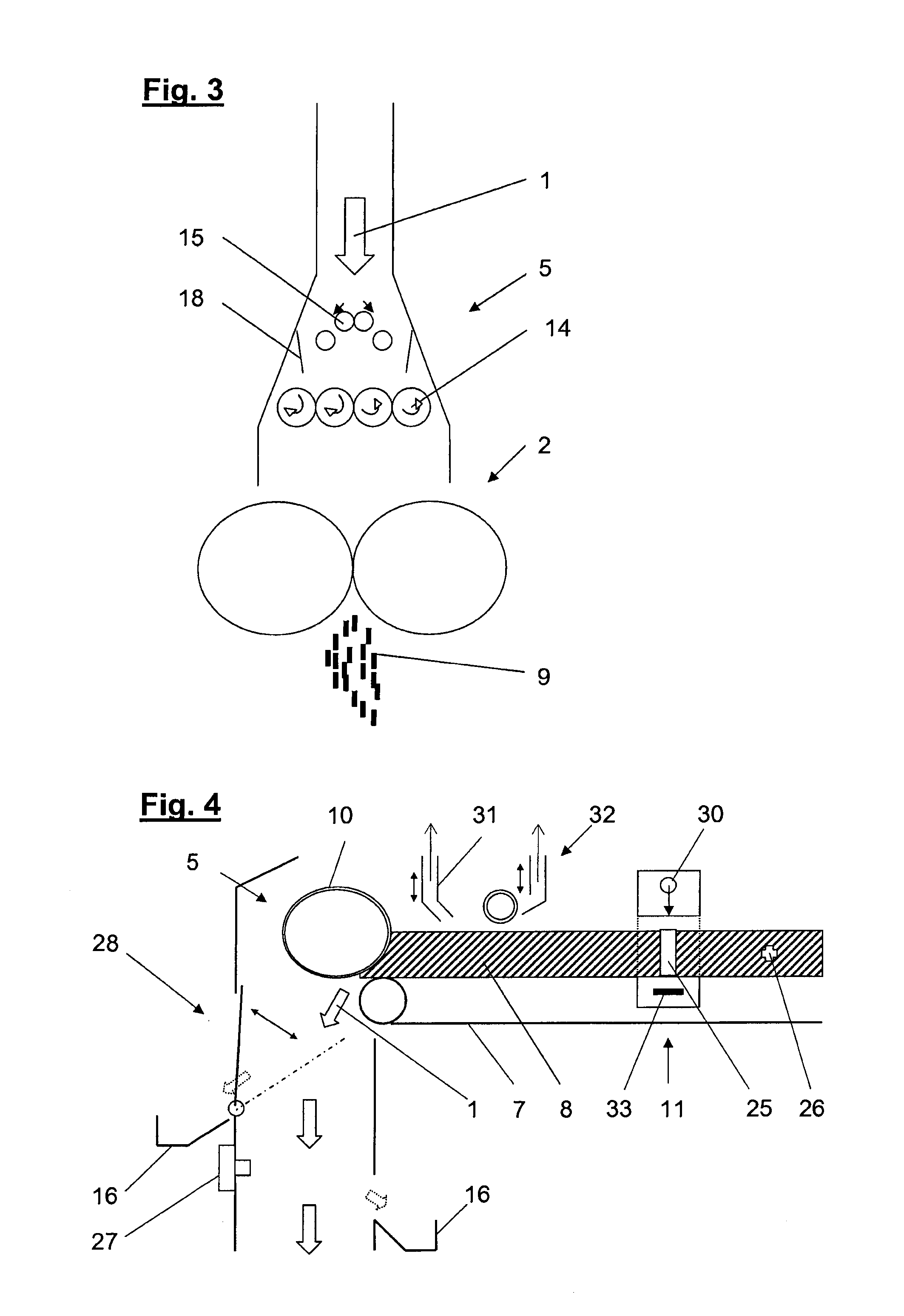

Method for granulating polyamide or polyamide composition

ActiveUS20160347915A1Little changeLess cobwebbingGranulation on conveyor beltsVitrificationPolyamide

The present invention provides a method for granulating a polyamide or a polyamide composition, whereby it becomes possible to granulate even a polyamide that has such a melt viscosity that the polyamide cannot be pelletized into a strand-like shape easily. In the present invention, a polyamide, whose melt viscosity at glass transition temperature+160° C. and a shear rate of 100 s−1 is 3 Pa·s to 200 Pa·s and whose terminal amino group concentration is 5 μeq / g to 70 μeq / g, is melted by heating to a range of glass transition temperature+160° C. to glass transition temperature+180° C. of the polyamide, and then is solidified by dropping the molten polyamide in the form of granules onto a metallic belt, thereby producing granules.

Owner:MITSUBISHI GAS CHEM CO INC

Method and assembly for producing pellets made of biomass in pelleting press for use as fuel in fireplaces

A method and an installation for producing pellets from prepared biomass in a pelleting press for use as fuel in fireplaces. The biomass is made of fibers, shavings or chippings containing cellulose and / or lignocellulose, with or without a binding agent and / or additives, and after being prepared is stored in a biomass bunker. The method includes: biomass discharged from the biomass bunker into a scatter device, a mat made of the biomass having a substantially uniform weight per unit area formed by the scatter device on a molding belt, the mat produced on the molding belt examined by an examining device for defective spots and / or foreign substances, and the mat supplied to a pelleting press. At least parts of the mat or a section of the mat include defective regions and / or foreign substances separated from the method upstream of the pelleting press.

