Chain belt type granulator for rapid one-step molding of high temperature liquid calcium carbide

A chain-belt type, granulator technology, applied in the direction of granulation, carbide, calcium carbide, etc. Occupation of manpower, material resources and space, shortening the cooling time, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are attached with accompanying drawings in detail as follows. The embodiments illustrated in the accompanying drawings are only used to illustrate the technical solution of the present invention , not to limit the present invention.

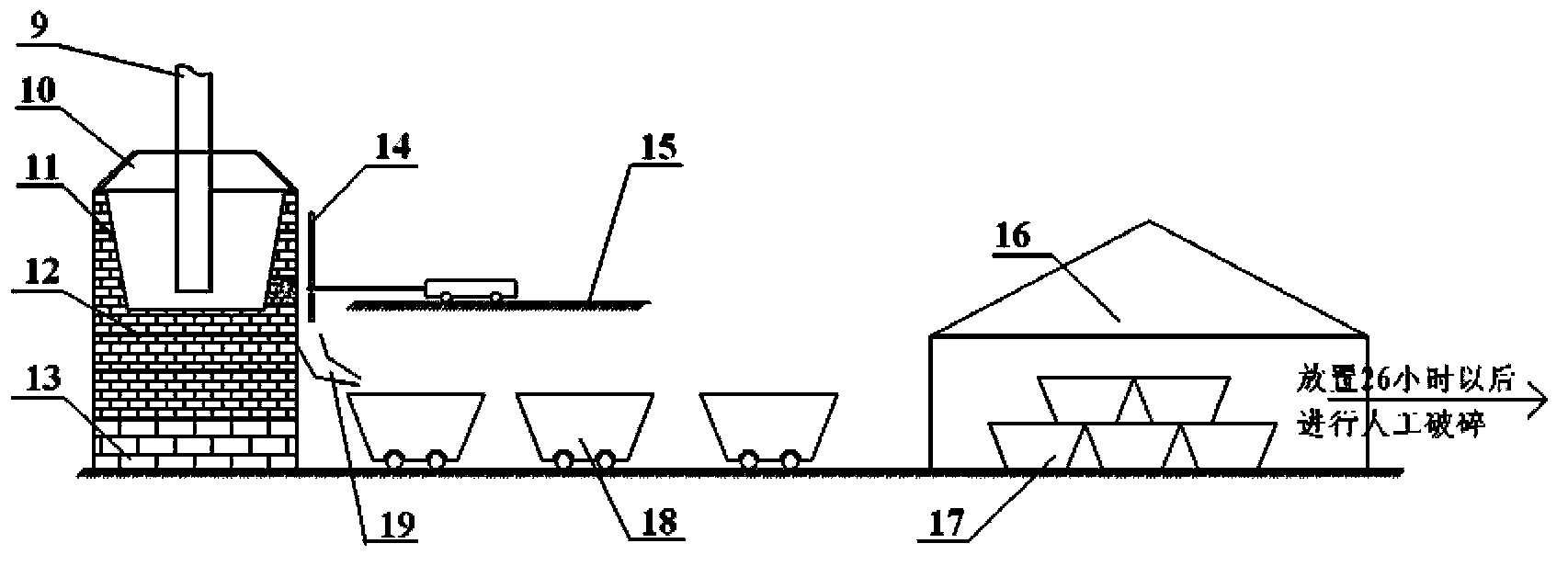

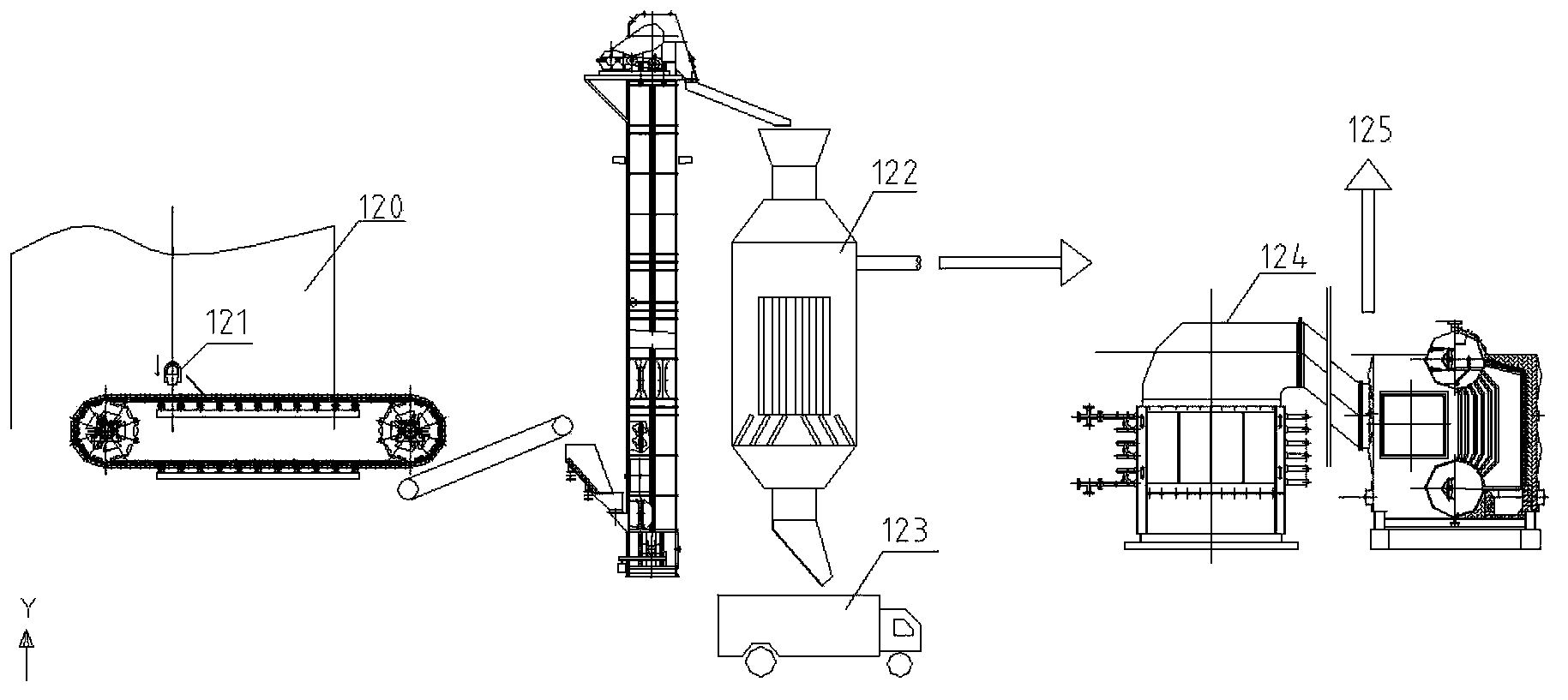

