Method and assembly for producing pellets made of biomass in pelleting press for use as fuel in fireplaces

A technology in biomass and furnace, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of damage to pellet press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

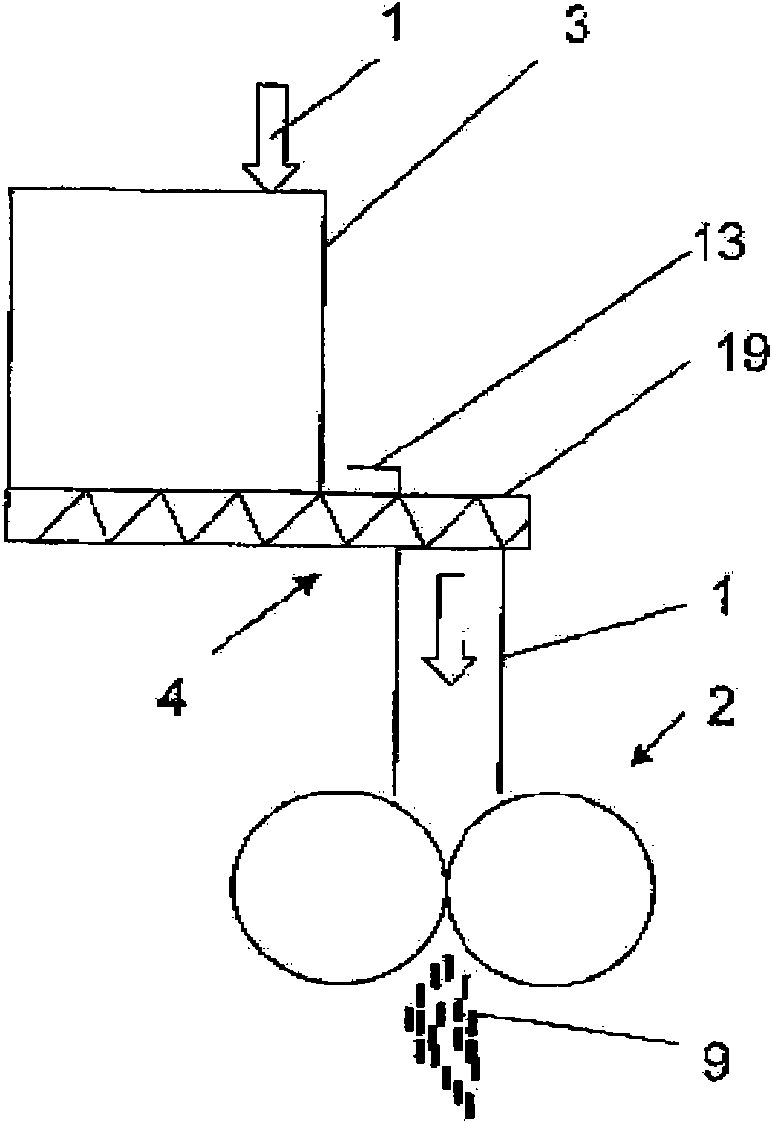

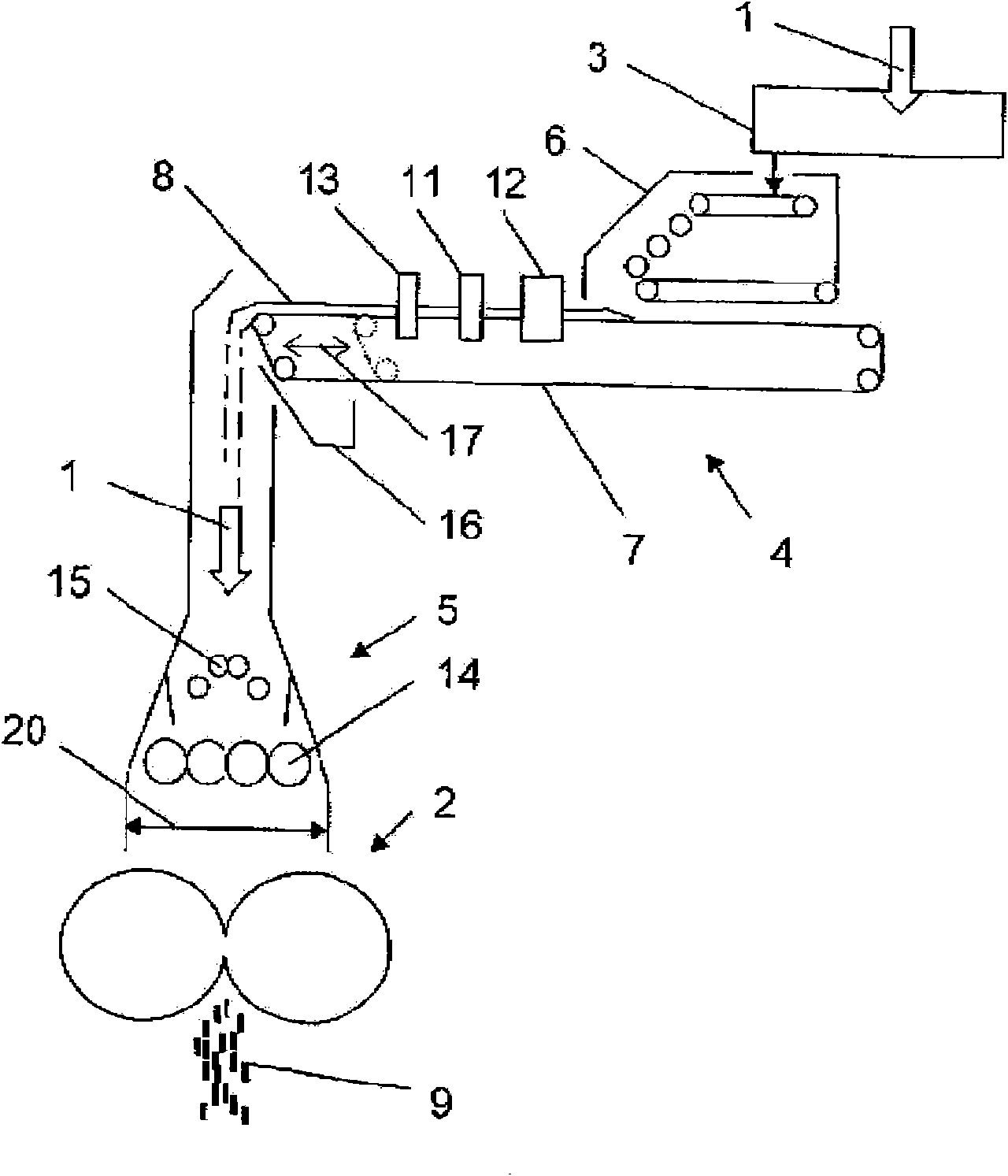

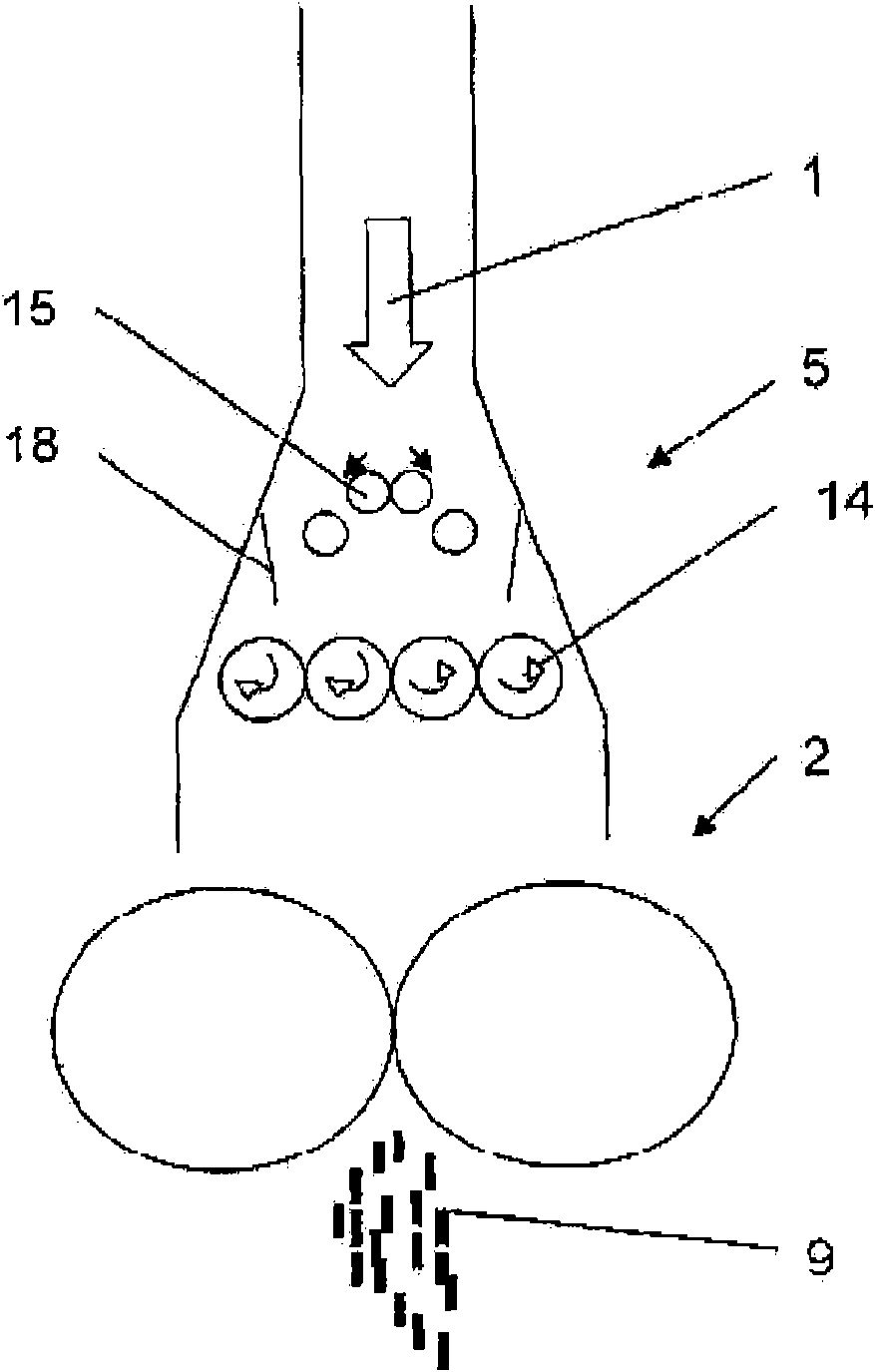

[0019] according to figure 1 , to describe the production process of pellets according to the prior art as follows. The pretreated and screened biomass 1 is placed and discharged into a biomass silo 3 . This can be done with an intermediate conveyor or directly with the dosing unit 4, according to figure 1 , the dosing device 4 is configured as a dosing screw conveyor 19 . According to requirements, the biomass 1 can be treated with steam by means of a steam treatment device 13 in the metering screw conveyor 19, or if necessary, can also be checked in an intermediate station for defective parts of the biomass, which are produced for granulation. Definition of hazardous impurities for presses. In the discharge area, the biomass falls off a metering screw conveyor 19 and is now pressed into pellets 9 in this example with a pelletizing press 2 comprising two rollers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com