Owner:DIEFFENBACHER GMBH & CO KG

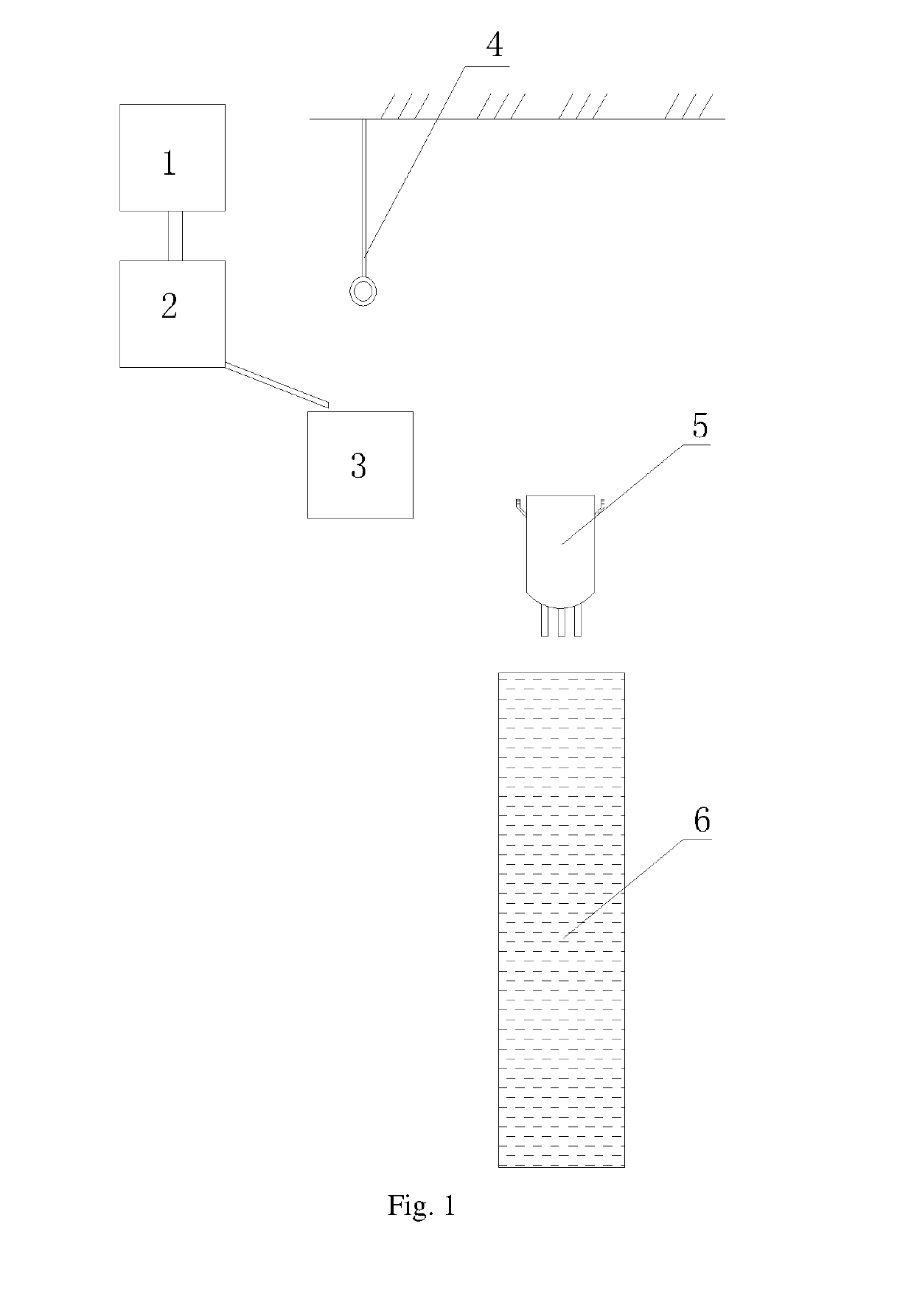

System for preparing powder with gas phase and liquid phase

The invention provides a system for preparing powder with a gas phase and a liquid phase. The system comprises a raw material heat treatment device, a mixing device and a spraying device; the mixing device comprises a mixing chamber, a first Laval spray pipe and a second Laval spray pipe; the first Laval spray pipe is arranged at the top of the mixing chamber in a penetrating mode, and the bottom of the mixing chamber is communicated with the second Laval spray pipe; the tail end of the second Laval spray pipe is introduced into the spraying device; the raw material heat treatment device mixes raw materials of different physical states and is connected with the mixing chamber of the mixing device through a guide pipe. By means of the system for preparing powder with the gas phase and the liquid phase, the raw materials can be fully mixed, the prepared powder material can be high in activity and small in powder granularity, and a composite powder material can be prepared.

Owner:深圳市航盛新材料技术有限公司

Hydrogenated petroleum resin granulator and granulation method thereof

InactiveCN106807305AAvoid brittleStable temperature differenceDomestic cooling apparatusLighting and heating apparatusEngineeringPetrochemical

The invention relates to the field of petrochemical industry, in particular to a hydrogenated petroleum resin granulator and a granulation method thereof, comprising a distributor, a conveying device, a cooling device, and a discharge bin. The cooling device includes a water spray pipe, a water spray pipe There is a water spray port on the top, and the water spray pipe is arranged at the lower part of the conveying device. The water spray pipe includes a pre-cooling section and a graded cooling section arranged in sequence. The pre-cooling section is close to the feeding end of the conveying device. stage or multi-stage cooling sections, the cooling sections of the pre-cooling section and the graded cooling section are respectively connected to the water inlet pipes, and the water inlet pipes are connected to the cooling water, and the cooling water in the water inlet pipes of the cooling sections of the pre-cooling section and the graded cooling section The water temperature decreases successively. The invention keeps the temperature difference between the material and the cooling medium stable, and prevents the material from becoming brittle during rapid cooling and difficult to separate from the bonded steel belt.