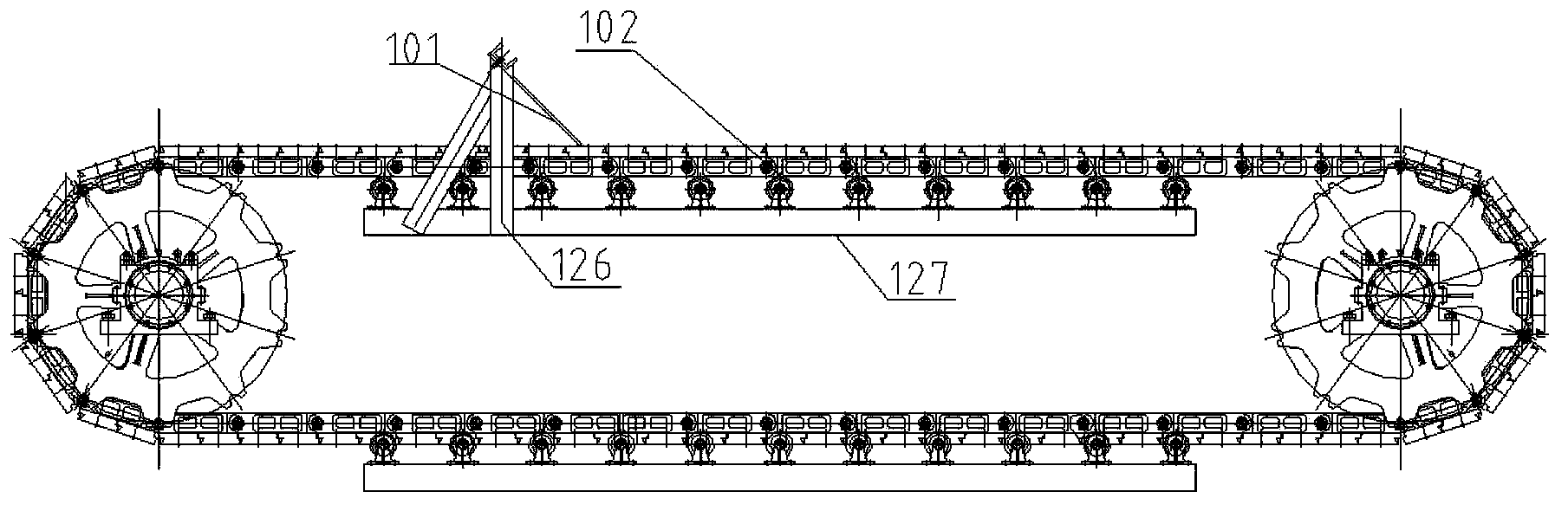

[0021] Such as figure 2 as shown, figure 2 It is a schematic diagram of a new technological process realized by utilizing the present invention. A chain granulator is installed at the calcium carbide outlet 121 of the calcium carbide furnace 120, and the calcium carbide mold 104 on the conveyor belt 105 of the chain granulator is used to form the liquid calcium carbide. Specifically, the high-temperature liquid calcium carbide discharged from the calcium carbide furnace 120 is directly placed in the calcium carbide mold 104 on the conveyor chain belt 105 of the chain-belt granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com