Owner:山东天景工程设计有限公司

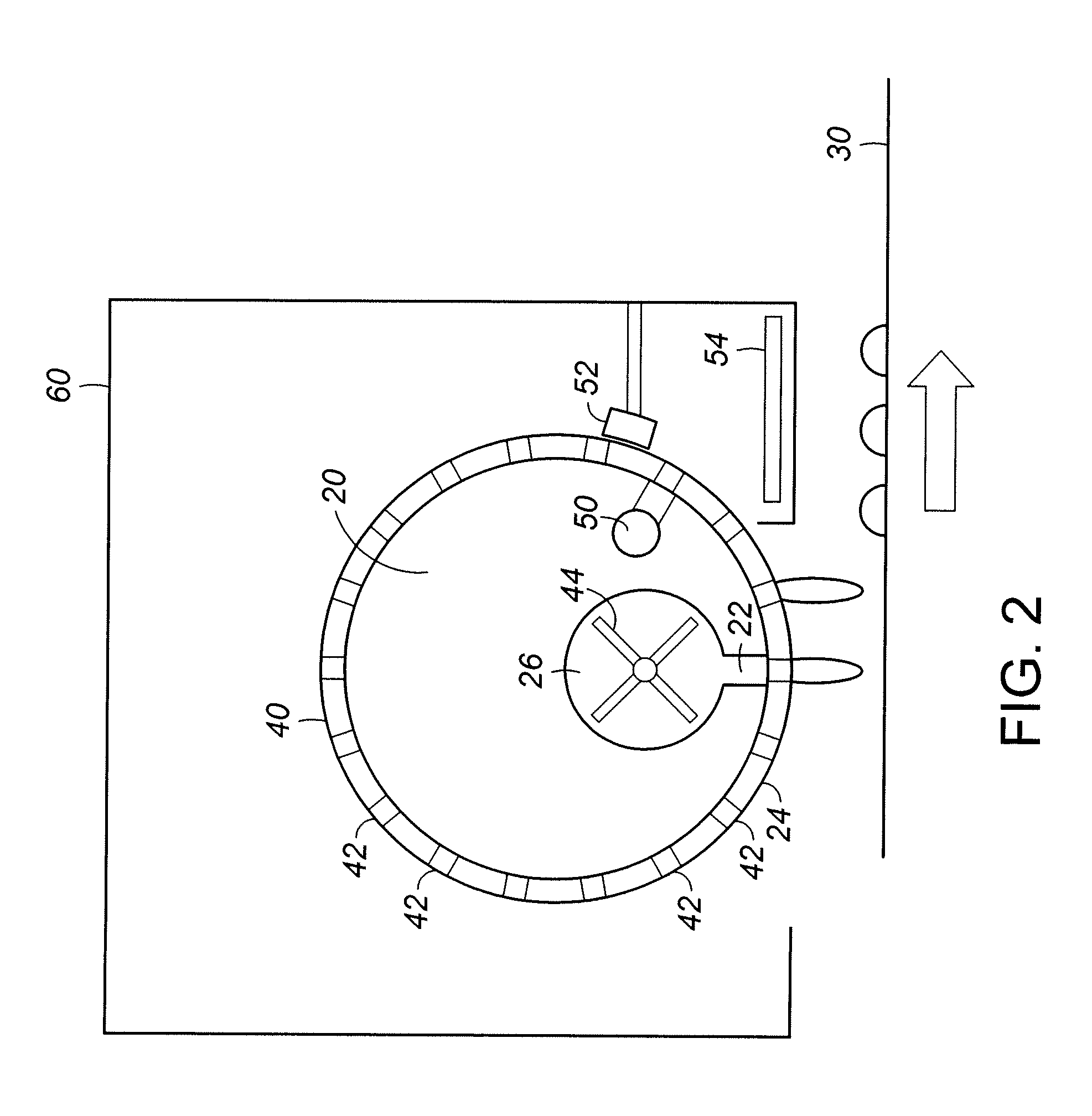

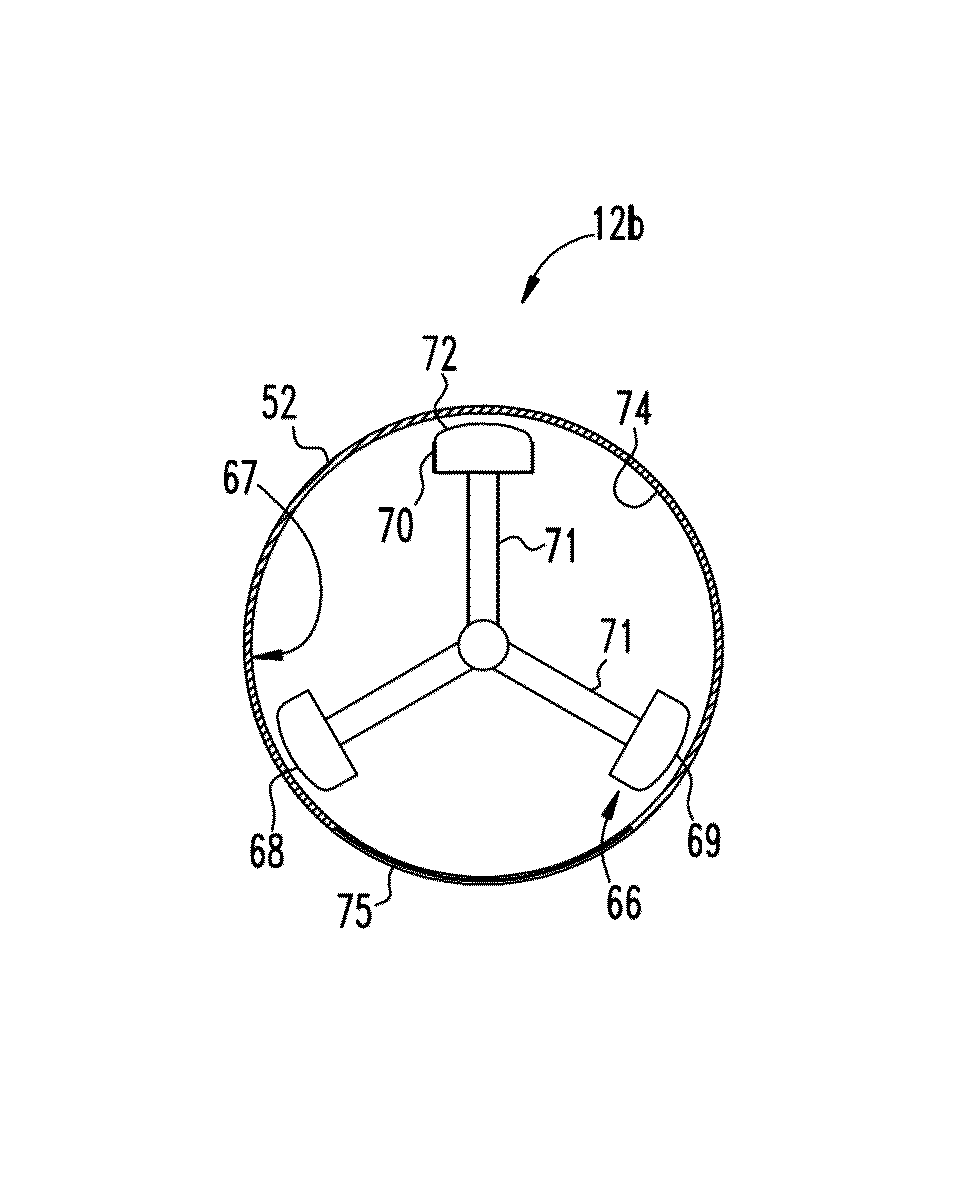

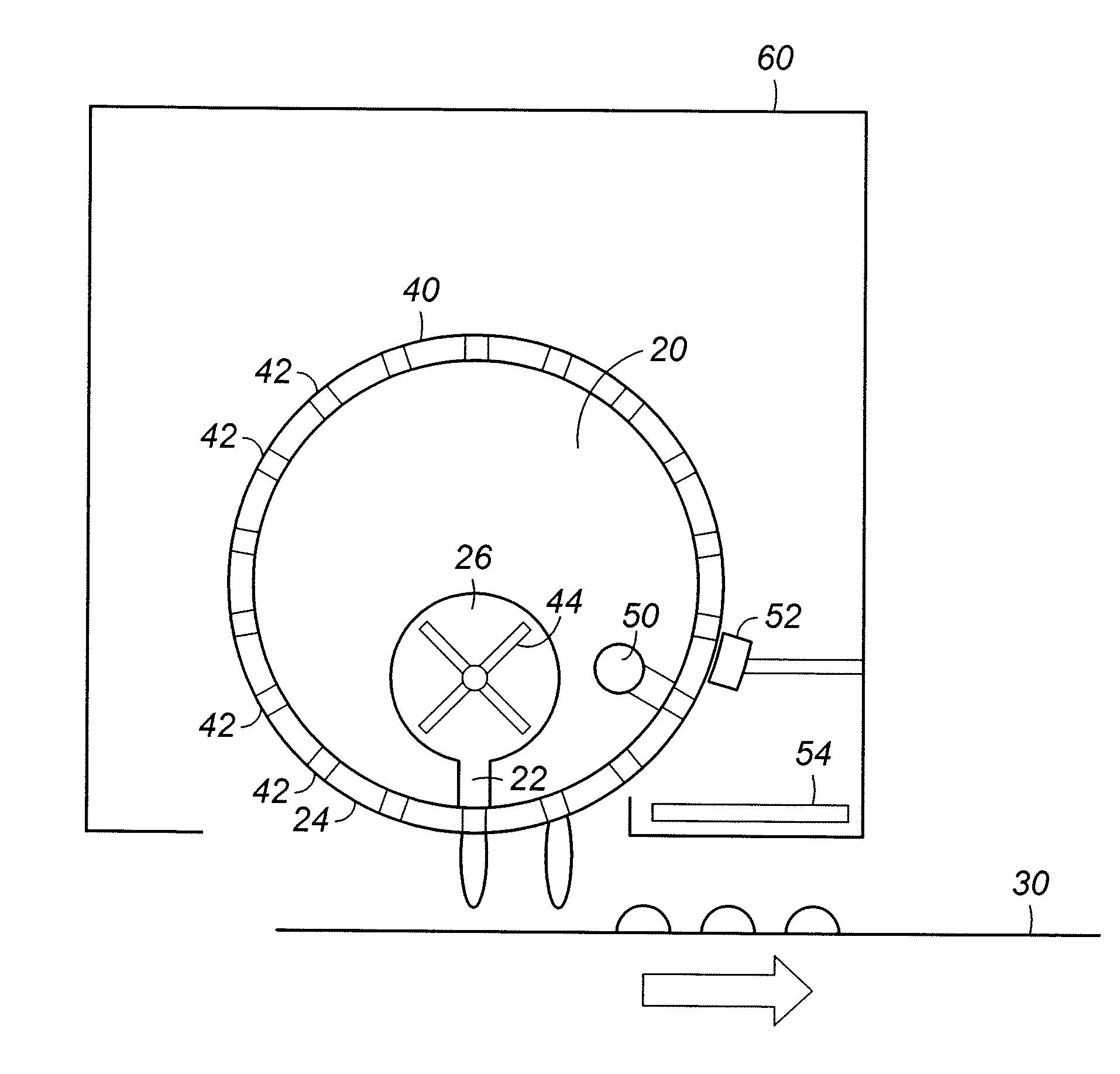

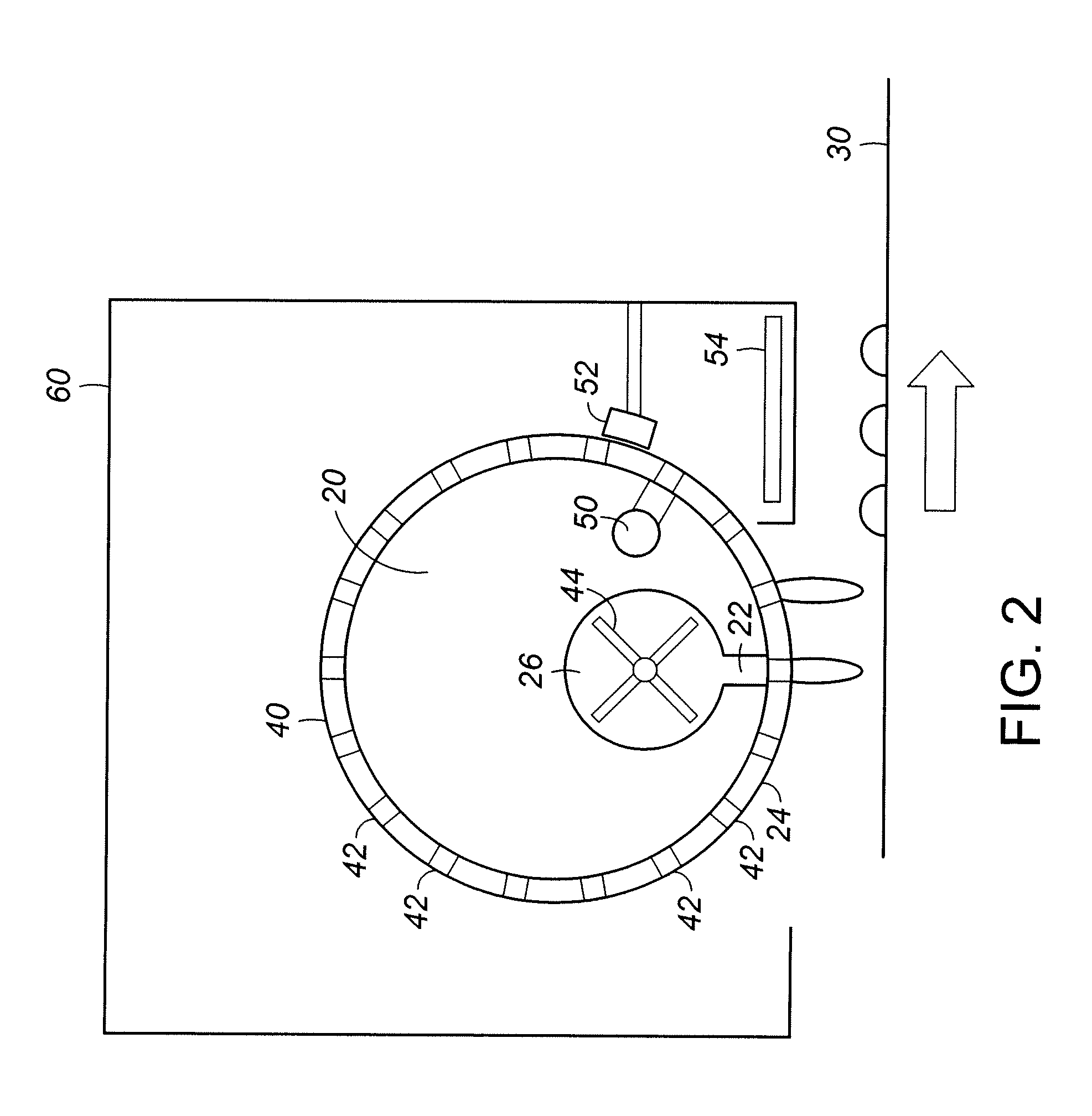

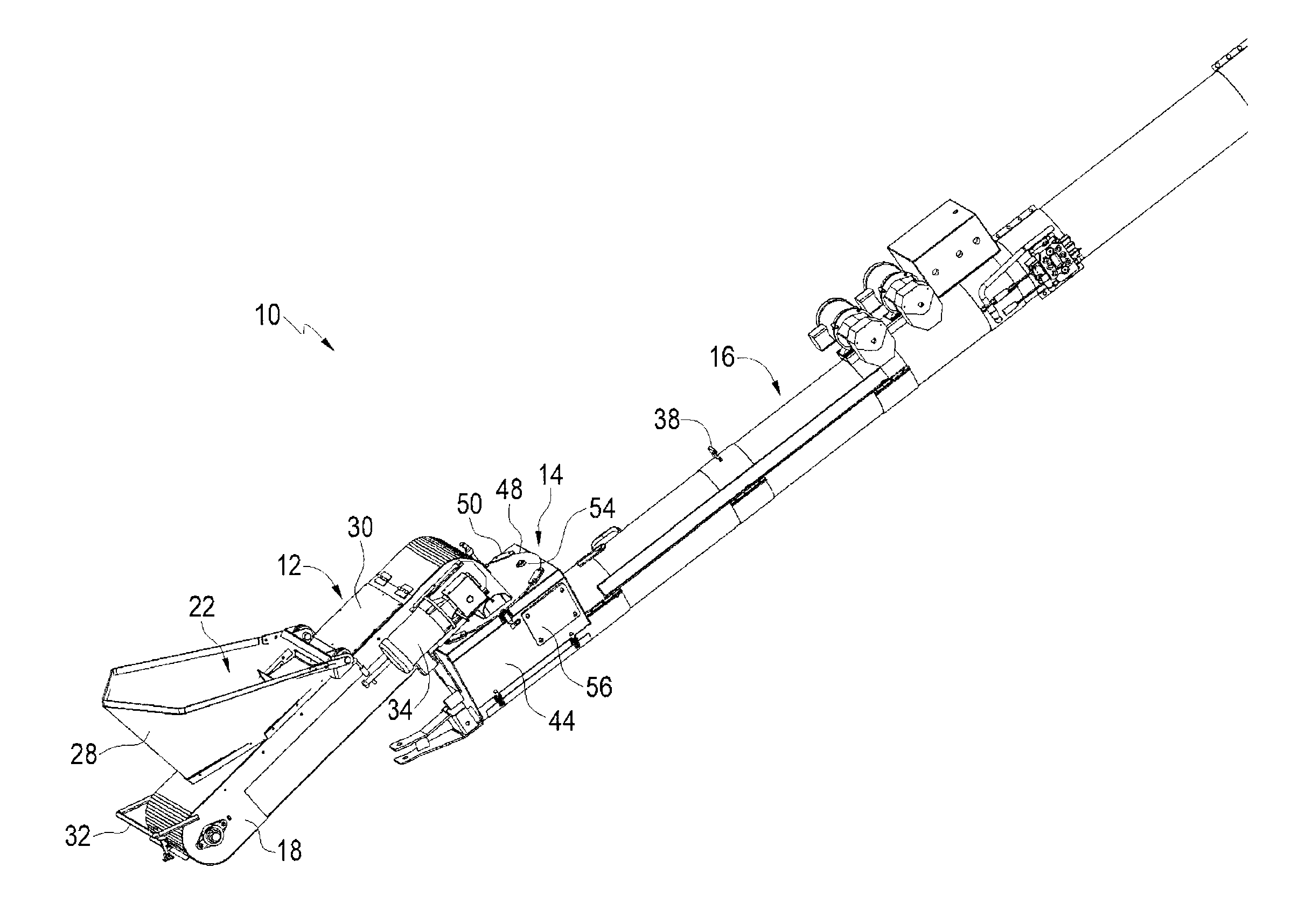

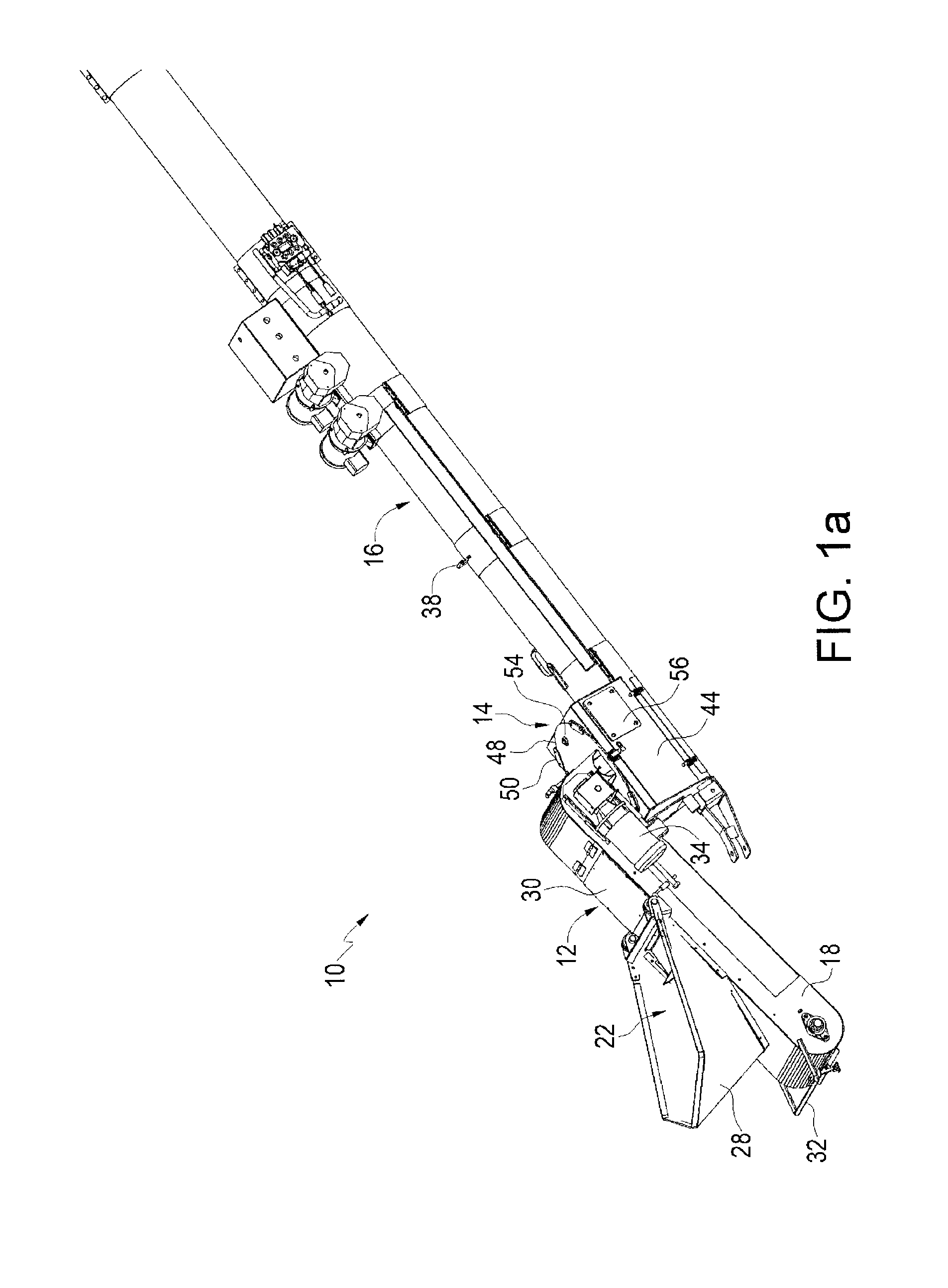

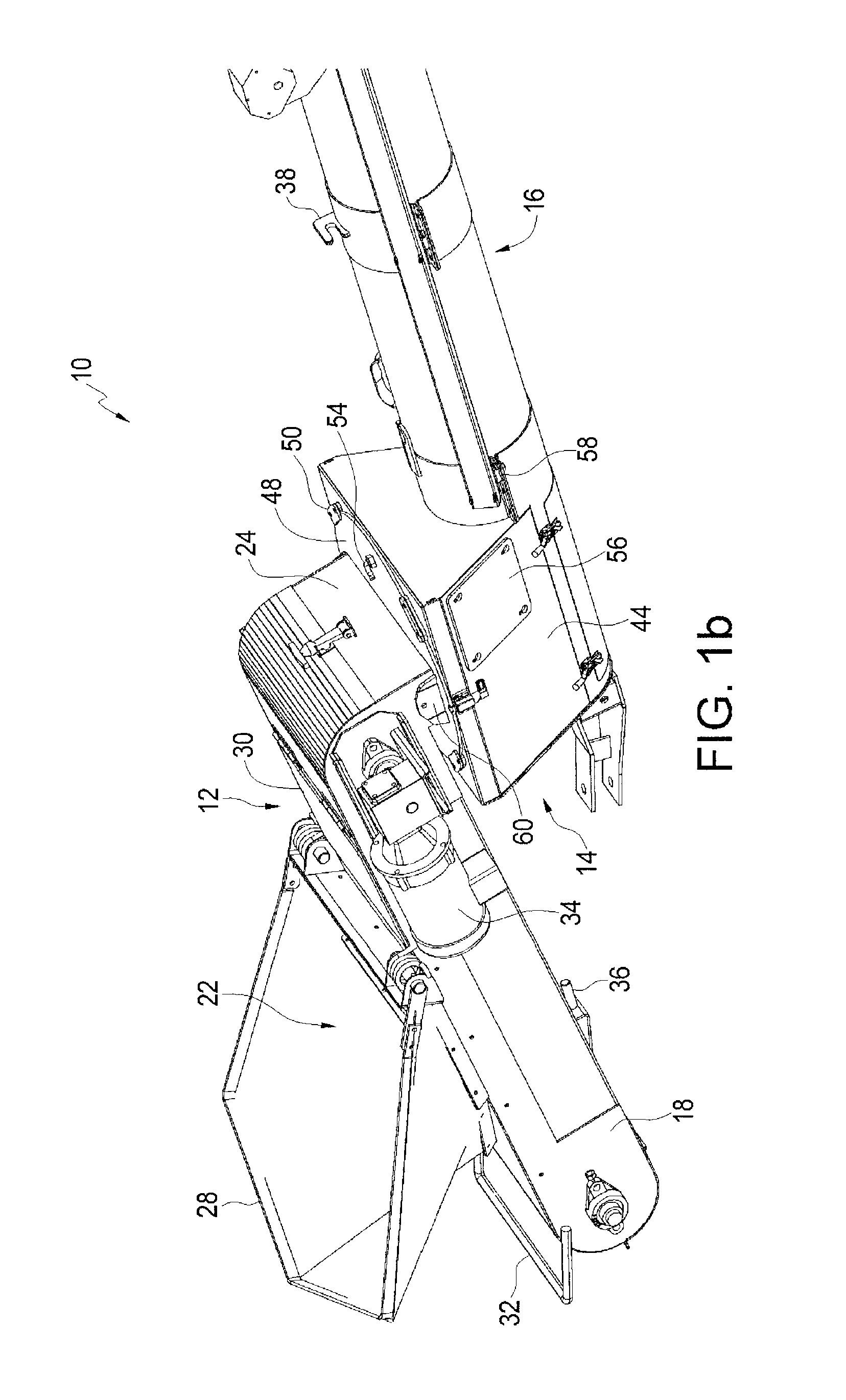

Rotatable apparatus for metering and treating agricultural granules

An agricultural apparatus for metering and treating granules such as seeds and granular crop additives. The apparatus comprises a metering device rotatably mounted on a spray chamber, the spray chamber connected to a conveyance device intake such as an auger. The metering device is rotatable between first (use) and second (transport) positions.

Owner:BAYER CROPSCIENCE INC +1

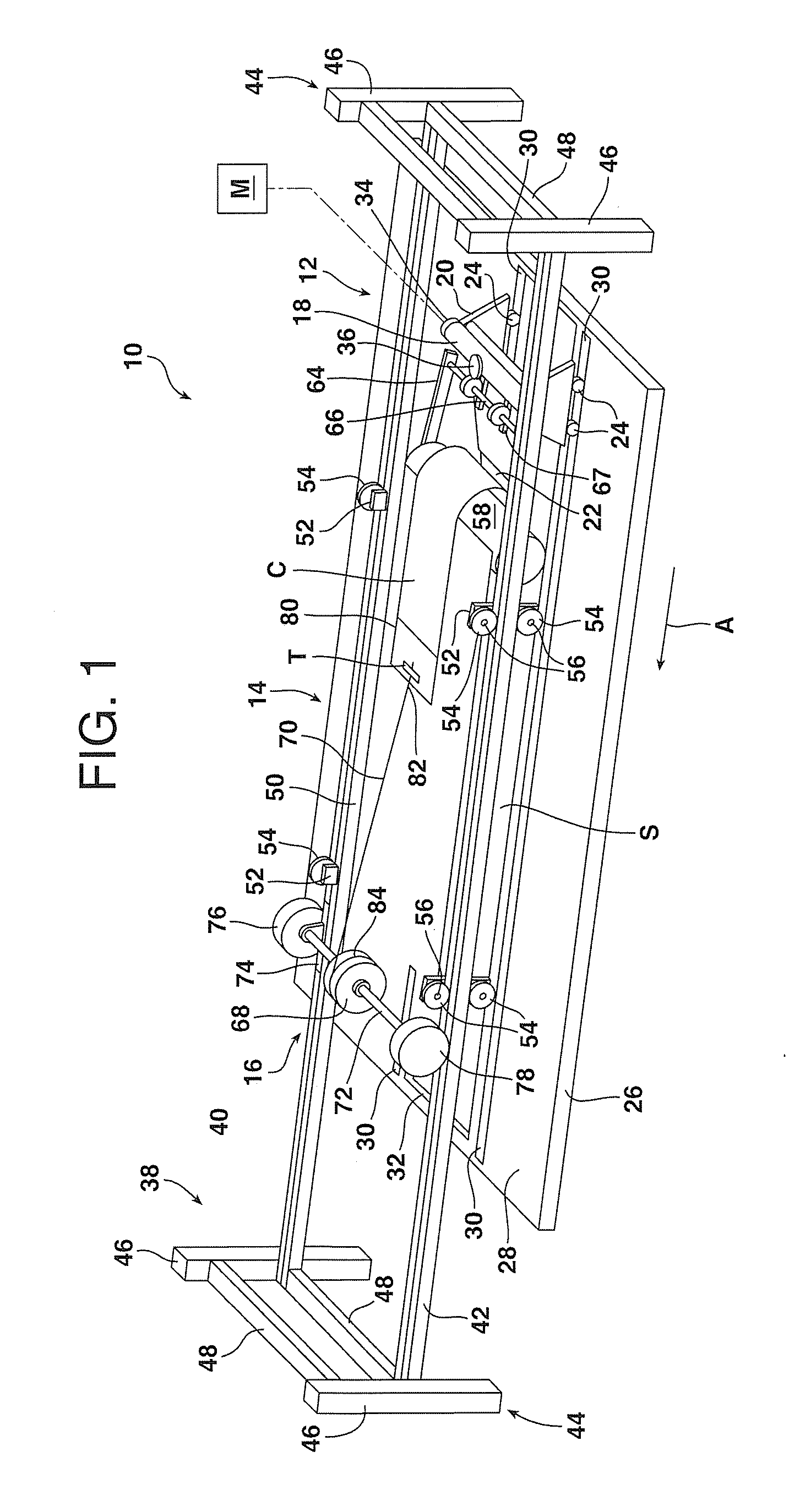

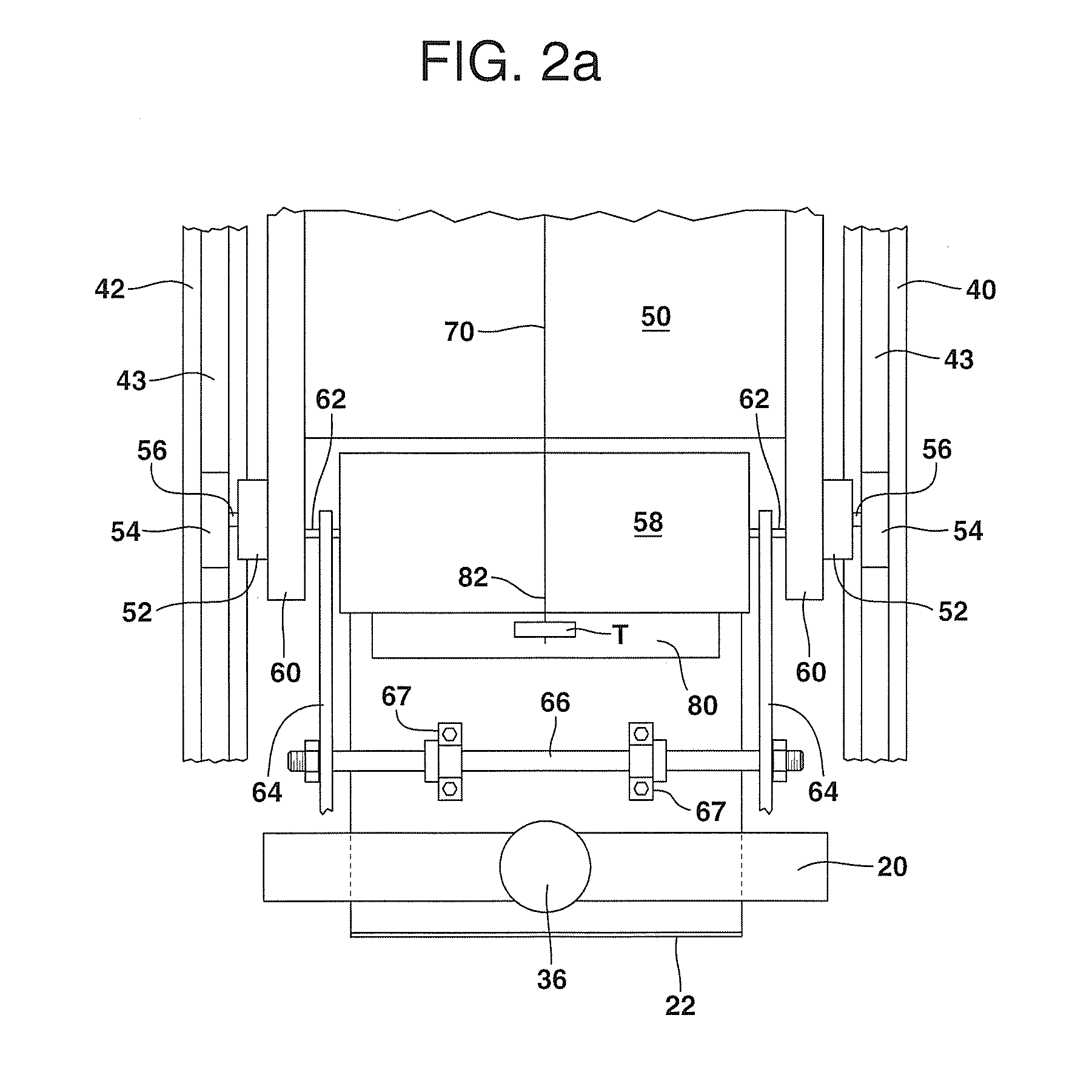

Method and Installation for the Production of Pellets from Biomass in a Pelletizing Press for Use as Fuel in Furnaces

A method and an installation for producing pellets from prepared biomass in a pelleting press for use as fuel in fireplaces. The biomass is made of fibers, shavings or chippings containing cellulose and / or lignocellulose, with or without a binding agent and / or additives, and after being prepared is stored in a biomass bunker. The method includes: biomass discharged from the biomass bunker into a scatter device, a mat made of the biomass having a substantially uniform weight per unit area formed by the scatter device on a molding belt, the mat produced on the molding belt examined by an examining device for defective spots and / or foreign substances, and the mat supplied to a pelleting press. At least parts of the mat or a section of the mat include defective regions and / or foreign substances separated from the method upstream of the pelleting press.

Owner:DIEFFENBACHER GMBH & CO KG

Control system and control method for recycling and smelting crushed silica from silicon plants

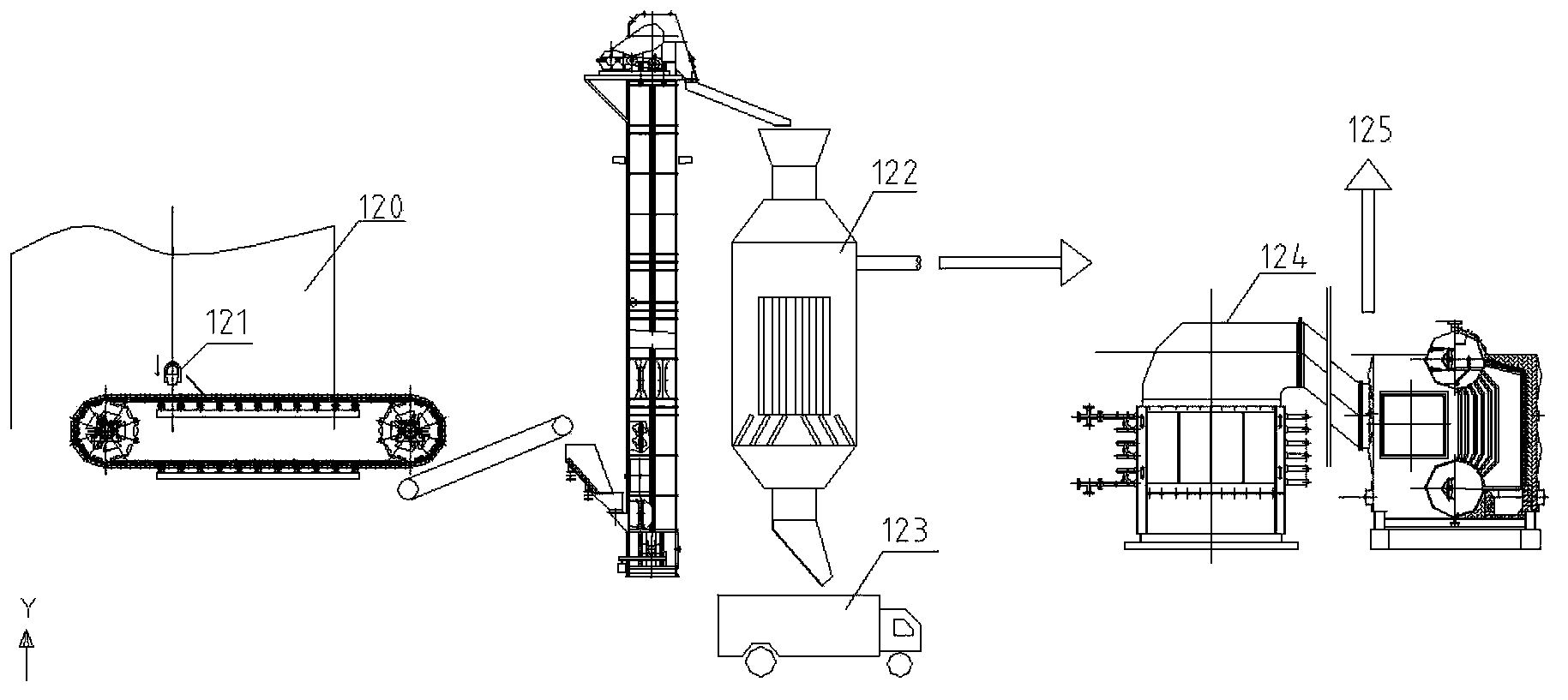

ActiveUS20190308882A1Avoid local instabilityRapidly and efficiently smeltHeat treatmentsSilicon compoundsControl systemSilicon dioxide

A manufacturing system and method for recycling and smelting crushed silica from silicon plants, including a crushed silica storage device, granulator, submerged arc furnace, transfer device, forming device and cooling system. Firstly silicon waste is collected, then crushed silica is output to a granulator. The granulator mixes the waste irregular crushed silica with water, and granulates and produces small particles having an uniform grain size as the raw material for smelting. The raw material is smelted in the submerged arc furnace. The forming device evenly pours the silicon liquid into the cooling system according to a set flow rate. The silicon liquid is solidified to form silicon pellets, and then a lift system is used to lift the formed silicon pellets, wherein the silicon liquid poured into the cooling system has a uniform diameter. The system can rapidly and efficiently smelt the silicon waste from the silicon plants.

Owner:CHENGDU SILICON TECH CO LTD

Method for belt pre-conditioning, method for pelletizing urea and pelletizing plant

InactiveCN1962042ADry fastImprove pellet qualityUrea compound fertilisersGranulation on conveyor beltsPre conditioningEngineering

Method for belt conditioning in pelletizing plants, method for pelletizing urea and pelletizing plant. The invention relates to a method for belt conditioning in pelletizing plants with a rotating steel belt to which is applied in drop-like manner a melt of a product to be pelletized which is then solidified on the steel belt. According to the invention there are steps of washing off product residues left on the steel belt after removing the solidified pellets using a washing liquid containing at least the dissolved product and drying the washing liquid adhering to the steel belt for forming a dry product film thereon prior to the renewed application of a melt of a product to be pelletized. Use e.g. for pelletizing urea.

Owner:SANTRADE LTD

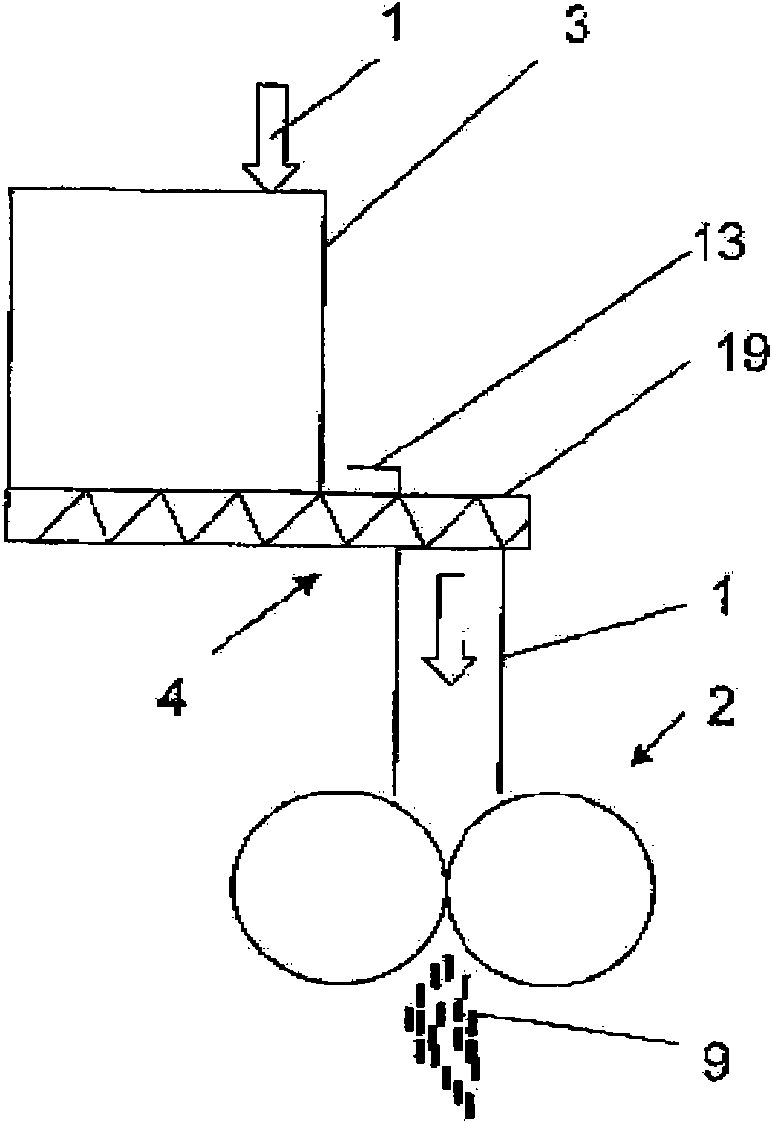

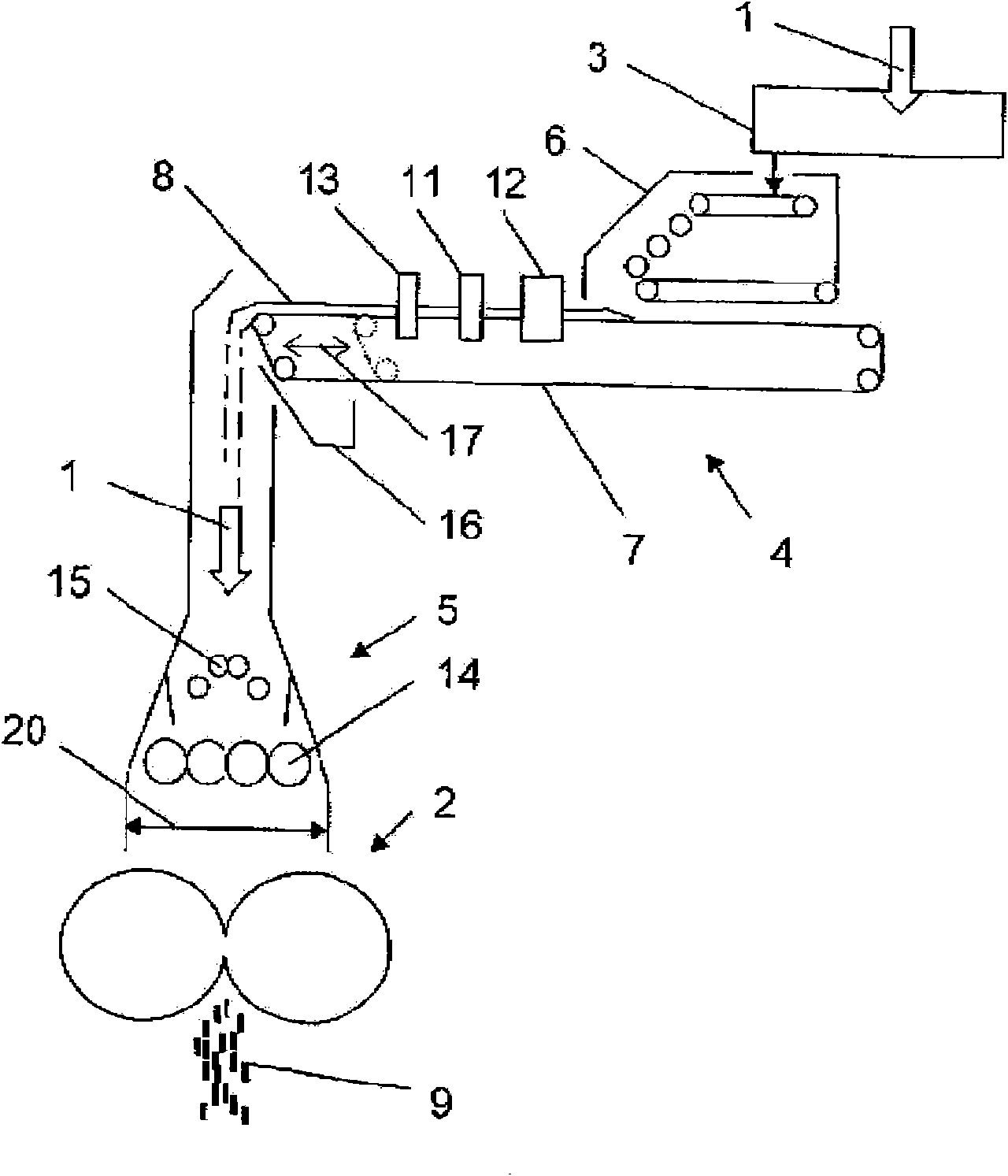

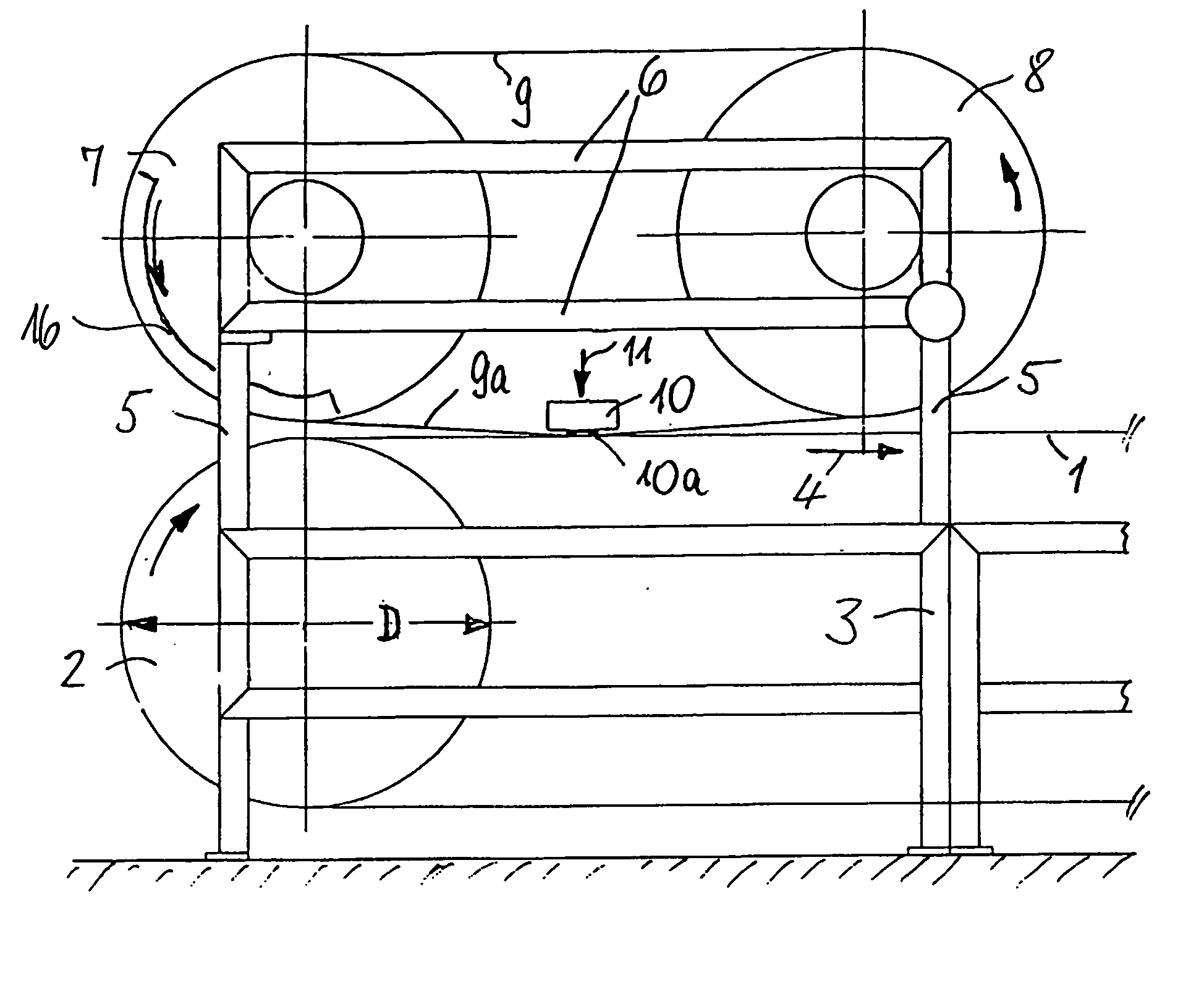

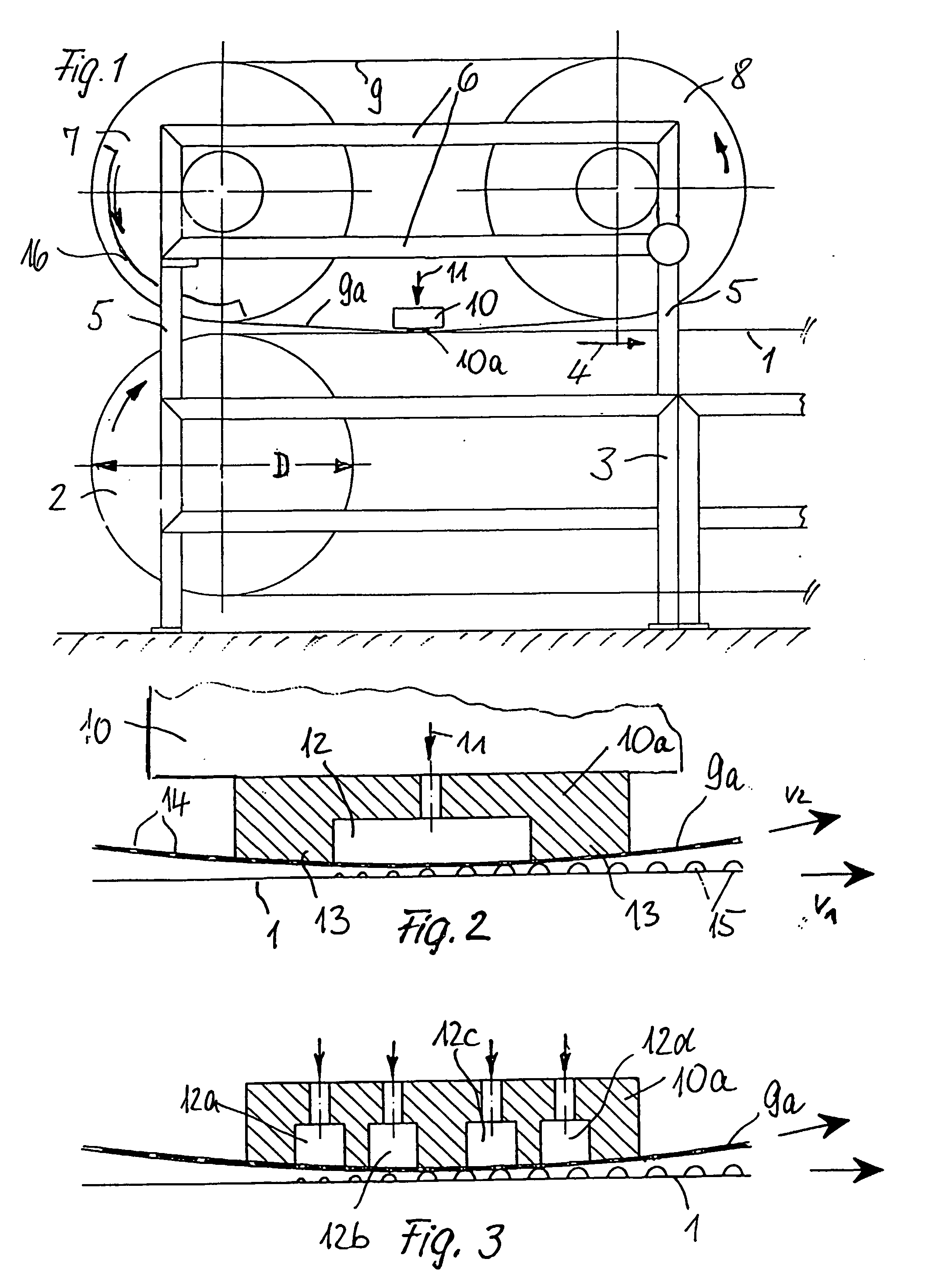

Device for producing granules

InactiveUS20050129792A1Improve insulation effectEasy constructionConfectionerySweetmeatsEngineeringMaterial Perforation

A belt drop shaper forms a viscous substance into the shape of drops. The drop shaper includes a container for the substance and a perforated steel belt pressing against a bottom surface of the container. The bottom surface includes at least one discharge opening that is periodically opened by perforations in the belt to enable drops of the substance to fall on a transport conveyor. A heater unit is provided, e.g., in a support drum around which the steel belt travels, to heat the steel belt at a location upstream of the discharge opening.

Owner:SANTRADE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com